Method for preparing large-specification TC4 titanium alloy cast ingot through high-proportion defective titanium materials

A technology with a high proportion of titanium residues is applied in the field of preparing large-scale TC4 titanium alloy ingots with high proportions of titanium residues, and can solve the problems of affecting the composition and surface quality of the ingots, low production efficiency, and low addition of residual materials, etc. Achieve the effect of improving the yield and production efficiency, saving costs, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

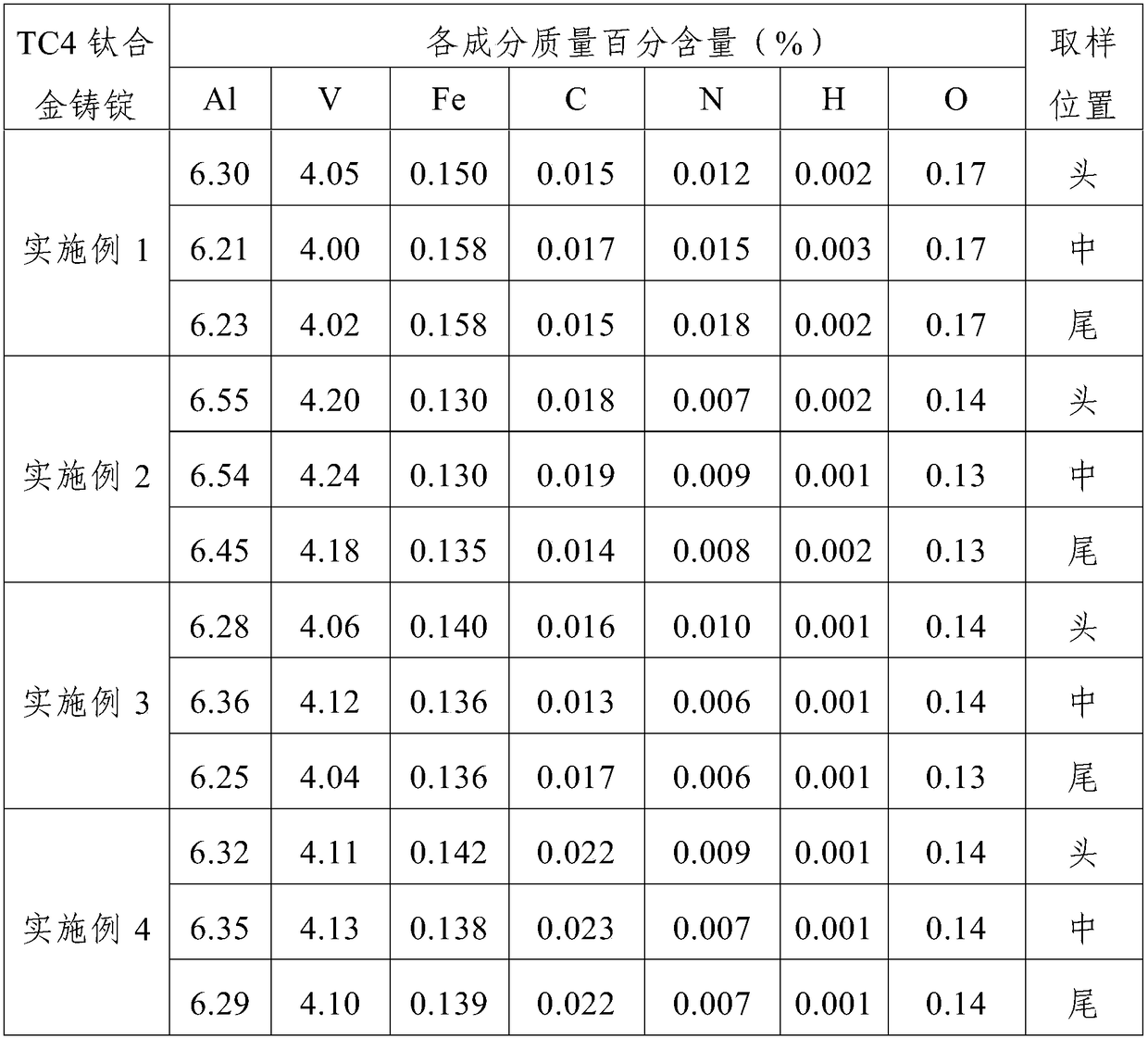

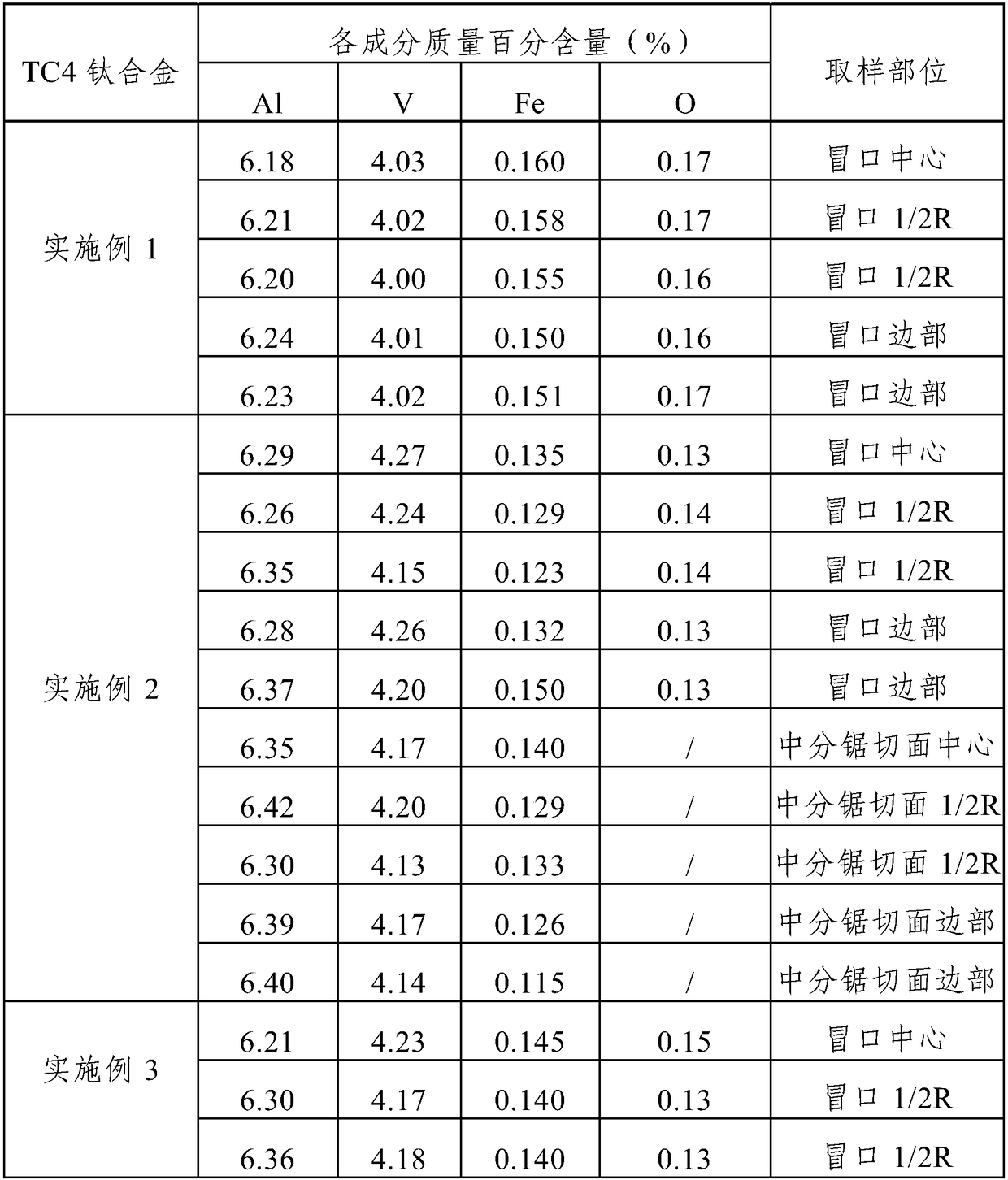

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] Step 1. Grinding, sawing, pickling and drying the block and flake TC4 residues in order to make the surface silvery white without acid stains and visible pollutants, and then use a strapping machine to dry The final TC4 residual material is bundled into 2 residual material electrodes, so that the TC4 residual material in the 2 residual material electrodes does not loosen and fall off; the diameter of the 2 residual material electrodes is 320mm, and the length is 4000mm;

[0031] Step 2. Use a plasma torch to weld the two residual electrodes obtained in step 1, and then use an angle grinder with a steel brush to clean the oxides at the solder joints formed by welding on the residual electrodes, so that the solder joints are silver white;

[0032] Step 3, placing the cleaned residue electrode in step 2 in a vacuum consumable electric arc furnace for two smelting to obtain 2 intermediate ingots; the diameters of the 2...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] Step 1. Grinding, sawing, pickling and drying the block and flake TC4 residues in order to make the surface silvery white without acid stains and visible pollutants, and then use a strapping machine to dry The final TC4 residual material is bundled into 4 residual material electrodes, so that the TC4 residual material in the 4 residual material electrodes does not loosen and fall off; the diameter of the 4 residual material electrodes is 320mm, and the length is 4000mm;

[0043] Step 2. Use a plasma torch to weld the 4 residual electrodes obtained in step 1, and then use an angle grinder with a steel brush to clean the oxides at the solder joints formed by welding on the residual electrodes, so that the solder joints are silver white;

[0044] Step 3, placing the cleaned residue electrode in step 2 in a vacuum consumable electric arc furnace for two smelting to obtain 2 intermediate ingots; the diameters of the 2 i...

