Nano loaded titanium-based electric catalytic film and preparation method thereof

An electrocatalytic film, titanium-based technology, applied in the field of nano-supported titanium-based electrocatalytic film and its preparation, can solve the problem of low strength, achieve high strength, low working voltage, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

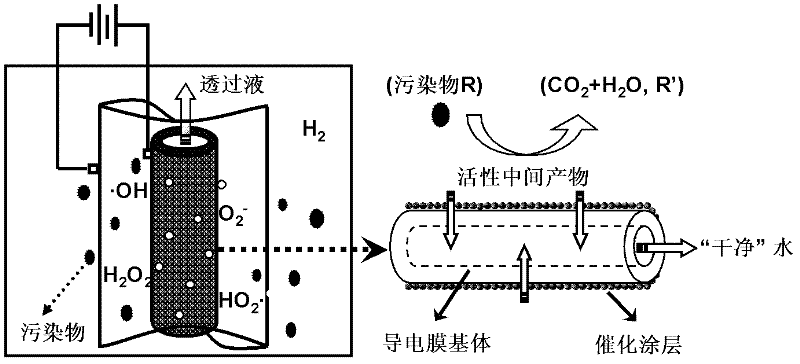

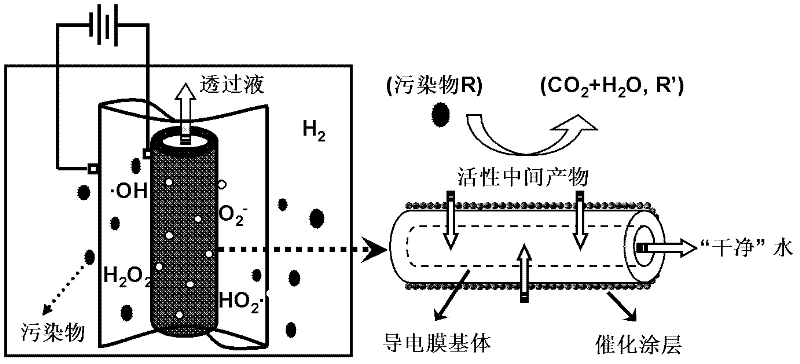

AI Technical Summary

Problems solved by technology

Method used

Image

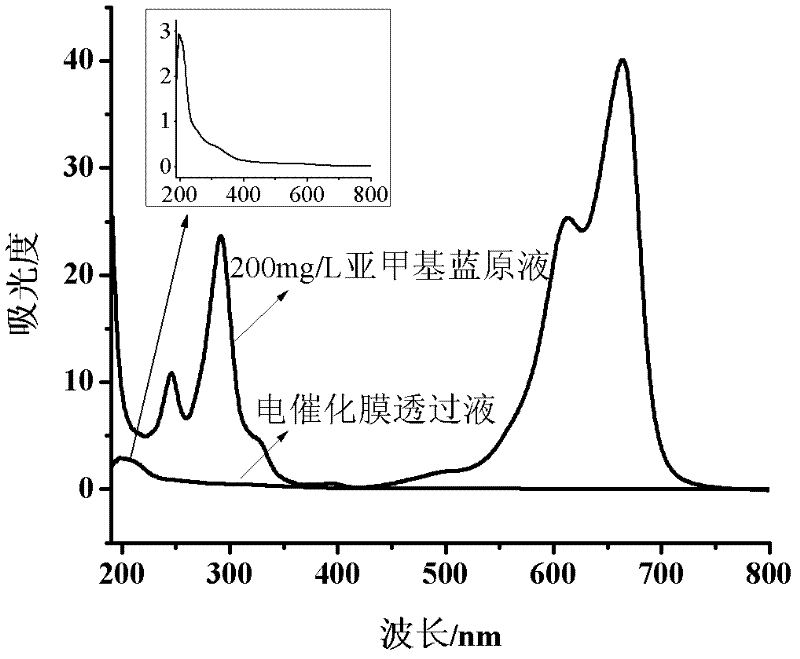

Examples

Embodiment 1

[0020] The titanium-based electrocatalytic membrane in this embodiment consists of a tubular titanium membrane substrate and a metal-semiconductor compound coating.

[0021] Conductive titanium film substrate: tubular titanium film (the average pore diameter is 2.0 μm, the diameter of the pipe is Ф30mm×5mm, which indicates the outer diameter and thickness of the pipe, and the expression method of the pipe diameter in the following examples is the same)

[0022] Catalytic coating: Au / TiO 2

[0023] Preparation method: sol-gel method

[0024] The titanium-based electrocatalytic membrane as described above is prepared by the following steps:

[0025] (1) Titanium film pretreatment: Sandblast the titanium film; then soak it in NaOH solution for 0.5h, wash it to neutrality, cook it in oxalic acid solution with a concentration of 10% by mass for 1h, wash it with water, and wash it at 105 Dry at ℃;

[0026] (2) Catalyst loading: Mix butyl titanate, absolute ethanol, and distilled...

Embodiment 2

[0029]The titanium-based electrocatalytic membrane in this embodiment consists of a tubular titanium membrane substrate and a metal oxide coating.

[0030] Conductive titanium film substrate: tubular titanium film (average pore diameter is 1.0μm, tube diameter is Ф28.8mm×4.5mm)

[0031] Catalytic coating: PbO 2

[0032] Preparation method: electrodeposition method

[0033] The titanium-based electrocatalytic membrane as described above is prepared by the following steps:

[0034] (1) Titanium film pretreatment: Sandblast the titanium film; then soak it in NaOH solution for 1 hour, wash it to neutrality, cook it in oxalic acid solution with a concentration of 10% by mass for 2 hours, wash it with water, and heat it at 120°C down drying;

[0035] (2) Catalyst loading: configure 150g / L lead nitrate plating solution, adjust the pH to about 2 with nitric acid, at a temperature of 70°C, and a current density of 15mA / m 2 Under the condition of 2 Coated Ti-based electrocatalytic...

Embodiment 3

[0038] The titanium-based electrocatalytic membrane in this embodiment is composed of a plate-type titanium membrane substrate and a diamond coating.

[0039] Conductive titanium film substrate: plate titanium film (average pore size is 0.5μm, plate film size is 50mm×30mm)

[0040] Catalytic Coating: Diamond

[0041] Preparation method: hot wire chemical vapor deposition

[0042] Its preparation steps of the above-mentioned composite electrocatalytic membrane are as follows:

[0043] (1) Titanium film pretreatment: Sandblast the titanium film; then soak it in NaOH solution for 2 hours, wash it to neutrality, cook it in an oxalic acid solution with a concentration of 10% by mass for 1.5 hours, wash it with water, and wash it at 100 Dry at ℃;

[0044] (2) Smear diamond powder on the surface of the titanium film, and ultrasonic for 15 minutes;

[0045] (3) Install the filament, wash and dry the titanium film with clean water, blow it off with an air pump, add boron, and wipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com