Preparation method of copper-based nano solar battery material

A solar cell, nanotechnology, applied in the directions of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as unfavorable large-scale industrial production, unfavorable solar cell light absorption, expensive high-vacuum system, etc., and achieves less harsh reaction conditions. , The yield is pollution-free, and the monodispersity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 2mmolCuCl 2 and 2mmolInCl 3 4H 2 O The two powders were mixed in a one-necked flask, and then 10mmol of sodium oleate was added, followed by 10ml of water, 15ml of ethanol and 30ml of n-hexane. It was heated to reflux at 60° C. for 4 hours to obtain a separated two-phase liquid. After separating the layered liquid with a separatory funnel, take the upper oil phase and evaporate ethanol and n-hexane at 70°C, and then evaporate the remaining water at 110°C to obtain a waxy mixture of copper oleate and indium oleate.

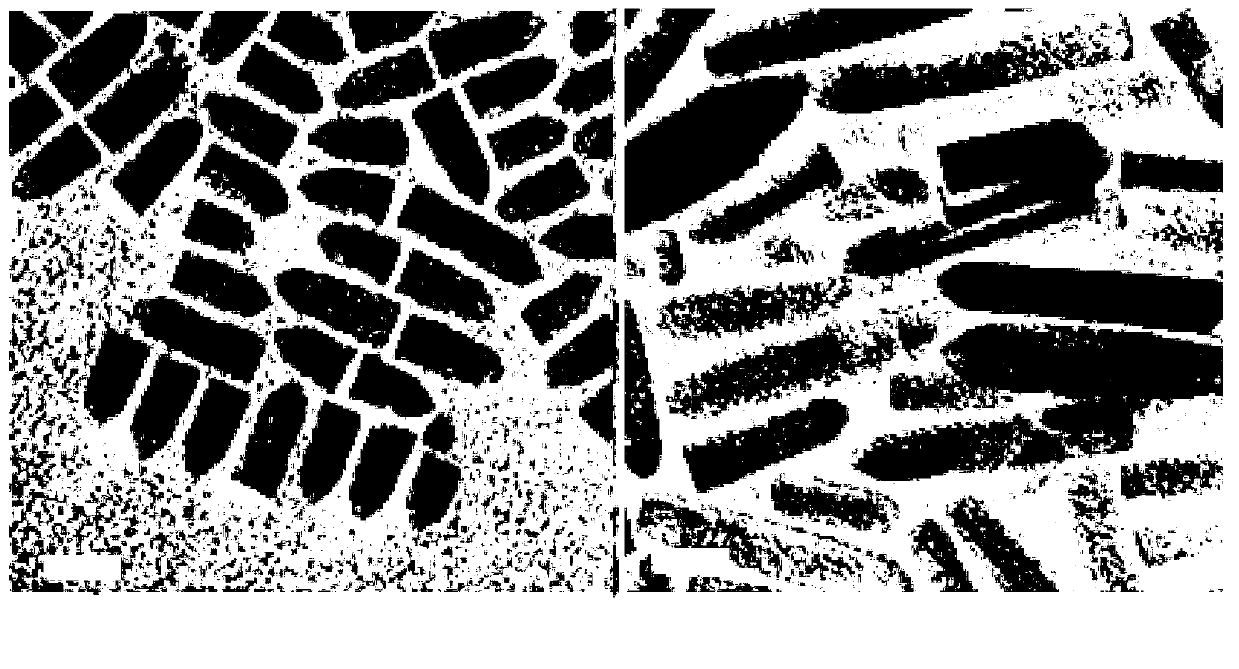

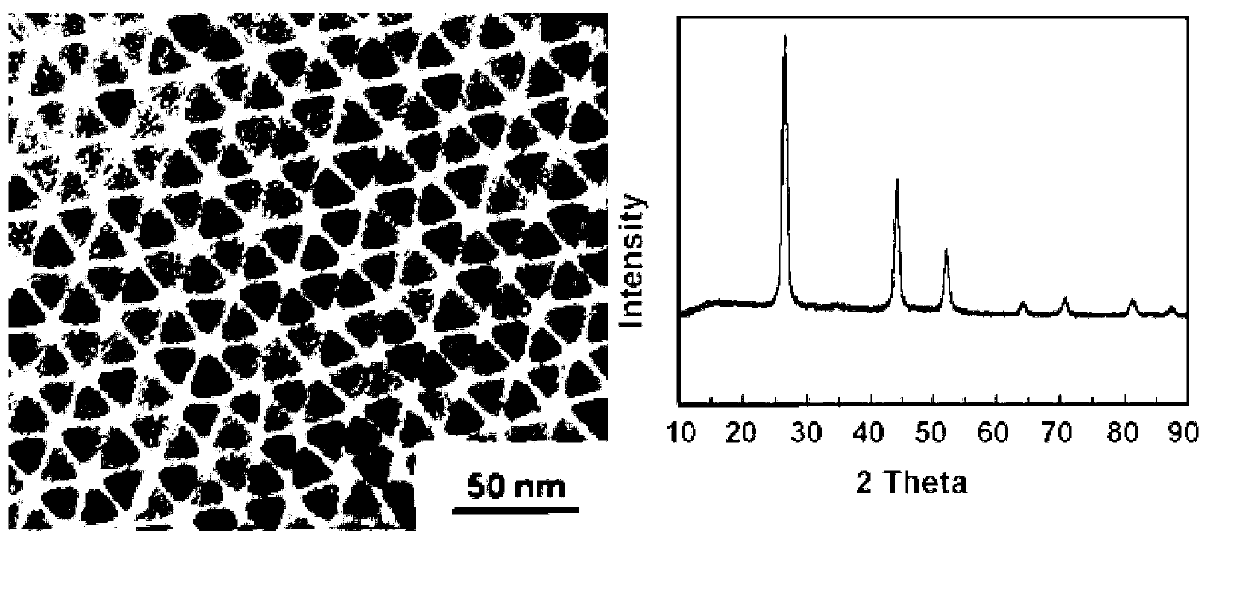

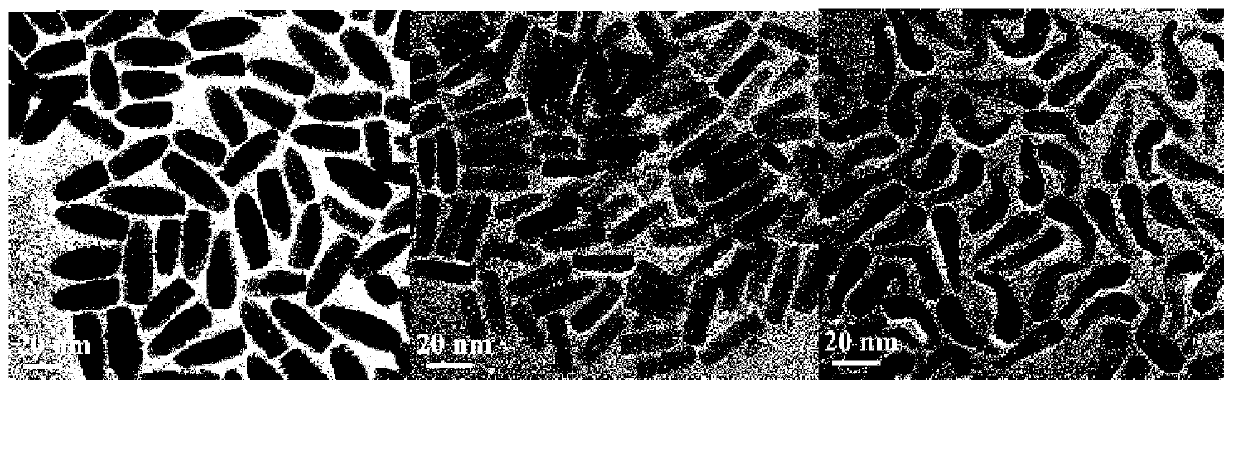

[0039] Take 30ml of oleylamine and 5ml of n-dodecanethiol and mix them in a three-necked flask filled with inert gas, and heat to 290°C. Take 2g of the synthesized mixture of copper oleate and indium oleate and completely dissolve it in 2ml of oleylamine at 150°C, and inject 0.4ml of the mixture into a flask, and keep it at 290°C for 25min to obtain a black solution. Cool to room temperature, wash with ethanol and n-hexane with a volume ratio of 1:3, cen...

Embodiment 2

