Patents

Literature

47results about How to "Precise Control of Chemical Composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chrome zirconium copper alloy and preparing and processing method thereof

InactiveCN101717876APrecise Control of Chemical CompositionImprove mechanical propertiesChemical compositionMetallic materials

The invention relates to chrome zirconium copper alloy and a preparing and processing method thereof, belonging to the field of metal materials. The chrome zirconium copper alloy comprises the components in percent by weight: 0.1% to 0.5% of chrome, 0.046% to 0.2% of zirconium, 0.05% to 0.2% of silver or tin and the balance of copper. The method comprises the steps of: preparing master alloy of chrome copper and zirconium copper in a vacuum melting furnace; melting the master alloy with the copper, the silver and the tin in vacuum to form the chrome zirconium copper alloy; equalizing an alloy ingot; then processing into a bar; solutionizing for 1 to 2 hours at 850 DEGC to 950 DEG C; cold processing until the processing deformation is from 70% to 98%; and time aging for 2 to 6 hours at 320 DEG C to 580 DEG C. The method can be used for accurately controlling the chemical components of the alloy; the tensile strength of the prepared alloy is from 450 MPa to 550 MPa by a test; the conductivity is from 85% to 95% IACS; and the alloy has higher strength and conductivity.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

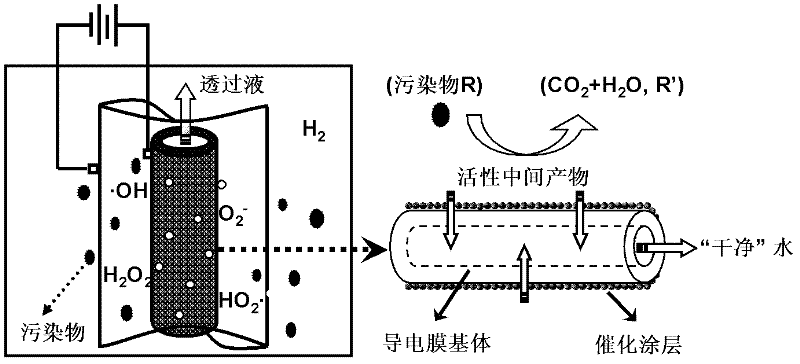

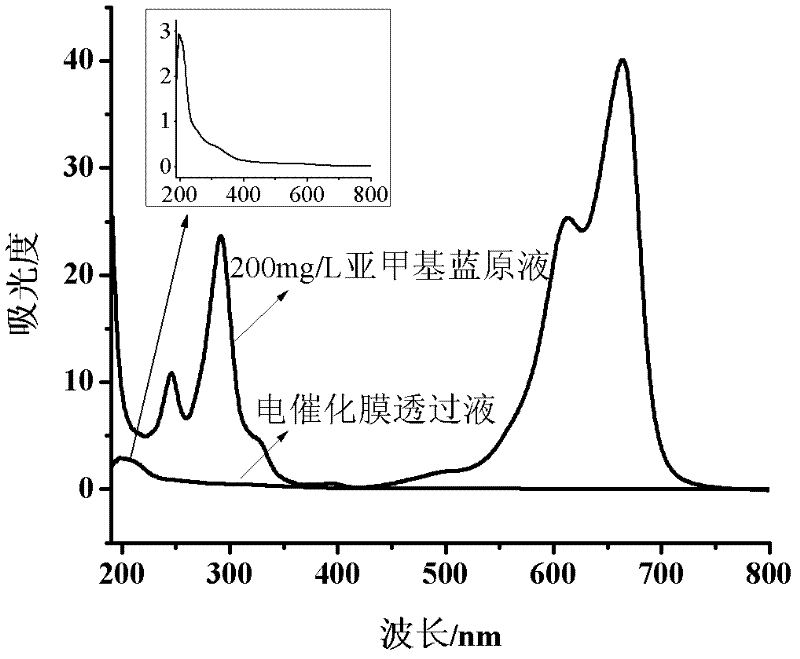

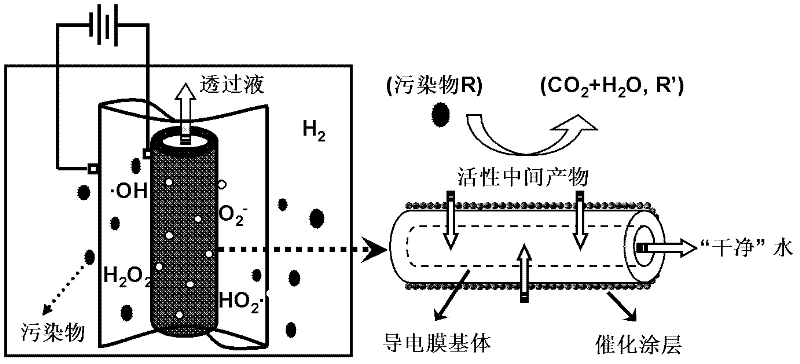

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

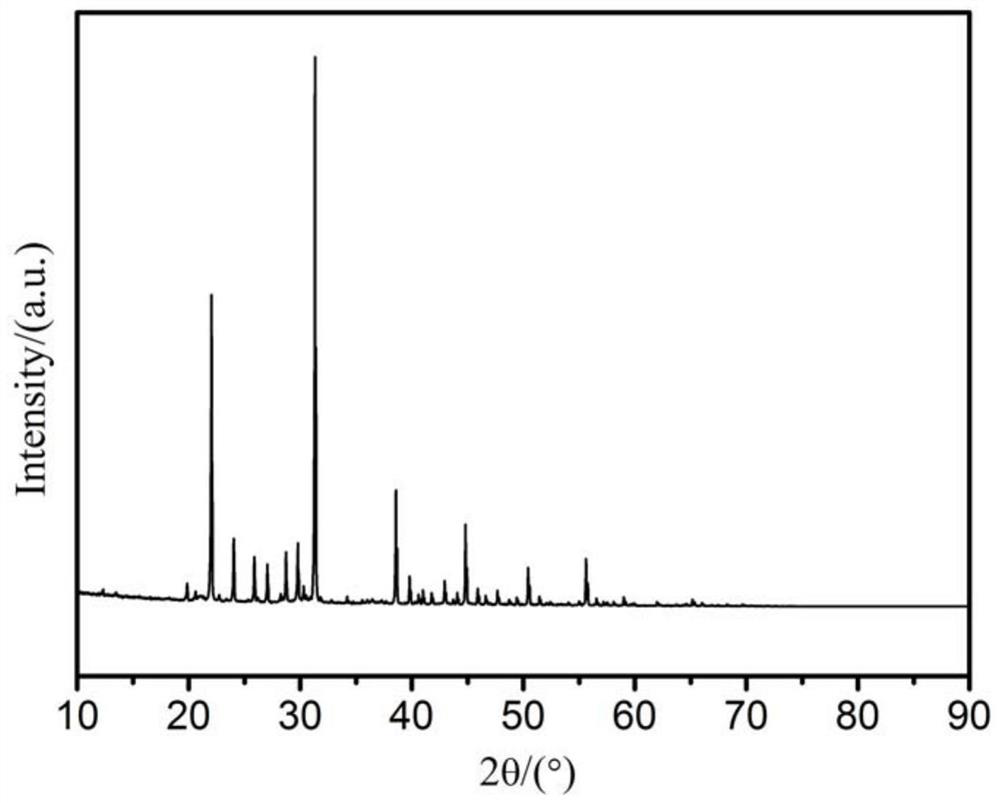

Preparation method of Bi1.5MgNb1.5O7 (BMN) dielectric film

InactiveCN102249307APrecise control of film chemical compositionHigh densityNiobium compoundsCrazingAqueous solution

The invention discloses a preparation method of a BMN dielectric film, comprising the steps of: (1) preparing a citric acid water solution of niobium; (2) adding glycol into the water solution, and conducting heating and stirring; (3) preparing a glycol solution of magnesium and bismuth; (4) adding the prepared glycol solution of magnesium and bismuth into the solution obtained in step (2), thus obtaining a bismuth-magnesium-niobium sol; (5) adding ethanol into the bismuth-magnesium-niobium sol, and carrying out heating and stirring so as to obtain a bismuth-magnesium-niobium precursor solution; (6) coating a substrate with the precursor solution uniformly and drying the substrate; (7) subjecting a dried film to a heat treatment at a temperature of 500-800DEG C for 10min; (8) repeating step (6) and (7) so as to prepare a multilayered film; (9) conducting a heat treatment to the multilayer film at a temperature of 550-800DEG C for 0.5-2h, thus obtaining a BMN dielectric film with a cubic pyrochlore structure. With accurately controlled chemical components and high density, the BMN dielectric film provided in the invention has no crack and pin hole as well as other defects. Characterized by simple process and low cost, the film of the invention as a microwave dielectric adjustable material boasts good application prospects.

Owner:TIANJIN UNIV

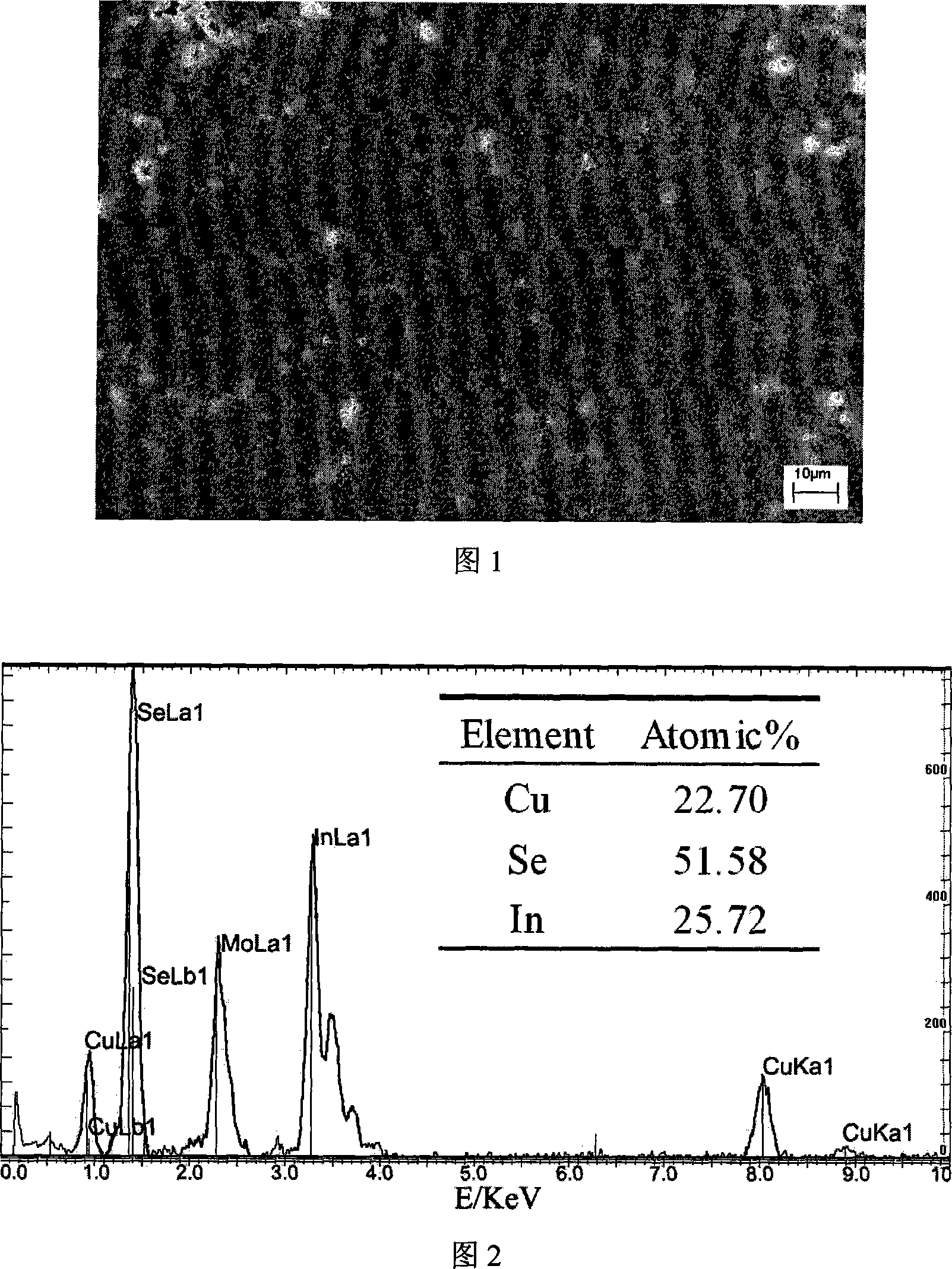

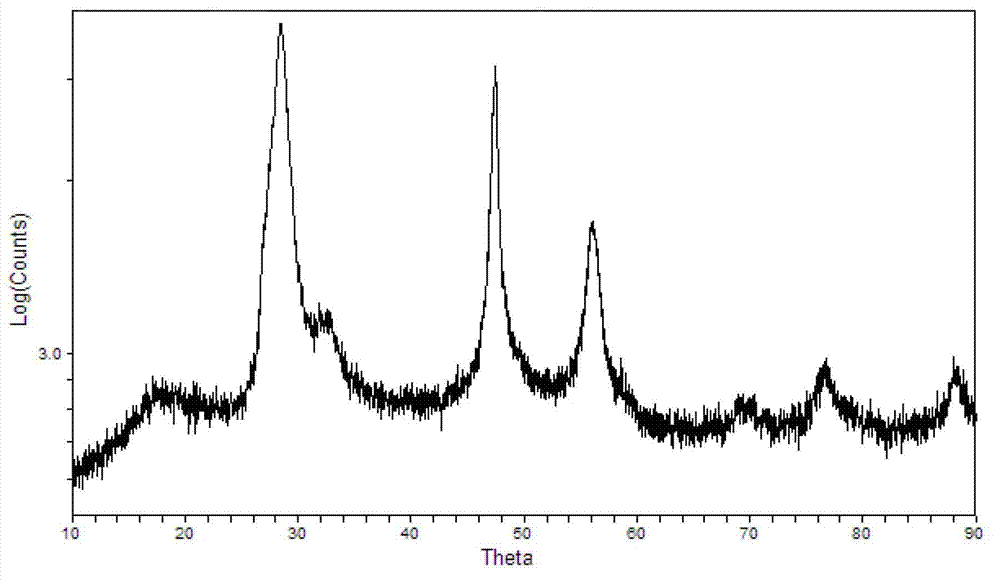

Method for producing copper-indium-selenium thin-film solar cell wealthy-indium optical absorption layer

InactiveCN101159298APrecise Control of Chemical CompositionLower sintering temperatureFinal product manufactureSemiconductor devicesIndiumAlloy

The invention provides a method of preparing an In-enriched light absorption layer for a CuInSe2 thin-film solar battery, belonging to the preparation of CuInSe2 semiconductor thin films. The method adopts coating-sintering process, and uses Cu-In alloy, Cu-In alloy and Se powder as raw material. The method comprises mixing Cu-In alloy, Cu-In alloy and Se powder with a molar ratio of 1:(1.1-1.25):2:(2-2.2), ball milling the mixture for 36-72 hr to form a black precursor slurry; coating the slurry on a molybdenum foil substrate or a titanium foil substrate to form a precursor thin-film, and drying at low temperature; densifying the precursor thin-film by exerting 10-300 MPa pressure, and subjecting the precursor thin-film to heat treatment under H2 atmosphere, N2 atmosphere or vacuum. The method can accurately control the chemical composition in the precursor thin-film, can ensure the preparation of the In-enriched CuInSe2 semiconductor thin-film solar battery, and is more suitable for forming the absorption layer with uniform composition, compact structure, and flat surface. And, the sintering process is performed under innoxious atmosphere, so as to be safe and practice in operation.

