Graphene-reinforced biphase metal aluminide composite material and preparation method thereof

A composite material and aluminide technology, applied in the field of high temperature materials, can solve the problems of high density and reduce the specific strength of composite materials, and achieve the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

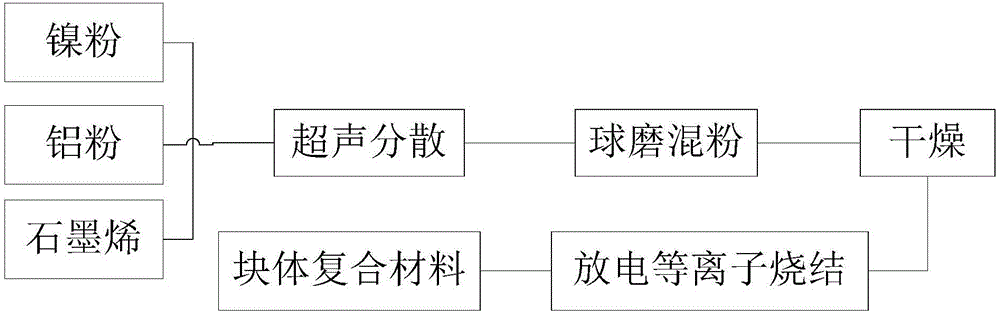

[0047] The present invention also provides a preparation method of a dual-phase metal aluminide composite material, comprising the following steps:

[0048] A) after graphene, dispersant and water are dispersed, obtain graphene dispersion liquid;

[0049] B) After adding nickel powder and aluminum powder to the graphene dispersion obtained in the above steps to disperse again, through ball milling, to obtain mixed powder;

[0050] C) After sintering the mixed powder obtained in the above steps, a dual-phase metal aluminide composite material is obtained.

[0051] The raw material ratio and optimization principles in the preparation method of the present invention correspond to the composition and ratio selection of the aforementioned dual-phase metal aluminide composite material, as well as the optimization principles, and will not be repeated here.

[0052] In the present invention, firstly, the graphene, the dispersant and water are dispersed to obtain the graphene dispersi...

