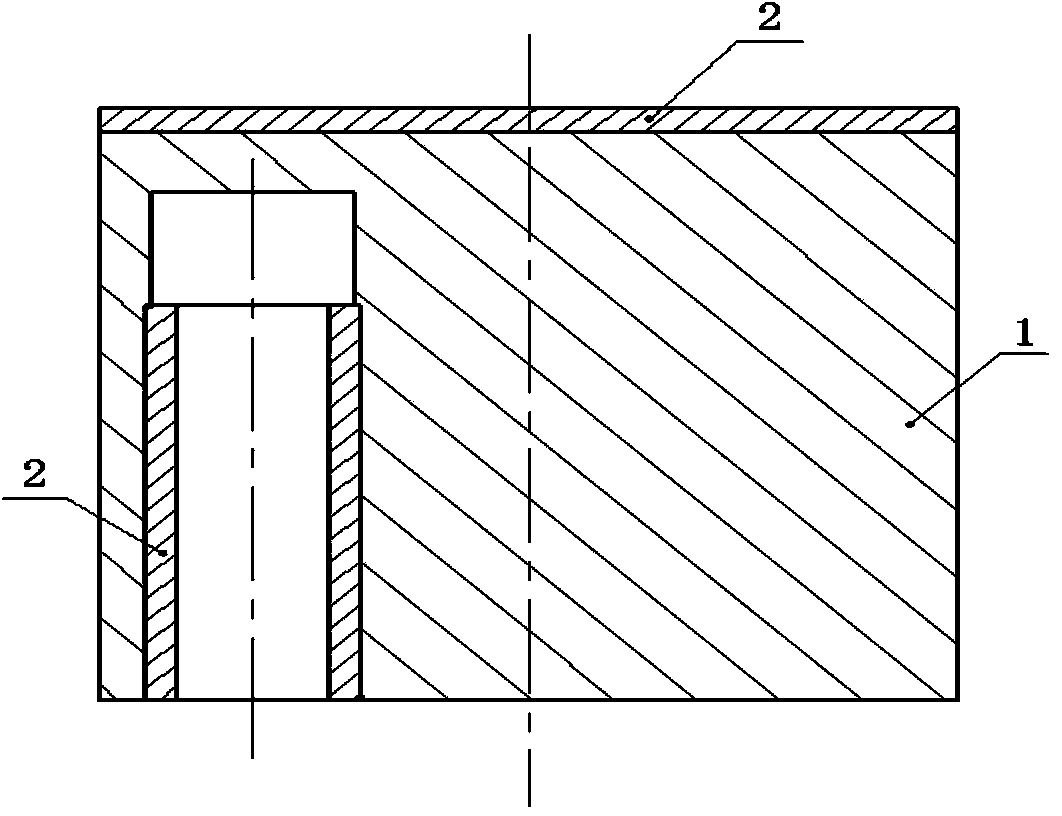

Steel-steel double-metal rotor and manufacturing method thereof

A bimetallic and rotor technology, applied in liquid fuel engines, mechanical equipment, components of pumping devices for elastic fluids, etc., can solve the problem of low melting point of copper alloy, pull out of the copper alloy layer in the plunger hole, and bond strength low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

