Nickel carbonyl synthesizing method

A synthesis method, carbonylation technology, applied in the field of powder metallurgy, can solve the problems of nickel sulfide being unable to be carbonylated, slow carbonylation reaction speed, high carbonylation synthesis pressure, etc., to achieve lower temperature, high carbonylation rate, and reaction speed Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] According to the chemical composition of the raw materials used in the present invention, 6 batches of nickel carbonyl were synthesized by using the synthesis method of the present invention. Wherein Table 1 is the chemical composition list of the raw materials used in the present invention, and Table 2 is the process steps, process parameters and synthesis rate table of the synthetic method adopted in the present invention.

[0021] serial number

[0022] Preface

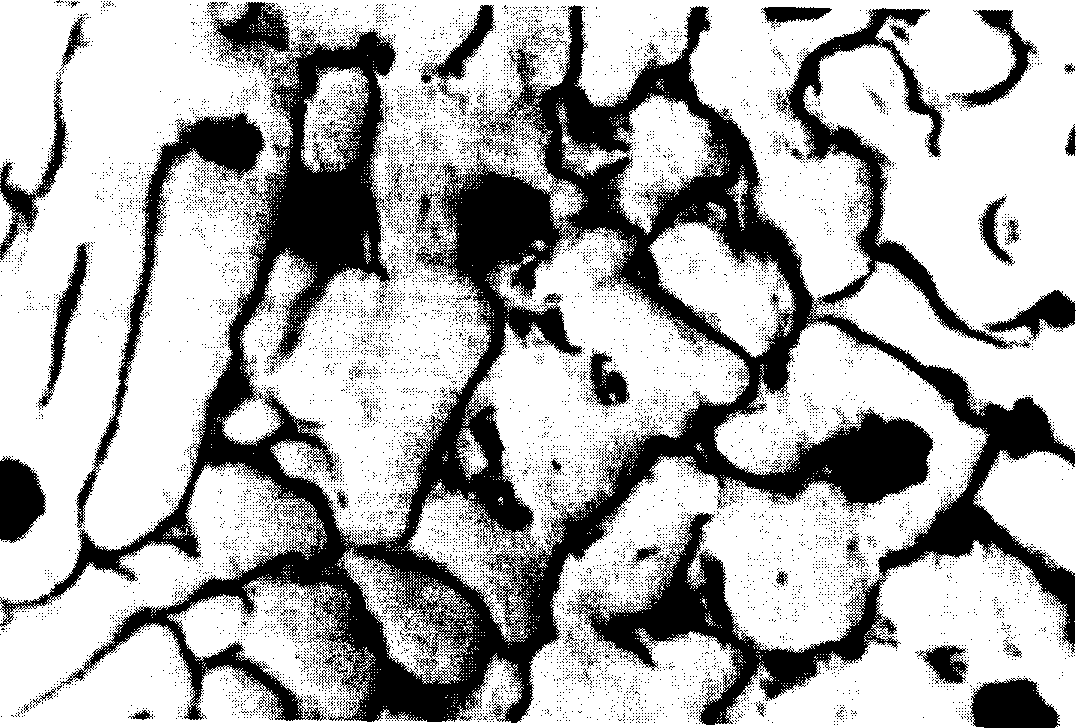

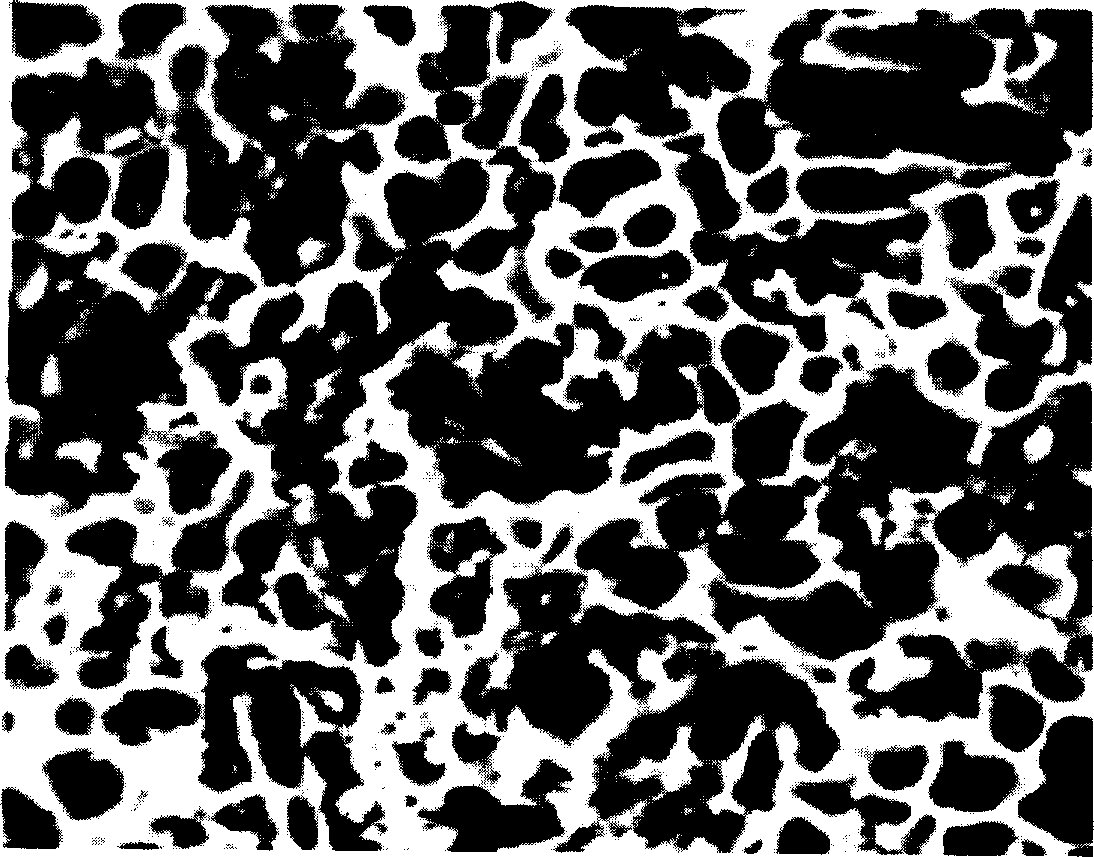

[0023] By adopting the raw materials and the synthesis method used in the invention, the sulfur is uniformly distributed in an interconnected network in the alloy, so the nickel carbonyl synthesis reaction proceeds very rapidly under relatively low pressure. The nickel carbonyl synthesis rate reaches 99.5% within 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com