Embodiment 1

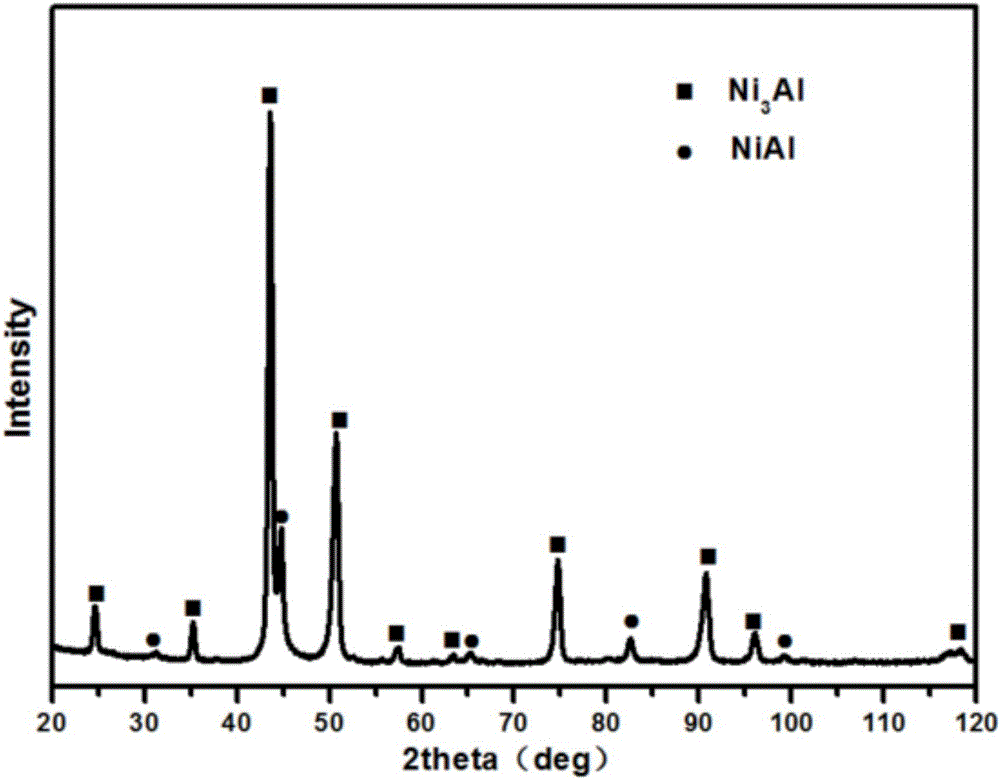

[0091] Preparation technology is the same as embodiment

[0092] Nickel powder and aluminum powder are used as raw powders (proportioned according to the atomic percentage of Ni being 72.5%), without adding graphene, nickel powder and aluminum powder are ultrasonically dispersed, ball milled, dried, and ground to form a sintered powder. The dried powder was sintered in a discharge plasma device, the heating rate was 150°C / min, the sintering pressure was 40MPa, the sintering temperature was 1250°C, the holding time was 6min, and the dual-phase metal aluminide was obtained.

[0093] The detection and characterization of the dual-phase metal aluminides prepared in the examples of the present invention were carried out.

Embodiment 2

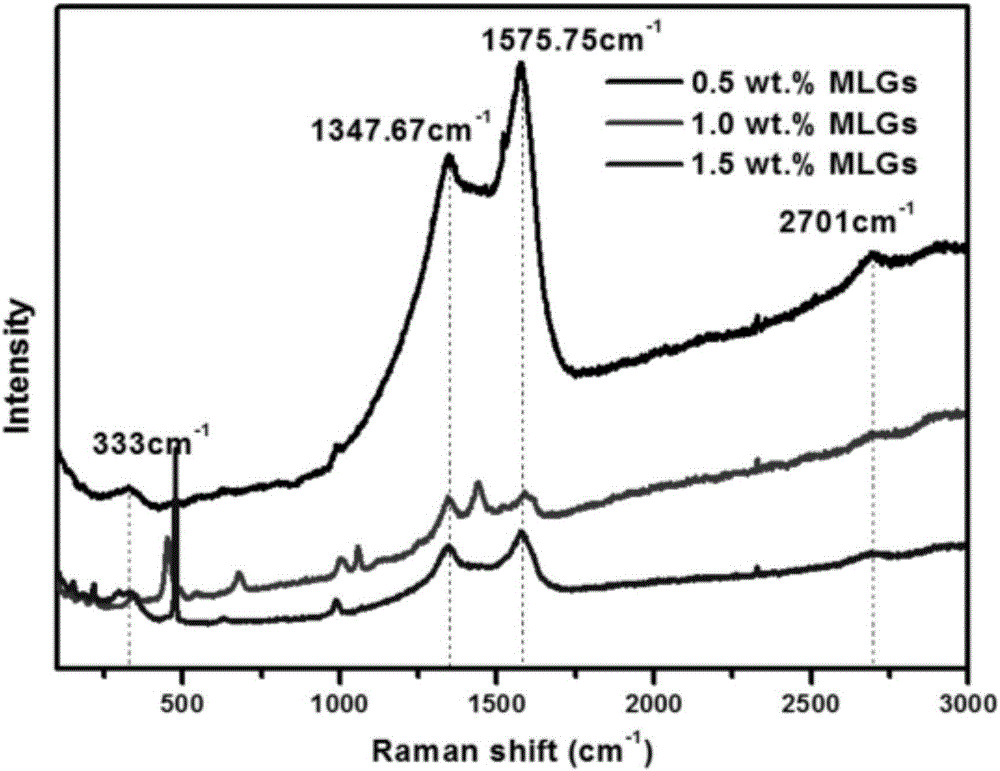

[0095] Preparation technology is the same as embodiment

[0096] Nickel powder, aluminum powder (proportioning according to the atomic percentage of Ni is 72.5%) and graphene are used as raw powder, wherein the weight ratio of graphene is weighed at 0.5wt%, and graphene, nickel powder and aluminum powder are ultrasonically dispersed respectively , ball milled, dried, and ground as a sintered mixed powder. The mixed powder was sintered in a discharge plasma device, the heating rate was 150°C / min, the sintering pressure was 40MPa, the sintering temperature was 1250°C, and the holding time was 6min to obtain a graphene-reinforced nickel-aluminum dual-phase intermetallic compound composite material .

[0097] The dual-phase metal aluminide composite material prepared in the embodiment of the present invention was detected and characterized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com