Boron nitride nanosheet reinforced nickel-aluminum intermetallic compound composite coating and preparation method thereof

An intermetallic compound and composite coating technology, which is applied in metal material coating process, coating, melt spraying and other directions, can solve problems such as reducing tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

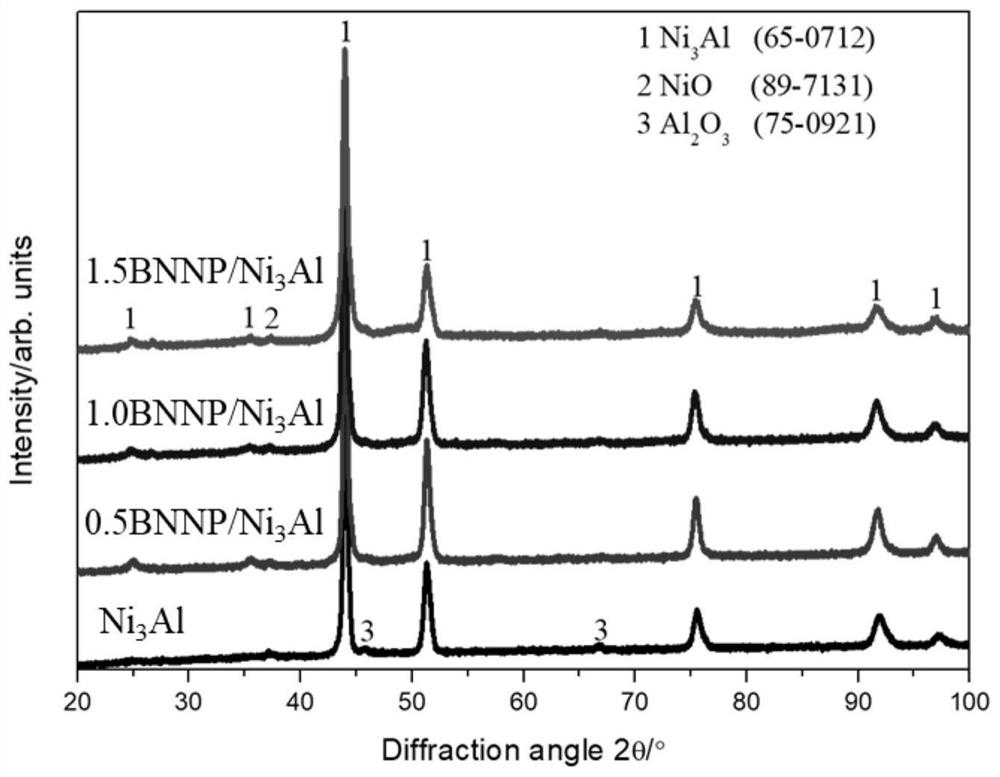

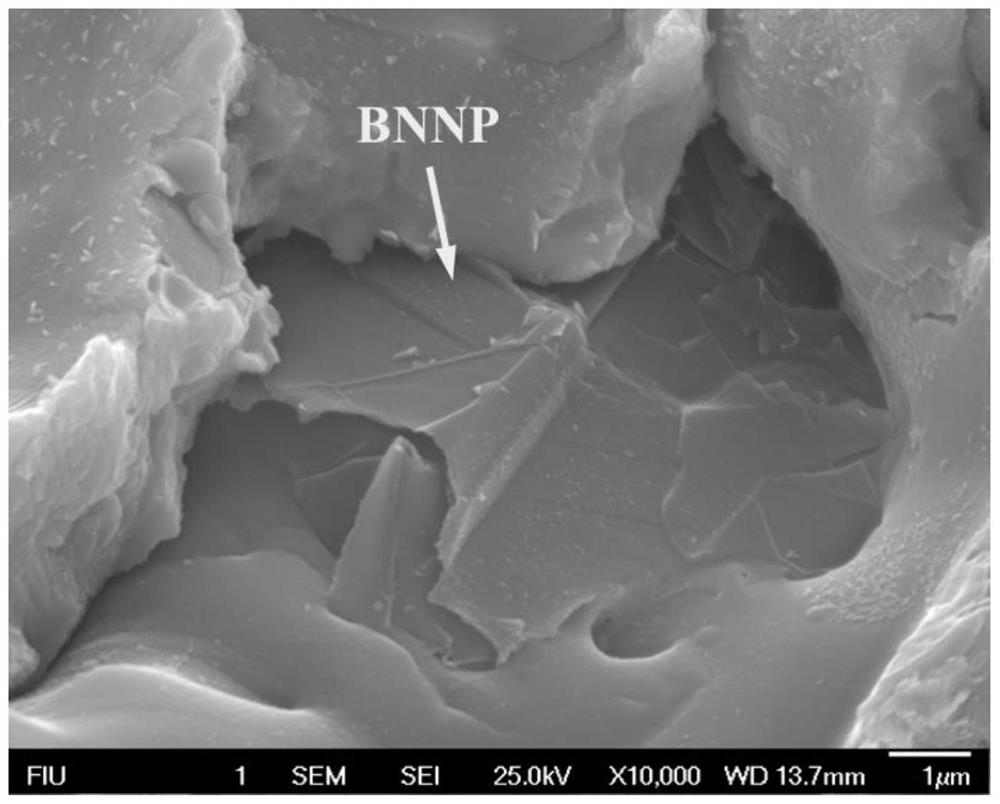

[0038] The invention provides a boron nitride nanosheet reinforced Ni 3 The preparation method of Al intermetallic compound composite coating comprises:

