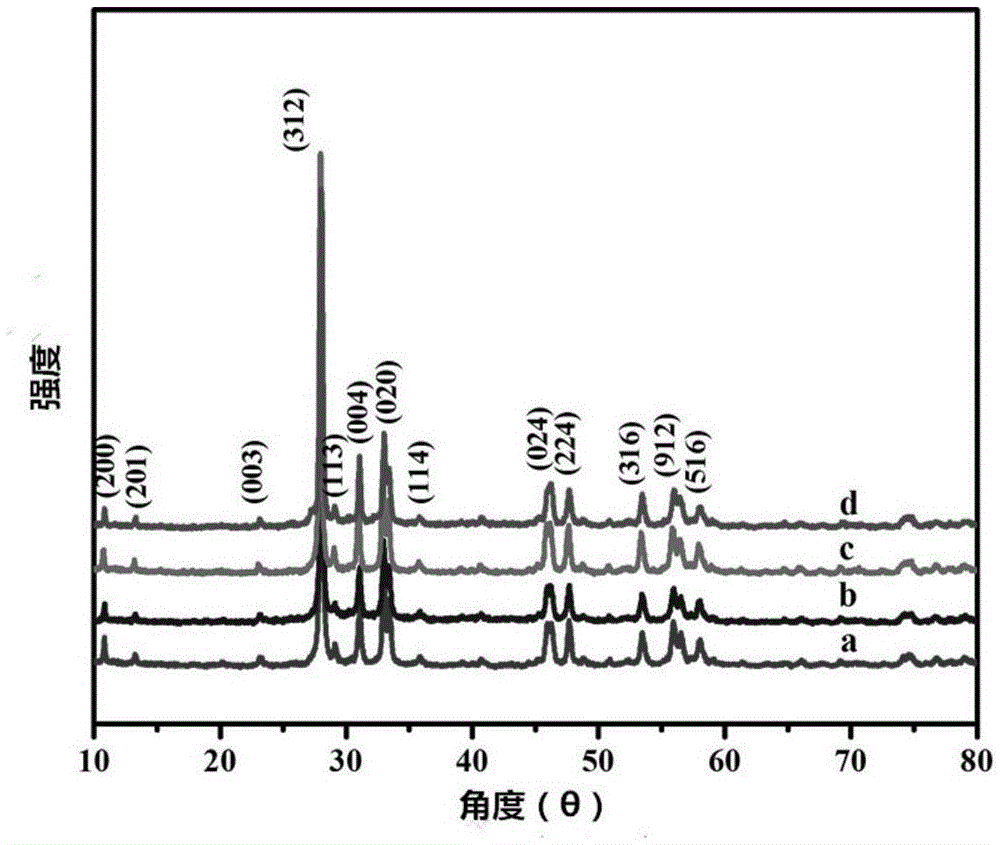

Nano mesoporous microspherical Bi5O7I photocatalyst and hydrothermal-thermal decomposition preparation method thereof

A photocatalyst and nano-mesoporous technology, which is applied in the field of photocatalytic material research, can solve the problems of different catalytic activity and no photocatalytic activity, and achieve the effect of low raw material cost, enhanced photocatalytic performance, and fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

