Titanium-based tungstenic alloy material used for 3D printing and preparation method thereof

A titanium-based alloy, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of poor plastic shear deformation resistance and wear resistance, low strain hardening index, limited use, etc., to break through limitations and resist high temperature wear. Excellent performance, high temperature hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

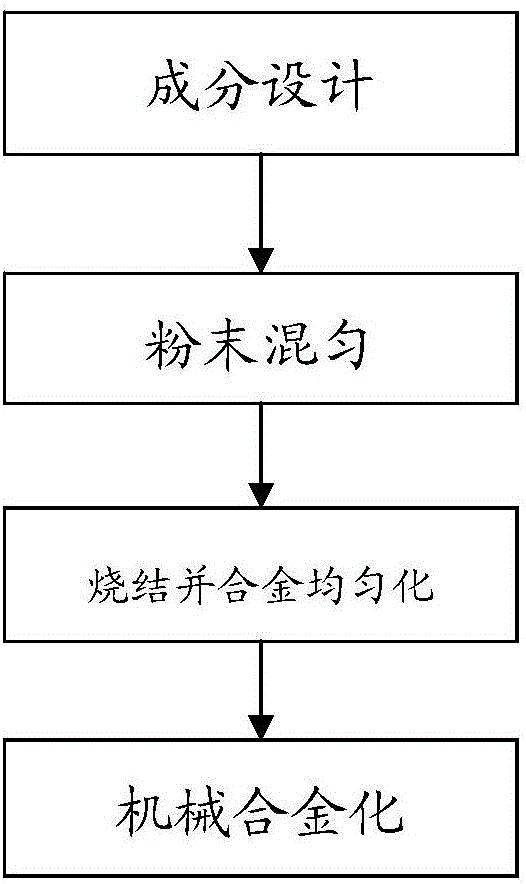

[0035] Please refer to figure 1 Take 1.5 kg of tungsten carbide powder, 0.5 kg of nickel powder, 0.8 kg of niobium powder, 0.3 kg of vanadium powder, 0.8 kg of copper powder, 1.0 kg of molybdenum powder, and 5.1 kg of titanium powder. The thickness is 30-150 μm, and the oxygen content is 0.07-0.12%. Put the obtained powder into a powder mixer and mix for 10 minutes until the mixture is uniform.

[0036] The mixed powder is sintered and subjected to alloy homogenization.

[0037] The product is mechanically alloyed to obtain a powder product. Mechanical alloying is a complex physical and chemical process in which powder undergoes repeated deformation, cold welding, and crushing through high-energy ball milling to achieve alloying at the atomic level between elements.

[0038] The alloy powder particles are spherical in shape, the particle diameter is 30-150 μm, and the oxygen content is 0.07-0.12%.

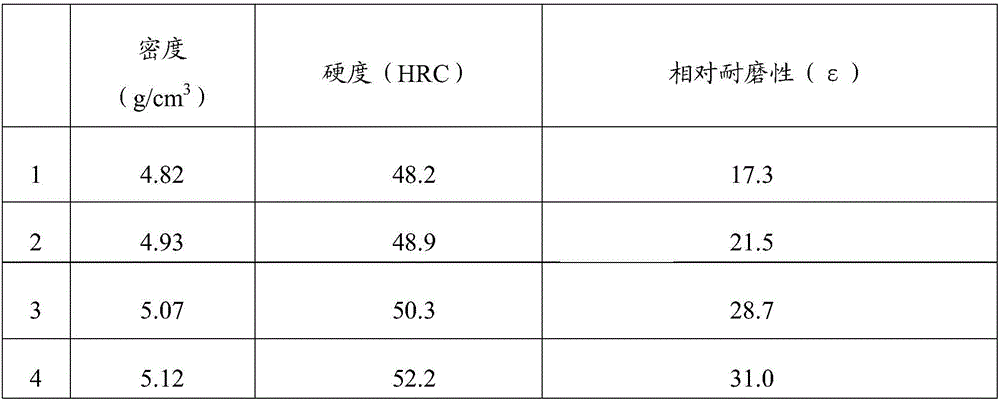

[0039] 3D printing with the obtained finished powder, the printing paramet...

Embodiment 2

[0042] Take 2.0 kg of tungsten carbide powder, 0.4 kg of nickel powder, 0.6 kg of niobium powder, 0.2 kg of vanadium powder, 0.7 kg of copper powder, 0.8 kg of molybdenum powder, and 5.3 kg of titanium powder. 30~150μm, oxygen content is 0.07~0.12%. Put the obtained powder into a powder mixer and mix for 10 minutes until the mixture is uniform.

[0043] The mixed powder is sintered and subjected to alloy homogenization.

[0044] The product is mechanically alloyed to obtain a powder product. Mechanical alloying is a complex physical and chemical process in which powder undergoes repeated deformation, cold welding, and crushing through high-energy ball milling to achieve alloying at the atomic level between elements.

[0045] The alloy powder particles are spherical in shape, the particle diameter is 30-150 μm, and the oxygen content is 0.07-0.12%.

[0046] 3D printing with the obtained finished powder, the printing parameters are: construction speed: 40cm 3 / h, laser scann...

Embodiment 3

[0049] Take 2.5 kg of tungsten carbide powder, 0.3 kg of nickel powder, 0.4 kg of niobium powder, 0.2 kg of vanadium powder, 0.6 kg of copper powder, 0.6 kg of molybdenum powder, and 5.4 kg of titanium powder. 30~150μm, oxygen content is 0.07~0.12%. Put the obtained powder into a powder mixer and mix for 10 minutes until the mixture is uniform.

[0050] The mixed powder is sintered and subjected to alloy homogenization.

[0051] The product is mechanically alloyed to obtain a powder product. Mechanical alloying is a complex physical and chemical process in which powder undergoes repeated deformation, cold welding, and crushing through high-energy ball milling to achieve alloying at the atomic level between elements.

[0052] The alloy powder particles are spherical in shape, the particle diameter is 30-150 μm, and the oxygen content is 0.07-0.12%.

[0053] 3D printing with the obtained finished powder, the printing parameters are: construction speed: 40cm 3 / h, laser scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com