Owner:UNIV OF SCI & TECH BEIJING

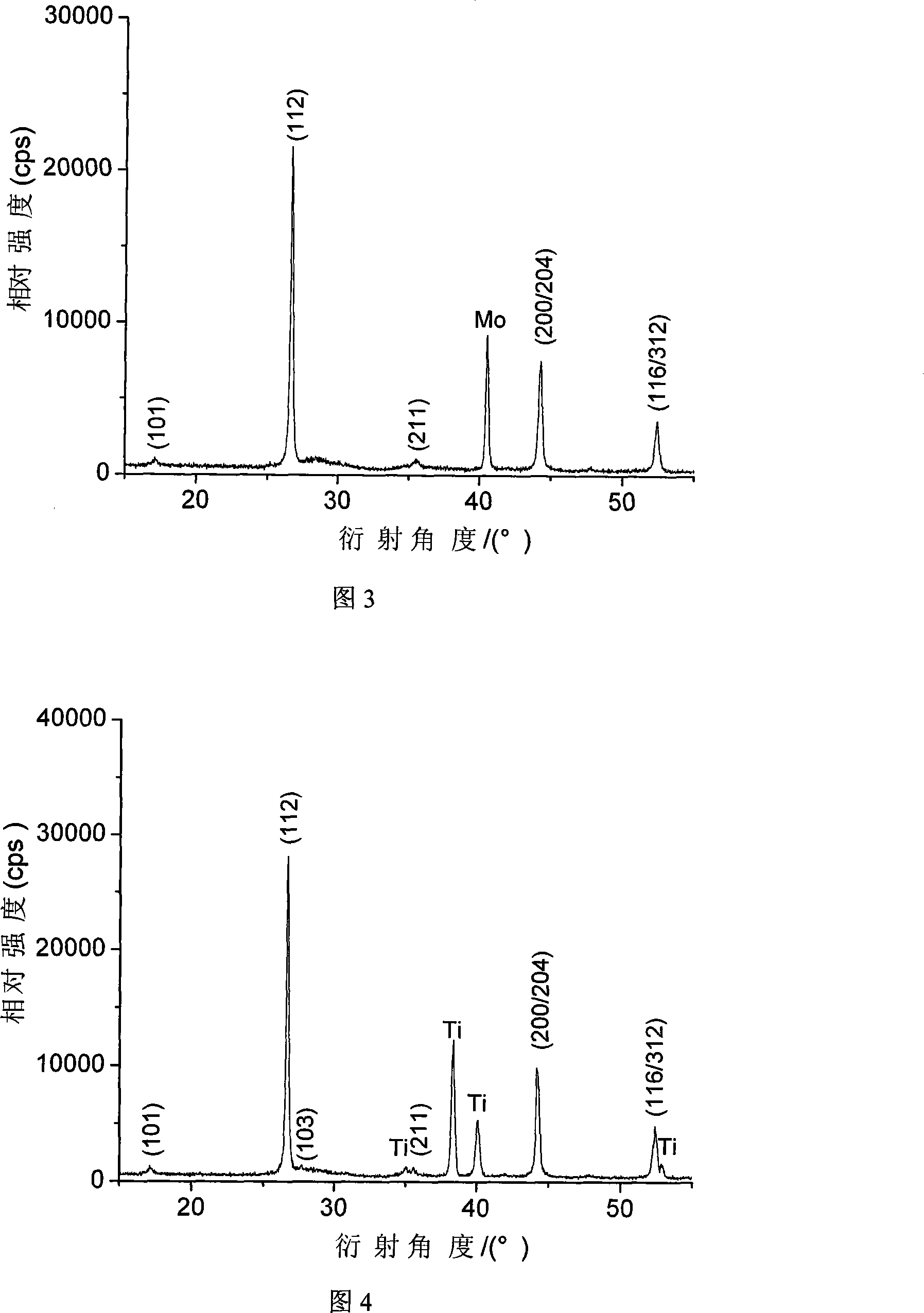

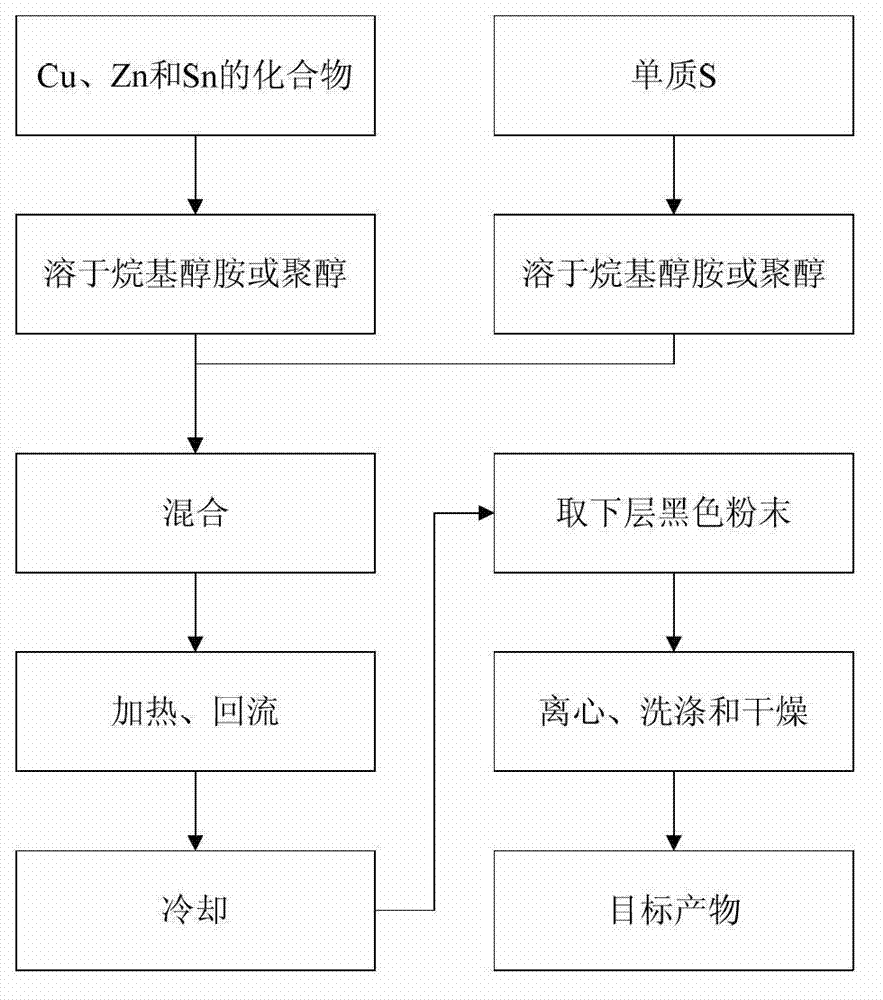

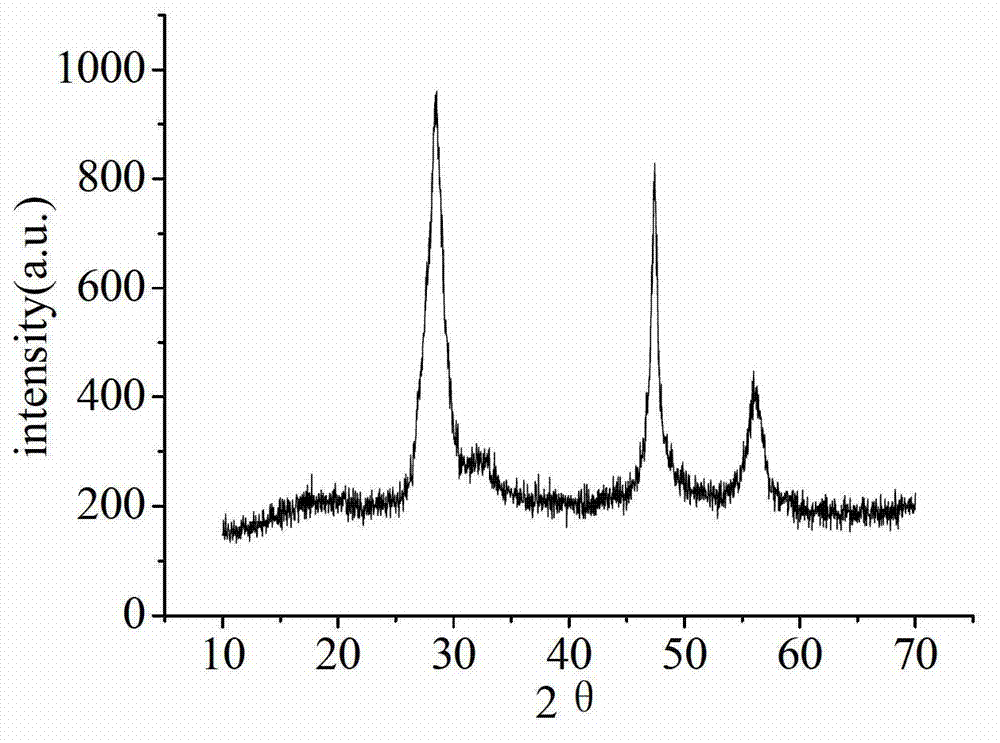

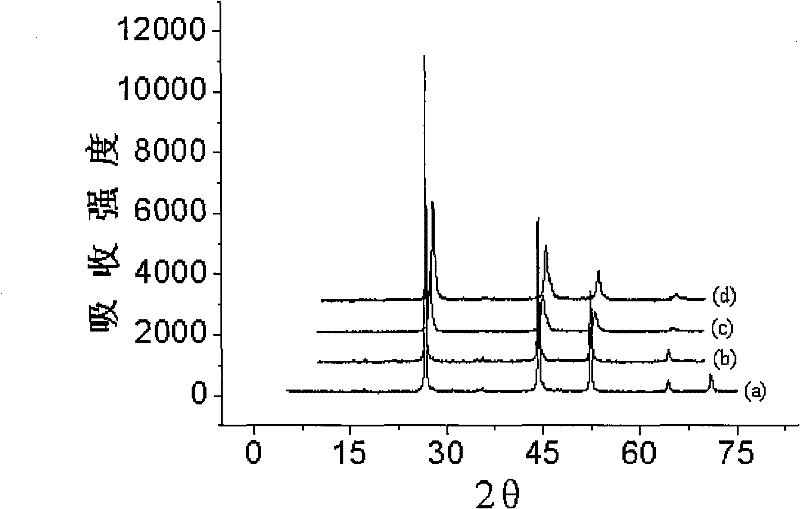

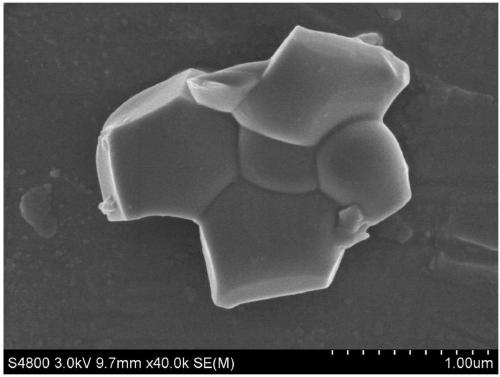

Preparation method for copper-zinc-tin-sulfur nano powder material

A preparation method for a copper-zinc-tin-sulfur nano powder material belongs to the technical field of inorganic chemical materials. The preparation method comprises the following steps of: selecting alkanolamine or polyalcohol as solvent and dissolving a compound containing Cu, Zn and Sn with the mol ratio of Cu to Zn to Sn being 2:1:1 into the solvent; then dissolving a simple substance S of which the molar weight is two times that of Cu into another alkanolamine or polyalcohol solvent; and mixing two liquid systems, stirring under the protection of inert gas, heating to 200-280DEG C, carrying out reflowing reaction for 4-10 hours and cooling to room temperature and taking black powder on a lower layer for centrifugal separating, washing and drying to obtain copper-zinc-tin-sulfur compound nano powder. The preparation method disclosed by the invention can be used for preparing the copper-zinc-tin-sulfur compound nano powder material with the advantages of nanoscale, uniformity in size, favorable dispersity and high phase purity and has the characteristics of high efficiency, high yield, low cost, favorable repeatability, simpleness in operation and easiness in control. The copper-zinc-tin-sulfur compound nano powder material prepared by the preparation method disclosed by the invention can be used for preparing slurry of a solar battery absorbing layer.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

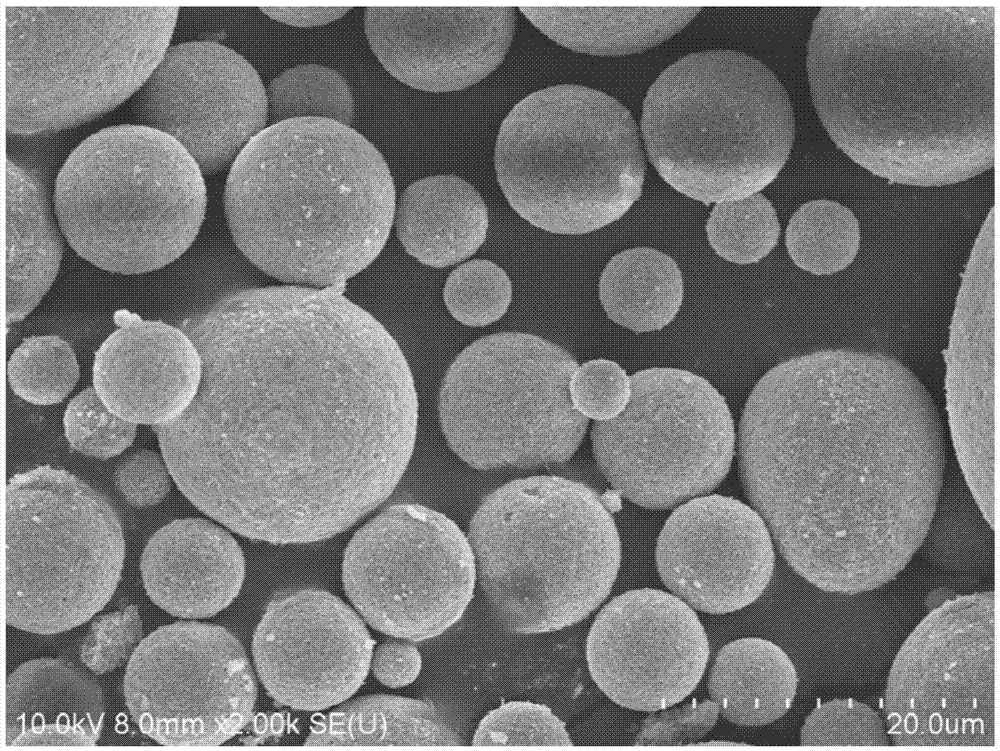

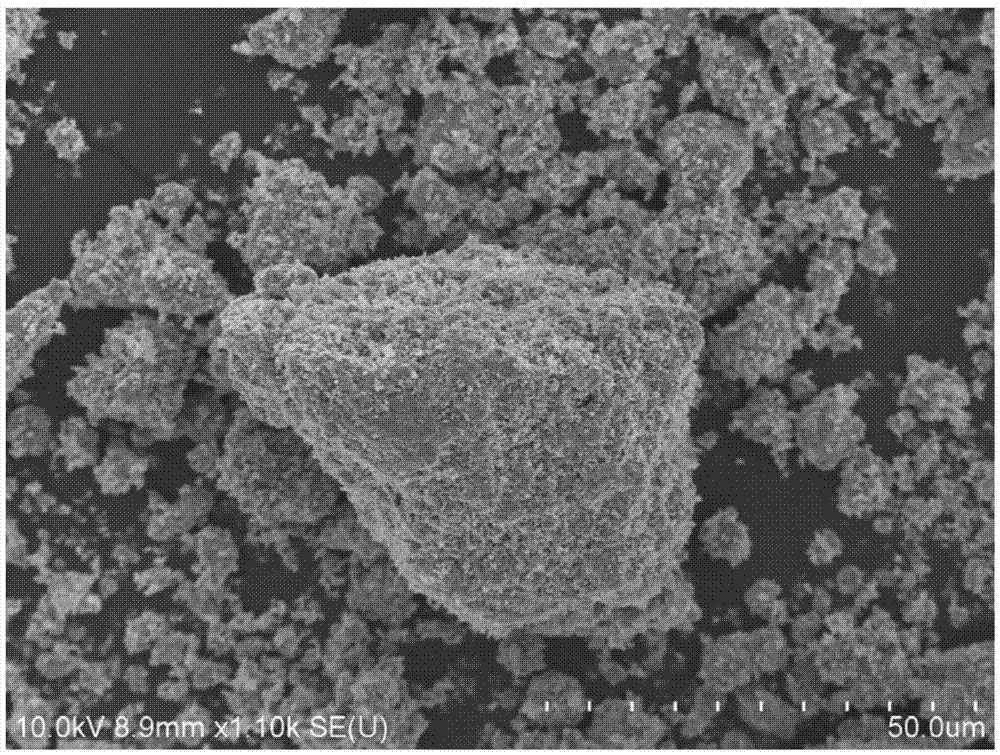

Lithium-rich manganese-based anode material, preparation method thereof and lithium ion battery containing anode material

ActiveCN106910887AThe problem of achieving compactionAchieve spherificationCell electrodesSecondary cellsManganeseLithium-ion battery

The invention discloses a lithium-rich manganese-based anode material, a preparation method thereof and a lithium ion battery containing the anode material. A chemical formula of the lithium-enrichment manganese-based anode material is Li1+xMnyMzAwOr, wherein the M is at least one of Ni, Co, Al, Mg, Ti, Fe, Cu, Cr, Mo, Zr, Ru and Sn; the A is at least one of S, P, B and F; the x is larger than 0 and smaller than or equal to 1, the y is larger than 0 and smaller than or equal to 1, the z is larger than or equal to 0 and smaller than 1, the w is larger than or equal to 0 and smaller than or equal to 0.2, and the r is larger than or equal to 1.8 and smaller than or equal to 3. The lithium-enrichment manganese-based anode material is prepared by methods of oxalate coprecipitation, spray drying and high-temperature roasting. The lithium-enrichment manganese-based anode material disclosed by the invention overcomes agglomeration of a material prepared through an oxalate coprecipitation method; a prepared material is controllable in particle size, meets requirements of engineering indexes and can achieve the purpose that transition metal ions are evenly mixed at an atom level; the particle size of the prepared lithium-enrichment manganese-based anode material is 3 to 25mu m, and the lithium-rich manganese-based anode material has good rate capability and circulation performance at the same time; furthermore, the lithium-enrichment manganese-based anode material has the advantages of simple preparation technology, low cost and wide application prospect.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

