Shielding functional textile integrating high fire resistance, high electric conduction and high magnetic permeability

A high-permeability, flame-retardant fabric technology, used in magnetic/electric field shielding, fire-retardant and flame-retardant filament manufacturing, electrical components, etc. Effectiveness, high flame retardancy, high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

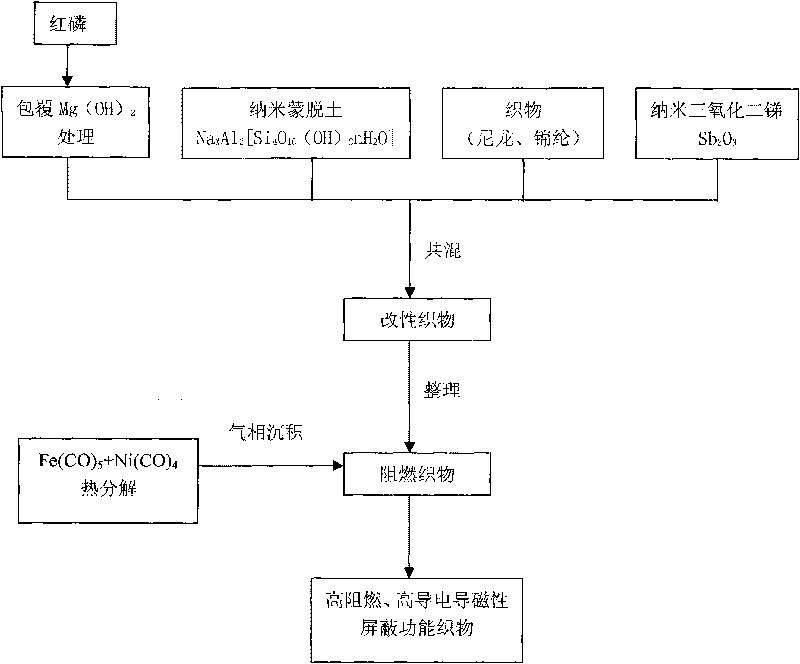

Method used

Image

Examples

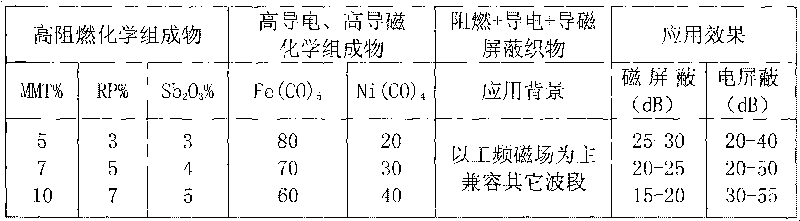

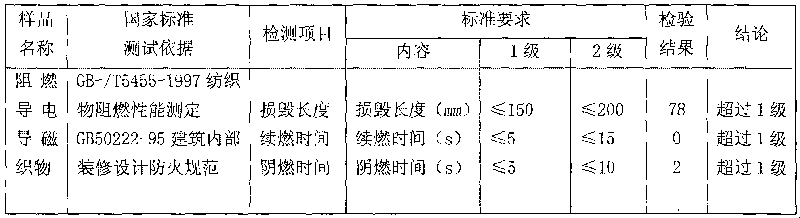

Embodiment 1

[0037] According to the preparation method of the shielding fabric which is compatible with high flame retardancy and high conductivity and high magnetic permeability of the present invention, according to the formula in Table 1, nylon fabric and nano-montmorillonite Na X Al 2 [Si 4 o 10 (OH) 2 nH 2 O], red phosphorus (RP), nano antimony trioxide (Sb 2 o 3 ) blending and finishing to prepare flame-retardant nylon, Fe(CO) 5 +Ni(CO) 4 Thermally decomposed and deposited on the flame-retardant nylon cloth to form a high-performance conductive and magnetically permeable film, and obtain the required high flame-retardant, high-conductivity and high-permeability shielding fabric. A total of three batches of shielded nylon fabric products were prepared and applied to power frequency magnetic field mainly compatible with other bands (suitable for human body protection). The shielding effectiveness test results are shown in Table 1, and the flame retardant performance test is sho...

Embodiment 2

[0043] According to the preparation method of the shielding fabric which is compatible with high flame retardancy and high electrical conductivity and magnetic permeability according to the present invention, according to the formula in Table 2, nylon fabric and nano-montmorillonite Na X Al 2 [Si 4 o 10 (OH) 2 nH 2 O], red phosphorus (RP), nano antimony trioxide (Sb 2 o 3 ) blending and finishing to prepare flame-retardant nylon, Fe(CO) 5 +Ni(CO) 4 Thermally decomposed and deposited on the flame-retardant nylon cloth to form a high-performance conductive and magnetically permeable film, and obtain the required high flame-retardant, high-conductivity and high-magnetic-permeability shielding nylon fabric. A total of three batches of shielded nylon fabrics compatible with other bands were prepared for low-frequency magnetic field applications. (Applicable to various high-voltage equipment and instruments), the shielding effectiveness test results are shown in Table 3.

...

Embodiment 3

[0047] According to the preparation method of the shielding fabric which is compatible with high flame retardancy and high conductivity and high magnetic permeability of the present invention, according to the formula in Table 3, nylon fabric and nano-montmorillonite Na X Al 2 [Si 4 o 10 (OH) 2 nH 2 O], red phosphorus (RP), nano antimony trioxide (Sb 2 o 3 ) blending and finishing to prepare flame-retardant nylon, Fe(CO) 5 +Ni(CO) 4 Thermally decomposed and deposited on the flame-retardant nylon cloth to form a high-performance conductive and magnetically permeable film, and obtain the required high flame-retardant, high-conductivity and high-permeability shielding fabric. A total of three batches of shielding nylon fabrics (applicable to various precision instruments and military electronics) mainly in the microwave band and compatible with other bands were prepared. The results of the shielding effectiveness test are shown in Table 4.

[0048] Table 4 Chemical compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com