Method for surface pre-treatment of titanium electrode substrate

A technology of surface pretreatment and titanium substrate, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of expensive, incomparable, electrocatalytic activity affecting the optimal parameters of sandblasting pretreatment, etc., Achieve the effects of increased service life, improved electrocatalytic activity, and reduced electrode operation and repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

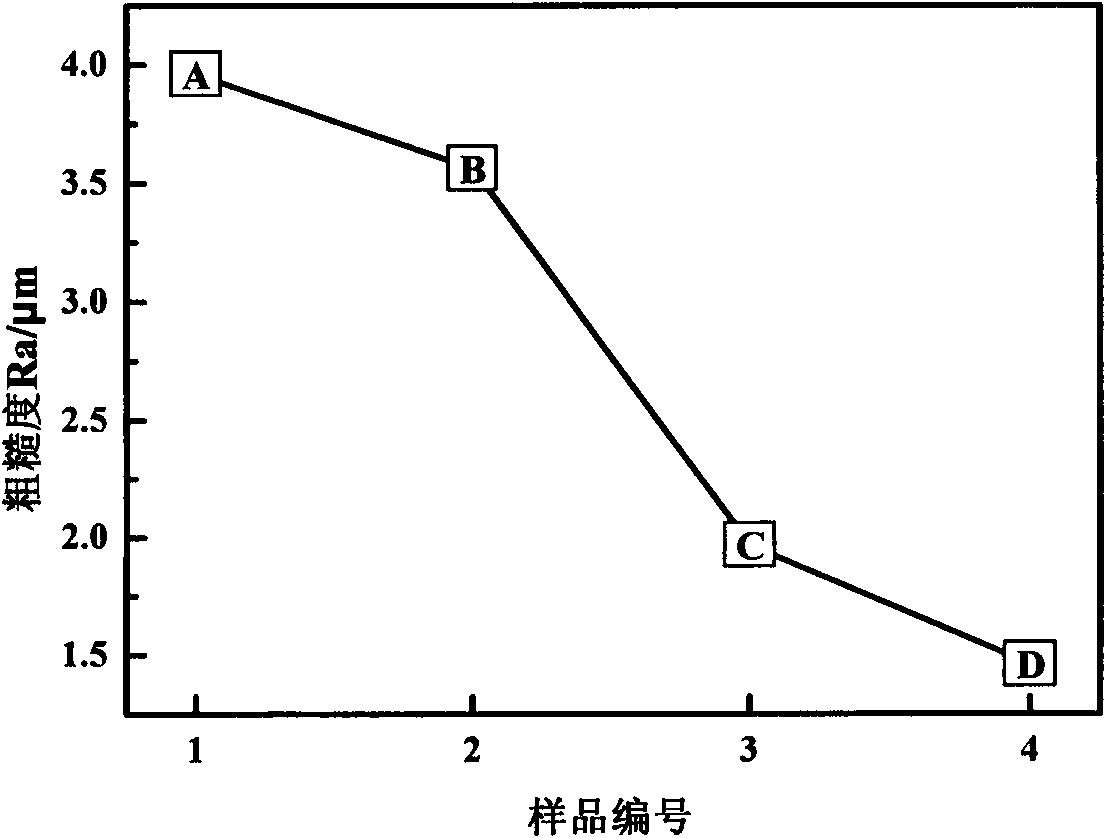

[0021] Titanium substrate pre-treatment: Sandblasting treatment of pure titanium plate: use coarse sand (30-50 mesh) and fine sand (70-90 mesh) 2 o 3 , the nozzle pressure of the sandblasting machine adopts low pressure (0.1-0.3MPa) and high pressure (0.3-0.5MPa) respectively, the spray angle is 45°-90°, the distance between the nozzle and the surface of the titanium plate is kept at about 1-2cm, and the coarsening Time 15-30s. After sandblasting, rinse with a large amount of tap water and then deionized water to remove sand particles and metal shavings remaining on the surface. Subsequently, the sandblasted titanium plate was etched with 10% (wt.%) oxalic acid solution at 90-95° C. for 2 hours, and then taken out for cleaning. Abrasive particle size and blasting pressure are shown in Table 1:

[0022] Table 1 Different blasting pretreatment process of titanium substrate

[0023] Table1.as-pretreatment procedure of Ti base according to sand-blast adopted

[0024]

[00...

example 2

[0029] Pre-treatment of titanium substrates: same as in Example 1, titanium substrates A to D with different roughnesses were obtained.

[0030] Coating of iridium and tantalum coating: The composition and coating method of the coating solution are the same as in Example 1, coating 5 layers, and sintering at 450° C. for 1 hour for the last time.

[0031] Surface morphology and electrocatalytic performance characterization: The current density i at the oxygen evolution potential (E=1.4V vs SCE) was compared to compare the oxygen evolution electrocatalytic activity of each pretreated electrode (similar to the attached Figure 10 , omitted), the catalytic activity of the electrodes obtained by the pretreatment of substrates A and D is equivalent, respectively 24.2mA·cm -2 and 24.7mA·cm -2 , the worst of C, only 20.8mA·cm -2 , the electrocatalytic activity (28.1mA·cm -2 ) increased by 14-35% compared to A, D and C, respectively.

[0032] Accelerated life test: choose high curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com