Method for manufacturing titanium base lead dioxide electrode capable of controlling coating granularity

A lead dioxide, coating technology, applied in the field of electrochemistry, can solve the problems of stay, application scope limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: A titanium plate (10 mm×30 mm×2 mm) was etched in 10 wt % hydrochloric acid solution for 1 hour, and then rinsed with distilled water. The treated titanium plate is placed in an oven and dried, and then the tin antimony oxide coating solution (coating solution consists of: 0.512g SnCl 2 2H 2 O, 0.057g SbCl 3 , 2ml of n-butanol solution, three drops of 37wt% concentrated hydrochloric acid) evenly coated on the surface of the titanium substrate, baked in an oven at 120°C for 5min, then placed it in a muffle furnace and sintered at 500°C for 5min, and took out Cool to room temperature. Repeat this step about twenty times, and finally sinter at 500°C for 1 hour. During the coating process, it is necessary to continuously feed oxygen into the muffle furnace.

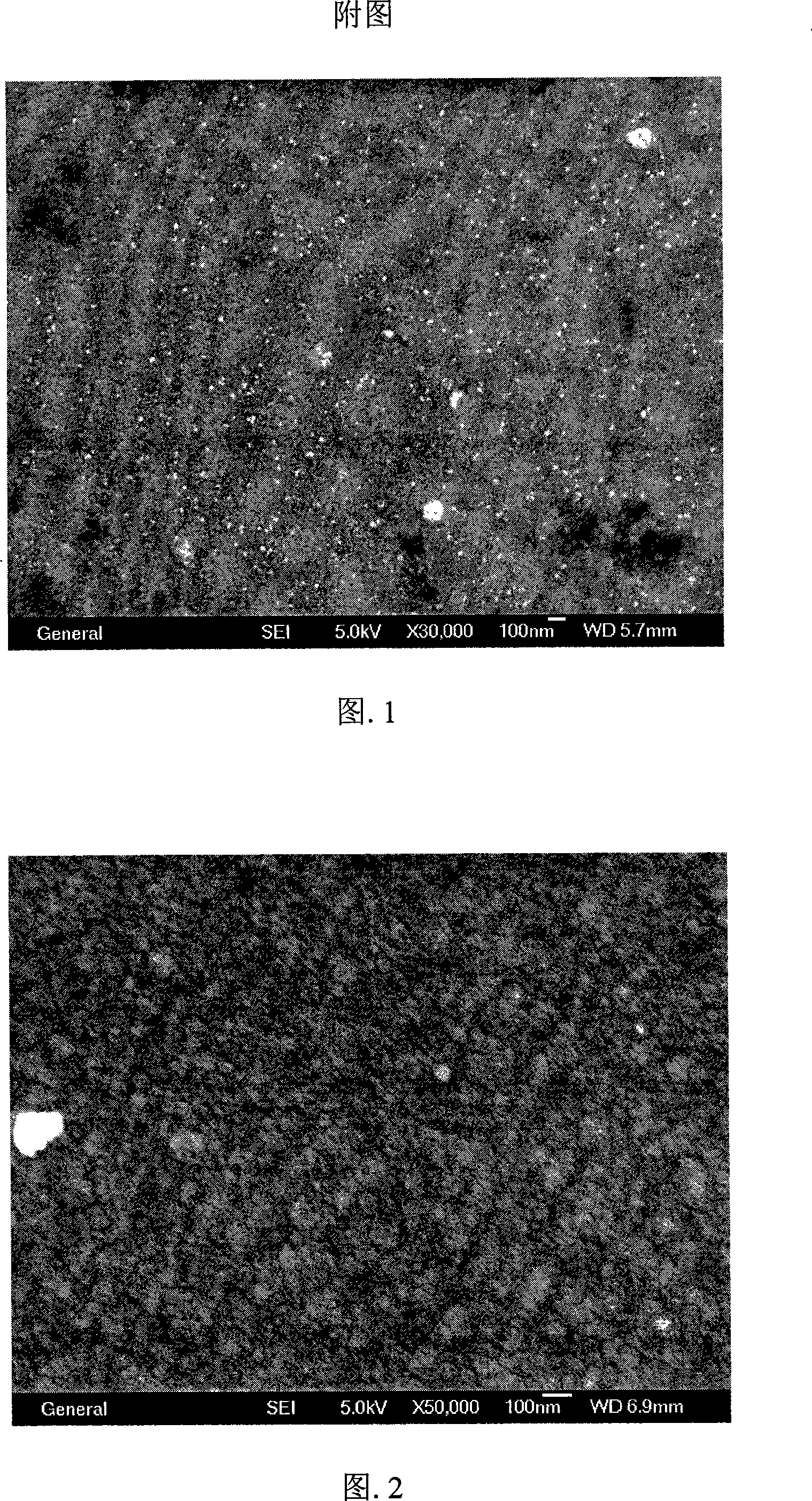

[0013] Electrodeposition of nanometer lead dioxide electrode: the composition of electrodeposition solution is 33.12g Pb(NO 3 ) 2 , 1.68g NaF, 7ml HNO 3 , with Ti / Ru-Ti-Sn (30mm×30mm×2mm) as the count...

