Tungsten-copper based diamond cutter bit and diamond round saw blade and manufacture method thereof

A circular saw blade and diamond technology, which is applied in the field of tungsten-copper-based diamond cutter head, circular saw blade and its preparation, can solve the problems of affecting processing efficiency, difficult processing, and slow cutting speed, so as to improve heat dissipation effect and reduce Heat damage, reduce the effect of heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned tungsten-copper-based diamond circular saw blade provided by the present invention comprises the following steps:

[0030] Step 1, mixing materials: first put ultrafine tungsten-copper alloy powder, copper-tin alloy powder, carbonyl nickel powder, silver powder, and iron powder into the mixing tank according to the above weight percentage and mix evenly, and then add diamond, The liquid paraffin continues to mix evenly, preferably, the total mixing time is 3-4h;

[0031] Step 2, cold pressing molding: put the raw materials mixed in step 1 into the assembled pressing mold cavity with steel matrix according to the preset amount of powder, press through the press, and demould to obtain the cold pressing blank , preferably, the pressing pressure is 200-300MPa, and the pressing time is 2-3min;

[0032] Step 3, hot-press sintering: put the cold-pressed blank into a sintering mold, and carry out pressure sintering in a sintering f...

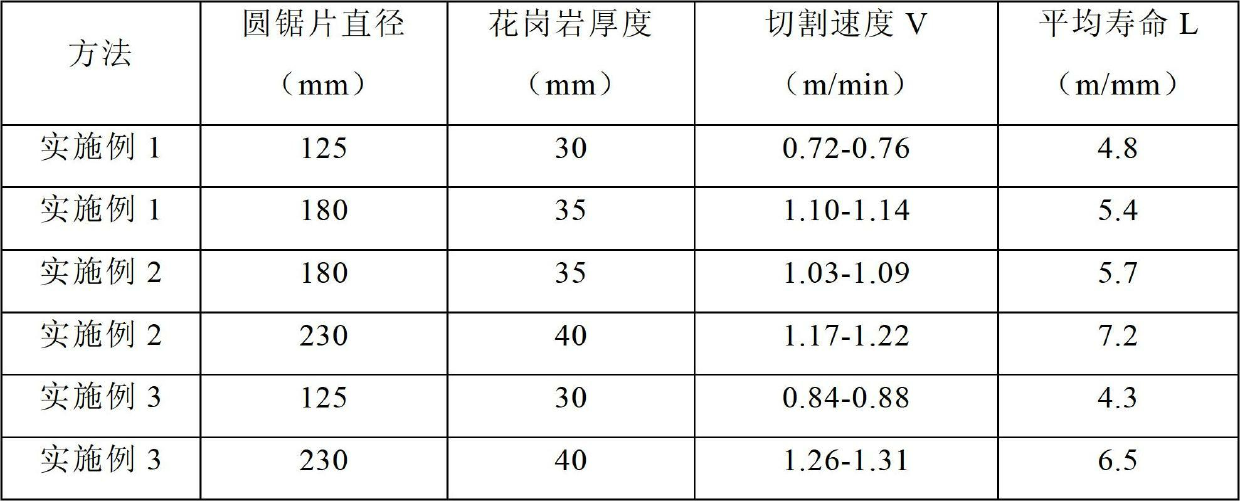

Embodiment 1

[0038] Take 3.31kg of superfine tungsten-copper alloy powder, 2.5kg of copper-tin alloy powder, 2.0kg of carbonyl nickel powder, 0.5kg of silver powder, and 1.5kg of iron powder, put them into the mixing tank, mix for 2 hours, add 0.07kg of liquid paraffin, Diamond 0.12kg, continue mixing for 2 hours. Put the mixed powder into the assembled pressing mold cavity equipped with a steel matrix according to the preset powder amount, and press it through a press for 3 minutes under a pressure of 260 MPa to obtain a cold-pressed blank. Put the cold-pressed blank into a sintering furnace, sinter at a sintering temperature of 820°C and a pressure of 25MPa, and sinter for 4 hours. After cooling out of the furnace, a semi-finished diamond circular saw blade is produced. The hardness of the inspection blade is HRB90-100. The semi-finished products are made into finished products after flat sheeting, sharpening, polishing and painting.

Embodiment 2

[0040] Take 2.7kg of superfine tungsten-copper alloy powder, 2.8kg of copper-tin alloy powder, 1.75kg of carbonyl nickel powder, 0.3kg of silver powder, and 2.3kg of iron powder, put them into the mixing tank, mix for 2 hours, add 0.05kg of liquid paraffin, Diamond 0.1kg, continue mixing for 2 hours. Put the mixed powder into the assembled pressing mold cavity equipped with the matrix according to the preset amount of powder, and press through the press for 2 minutes under the pressure of 200MPa to obtain the cold-pressed blank. Put the blank into a sintering furnace, sinter at a sintering temperature of 815°C and a pressure of 25MPa for 3.5 hours, cool it out of the furnace to produce a semi-finished diamond saw blade, and check that the hardness of the blade is HRB90-100. The semi-finished products are made into finished products after flat sheeting, sharpening, polishing and painting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com