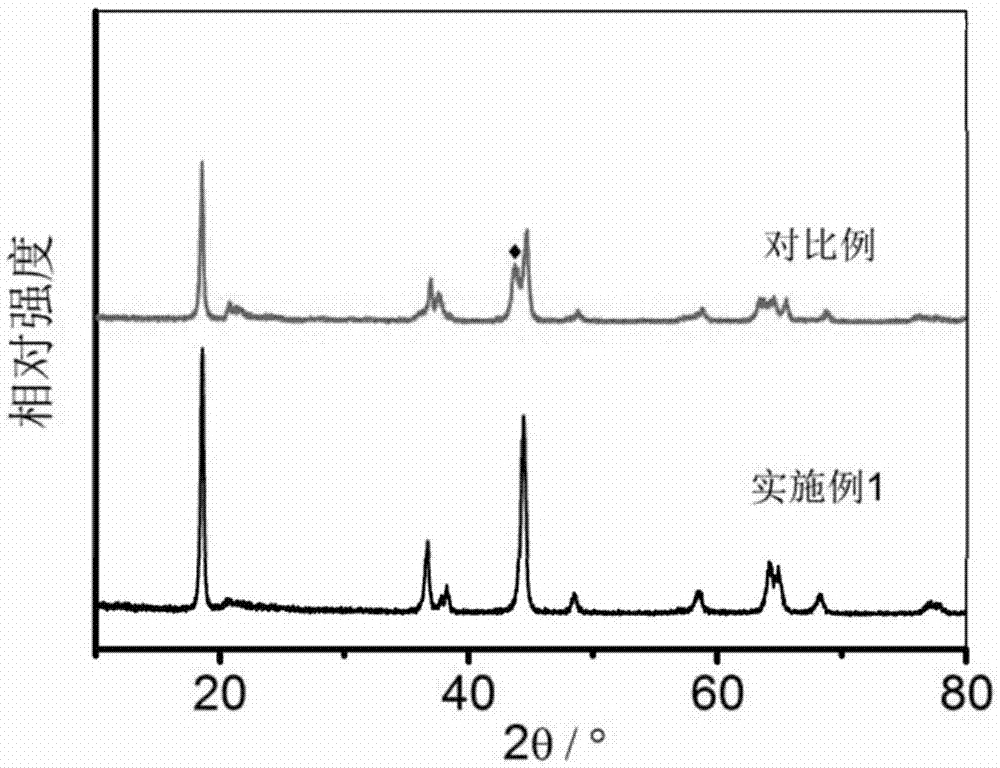

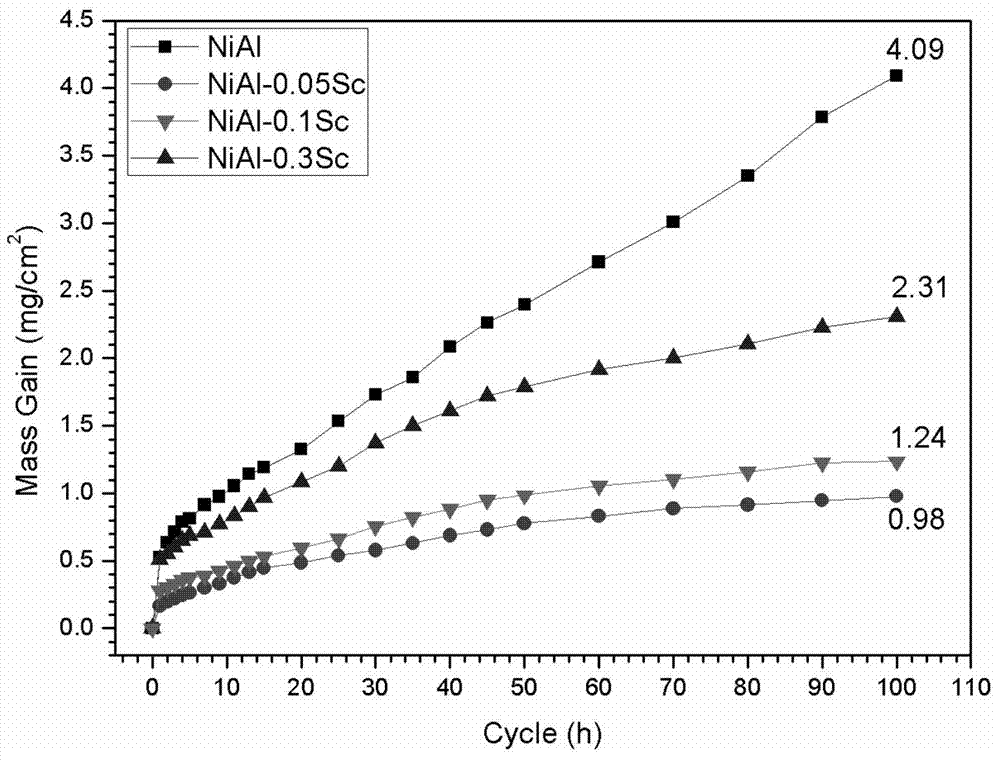

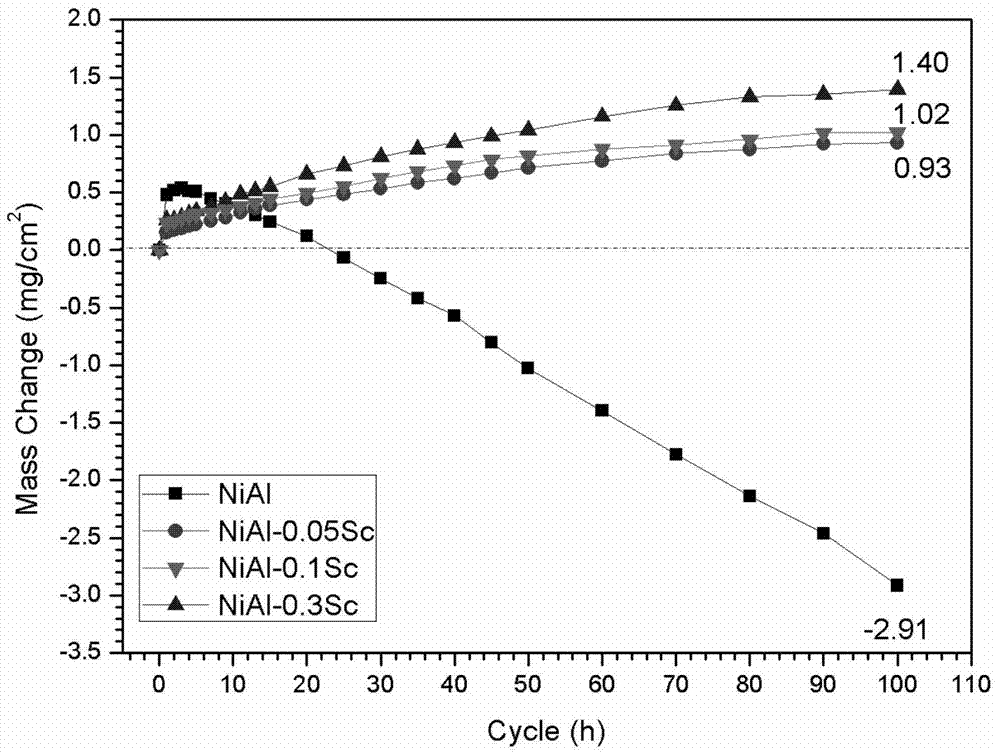

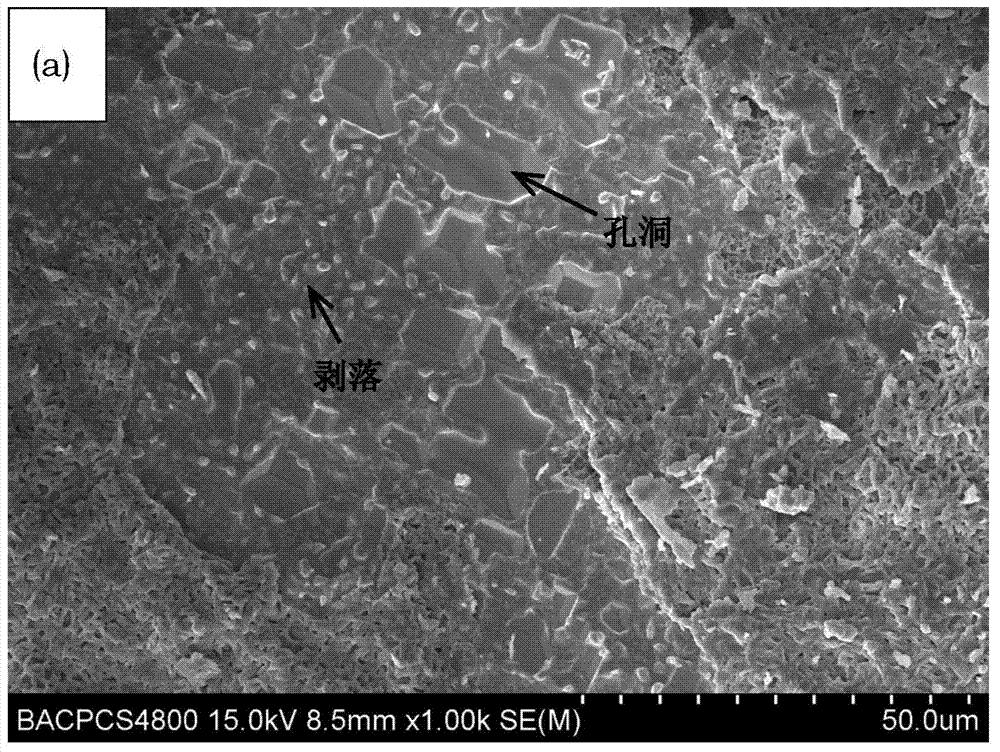

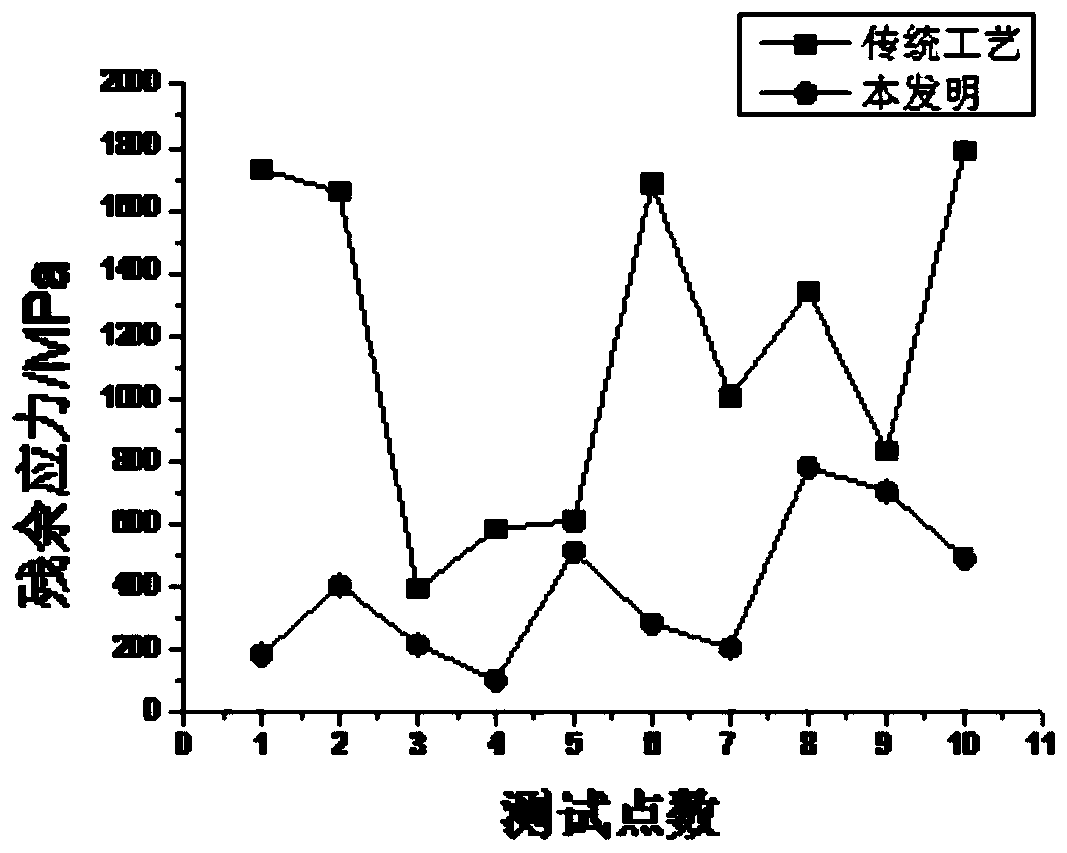

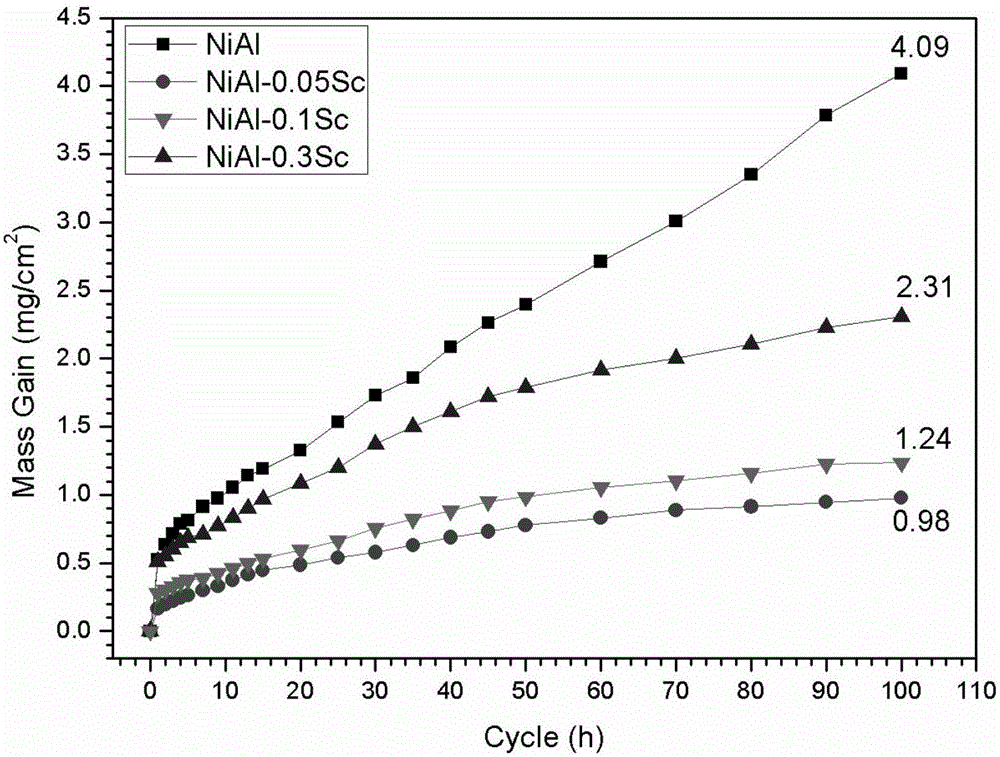

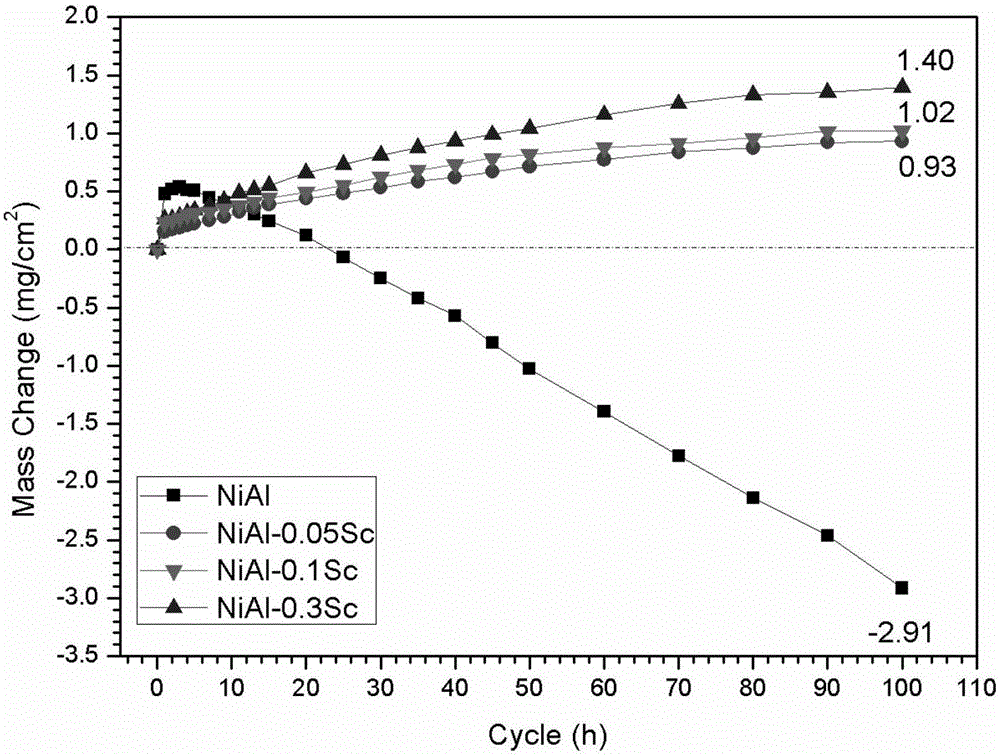

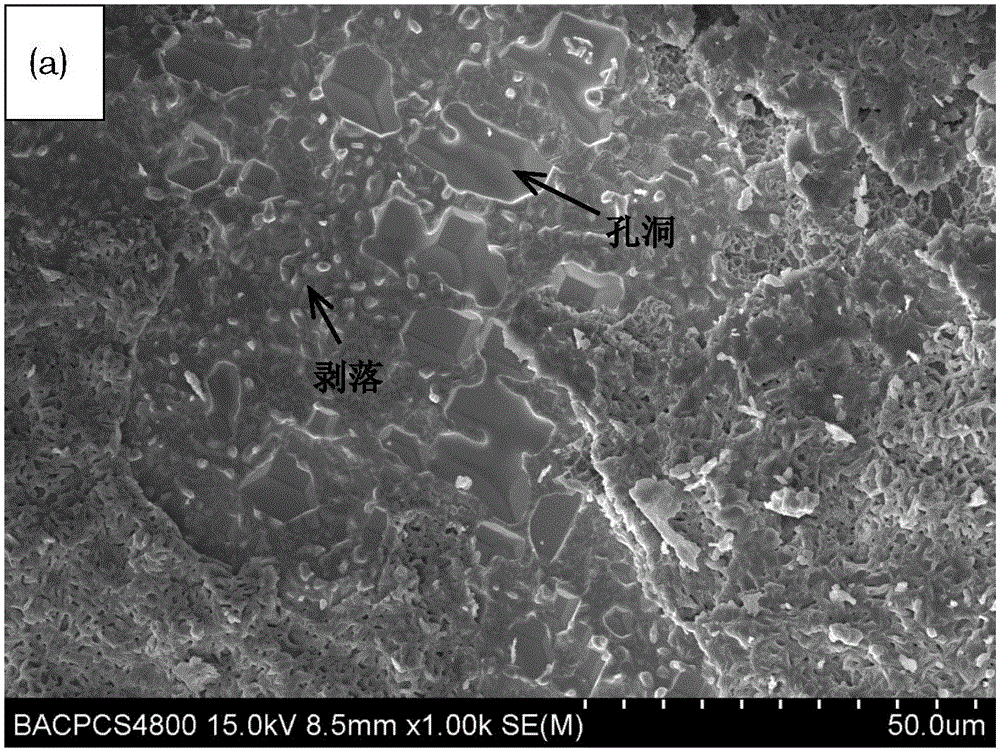

Active-element Sc-modified (Ni, Pt)Al high-temperature-oxidation-resisting bonding layer material and preparation method thereof

