Preparation method of carbon encapsulated magnetic C/Fe3O4 nano composite material and application thereof

A nanocomposite material, carbon coating technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of low specific surface area, increased functional groups, low porosity, etc., and achieves a simple process. , The effect of improving water solubility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

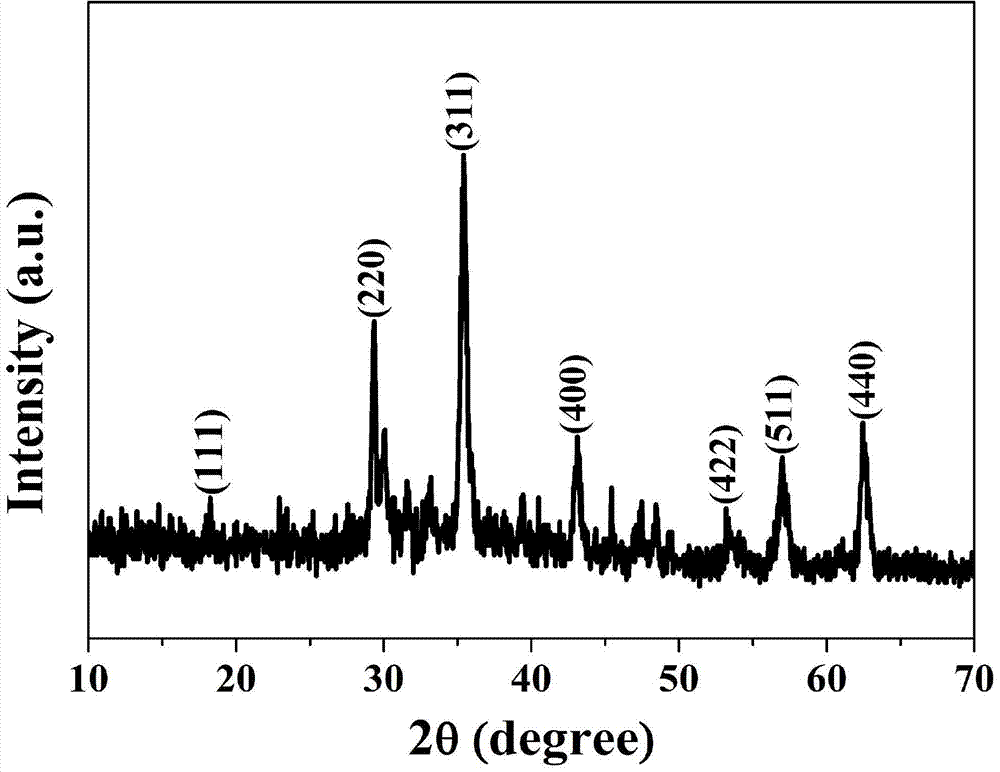

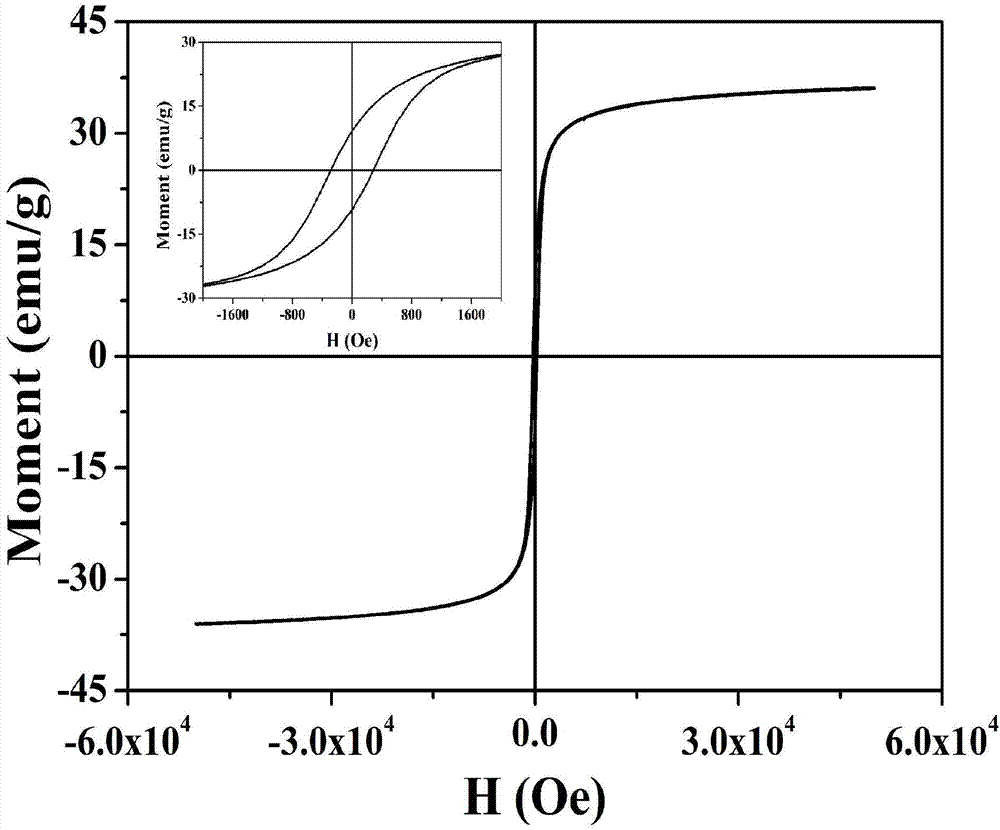

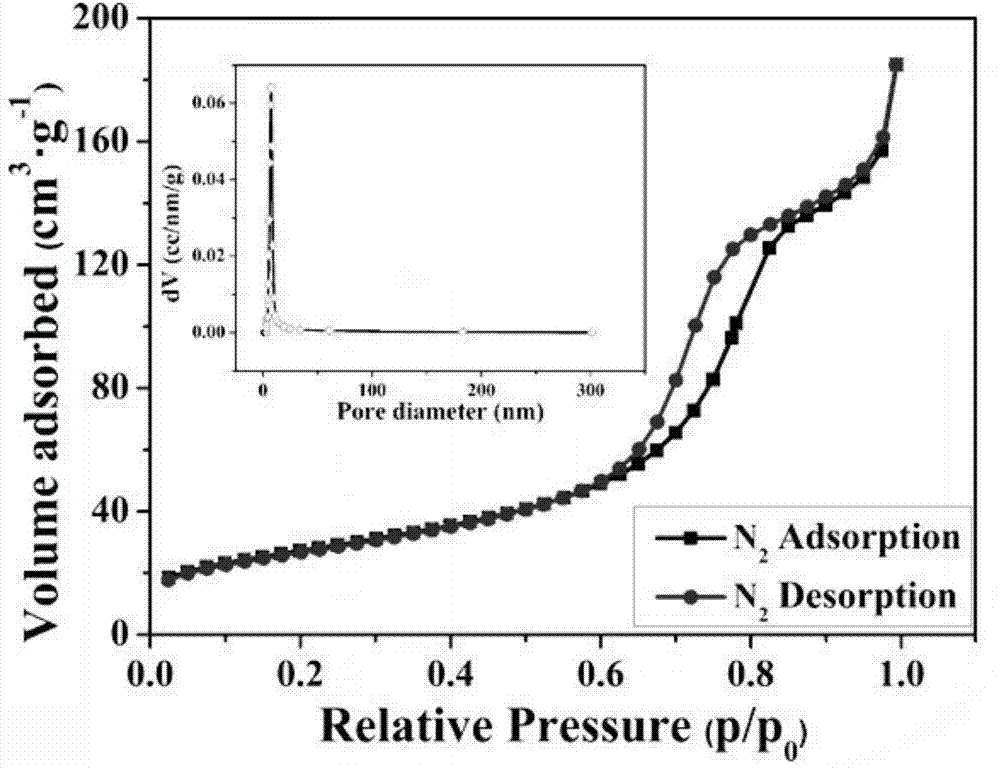

[0029] Carbon coated magnetic C / Fe 3 o 4 The preparation method of the nanocomposite material adopts hydrothermal method and thermal decomposition method, using pure water as a solvent, and the specific steps are: at room temperature, add 1mmol FeCl to a polytetrafluoroethylene-lined reactor containing 40ml of water 3 ·6H 2 O and 2 mmol Na 2 B 4 o 7 , after stirring evenly, add 8mmol solid NaOH, stir until completely dissolved, put the reaction kettle at 140°C for constant temperature reaction for 12h, then cool down, and centrifuge the reaction solution at 6000r / min. Collect the precipitate, divide distilled water, wash several times with absolute ethanol, and then place it in a vacuum oven at 60°C for drying; then the obtained 1.5g Fe 2 o 3 Add the nanoparticles into the dissolved sodium alginate solution with a concentration of 15g / L. After stirring for 30min, add the obtained mixed solution dropwise to the prepared CaCl solution with a concentration of 21g / L using a ...

Embodiment 2