Embodiment 2

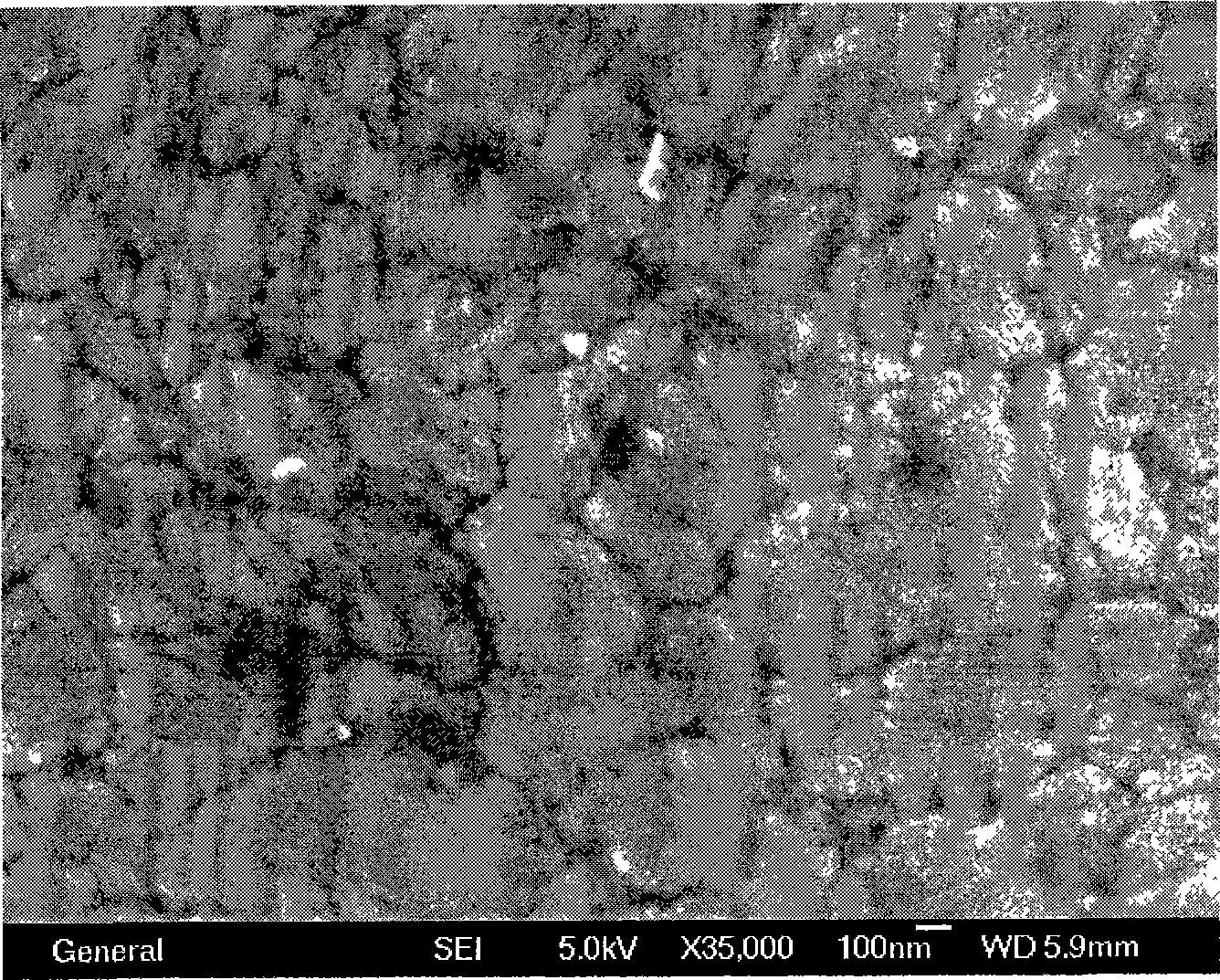

[0014] Embodiment 2: Prepare nano lead dioxide electrode according to the electrodeposition process of embodiment 1, but control potential at 1.60V. As the electrode potential decreases, the electrode reaction rate decreases, the current decreases to about 20mA, and the oxygen evolution rate on the electrode decreases accordingly. A black bright electrode is obtained, and the deposited layer is firmly combined with the substrate. The particle size changes to around 100nm, as shown in Figure 2. PbO 2 The particle size has changed significantly.

