Cathode material of lithium ion battery and battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor battery consistency, easy heating, and failure of small-capacity batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

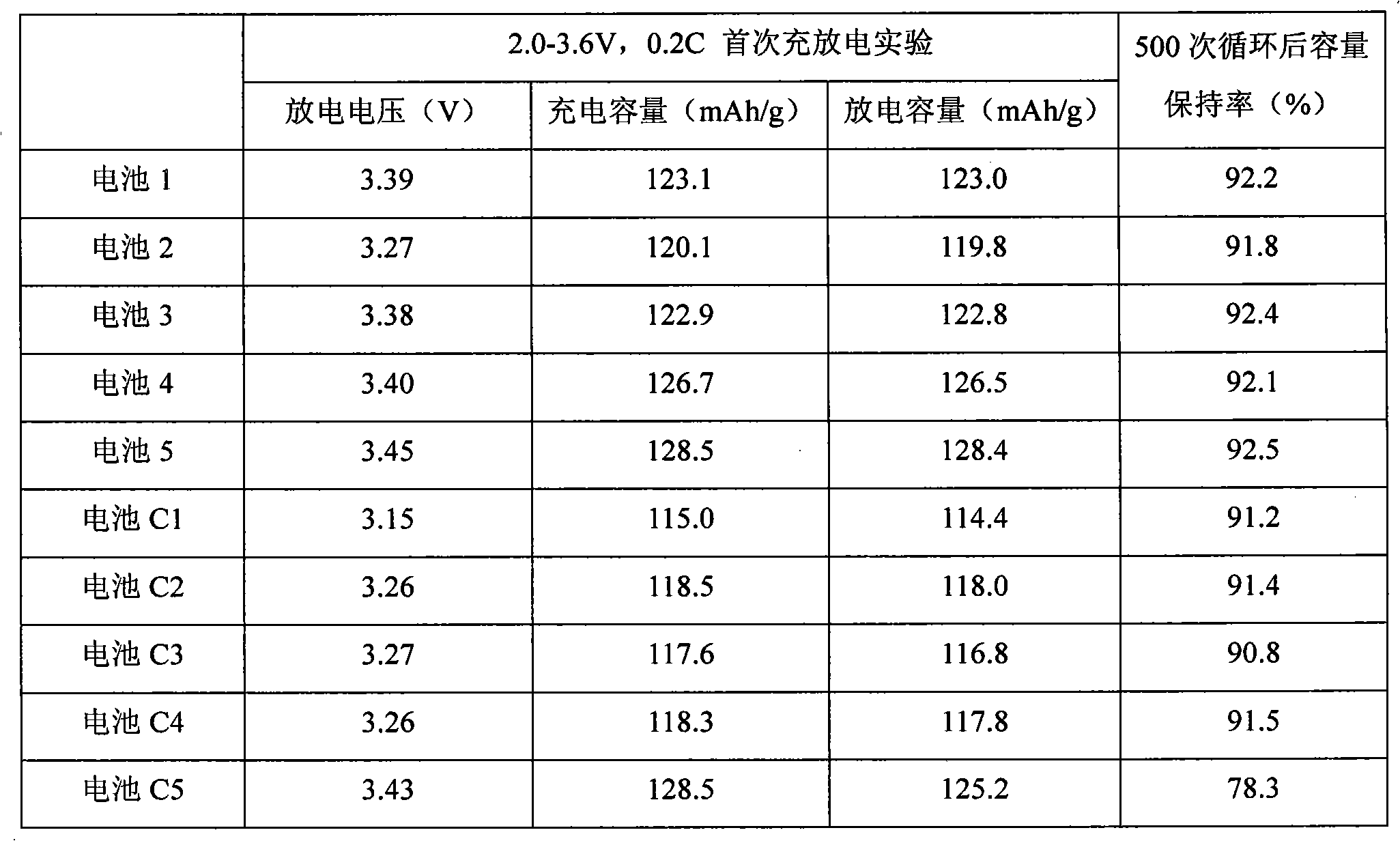

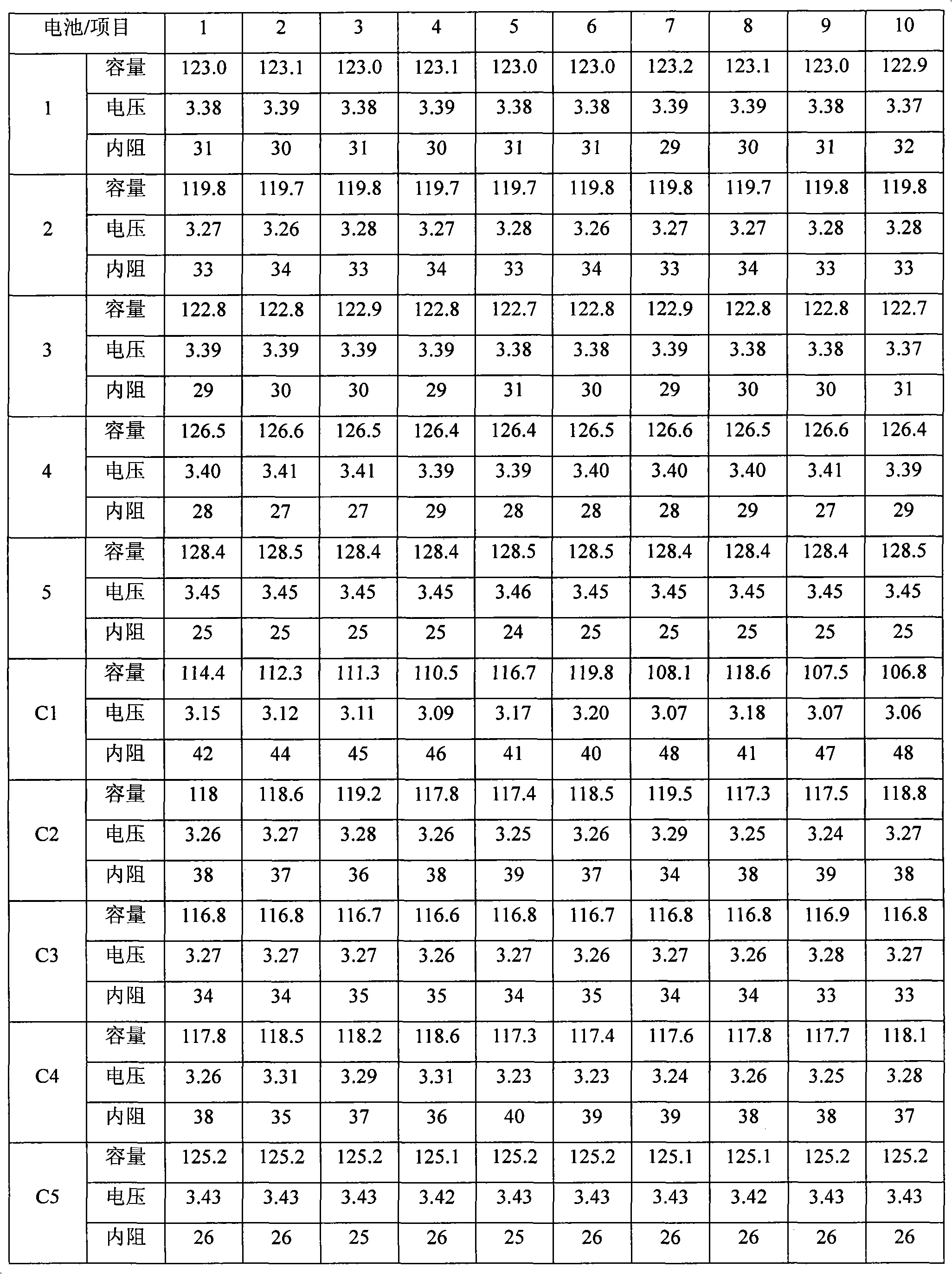

Examples

preparation example Construction

[0017] The preparation method of the positive electrode can adopt various methods commonly used in the art. For example, the positive electrode active material, the binder and the conductive agent are prepared into a positive electrode material slurry with a solvent. The amount of the solvent added is well known to those skilled in the art and can be based on the positive electrode slurry. The viscosity and operability requirements of the slurry coating can be adjusted. Then the prepared positive electrode material slurry is drawn and coated on a current collector (any current collector known in the art, such as aluminum foil), dried and pressed, and then cut to form a lithium ion battery positive electrode. The drying temperature can be selected in the range of 90 to 150°C, and the drying time can be 10 to 40 minutes.

[0018] The solvent can be various solvents known in the art, preferably water, N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF), N,N-dimethylacetamide ( O...

Embodiment 1

[0024] Add 4ml of 3-carboxypyrrole into a three-necked flask containing 150mL of distilled water. Under mechanical stirring, add the iron p-toluenesulfonate solution at a ratio of 1:1 to the amount of 3-carboxypyrrole and iron p-toluenesulfonate hexahydrate. As an oxidant and dopant, polymerize at 0°C for 6h under the protection of Ar gas, wash the filtered powder with distilled water and anhydrous alcohol 3 times each, and vacuum dry at 60°C for 24h to obtain poly(3-carboxy)pyrrole powder .

Embodiment 2

[0026] Add 134g of iron p-toluenesulfonate hexahydrate to the 1mol / L HCl solution at room temperature, stir, add 68.6g of 2-sulfonic acid aniline to the above solution, continue the reaction for 6h, stand still, filter with suction, and filter the obtained The powder was washed with distilled water and anhydrous alcohol three times each, and dried in vacuum at 60° C. for 24 hours to obtain poly(2-sulfonic acid) aniline powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com