Extra-low oxygen rare earth alloy and use

A rare earth alloy and ultra-low oxygen technology, applied in the direction of reducing gas emissions, can solve the problems of ignoring the control of oxygen content, deteriorating material performance, and little harm, and achieve the goal of wide coverage, improved material performance, and improved purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

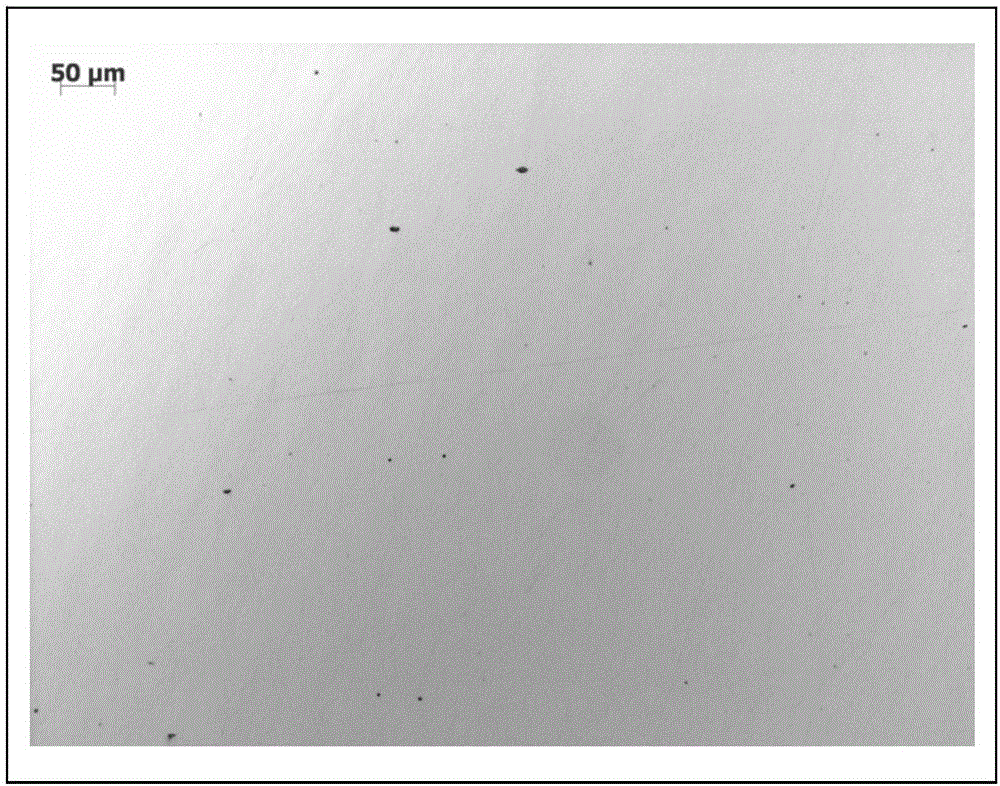

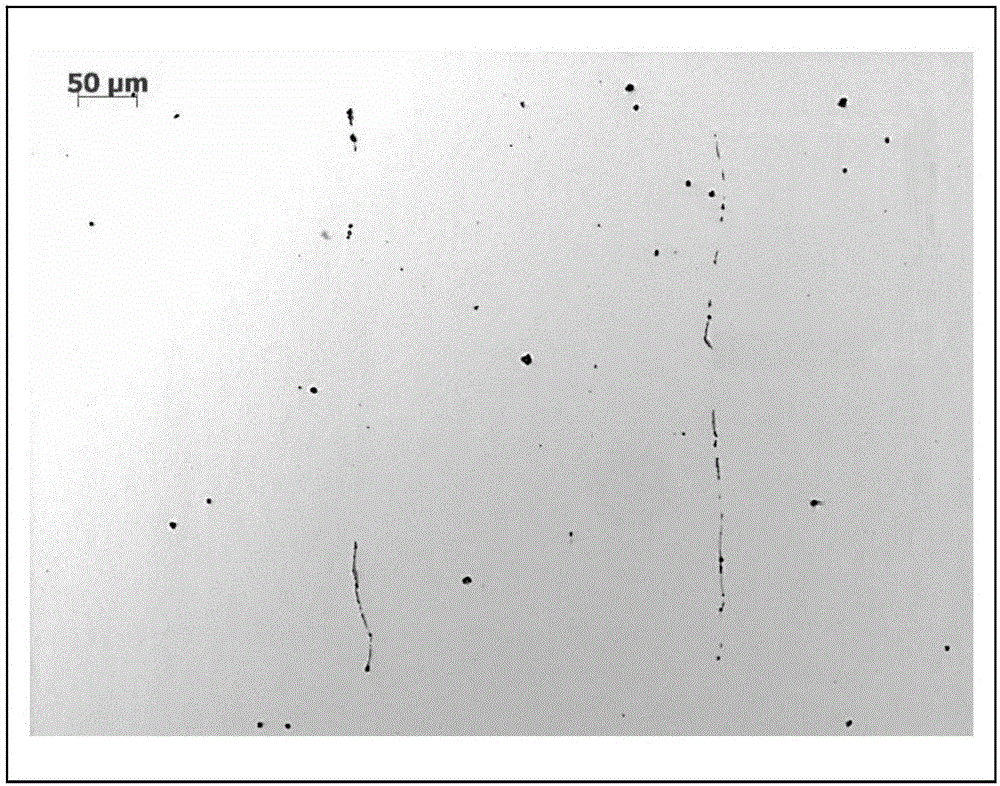

Image

Examples

preparation example Construction

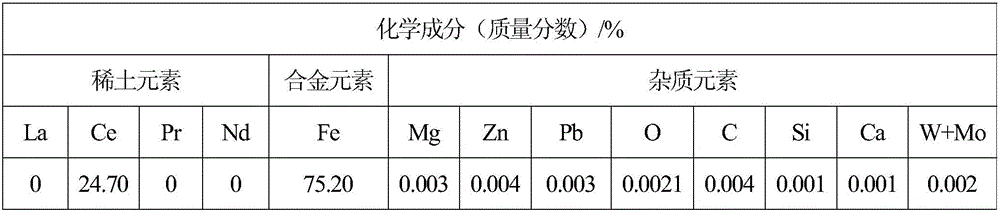

[0028] The preparation method of the above-mentioned ultra-low oxygen rare earth alloy comprises the following steps:

[0029] 1) Electrolysis step: using rare earth oxides or rare earth oxide fluorine salts as raw materials, using electrolysis to reduce the rare earth metals to a molten state to prepare ultra-low oxygen rare earth metals, the rare earth metals are single metals of lanthanum, cerium, praseodymium, neodymium or A mixture of several metals in any proportion.

[0030] 2) Smelting or sintering step: the rare earth metal obtained by electrolysis is mixed with high-purity, ultra-low oxygen (generally O≤0.005%, weight percent) iron, silicon, magnesium, and aluminum in a certain proportion, and then smelted in an induction furnace to prepare an alloy. Or the ultra-low oxygen rare earth metal powder is evenly mixed with the ultra-low oxygen iron, silicon, magnesium, aluminum metal powder, and then sintered under high temperature and high pressure to prepare the ultra-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com