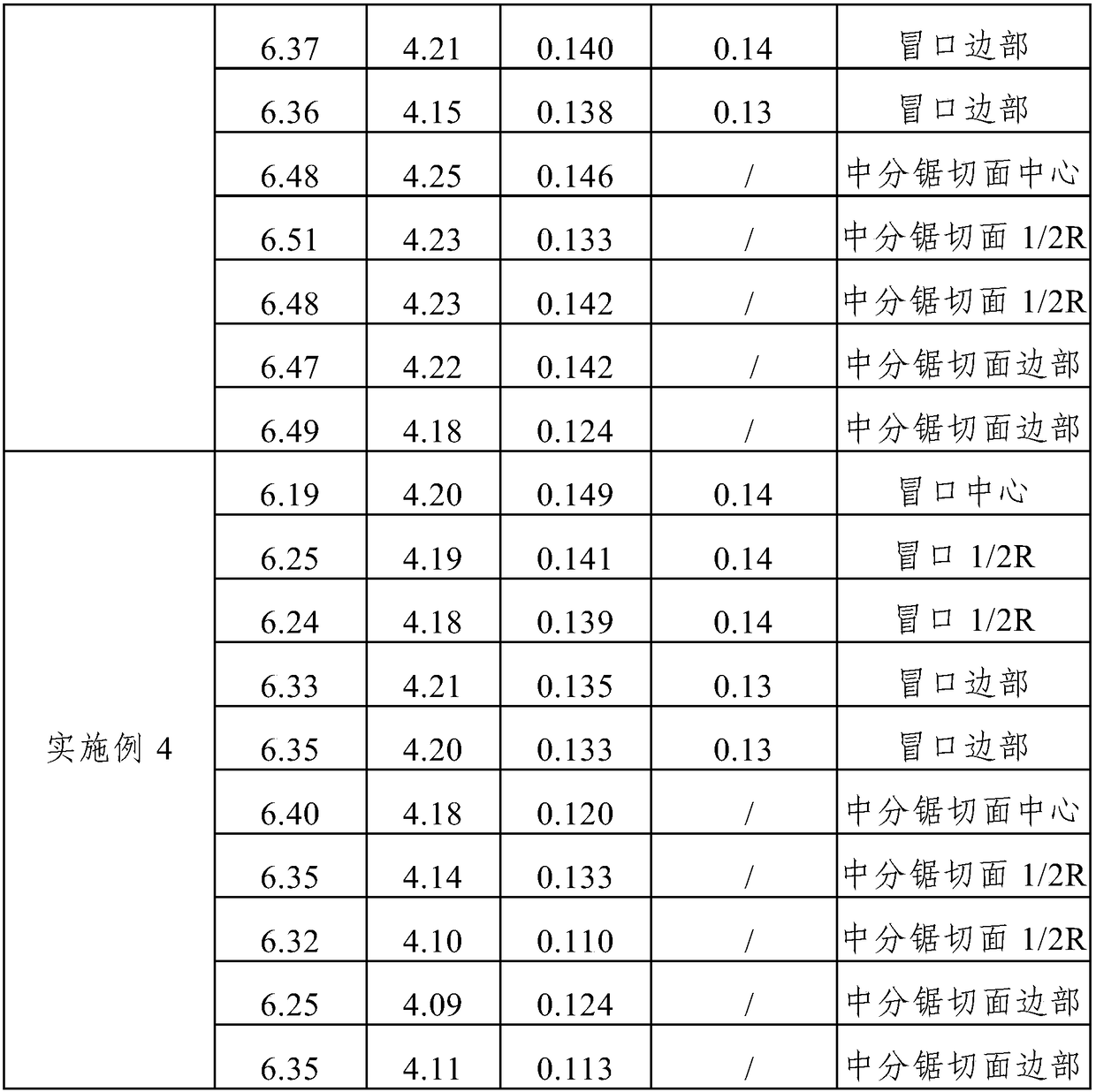

Embodiment 3

[0053] This embodiment includes the following steps:

[0054] Step 1. Grinding, sawing, pickling and drying the block and flake TC4 residues in order to make the surface silvery white without acid stains and visible pollutants, and then use a strapping machine to dry The final TC4 residual material is bundled into 4 residual material electrodes, so that the TC4 residual material in the 4 residual material electrodes does not loosen and fall off; the diameter of the 4 residual material electrodes is 480mm, and the length is 4000mm;

[0055] Step 2. Use a plasma torch to weld the 4 residual electrodes obtained in step 1, and then use an angle grinder with a steel brush to clean the oxides at the solder joints formed by welding on the residual electrodes, so that the solder joints are silver white;

[0056] Step 3, placing the cleaned residue electrode in step 2 in a vacuum consumable electric arc furnace for two smelting to obtain 2 intermediate ingots; the diameters of the 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com