InactiveCN103667795AImprove adhesionReduce oxidation rateVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionHigh resistance

The invention discloses an active-element Sc-modified (Ni, Pt) Al high-temperature-oxidation-resisting bonding layer material and a preparation method thereof and belongs to the technical field of thermal barrier coatings. Electroplating and electron beam physical vapor deposition methods are adopted to prepare an Sc-modified (Ni, Pt) Al coating on nickel-base superalloy. The bonding layer material can be applied for a long time in the environment with the temperature more than 1150 DEG C. Compared with unmodified NiAl, the bonding layer material has the advantages that after Sc is doped, the oxidation rate of (Ni, Pt) Al is obviously reduced, the adhesion of an oxidation film is improved, and the peeling situation is inhibited; the oxidation film / Ni Al interface becomes straight, and holes in the interface are eliminated; the bonding layer material has high resistance to high temperature oxidation and can be used as the bonding layer material of a high-temperature-resisting thermal barrier coating. The preparation method respectively adopts the electroplating method to prepare a Pt layer and adopts the electron beam physical vapor deposition method to prepare the Sc-modified (Ni, Pt) Al coating, can precisely control the thickness and chemical components of the coating by regulating various parameters, and makes up for the deficiencies of a pack cementation method for preparing the (Ni, Pt) Al coating.

Owner:BEIHANG UNIV

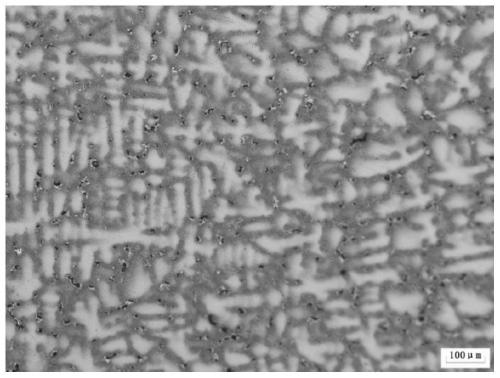

Preparation method of deformed high-temperature alloy ingot

ActiveCN110396605AReduce and reduce thermal stressAvoid crackingIncreasing energy efficiencySelf consumptionEconomic benefits

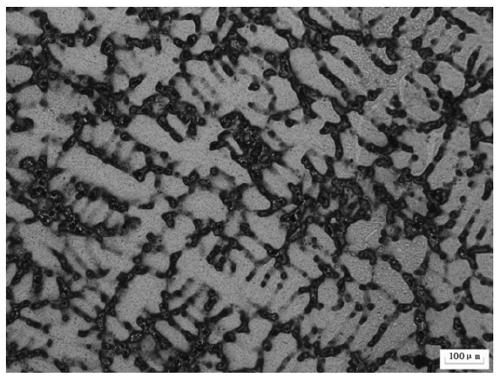

The invention discloses a preparation method of a deformed high-temperature alloy ingot. The method adopts the preparation process of raw material pretreatment, vacuum induction smelting, hot-fittingannealing, electroslag remelting, hot-fitting annealing, vacuum self-consumption and hot-fitting annealing; the cleanliness of a smelting furnace material is improved through the raw material pretreatment; electrodes with uniform components can be obtained through vacuum induction smelting; the impurities can be further reduced by electroslag remelting, so that a cast ingot is compact in structureso as to obtain an electrode ingot with more excellent quality; and vacuum self-consumption remelting further enables an alloy cast-state dendritic crystal tissues to be refined and the tissues to behomogenized so as to realize a good feeding effect, and the metallurgical defects of severe segregation, looseness, shrinkage and the like are avoided. According to the method, hot-fitting annealingafter smelting in each step is carried out, so that cracks of the electrode or the re-molten ingot in the cooling process can be prevented, and finally a high-quality cast ingot with good surface quality, no crack defect, fine cast dendritic structure, low segregation and low stress is obtained, the percent of pass of the cast ingot is improved, and the high-quality cast ingot has remarkable economic benefits.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of rare earth doped Bi2Te3 based thermoelectric film material

InactiveCN101956158AIncrease concentrationImprove thermoelectric performanceThermoelectric device manufacture/treatmentVacuum evaporation coatingThermoelectric materialsRare-earth element

The invention relates to a rare earth doped Bi2Te3 based thermoelectric film material which is prepared by the steps of: adding rare earth elements during vacuum melting to obtain a Bi2-xTe3REx block thermoelectric material, wherein RE represents the rare earth elements, x is equal to 0.002-0.01, and the doped rare earth elements are light rare earth elements of La and Ce; and grinding the molten material into powder particles of 200-300 mu m to be used as a raw material of a flash evaporation method. The film is prepared by adopting the flash evaporation method, and the deposited film is annealed to obtain the rare earth doped Bi2-xTe3REx thermoelectric film material. The thermoelectric property of the rare earth doped Bi2-xTe3REx thermoelectric film material is superior to an undoped Bi2Te3 based thermoelectric film material, a doping principle is that the rare earth elements have properties similar to alkaline earth, and when the rare earth elements are added, a Bi position is easily replaced to be used as donor doping, which improves carrier concentration, thus the thermoelectric property of the Bi2Te3 based film material is improved.

Owner:JIUJIANG UNIVERSITY

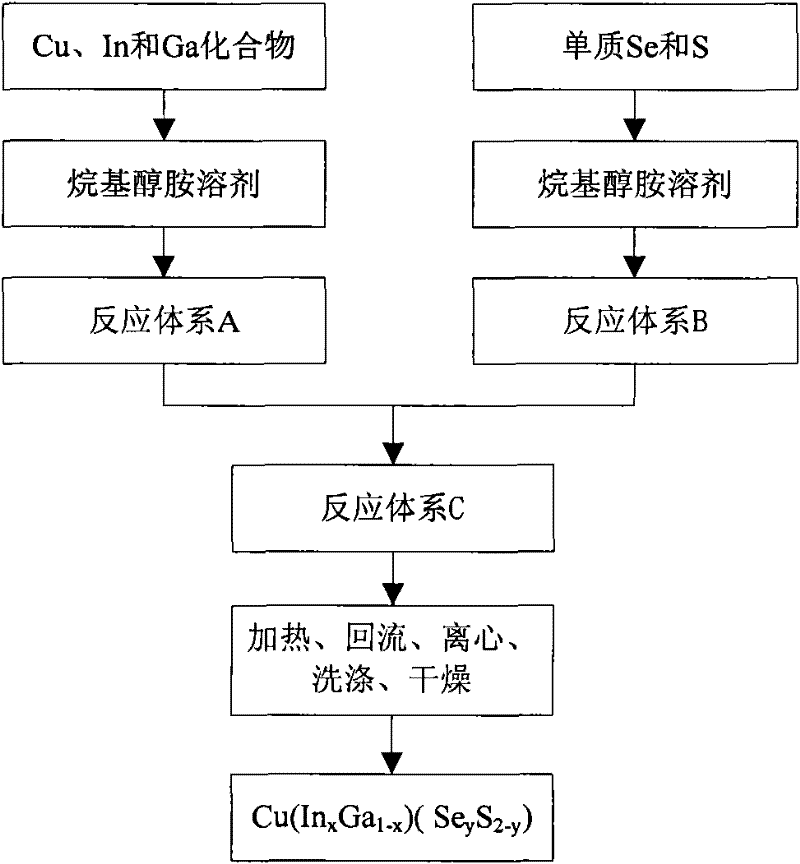

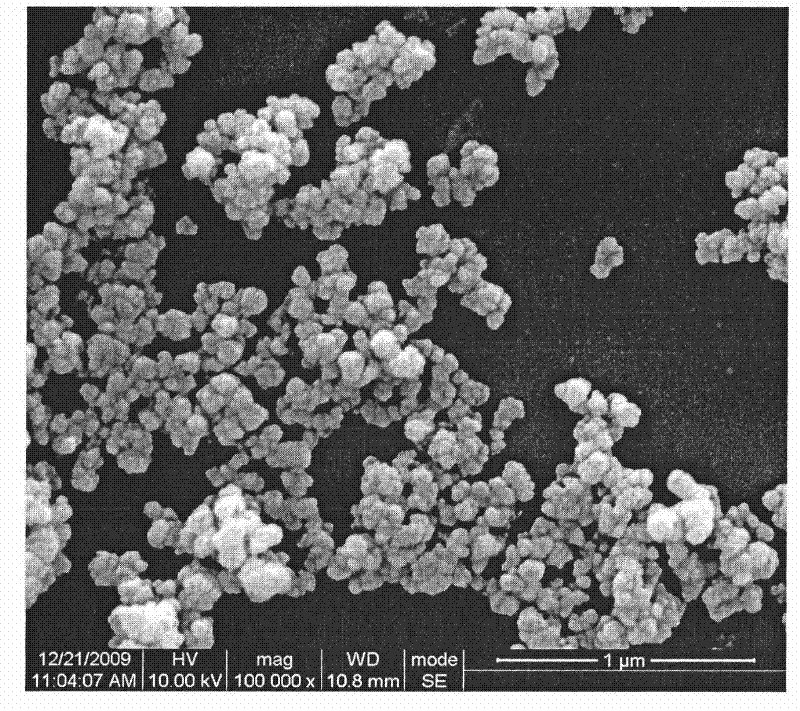

Preparation method of Cu-In-Ga-Se-S nano powder material

The invention provides a preparation method of a Cu-In-Ga-Se-S nano powder material, belonging to the technical field of inorganic chemical materials. The preparation method comprises the following steps: based on alkanolamine with a boiling point large than or equal to 180 DEG C as a solvent, dissolving Cu, In and Ga compounds into the alkanolamine in a mole ratio of Cu: (In+Ga) of 1: (1-1.5); then dissolving Se and S in the alkanolamine, wherein the sum of molar weights of Se and S is twice as heavy as molar weight of Cu; and subsequently, mixing two solutions, stirring under the protective condition of inert gas, heating to 200-280 DEG C for refluxing, maintaining the reaction for 4-10 hours and then stopping heating and stirring, cooling to room temperature, centrifuging, washing and drying the black powder on the lower layer, so as to obtain the Cu-In-Ga-Se-S nano powder material. By using the preparation method in the invention, the Cu-In-Ga-Se-S nano powder material which is in a nano grade and has uniform scale, good dispersibility and high phase purity can be prepared, the whole preparation process is high in efficiency and low in cost, and operation is simple and is easy to control. The Cu-In-Ga-Se-S nano powder material prepared by the method in the invention can be used in a solar battery as an absorption layer material.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA +1

Nano-ZnO varistor composite powder material and preparation method thereof

InactiveCN104193320AImprove stabilityRaise the potential gradientAqueous solutionParticle-size distribution

The invention relates to a nano-ZnO varistor composite powder material and a preparation method thereof. The material is composed of ZnO, Co2O3, Bi2O3, Sb2O3 and Y2O3. The preparation method adopts a chemical coprecipitation method and particularly comprises the following steps: adding ZnO, Bi2O3, Co2O3, Sb2O3 and Y2O3 in dilute hydrochloric acid serving as a solvent, dissolving to form a transparent solution in a constant-temperature water bath environment; dropwise adding an ammonia solution serving as a precipitant into the transparent solution at a constant speed; and precipitating, filtrating, washing, drying, grinding and calcinating, thus obtaining the nano-ZnO varistor composite powder material. The preparation of nano-ZnO composite powder with excellent performances is a key of manufacture of a high-performance varistor. The ZnO composite powder prepared by using the method disclosed by the invention has the advantages of small particle size, uniform modified oxide distribution and narrow particle size distribution; and the preparation method disclosed by the invention is simple, and precisely controllable in component, and products have the characteristics of good morphology consistency, excellent electrical properties and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Method of producing wind power casting from blast furnace molten iron

InactiveCN102312034APrecise Control of Chemical CompositionMeet production requirementsHot blastElectricity

The invention discloses a method of producing a wind power casting from blast furnace molten iron, which belongs to the technical field of casting. The method comprises the following steps: 1) adding melted iron obtained in the process of melting in a blast furnace into an arc furnace, heating the melted iron and adjusting components in the melted iron; 2) pouring the melted iron in a ladle when the temperature of and the components in the melted iron meet requirements, and carrying out desulphurization and spheroidization on the melted iron with a nodulizer; 3) adding an inoculant into the melted iron that has undergone desulphurization and spheroidization for inoculation; 4) carrying out micro-alloying on the melted iron; 5) after treatment in the previous steps, pouring the melted iron into a casting mold with casting temperature being controlled at 1300 to 1340 DEG C, and carrying out slow cooling so as to obtain the wind power casting with performance meeting requirements. The advantages of the invention are as follows: process flow is substantially shortened, production efficiency is improved, and cost is saved; the invention is of important significance to energy conservation and consumption reduction.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

