Preparation method of nanoparticle reinforced wear-resistant coating layer on blade top of single-crystal turbine blade

A technology of turbine blades and wear-resistant coatings, applied in coatings, metal material coating processes, etc., can solve problems affecting engine performance and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

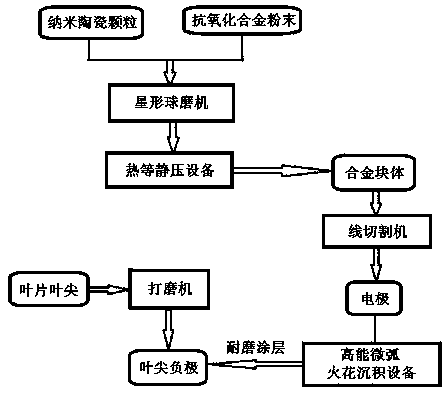

Method used

Image

Examples

Embodiment 1

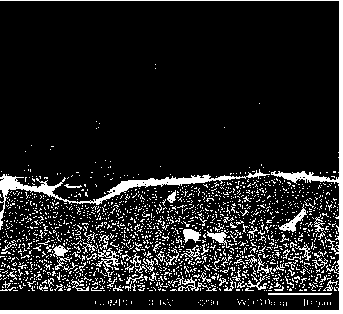

[0032] Nano Y with a nominal particle size of 50nm 2 o 3 The powder is added to the NiCoCrAlY anti-oxidation powder at a weight ratio of 3%. After ball milling in a planetary ball mill at a speed of 400r / min for 4 hours, it is placed in a hot isostatic pressing device with a heating temperature of 1250 oC , the pressure is 100MPa, and the alloy composite material block with a density of 90% is formed after holding the pressure for 1 hour, and then an alloy electrode rod with a diameter of 4mm is prepared by wire cutting. Using high-energy micro-arc spark deposition equipment, the DD26 single crystal superalloy turbine blade was polished with 1000# sandpaper on the crystal surface of the blade tip, and then cleaned and dried with acetone and then connected to the negative electrode as the base material, nano-Y 2 o 3 The particle-reinforced NiCoCrAlY alloy rod is connected to the positive electrode, and the nano-Y 2 o 3 Particle-reinforced NiCoCrAlY wear-resistant sealing ...

Embodiment 2

[0034] Add nano-TaC powder with a nominal particle size of 100nm to NiCoCrAlTaY anti-oxidation powder at a weight ratio of 4%. After ball milling in a planetary ball mill at a speed of 500r / min for 2 hours, put it into a hot isostatic pressing device and heat it to a temperature of 1300 oC, the pressure is 150MPa, and after holding the pressure for 1.5 hours, an alloy composite material block with a density of 95% is formed, and then an alloy electrode rod with a diameter of 6mm is prepared by wire cutting. Using high-energy micro-arc spark deposition equipment, the PWA1484 turbine blade was polished with 1500# sandpaper on the crystal surface of the blade tip, then cleaned and dried with acetone, and then connected to the negative electrode as the base material, NiCoCrAlTaY alloy rod reinforced with nano-TaC particles Connected to the positive electrode, under the process parameters of voltage 80V, capacitance 350μf, pulse frequency 400Hz, inclination angle 60°, and relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com