[0033] Carbon coated magnetic C / Fe 3 o 4 The preparation method of the nanocomposite material adopts hydrothermal method and thermal decomposition method, using pure water as a solvent, and the specific steps are: at room temperature, add 1mmol FeCl to a polytetrafluoroethylene-lined reactor containing 40ml of water 3 ·6H 2 O and 2 mmol Na 2 B 4 o 7 , after stirring evenly, add 8mmol solid NaOH, stir until completely dissolved, put the reaction kettle at 140°C for constant temperature reaction for 12h, then cool down, and centrifuge the reaction solution at 6000r / min. Collect the precipitate, divide distilled water, and wash several times with absolute ethanol, and then place it in a vacuum oven at 80°C for drying; then the obtained 1.5g Fe 2 o 3 Add the nanoparticles into the dissolved sodium alginate solution with a concentration of 15g / L. After stirring for 30min, add the obtained mixed solution dropwise to the prepared CaCl solution with a concentration of 21g / L usin...

Embodiment 3

[0035] Carbon coated magnetic C / Fe 3 o 4 The preparation method of the nanocomposite material adopts hydrothermal method and thermal decomposition method, using pure water as a solvent, and the specific steps are: at room temperature, add 2mmol FeCl to a polytetrafluoroethylene-lined reactor containing 80ml of water 3 ·6H 2 O and 4 mmol Na 2 B 4 o 7 , after stirring evenly, add 16mmol solid NaOH, stir until completely dissolved, put the reaction kettle at 140°C for constant temperature reaction for 12h, then cool down, and centrifuge the reaction solution at 6000r / min. The precipitate was collected, washed with distilled water and absolute ethanol several times, and then dried in a vacuum oven at 60°C; then the obtained 1.5g Fe 2 o 3 Add the nanoparticles into the dissolved sodium alginate solution with a concentration of 15g / L. After stirring for 30min, add the obtained mixed solution dropwise to the prepared CaCl solution with a concentration of 21g / L using a syringe. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com