High-temperature-resistant alloy casting and preparation method thereof

A high-temperature-resistant alloy and alloy material technology, which is applied to the materials and preparation of castings, alloy material castings and the preparation of the castings, can solve the problems of accelerating inner core cup deformation, fracture, inner core cup deformation, and deterioration of the combustion environment. Achieve the effects of increasing strength, reducing the tendency to form, reducing the tendency of cracks and high-temperature deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

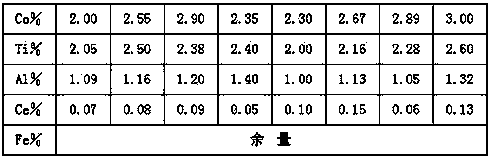

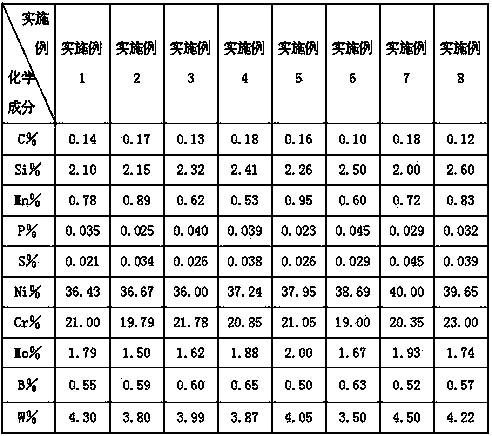

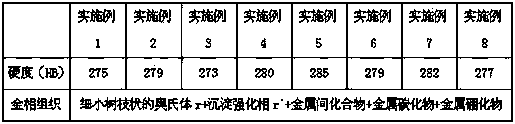

[0019] The alloy material of the casting described in the present invention adopts Invar's nickel base, low carbon, and high chromium, and by adding elements related to high temperature resistance, high boron, high amount of rare earth cerium, solid solution strengthening refractory metal tungsten, cobalt, and molybdenum, Solid solution precipitation strengthening elements titanium and aluminum. The analysis of the role of the above main chemical components in steel is as follows:

[0020] 1. Nickel Ni: The mass percentage of nickel in steel is 36-40%. As the chemical composition of the matrix material, the chemical fraction of nickel in Invar is used as the matrix, and the expansion coefficient is very small. High Ni chemical composition mass percentage can form stable austenite r solid solution and intermetallic compound, improve the strength of steel in high temperature environment, enhance carburization resistance, and reduce the tendency of casting cracks.

[0021] 2. Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com