Diamond-coated tool

A technology of diamond and diamond layer, applied in the direction of manufacturing tools, metal processing equipment, metal material coating technology, etc., can solve problems such as wear or defect, and achieve the effect of improving tool life, oxidation resistance and defect resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

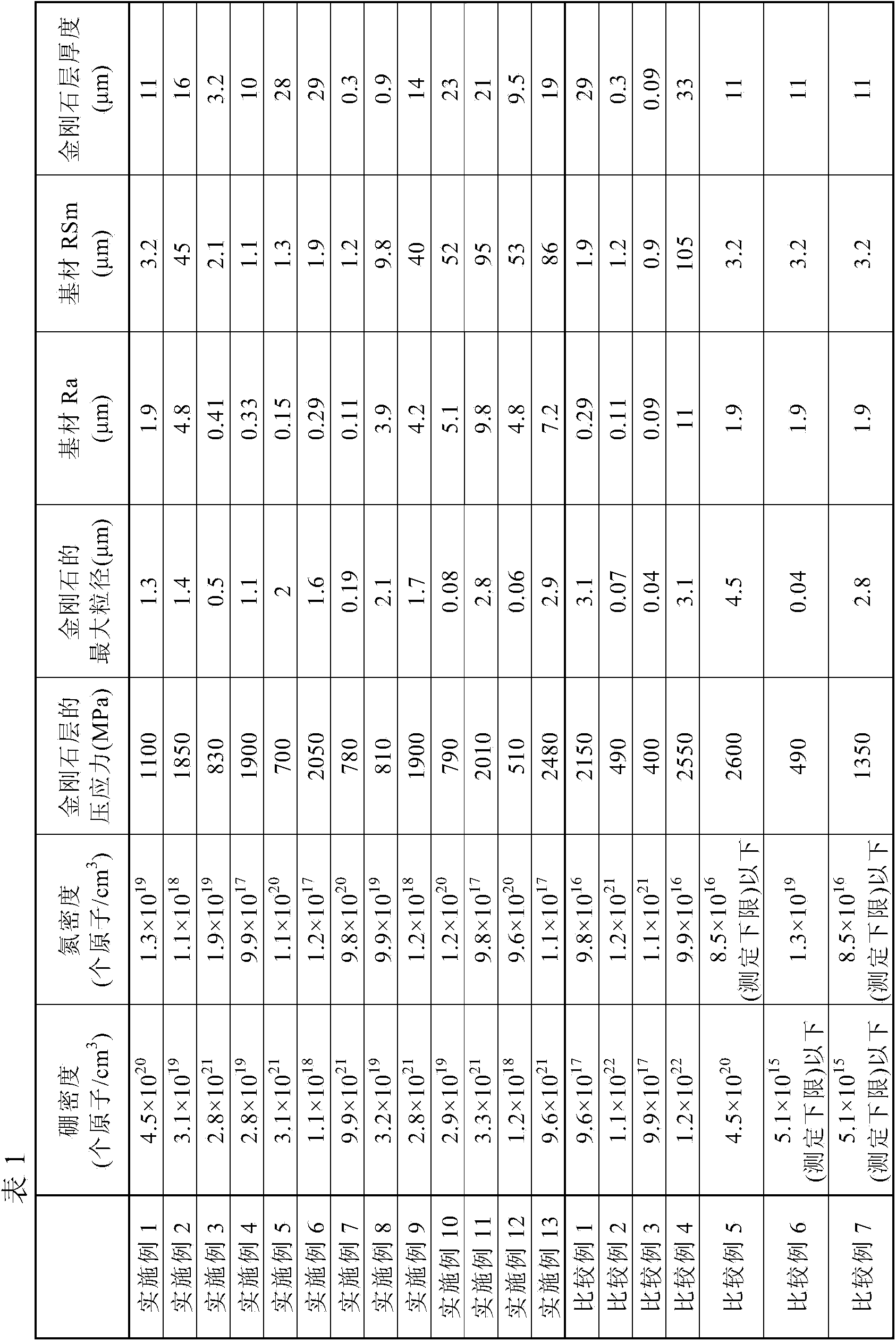

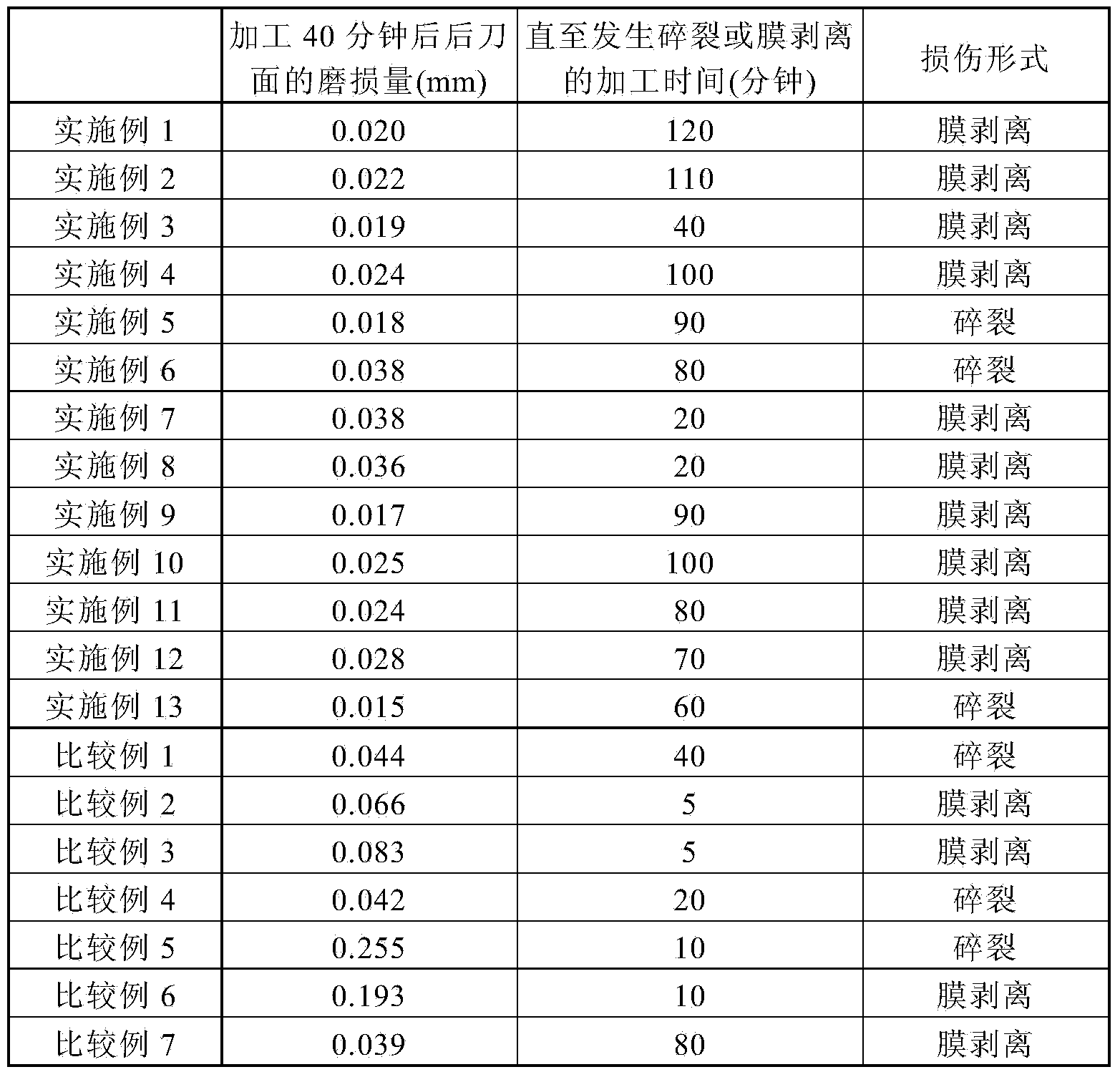

[0055] The present invention will be described in more detail with reference to Examples, which are not intended to limit the present invention.

[0056] Although the diamond layer is formed using a hot filament CVD method hereinafter, the diamond layer may be formed using a conventionally known CVD method such as microwave plasma CVD or plasma jet CVD.

[0057] In the manufacture of the diamond-coated tools of Examples and Comparative Examples, a material made of a material equivalent to JIS K10 type cemented carbide (WC-6% Co) and having a material equivalent to SPGN090308 (JIS B4120:1998) was used. Shaped blades serve as the base material for diamond-coated tools.

[0058] First, as the surface roughening treatment of the base material, the surface of the base material was blasted with various SiC fine powders (average particle diameter: 4 μm to 100 μm). The injection pressure is 0.15 MPa to 0.35 MPa, and the irradiation time is 10 seconds to 30 seconds. Subsequently, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com