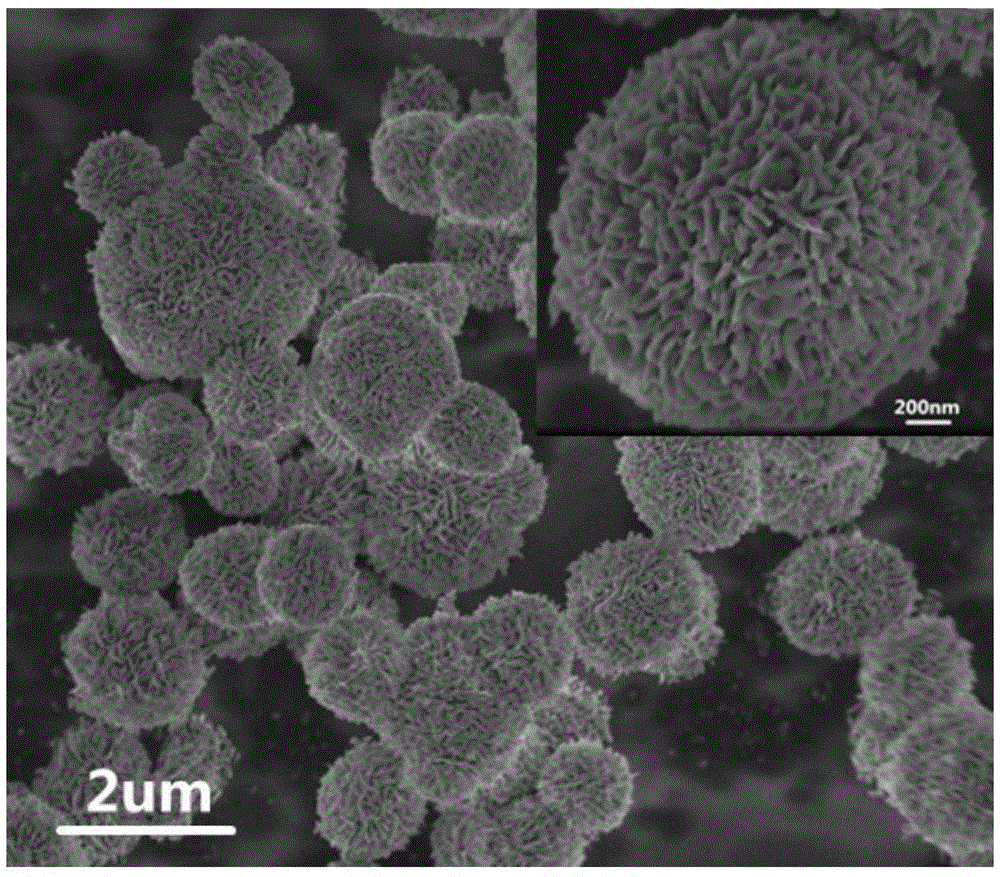

Embodiment 1

[0026] (1) The weighed Bi(NO 3 ) 3 ·5H 2 O is placed in 30mL ethylene glycol solution, so that Bi(NO 3 ) 3 ·5H 2 The dissolved concentration of O is 0.09mol / L. At the same time, place the weighed KI in 20mL of ethylene glycol solution so that the dissolved concentration of KI is 0.15mol / L, and ultrasonically vibrate them respectively at a frequency of 90Hz for 25min. Until it is completely dissolved, it is prepared into bismuth salt solution A and iodine salt solution B respectively.

[0027] (2) slowly join iodine salt solution B solution in the bismuth salt solution A, make n Bi :n I =0.9:1, magnetically stirred for 60 min to prepare a precursor BiOI solution.

[0028] (3) Put the precursor BiOI solution into a polytetrafluoroethylene reactor with a filling ratio of 50%, place the reactor in a constant temperature heating box, set the reaction temperature to 180°C, and the holding time to 10h. After the reaction is completed, , naturally cooled to room temperature, t...