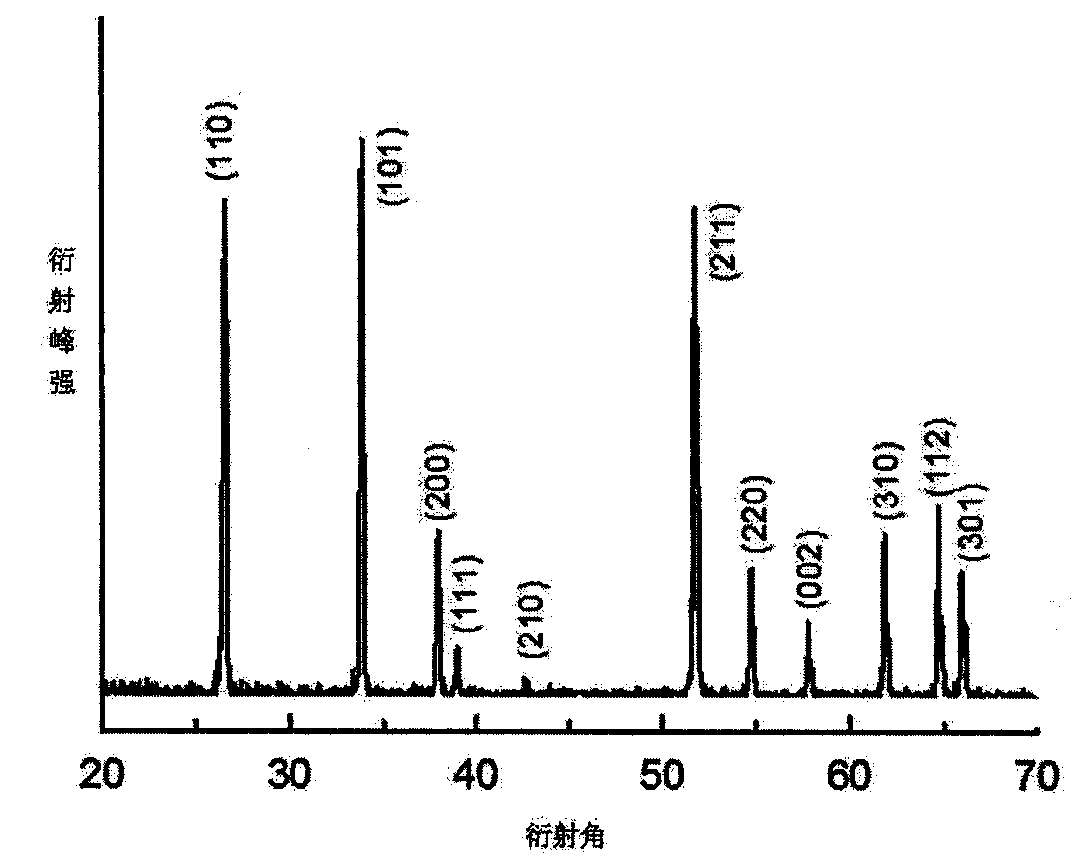

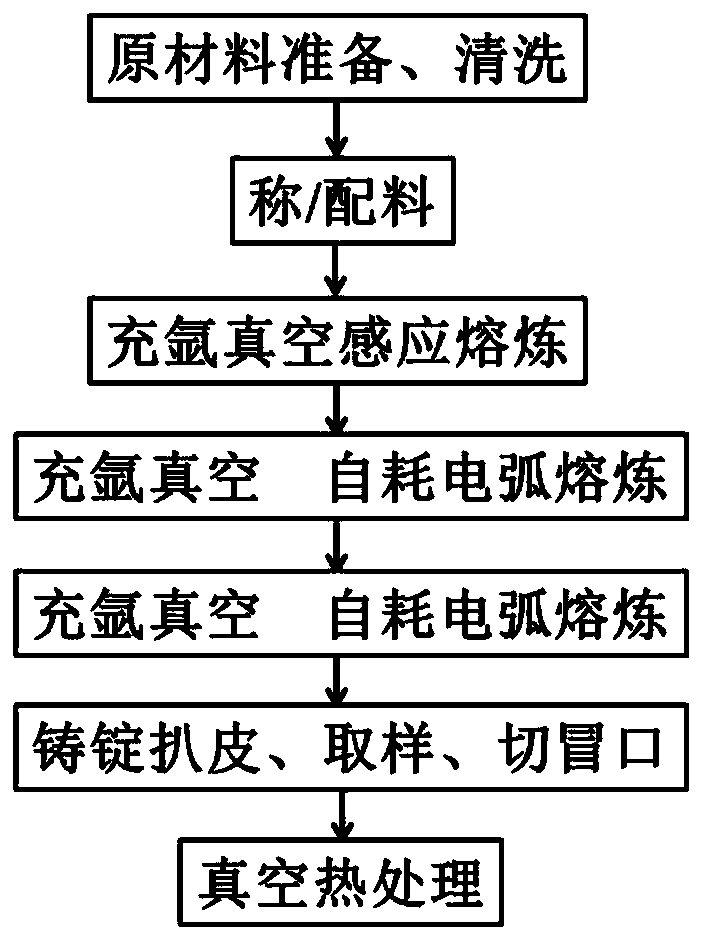

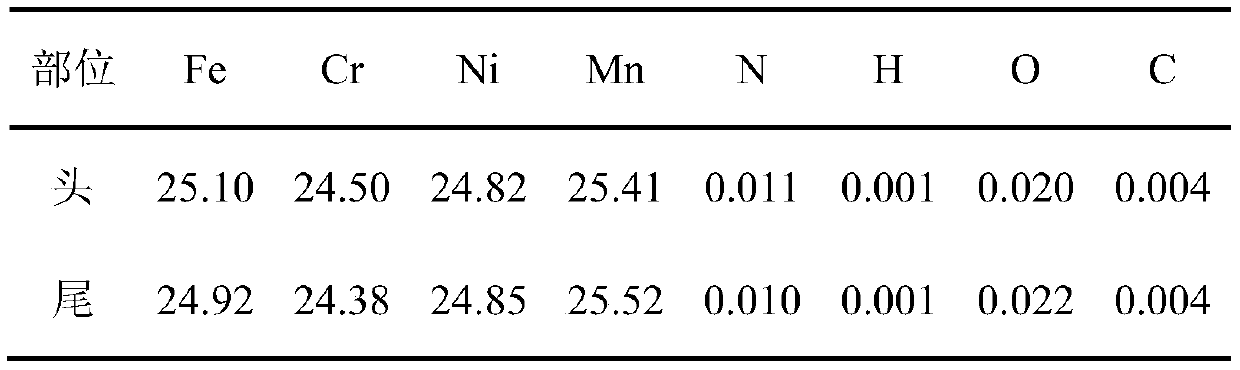

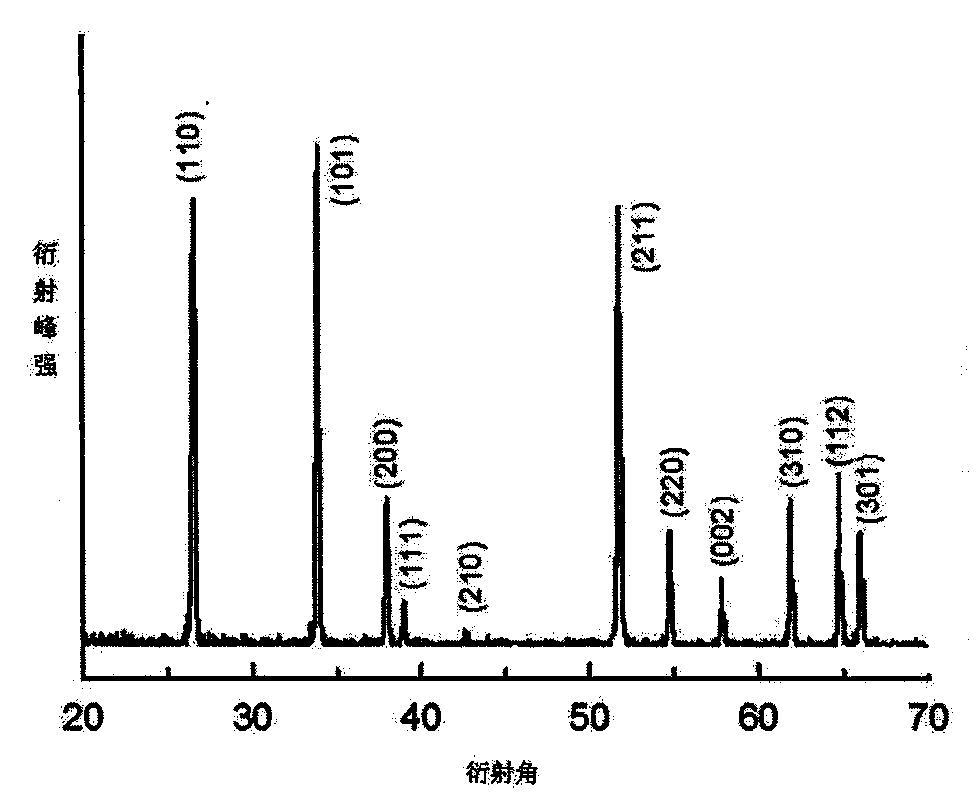

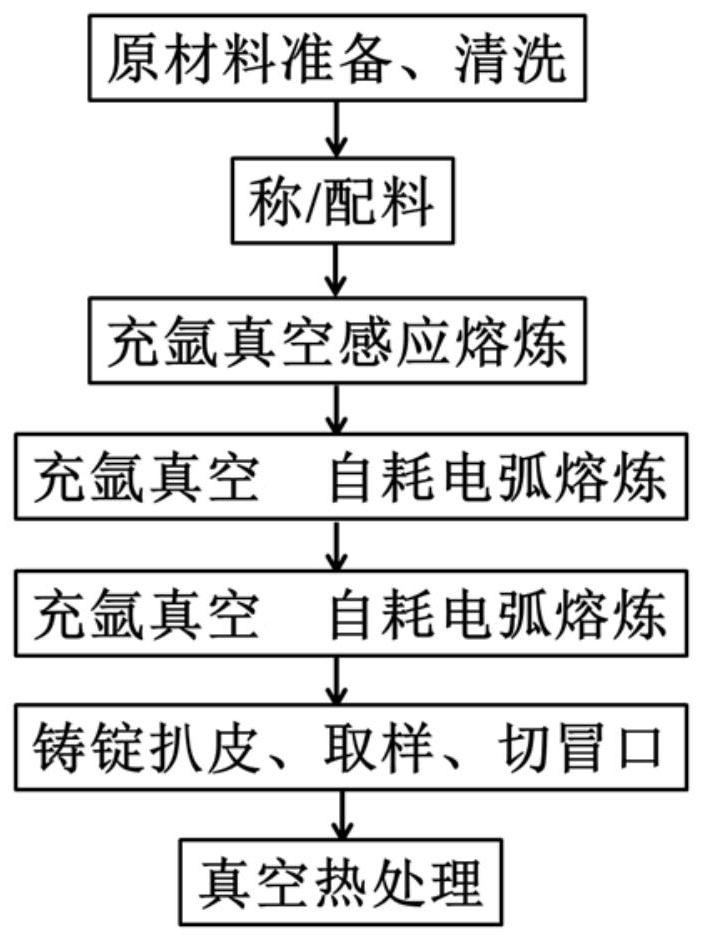

Preparation method for large-specification manganese-containing high-entropy alloy cast ingot

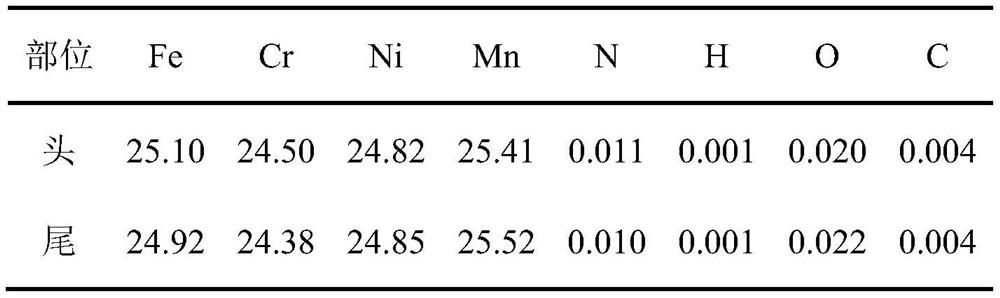

The invention discloses a preparation method for a large-specification manganese-containing high-entropy alloy cast ingot. The preparation method for the large-specification manganese-containing high-entropy alloy cast ingot comprises the following steps: weighing the weights of Fe, Cr, Ni and Mn according to the content of 25at.% of Fe, Cr, Ni and Mn elements in a Fe-Cr-Ni-Mn high-entropy alloy,and adding Fe, Cr, Ni and Mn into a crucible; then carrying out primary argon-filled vacuum induction smelting to obtain a primary cast ingot of the high-entropy alloy, then carrying out argon-filledconsumable electro-arc smelting twice, and finally carrying out vacuum heat treatment to obtain the large-specification manganese-containing high-entropy alloy cast ingot. In the aspect of preparationfor the high-entropy alloy, the alloy cast ingot is obtained by carrying out the primary argon-filled vacuum induction smelting, then carrying out the argon-filled consumable electro-arc smelting twice, and then carrying out the vacuum heat treatment; and the method is simple and practicable in a process for preparing a high-entropy material, high in efficiency, low in requirement on equipment, and low in cost. The high-entropy alloy cast ingot prepared by the preparation method is accurate in component and high in uniformity, and provides an excellent blank for the subsequent hot-processingprocedure.

Owner:SUZHOU NUCLEAR POWER RES INST +1

Stannic oxide pressure sensitive resistor composite powder material and preparation method thereof

The invention relates to a stannic oxide pressure sensitive resistor composite powder material with excellent properties, and a preparation method thereof. The powder material is prepared from SnO2, Co2O3, Bi2O3, Pr2O3 and Y2O3. The preparation method comprises the following steps: by adopting a chemical coprecipitation method and by taking absolute ethyl alcohol as an organic solvent and polyethylene glycol as a dispersing agent, adding stannic chloride, tribismuth chloride, tricobalt chloride, praseodymium nitrate and yttrium nitrate, dissolving the components into a transparent solution in a constant temperatue water bath environment, dropwise adding an ammonia water solution used as a precipitator into the transparent solution at a uniform speed, precipitating, filtering, washing, drying, grinding and calcining, thereby obtaining the stannic oxide pressure sensitive resistor composite powder material. The stannic oxide composite powder with excellent properties is essential to manufacturing of high-performance pressure sensitive resistors. The stannic oxide composite powder prepared by using the method disclosed by the invention has the advantages of small particle size, uniform modified oxide distribution and narrow particle size distribution. The stannic oxide pressure sensitive resistor composite powder material disclosed by the invention is simple in preparation method, precise and controllable in component, relatively good in product morphology consistence and excellent in electric property.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