[0043] 2mmolCuCl 2 and 2mmolInCl 3 4H 2 O The two powders were mixed in a one-necked flask, and then 10mmol of sodium oleate was added, followed by 10ml of water, 15ml of ethanol and 30ml of n-hexane. It was heated to reflux at 60° C. for 4 hours to obtain a separated two-phase liquid. After separating the layered liquid with a separatory funnel, take the upper oil phase and evaporate ethanol and n-hexane at 70°C, and then evaporate the remaining water at 110°C to obtain a waxy mixture of copper oleate and indium oleate.

[0044] Take 20ml of oleylamine, 10ml of oleic acid and 5ml of n-dodecanethiol and mix them in a three-necked flask filled with inert gas, and heat to 290°C. Take 2g of the synthesized mixture of copper oleate and indium oleate and completely dissolve it in 2ml of oleylamine at 150°C, and inject 0.4ml of the mixture into a flask, and keep it at 290°C for 5min to obtain a black solution. Cool to room temperature, wash with ethanol and chloroform at a volum...

Embodiment 3

[0048] 2mmolCuCl 2 and 2mmolInCl 3 4H 2 O The two powders were mixed in a one-necked flask, and then 10mmol of sodium oleate was added, followed by 10ml of water, 15ml of ethanol and 30ml of n-hexane. It was heated to reflux at 60° C. for 4 hours to obtain a separated two-phase liquid. After separating the layered liquid with a separatory funnel, take the upper oil phase and evaporate ethanol and n-hexane at 70°C, and then evaporate the remaining water at 110°C to obtain a waxy mixture of copper oleate and indium oleate.

[0049] Take 20ml of oleylamine, 10ml of 1-octadecene and 5ml of n-dodecanethiol and mix them in a three-necked flask filled with inert gas, and heat to 290°C. Take 2g of the synthesized mixture of copper oleate and indium oleate and completely dissolve it in 2ml of oleylamine at 150°C, and inject 0.4ml of the mixture into a flask, and keep it at 290°C for 25min to obtain a black solution. Cool to room temperature, wash with ethanol and acetone at a volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com