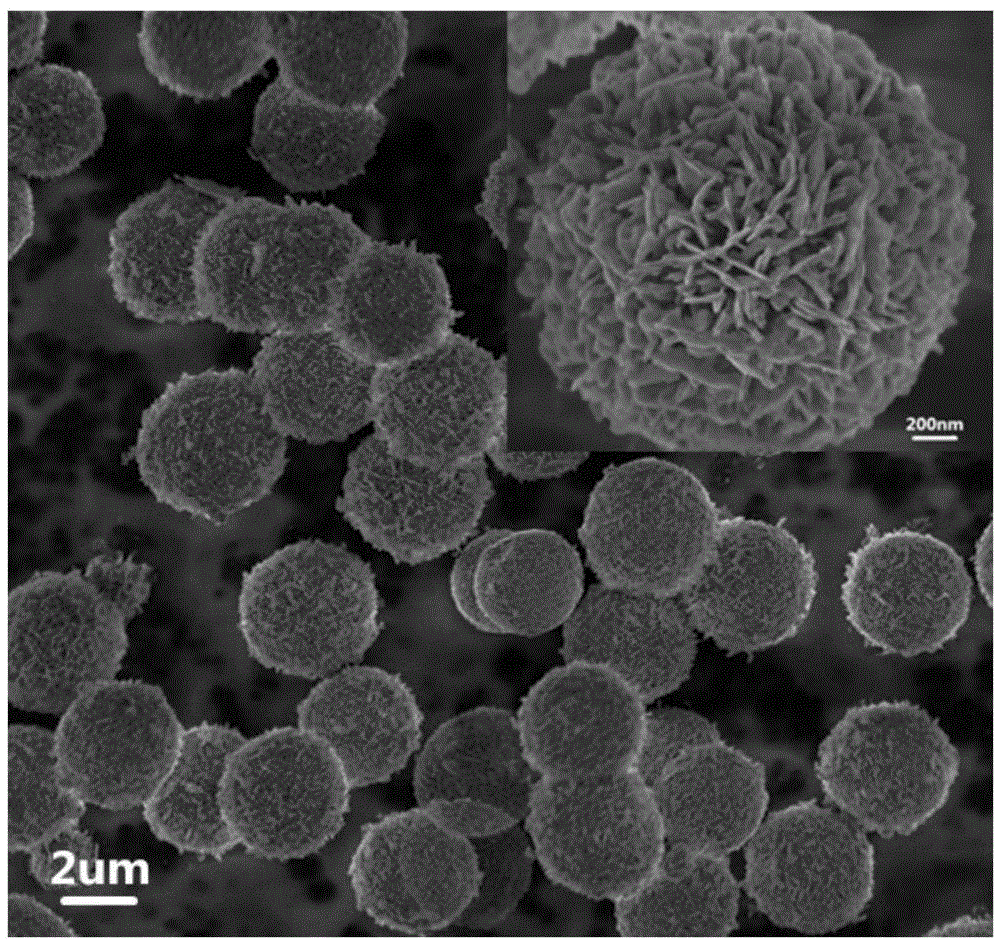

Embodiment 2

[0034] (1) Bi(NO 3 ) 3·5H 2 O and KI were placed in 22.1mL and 20mL ethylene glycol solution respectively, so that Bi(NO 3 ) 3 ·5H 2 The dissolved concentration of O is 0.1mol / L, and the dissolved concentration of KI in the iodized salt solution is 0.13mol / L, and the frequency is 100Hz under the condition of ultrasonic vibration for 30min, until it is completely dissolved, and respectively prepared into bismuth salt solution A and iodized salt solution B .

[0035] (2) slowly join iodine salt solution B solution in the bismuth salt solution A, make n Bi :n I =0.85:1, magnetically stirred for 50 minutes to prepare a precursor BiOI solution.

[0036] (3) Put the precursor BiOI solution into a polytetrafluoroethylene reactor with a filling ratio of 65%, place the reactor in a constant temperature heating box, set the reaction temperature to 160°C, and the holding time to 12h. After the reaction is completed, , naturally cooled to room temperature, the yellow precipitate i...

Embodiment 3

[0042] (1) The weighed Bi(NO 3 ) 3 ·5H 2 O is placed in 30mL ethylene glycol solution, so that Bi(NO 3 ) 3 ·5H 2 The dissolved concentration of O is 0.1mol / L. At the same time, place the weighed KI in 20mL ethylene glycol solution so that the dissolved concentration of KI is 0.17mol / L, and ultrasonically vibrate them respectively at a frequency of 100Hz for 20min. Until it is completely dissolved, it is prepared into bismuth salt solution A and iodine salt solution B respectively.

[0043] (2) slowly join iodine salt solution B solution in the bismuth salt solution A, make n Bi :n I =0.88:1, magnetically stirred for 40 minutes to prepare a precursor BiOI solution.

[0044] (3) Put the precursor BiOI solution into a polytetrafluoroethylene reactor with a filling ratio of 70%, place the reactor in a constant temperature heating box, set the reaction temperature to 120°C, and the holding time to 11h. After the reaction is completed, , naturally cooled to room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com