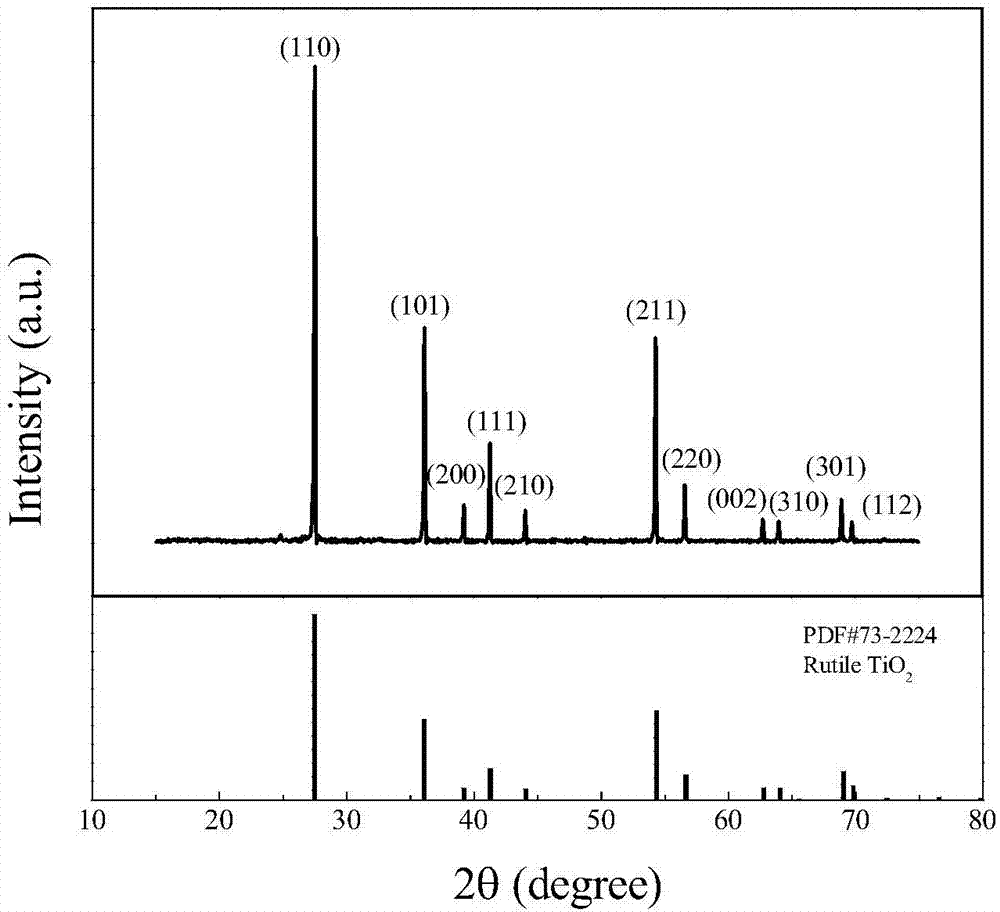

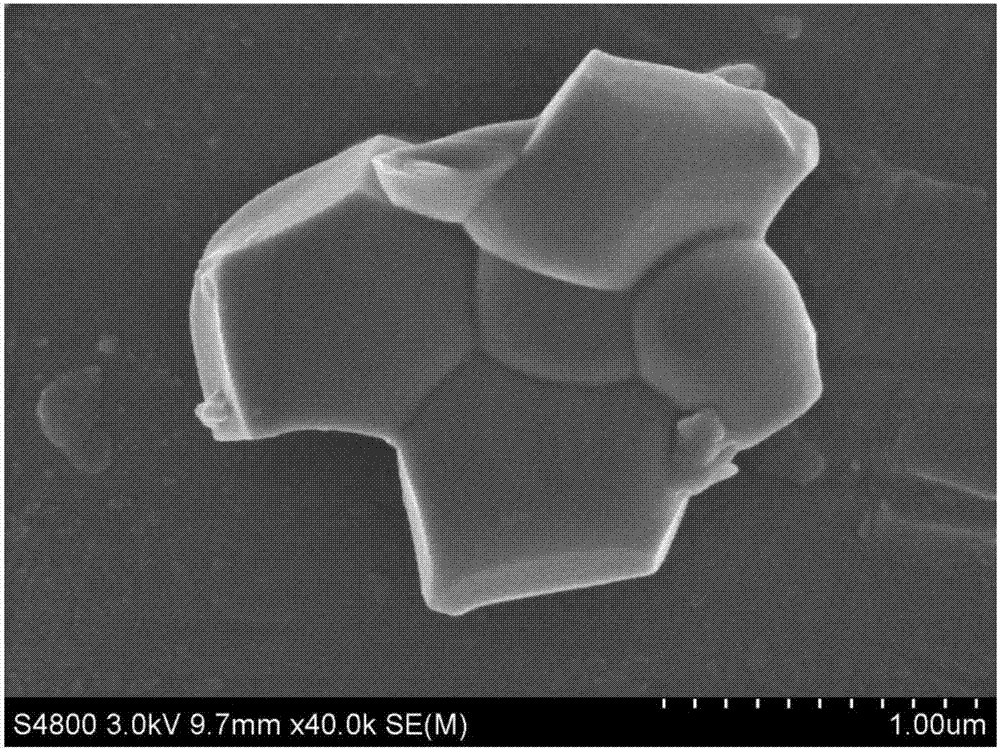

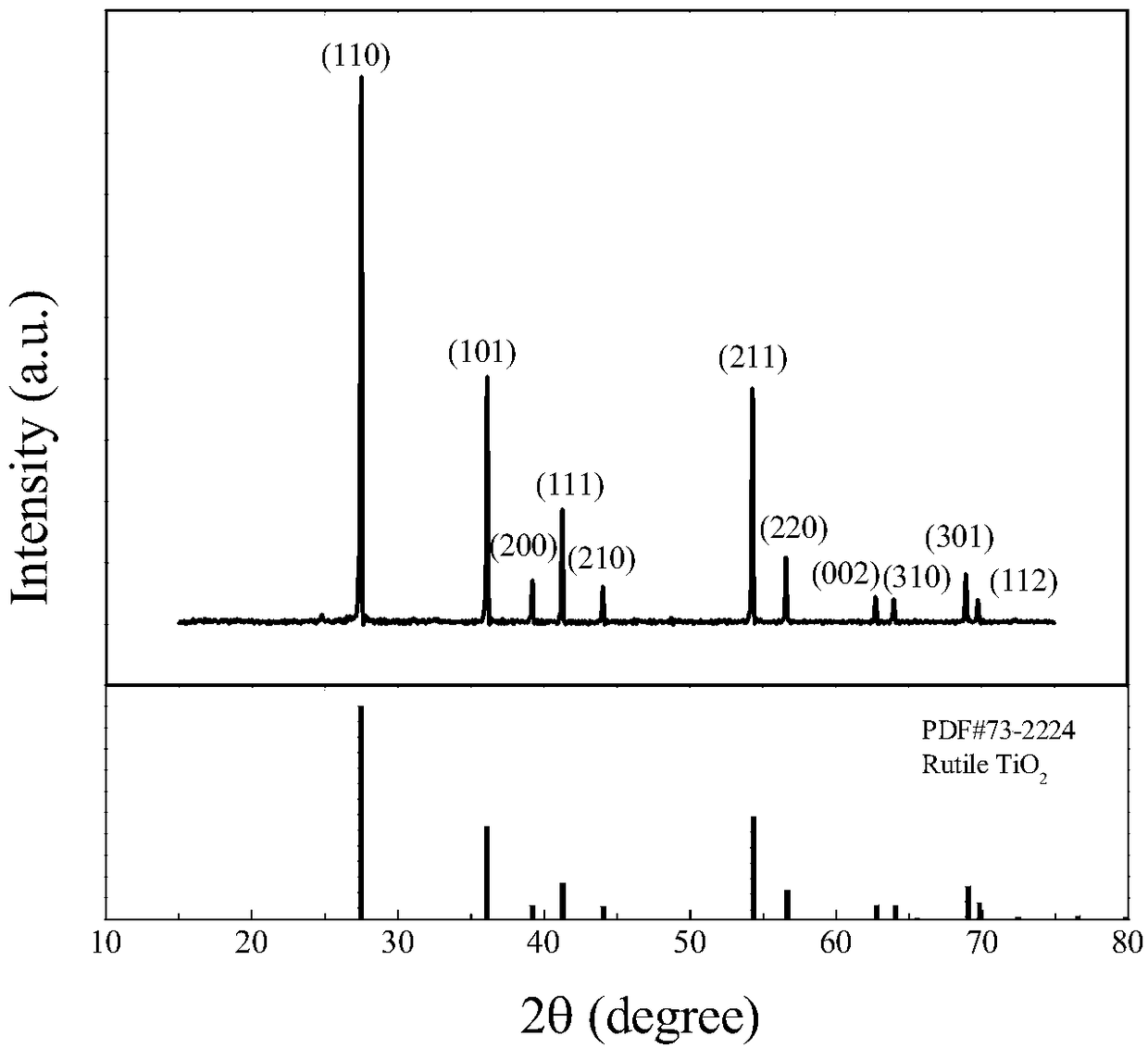

Method for preparing indium niobium co-doped titanium dioxide powder through co-precipitation method

ActiveCN106865612ANarrow particle size distributionRegular shapeTitanium dioxideNiobium compoundsIndiumAlcohol

The invention relates to a method for preparing indium niobium co-doped titanium dioxide powder through a co-precipitation method. The method comprises the following steps: (1) preparing a solution, weighting InCl3.4H2O and NbCl and respectively dissolving in absolute ethyl alcohol, thereby obtaining an InCl3 solution and a NbCl5 solution; (2) weighting TiCl4 and dissolving in absolute ethyl alcohol, thereby obtaining a TiCl4 absolute ethyl alcohol solution; (3) dropwise adding the InCl3 solution into the NbCl5 solution, thereby obtaining a mixed solution A; (4) dropwise adding the TiCl4 absolute ethyl alcohol solution into the mixed solution A, thereby obtaining a mixed solution B; (5) using ammonium hydroxide for adjusting pH of the mixed solution B till pH is more than or equal to 11, thereby forming a suspension; (6) performing suction filtration on the suspension, drying the obtained precipitate, grinding and sieving, thereby obtaining precursor powder; (7) roasting the precursor powder prepared in the step (6) at 1100-1200 DEG C, thereby obtaining the indium niobium co-doped titanium dioxide powder.

Owner:SHAANXI UNIV OF SCI & TECH

(ni,pt)al high temperature oxidation resistant adhesive layer material modified by active element sc and its preparation method

InactiveCN103667795BImprove adhesionReduce oxidation rateVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionHigh resistance

The invention discloses an active-element Sc-modified (Ni, Pt) Al high-temperature-oxidation-resisting bonding layer material and a preparation method thereof and belongs to the technical field of thermal barrier coatings. Electroplating and electron beam physical vapor deposition methods are adopted to prepare an Sc-modified (Ni, Pt) Al coating on nickel-base superalloy. The bonding layer material can be applied for a long time in the environment with the temperature more than 1150 DEG C. Compared with unmodified NiAl, the bonding layer material has the advantages that after Sc is doped, the oxidation rate of (Ni, Pt) Al is obviously reduced, the adhesion of an oxidation film is improved, and the peeling situation is inhibited; the oxidation film / Ni Al interface becomes straight, and holes in the interface are eliminated; the bonding layer material has high resistance to high temperature oxidation and can be used as the bonding layer material of a high-temperature-resisting thermal barrier coating. The preparation method respectively adopts the electroplating method to prepare a Pt layer and adopts the electron beam physical vapor deposition method to prepare the Sc-modified (Ni, Pt) Al coating, can precisely control the thickness and chemical components of the coating by regulating various parameters, and makes up for the deficiencies of a pack cementation method for preparing the (Ni, Pt) Al coating.