[0039] Mix nickel powder and aluminum powder to obtain mixed powder;

[0040] mixing the mixed powder with the boron nitride nanosheet dispersion and drying to obtain a powder;

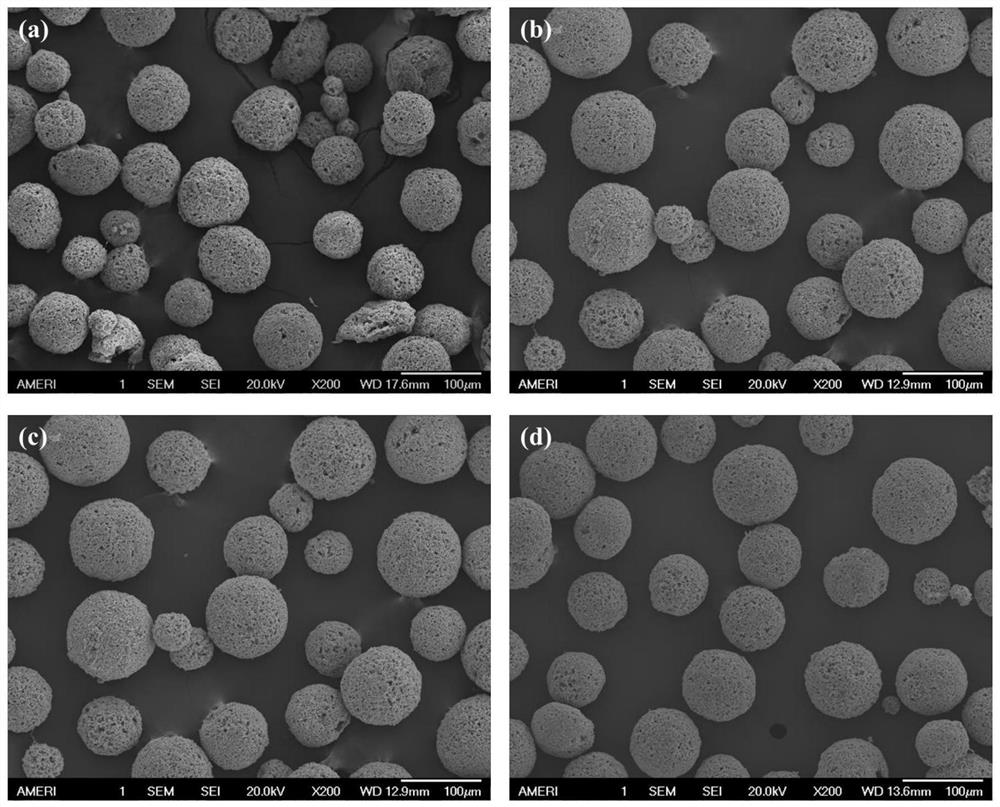

[0041] The powder is subjected to spray granulation to obtain a spray feed;

[0042] The spraying feed material is carried out plasma spraying, obtains the boron nitride nanosheet reinforced Ni 3 Al intermetallic composite coating.

[0043] In the present invention, the preparation method of the mixed powder preferably includes:

[0044]The nickel powder and the aluminum powder are ball-milled with isopropanol to obtain a slurry;

[0045] The slurry was dried and ground to obtain a mixed powder.

[0046] In the present invention, the equipment of the ball mill is preferably a horizontal planetary ball mill, and the ratio of ball to material in...

Embodiment 1

[0074] Weigh 85wt.% nickel powder (~1μm) and 15wt.% aluminum powder (~1μm) with an electronic balance;

[0075] Put the nickel powder and aluminum powder into a horizontal planetary ball mill and add isopropanol for ball milling. During the ball milling process, the ratio of ball to material is 4:1, the speed of the ball mill is 300r / min, and the ball mill is 6 hours to obtain a mixed slurry;

[0076] The above mixed slurry was dried in a vacuum drying oven at 70°C, and then ground into powder to obtain a mixed powder;

[0077] placing the boron nitride nanosheets in isopropanol for ultrasonic dispersion for 4 hours to obtain a boron nitride nanosheet dispersion;

[0078] Put the mixed powder into the dispersion of boron nitride nanosheets, stir and disperse with a homogenizer at a speed of 5000 rpm for 5 hours, dry the obtained mixture in a vacuum oven at 80°C, and then grind it into Powder, to obtain a powder, the mass content of boron nitride nanosheets in the powder is 0....

Embodiment 2

[0082] Weigh 85wt.% nickel powder (~1μm) and 15wt.% aluminum powder (~1μm) with an electronic balance;

[0083] Put the nickel powder and aluminum powder into a horizontal planetary ball mill and add isopropanol for ball milling. During the ball milling process, the ratio of ball to material is 4:1, the speed of the ball mill is 300r / min, and the ball mill is 6 hours to obtain a mixed slurry;

[0084] The above mixed slurry was dried in a vacuum drying oven at 70°C, and then ground into powder to obtain a mixed powder;

[0085] placing the boron nitride nanosheets in isopropanol for ultrasonic dispersion for 4 hours to obtain a boron nitride nanosheet dispersion;

[0086] Put the mixed powder into the dispersion of boron nitride nanosheets, stir and disperse with a homogenizer at a speed of 5000 rpm for 5 hours, dry the obtained mixture in a vacuum oven at 80°C, and then grind it into Powder, to obtain a powder, the mass content of boron nitride nanosheets in the powder is 1%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com