Embodiment 3

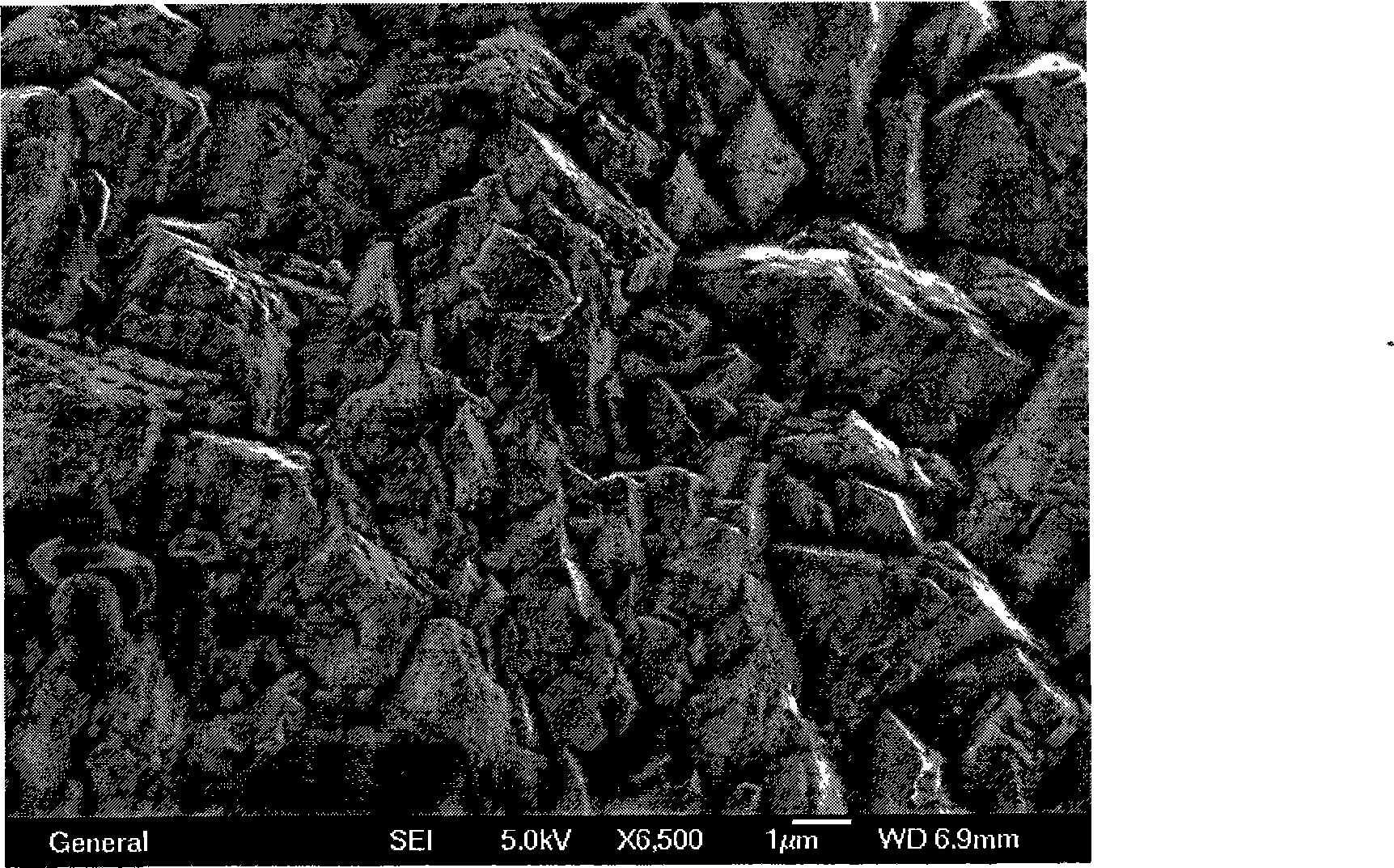

[0015] Embodiment 3: Prepare lead dioxide electrode according to the electrodeposition process of embodiment 1, but control potential at 1.55V. The drop in potential resulted in almost no observable evolution of oxygen during electrodeposition, the current was on the order of a few mA, and the resulting electrode surface was glossy black. The particle size is around 500 nanometers, as shown in Figure 3. Due to the smaller current, the deposited layer is thinner than the electrode prepared above in the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com