Owner:BEIHANG UNIV

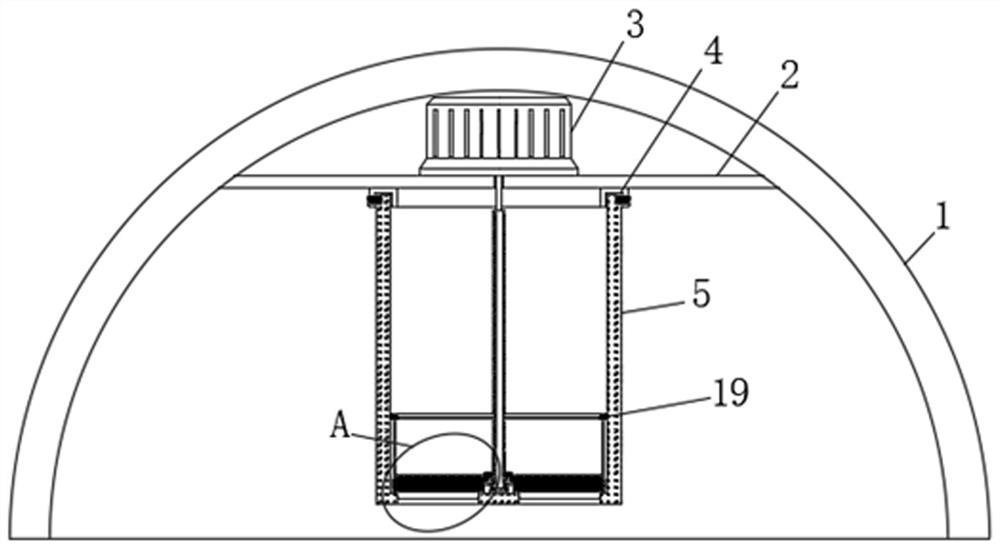

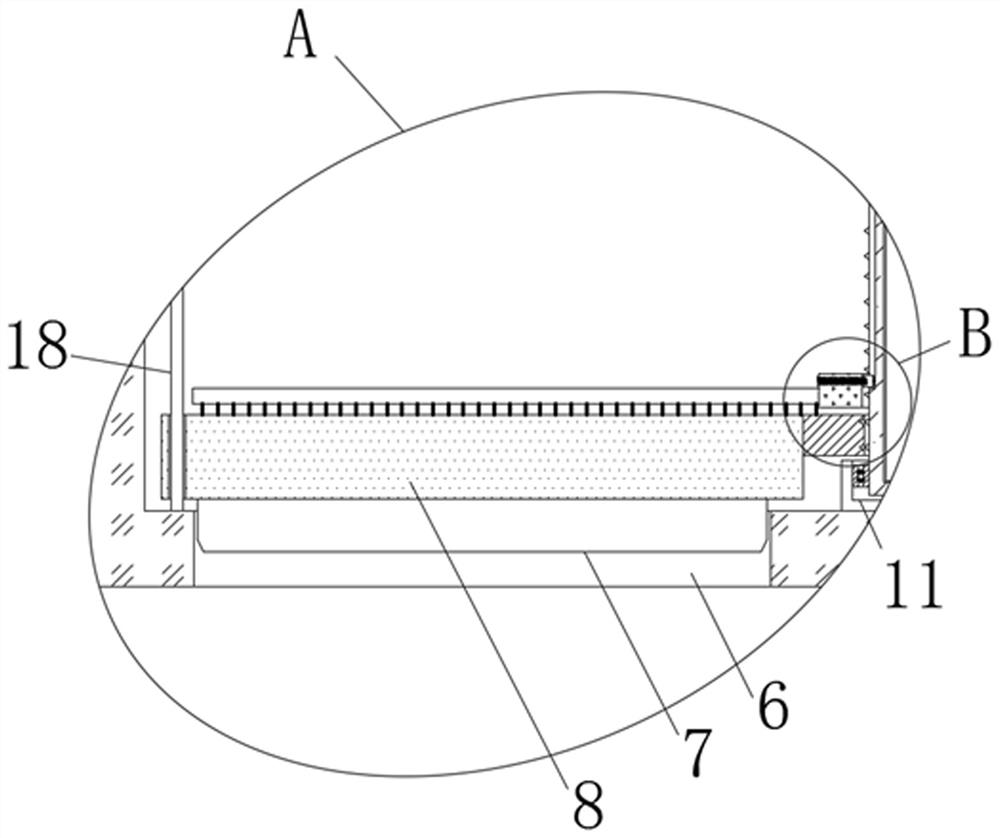

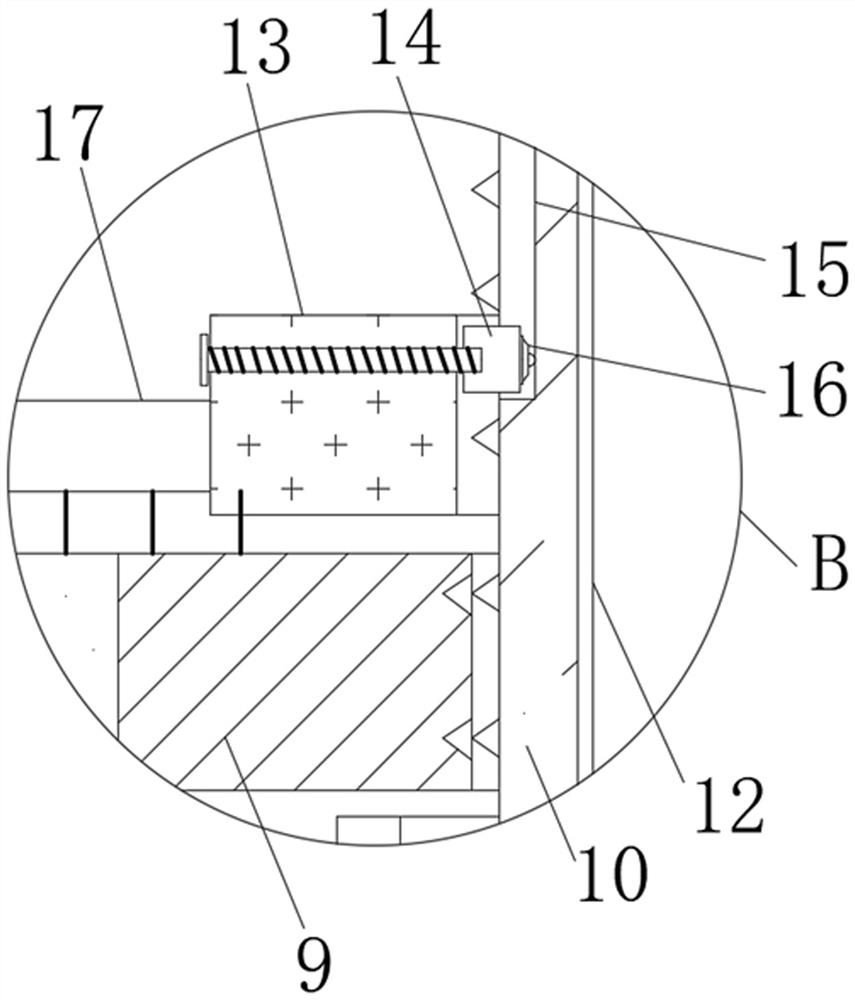

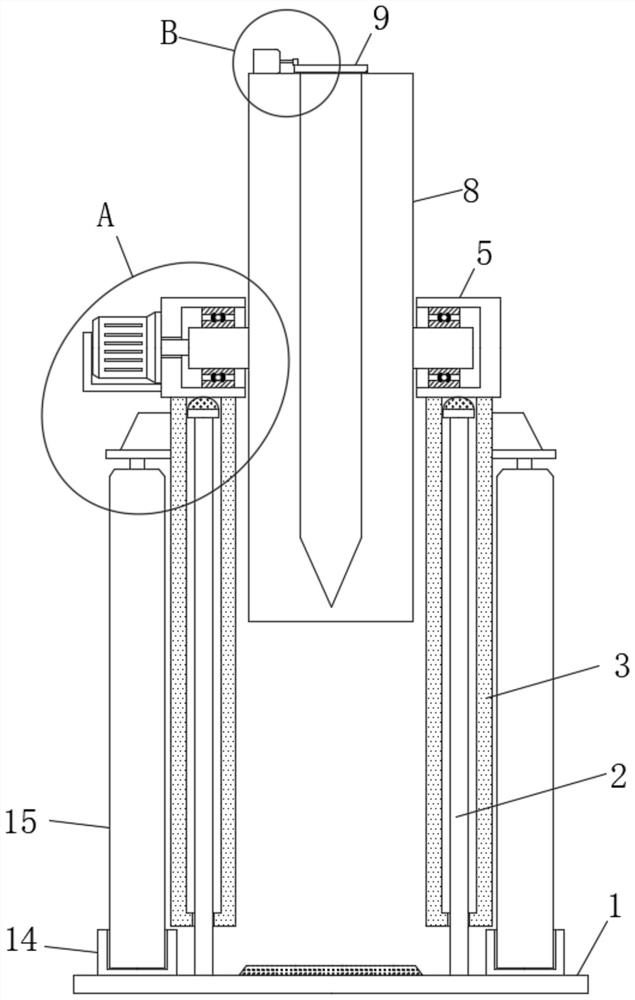

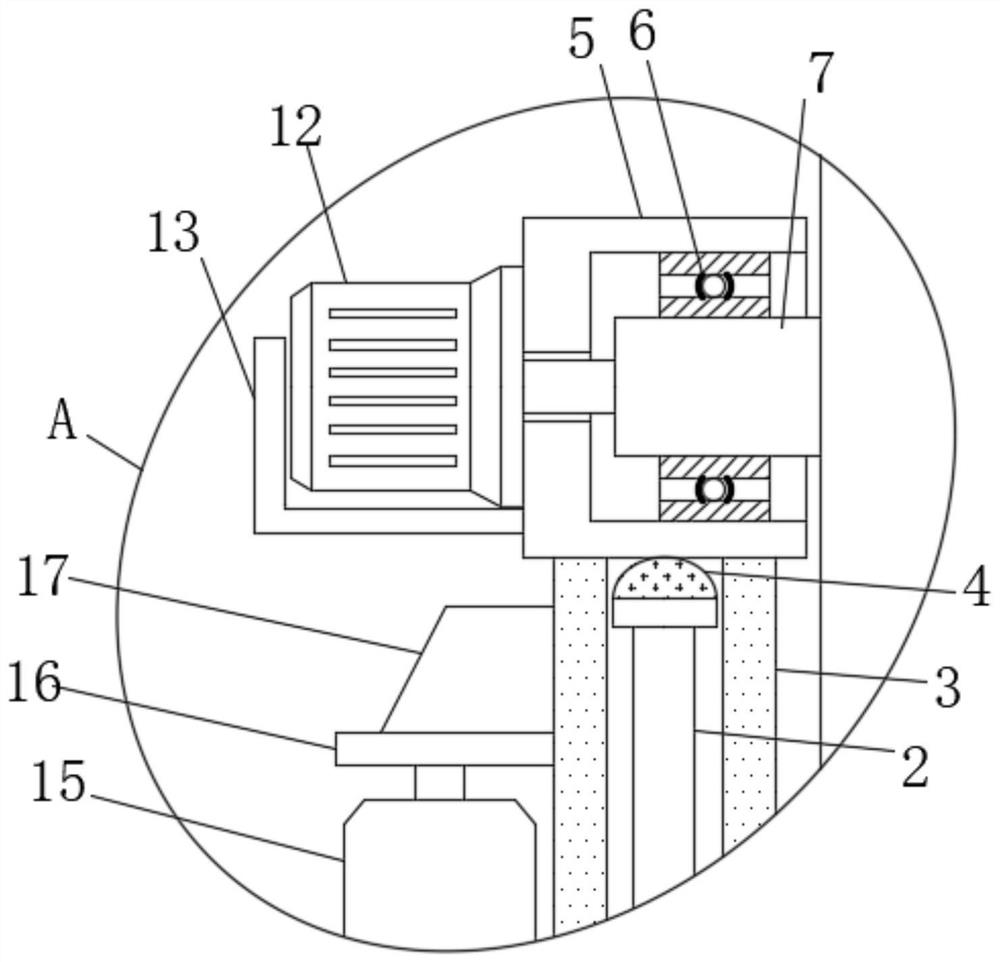

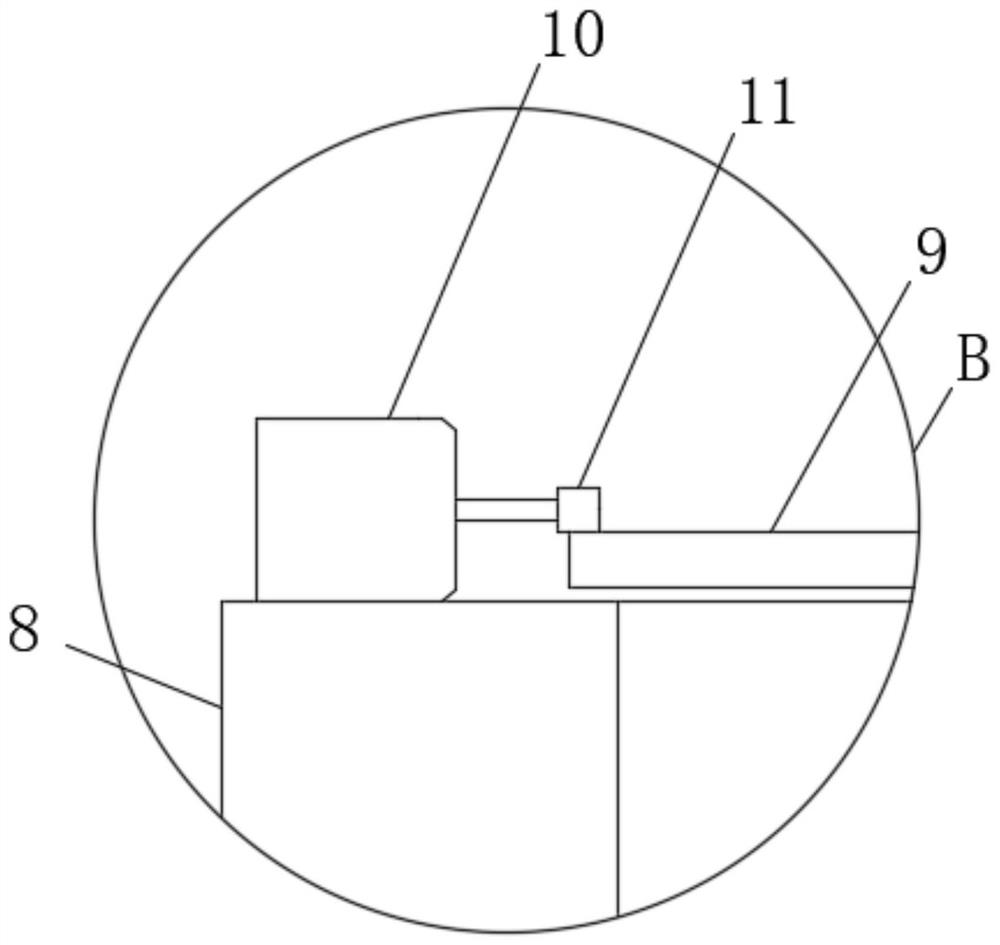

High-purity smelting method for low-Si and low-Al blade steel

The invention provides a high-purity smelting method for low-Si and low-Al blade steel. The high-purity smelting method comprises the following steps of AOD smelting, VOD smelting and LF refining. The invention further provides a low-Si and low-Al blade steel high-purity smelting vacuum steel ladle feeding mechanism comprising a steel ladle cover, an installation plate is arranged on the inner wall of the steel ladle cover, a driving motor is arranged on the top face of the installation plate, a connecting buckle frame is arranged on the bottom face of the installation plate, a material barrel is inserted into a groove body of the connecting buckle frame, and a material leakage opening is formed in a bottom plate of the material barrel. A plug plate is inserted into the material leakage opening and fixed to the bottom face of a connecting plate, and the connecting plate is fixed to the surface of a lifting ring. The low-Si and low-Al blade steel high-purity smelting vacuum steel ladle feeding mechanism has the beneficial effects that automatic feeding in a steel ladle sealing state is achieved, in other words, after the plug plate is separated from the material leakage opening, an additive falls, and when a shaft sleeve drives a rotating ring to rotate, the additive left on the top face of the connecting plate is swept off through a material stirring plate.

Owner:AVIC SHANGDA METAL REGENERATION TECH

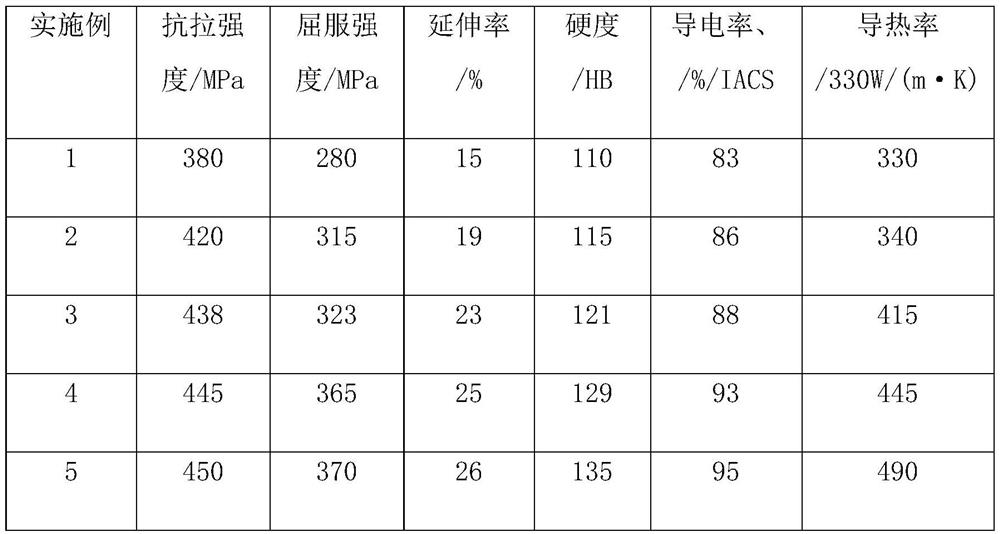

Manufacturing method for airspace engine combustion chamber inner wall blank

ActiveCN113653573APrecise Control of Chemical CompositionImprove mechanical propertiesEngine componentsRocket engine plantsVacuum induction meltingCombustion chamber

The invention discloses a manufacturing method for an airspace engine combustion chamber inner wall blank. The manufacturing method comprises the steps that S1, Cu, Cr and Zr materials are weighed; S2, the materials obtained in the step S1 is subjected to vacuum induction melting, and an alloy solution is obtained; S3, the alloy solution obtained in the step S2 is poured to obtain an alloy cast ingot; S4, the alloy cast ingot obtained in the step S3 is subjected to forging, upsetting, drawing-out and punching treatment, and a combustion chamber inner wall blank is obtained; S5, the combustion chamber inner wall blank obtained in the step S4 is subjected to solid heat melting treatment; S6, the combustion chamber inner wall blank treated in the step S5 is subjected to upsetting and secondary chambering treatment; S7, the treated combustion chamber inner wall blank is subjected to rough turning, aging heat treatment, performance detection and finish turning treatment, and the combustion chamber inner wall blank is obtained; and S8, size detection and appearance detection are conducted on the combustion chamber inner wall blank obtained in the step S7, and packaging is conducted. The manufacturing method for the airspace engine combustion chamber inner wall blank is reasonable in process design, the obtained combustion chamber inner wall blank can meet the high-strength and high-heat-dissipation requirements of an airspace engine combustion chamber, and the manufacturing method is suitable for large-scale popularization.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Process for smelting special alloy steel

The invention discloses a process for smelting a special alloy steel. The process comprises a primary smelting process and a refining process, wherein, the primary smelting process is completed in an atmosphere state, the refining process is completed in a vacuum induction furnace. The invention can greatly shorten the smelting period, improve the production efficiency, have low demand for the quality of the smelting base material, use little or not use pure metal raw materials in the primary smelting process, simplify the processing technology and reduce the production cost. At the same time, the process can precisely control chemical compositions, which creates a good condition for obtaining the stable performance and giving full play to the role of alloy elements, can obviously improve the property of alloy and adjust the refining time, temperature and vacuum degree in a wide range, which creates a favorable thermodynamics condition and a favorable kinetics condition for metallurgical reaction.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

A method for preparing indium-niobium co-doped titanium dioxide powder by co-precipitation

ActiveCN106865612BNarrow particle size distributionRegular shapeTitanium dioxideNiobium compoundsIndiumAlcohol

The invention relates to a method for preparing indium niobium co-doped titanium dioxide powder through a co-precipitation method. The method comprises the following steps: (1) preparing a solution, weighting InCl3.4H2O and NbCl and respectively dissolving in absolute ethyl alcohol, thereby obtaining an InCl3 solution and a NbCl5 solution; (2) weighting TiCl4 and dissolving in absolute ethyl alcohol, thereby obtaining a TiCl4 absolute ethyl alcohol solution; (3) dropwise adding the InCl3 solution into the NbCl5 solution, thereby obtaining a mixed solution A; (4) dropwise adding the TiCl4 absolute ethyl alcohol solution into the mixed solution A, thereby obtaining a mixed solution B; (5) using ammonium hydroxide for adjusting pH of the mixed solution B till pH is more than or equal to 11, thereby forming a suspension; (6) performing suction filtration on the suspension, drying the obtained precipitate, grinding and sieving, thereby obtaining precursor powder; (7) roasting the precursor powder prepared in the step (6) at 1100-1200 DEG C, thereby obtaining the indium niobium co-doped titanium dioxide powder.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of ferritic stainless steel for stopper rod

InactiveCN113278866AMeet the needs of pouringImprove purityFoundry mouldsFoundry coresSS - Stainless steelSmelting

The invention discloses ferritic stainless steel for a stopper rod. A formula of the ferritic stainless steel for the stopper rod comprises the following components of 24.0-25.0% of Cr, 0.1-0.15% of C, 0.10-0.15% of N and the balance of microelements. The invention further discloses a preparation method of the ferritic stainless steel for the stopper rod. The preparation method comprises the following steps of quantitative weighing, smelting and forging / rolling. The material provided by the invention is designed to be high-Cr stainless steel, the content of precious elements such as Ni and Mo is low, the material belongs to a nickel-saving environment-friendly material, and the cost is low. According to the technical scheme, a vacuum induction and electroslag process is adopted for smelting, so that the chemical components can be accurately controlled, and the purity of the steel is high. A product with refined structure and excellent performance can be obtained after forging and rolling.

Owner:AVIC SHANGDA METAL REGENERATION TECH

A kind of gh2018 alloy electroslag ingot and preparation method thereof

ActiveCN111778439BGuaranteed surface qualityImproves ingredient uniformityIncreasing energy efficiencyAl powderElectro-slag remelting

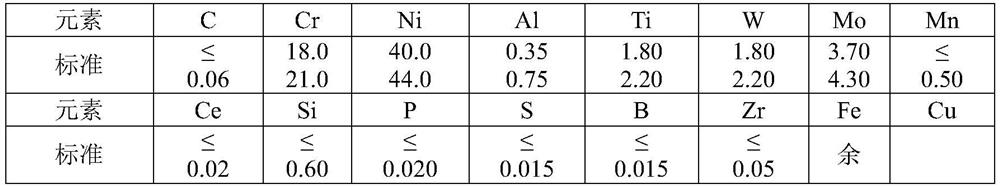

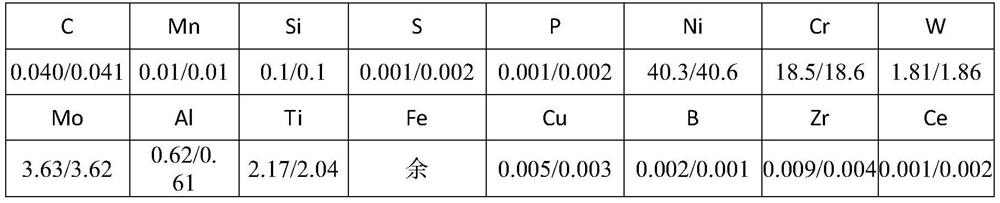

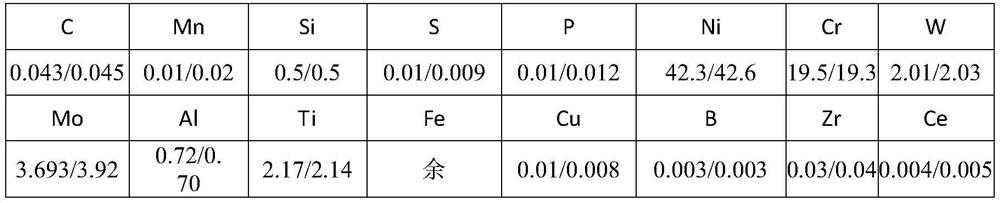

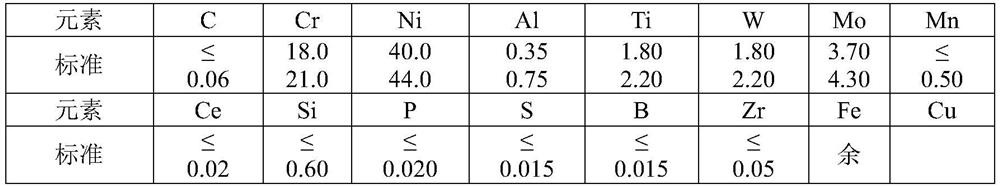

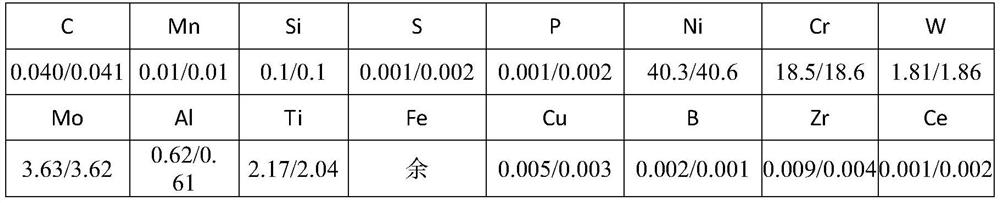

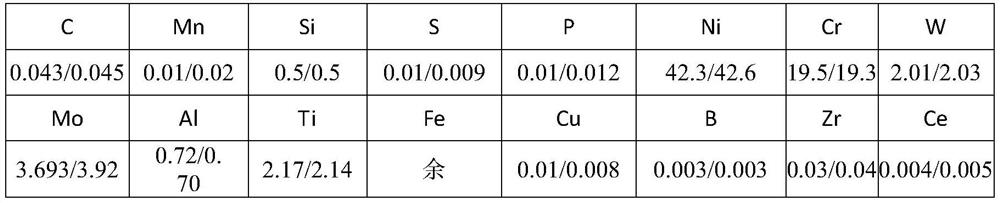

The invention provides a GH2018 alloy electroslag ingot, the composition content of elements in the alloy is: C 0.040-0.050wt%, Cr 18.5-20.5wt%, Ni 40.5-43.5wt%, Al 0.6-0.7wt%, Ti 2.0 ~2.2wt%, W 1.85~2.15wt%, Mo 3.8~4.2wt%, Mn 0.01~0.03wt%, Ce 0.002~0.02wt%, Si 0.2~0.6wt%, P 0.001~0.02wt%, S 0.001~ 0.01wt%, B 0.001-0.01wt%, Zr 0.005-0.05wt%, Cu 0.02-0.2wt%, the balance being Fe. In the alloy electroslag ingot electroslag remelting process of the invention, aluminum powder and inert argon gas are added to improve the composition uniformity of the electroslag ingot.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