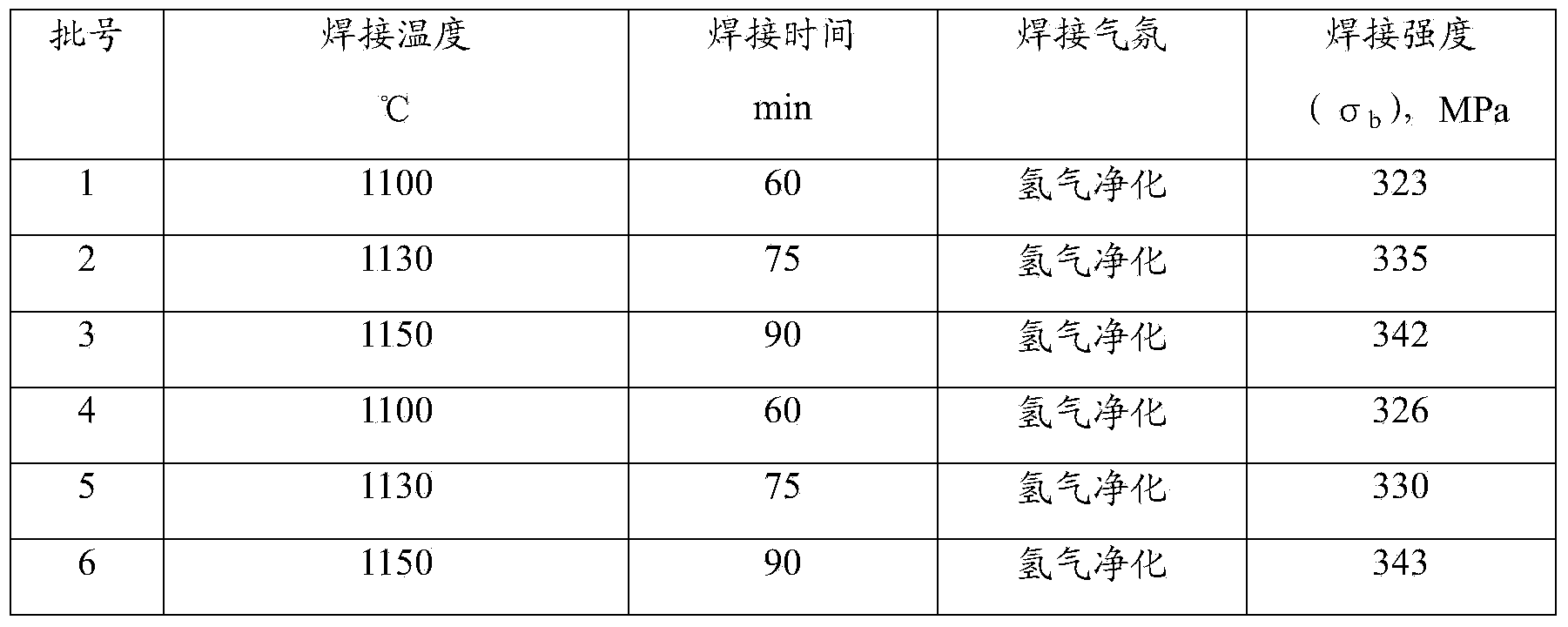

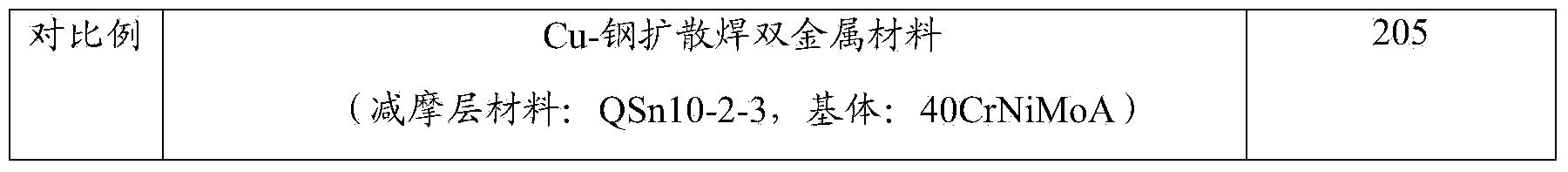

[0048] Using the bimetal manufacturing process of the present invention, 6 batches of welding samples were prepared. Table 1 shows the materials used in the preparation of welding samples, and Table 2 shows the process parameters and welding performance of the preparation of welding samples. For comparison, Table 2 lists the welding strength of Cu-steel diffusion welding bimetallic materials.

[0049] Table 1 Materials used to prepare welding samples

[0050] batch number

Anti-friction layer material

Matrix material

Welding materials

1

Self-lubricating wear-resistant steel anti-friction layer material

40CrNiMoA

Cu-10Sn-20Ni

2

Self-lubricating wear-resistant steel anti-friction layer material

40CrNiMoA

Cu-10Sn-20Ni

3

Self-lubricating wear-resistant steel anti-friction layer material

40CrNiMoA

Cu-10Sn-20Ni

4

Self-lubricating wear-resistant steel anti-friction layer material

40CrNiMoA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com