Titanium carbonitride metal ceramic material for extrusion die and preparation method thereof

A technology of titanium carbonitride and cermet, applied in the direction of metal extrusion dies, etc., can solve the problems of high consumption cost of extrusion dies, lack of wear resistance, high temperature hardness extrusion die materials, etc., to improve high temperature performance and thermal shock properties, improve material toughness and high temperature performance, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

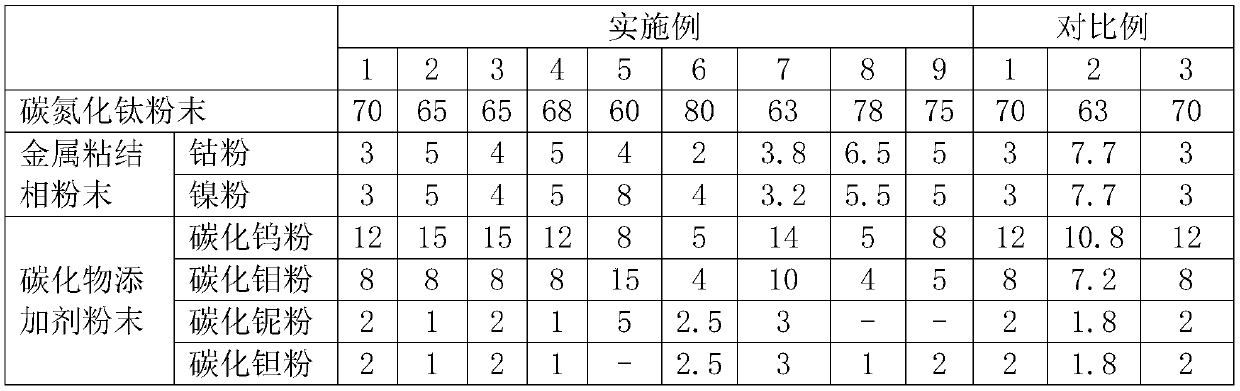

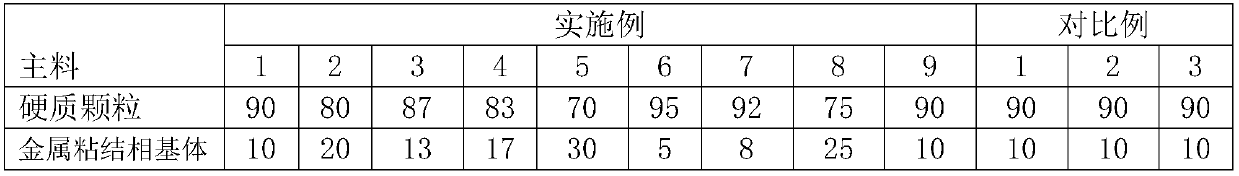

Embodiment 1

[0057] A titanium carbonitride cermet material for an extrusion die is prepared, and the preparation steps are as follows:

[0058] (1) Prepare the components and the metal binder phase matrix for preparing hard particles according to the proportioning ratio;

[0059] (2) Preparation of hard particles:

[0060] ① Pour the components for preparing hard particles into the ball milling tank, and at the same time add carbon source, forming agent and ball milling medium to carry out wet milling for 50 hours. The ball-to-material ratio of ball milling is 6:1, and the mixture is obtained after ball milling;

[0061] ② Then dry the mixture and granulate to obtain granules;

[0062] The method used for granulation is spray drying granulation, and the slurry is prepared before spraying, and the weight ratio of the solid and liquid for preparing the slurry is 55:50 (preparing the slurry: the solid is the mixture obtained after ball milling in step ①; the liquid is Alcohol), the tempera...

Embodiment 2

[0071] A titanium carbonitride cermet material for an extrusion die is prepared, and the preparation steps are as follows:

[0072] (1) Prepare the components and the metal binder phase matrix for preparing hard particles according to the proportioning ratio;

[0073] (2) Preparation of hard particles:

[0074] ① Pour the components for preparing hard particles into the ball milling tank, and at the same time add carbon source, forming agent and ball milling medium to carry out wet milling for 60 hours. The ball-to-material ratio of ball milling is 8:1, and the mixture is obtained after ball milling;

[0075] ② Then dry the mixture and granulate to obtain granules;

[0076] The method used for granulation is spray drying granulation, and the slurry is prepared before spraying, and the weight ratio of the solid and liquid for preparing the slurry is 30:70 (preparing the slurry: the solid is the mixture obtained after ball milling in step ①; the liquid is Alcohol), the tempera...

Embodiment 3

[0085] A titanium carbonitride cermet material for an extrusion die is prepared, and the preparation steps are as follows:

[0086] (1) Prepare the components and the metal binder phase matrix for preparing hard particles according to the proportioning ratio;

[0087] (2) Preparation of hard particles:

[0088] ① Pour the components for preparing hard particles into the ball milling tank, and at the same time add carbon source, forming agent and ball milling medium to carry out wet milling for 55 hours. The ball-to-material ratio of ball milling is 8:1, and the mixture is obtained after ball milling;

[0089] ② Then dry the mixture and granulate to obtain granules;

[0090] The method that granulation adopts is spray drying granulation, prepares slurry before spraying, and the weight ratio of the solid and liquid of preparation slurry is 70:30 (preparation slurry: solid is the mixture obtained after ball milling in step 1; liquid is Alcohol), the temperature of entering the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com