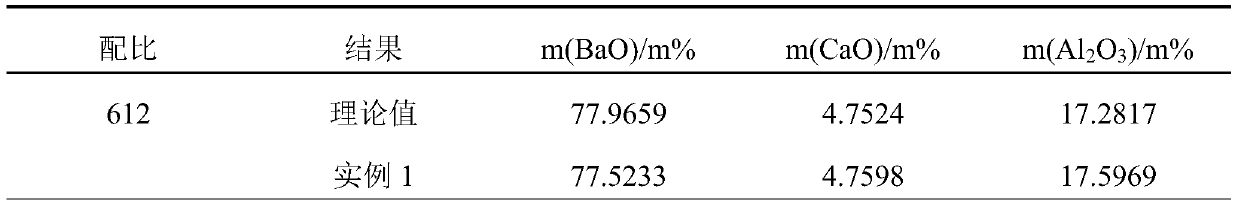

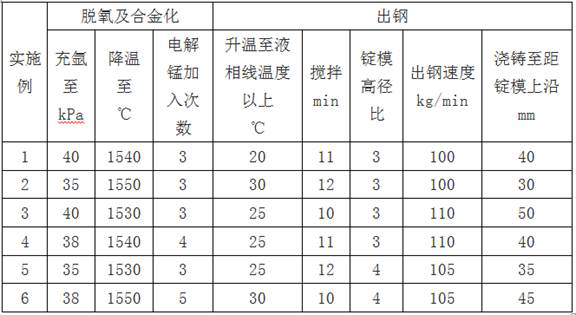

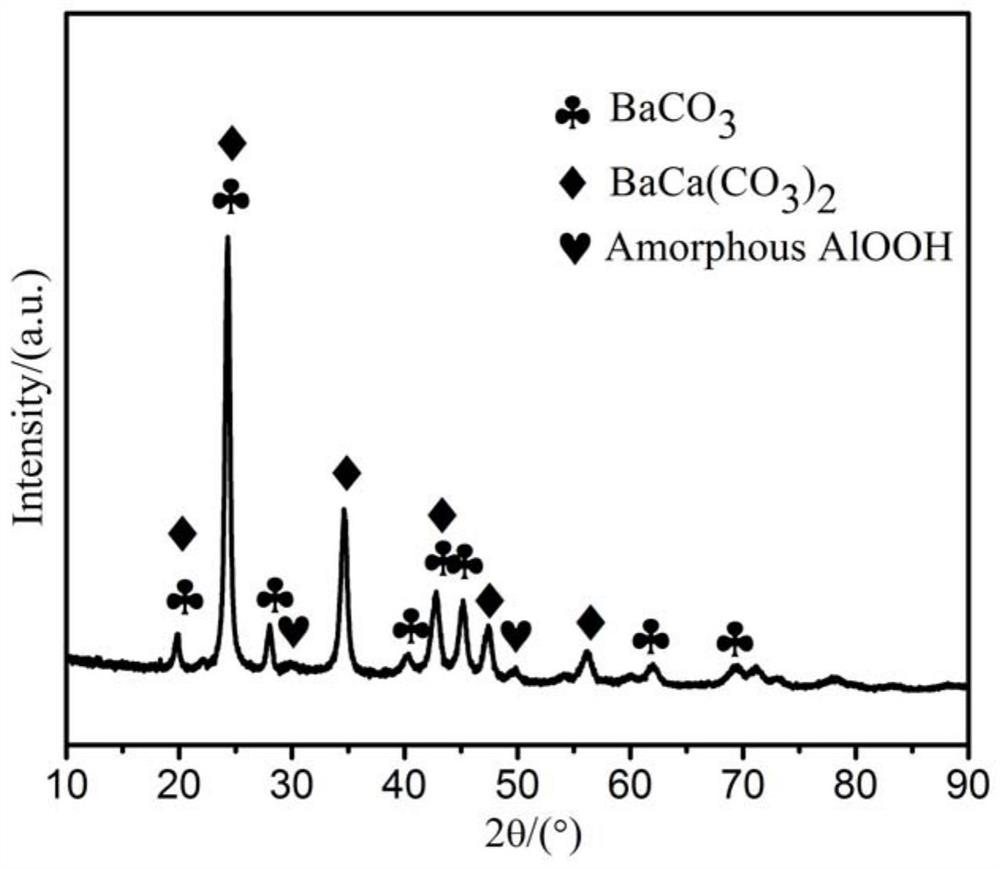

Preparation method of mixed salt solution for co-precipitation synthesis of aluminate electron emission materials

ActiveCN108766859BReasonable process designEasy to operateDischarge tube/lamp detailsThermionic cathode manufactureChemical compositionBarium nitrate

The invention provides a preparation method of a mixed salt solution for coprecipitation synthesis of an aluminate electron emissive material. The method comprises the following steps that (1) bariumnitrate, calcium nitrate and aluminum nitrate solutions are weighed accurately, and dried, sintered and weighed accurately to obtain the weights of barium nitrate, calcium nitrate and aluminum nitrate; (1) the purity of the barium nitrate, calcium nitrate and aluminum nitrate in the sintered barium nitrate, calcium nitrate and aluminum nitrate is measured accurately; (3) the weights of barium nitrate, calcium nitrate and aluminum nitrate after drying and sintering of a 100g of barium nitrate solution, a 100g of calcium nitrate solution and a 100g of aluminum nitrate solution are calculated respectively; (4) the needed weights of the barium nitrate, calcium nitrate and aluminum nitrate solutions are calculated to the chemical composition and weight of an aluminate to be prepared; and (5) the barium nitrate, calcium nitrate and aluminum nitrate solutions are weighed accurately according to a calculation result, and mixed to obtain the mixed salt solution for coprecipitation synthesis ofthe aluminate electron emissive material. The preparation method is reasonable in technical design and easy to operation.

Owner:NANJING TECH UNIV

Preparation method of Bi1.5MgNb1.5O7 (BMN) dielectric film

The invention discloses a preparation method of a BMN dielectric film, comprising the steps of: (1) preparing a citric acid water solution of niobium; (2) adding glycol into the water solution, and conducting heating and stirring; (3) preparing a glycol solution of magnesium and bismuth; (4) adding the prepared glycol solution of magnesium and bismuth into the solution obtained in step (2), thus obtaining a bismuth-magnesium-niobium sol; (5) adding ethanol into the bismuth-magnesium-niobium sol, and carrying out heating and stirring so as to obtain a bismuth-magnesium-niobium precursor solution; (6) coating a substrate with the precursor solution uniformly and drying the substrate; (7) subjecting a dried film to a heat treatment at a temperature of 500-800DEG C for 10min; (8) repeating step (6) and (7) so as to prepare a multilayered film; (9) conducting a heat treatment to the multilayer film at a temperature of 550-800DEG C for 0.5-2h, thus obtaining a BMN dielectric film with a cubic pyrochlore structure. With accurately controlled chemical components and high density, the BMN dielectric film provided in the invention has no crack and pin hole as well as other defects. Characterized by simple process and low cost, the film of the invention as a microwave dielectric adjustable material boasts good application prospects.

Owner:TIANJIN UNIV

Method for preparing copper-zinc-tin-selenium nano powder material

The invention discloses a method for preparing a copper-zinc-tin-selenium nano powder material, and belongs to the technical field of photoelectric materials. The method comprises the following steps of: preparing alkyl alcohol amine solution (system A) of Cu, Zn and Sn in a molar ratio of 2: 1: 1 by using alkyl alcohol amine with a boiling point of no less than 180 DEG C as a solvent, preparing alkyl alcohol amine solution (system B) of Se at the same time, then mixing the system A and the system B in a molar ratio of Se to Cu of 2: 1, and reacting the mixture with stirring and heating reflux under the protection of inert gas to obtain the copper-zinc-tin-selenium nano powder material. The copper-zinc-tin-selenium nano particles with nano scale, uniform size, good dispersion and high phase purity are prepared by selecting and using rich and environment-friendly Zn and Sn elements to replace rare metals In and Ga; and the whole preparation process has simple equipment requirement, is green and pollution-free, and does not need selenium atmosphere. The copper-zinc-tin-selenium nano powder material prepared by the method is mainly used in a solar cell and used as an absorption layermaterial.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

GH2018 alloy electroslag ingot and preparation method thereof

ActiveCN111778439AGuaranteed surface qualityImproves ingredient uniformityIncreasing energy efficiencyAl powderElectro-slag remelting

The invention provides a GH2018 alloy electroslag ingot. An alloy comprises components: by weight, 0.040-0.050% of C, 18.5-20.5% of Cr, 40.5-43.5% of Ni, 0.6-0.7% of Al, 2.0-2.2% of Ti, 1.85-2.15% ofW, 3.8-4.2% of Mo, 0.01-0.03% of Mn, 0.002-0.02% of Ce, 0.2-0.6% of Si, 0.001-0.02% of P, 0.001-0.01% of S, 0.001-0.01% of B, 0.005-0.05% of Zr, 0.02-0.2% of Cu, and the balance Fe. According to the preparation method of the GH2018 alloy electroslag ingot, provided by the invention, aluminum powder and inertia argon are supplemented in the remelting process, and the component uniformity of the electroslag ingot is improved.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

A method for preparing large-scale manganese-containing high-entropy alloy ingots

The invention discloses a preparation method for a large-specification manganese-containing high-entropy alloy cast ingot. The preparation method for the large-specification manganese-containing high-entropy alloy cast ingot comprises the following steps: weighing the weights of Fe, Cr, Ni and Mn according to the content of 25at.% of Fe, Cr, Ni and Mn elements in a Fe-Cr-Ni-Mn high-entropy alloy,and adding Fe, Cr, Ni and Mn into a crucible; then carrying out primary argon-filled vacuum induction smelting to obtain a primary cast ingot of the high-entropy alloy, then carrying out argon-filledconsumable electro-arc smelting twice, and finally carrying out vacuum heat treatment to obtain the large-specification manganese-containing high-entropy alloy cast ingot. In the aspect of preparationfor the high-entropy alloy, the alloy cast ingot is obtained by carrying out the primary argon-filled vacuum induction smelting, then carrying out the argon-filled consumable electro-arc smelting twice, and then carrying out the vacuum heat treatment; and the method is simple and practicable in a process for preparing a high-entropy material, high in efficiency, low in requirement on equipment, and low in cost. The high-entropy alloy cast ingot prepared by the preparation method is accurate in component and high in uniformity, and provides an excellent blank for the subsequent hot-processingprocedure.

Owner:SUZHOU NUCLEAR POWER RES INST +1

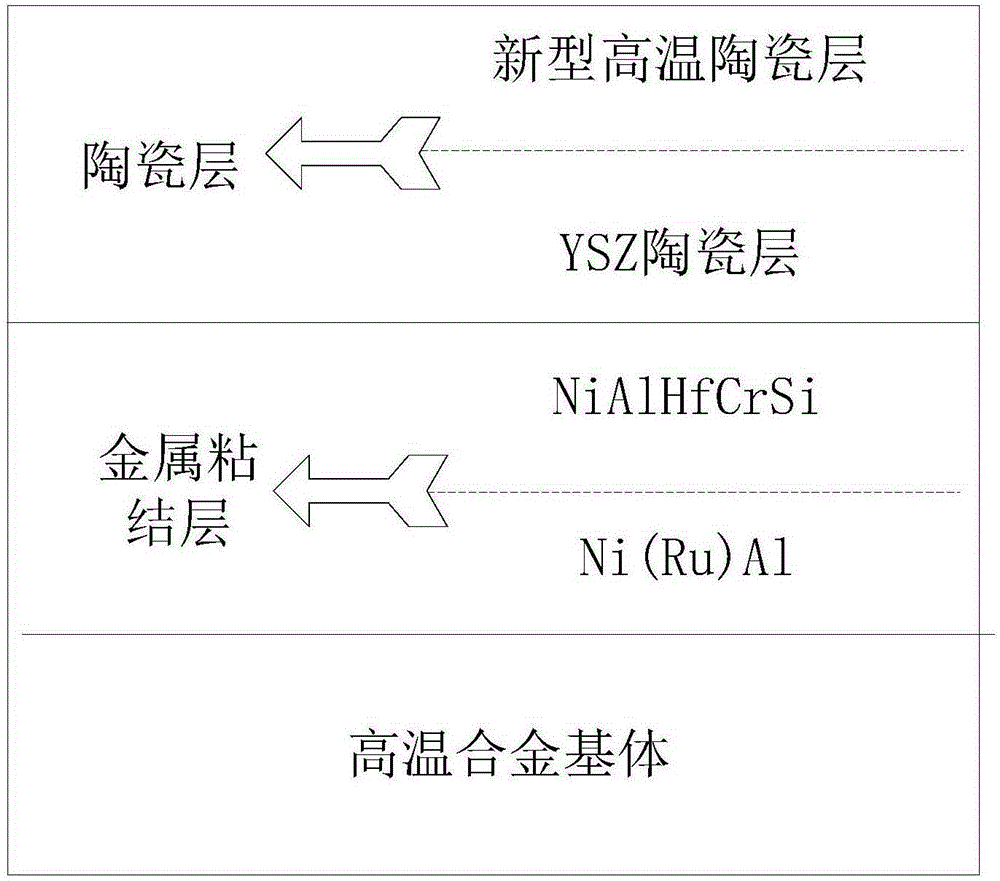

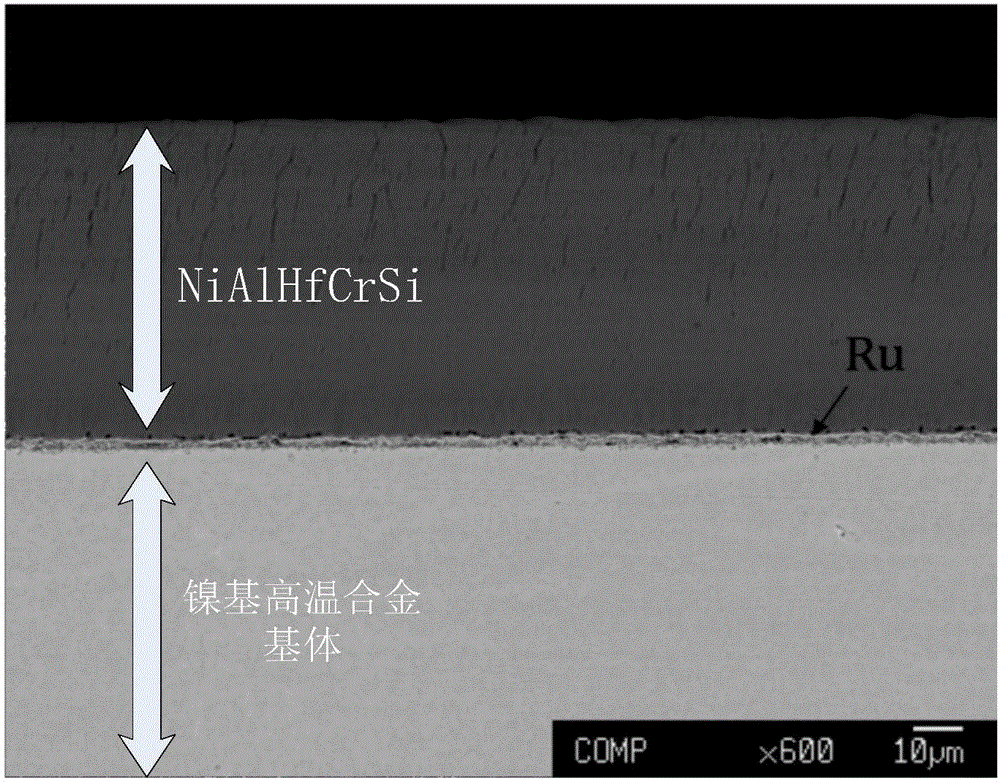

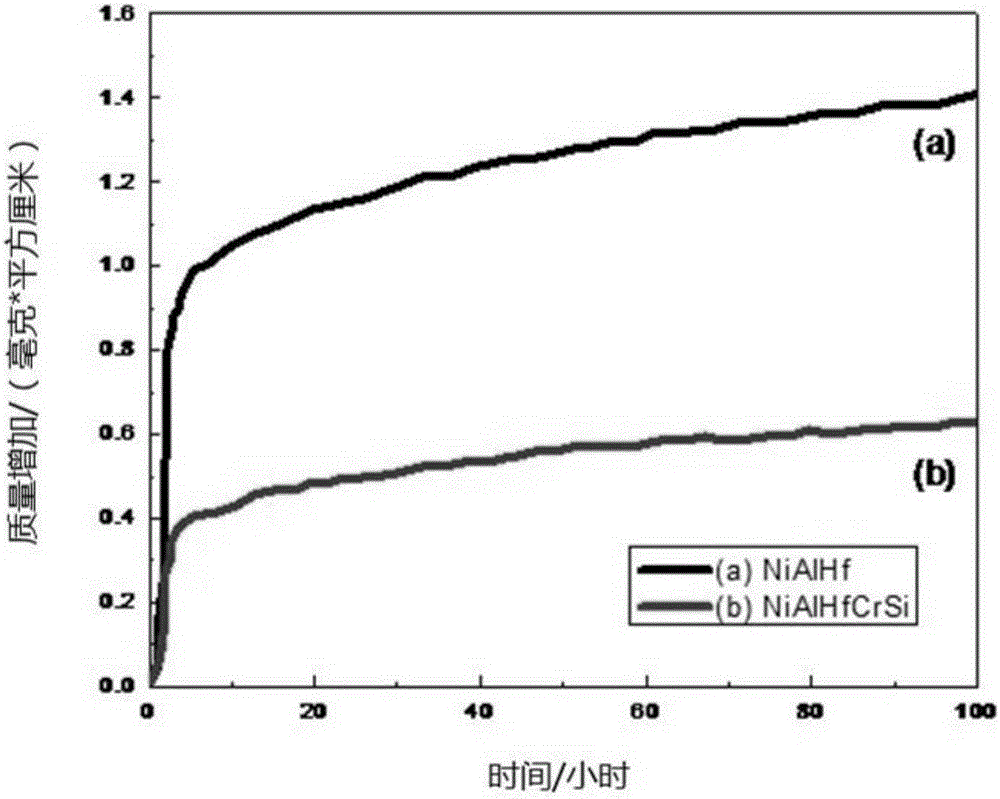

A composite adhesive layer material resistant to 1200°C high temperature oxidation and gas thermal corrosion resistance and its preparation method

InactiveCN103484824BImprove bindingImprove antioxidant capacityVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

The invention discloses a compound binding layer material with 1200 DEG C high-temperature oxidization resistance and fuel gas thermal corrosion resistance and a preparation method of the compound binding layer material. The preparation method comprises the following steps of firstly, depositing a layer of Ru on a base body by adopting an electroplating or electron beam physical vapor deposition method; then, depositing a layer of NiAlHfCrSi on the Ru layer by adopting the electron beam physical vapor deposition method; and finally, carrying out thermal treatment to obtain a Ni(Ru)Al / NiAlHfCrSi double-layer structure binding layer, wherein the content of Ru in the Ni(Ru) Al layer is gradually reduced from a base body surface layer to an outer layer direction in a gradient manner. The double-layer structure binding layer can be used for effectively blocking mutual diffusion between the base body and a coating to restrain formation of a second reaction region (SRZ), restrain formation of similar spinel in a thermal corrosion process and improve high temperature oxidization resistance and thermal corrosion resistance of a high-temperature alloy, and therefore, the double-layer structure binding layer is a novel thermal barrier coating binding layer material. The binding layer material can reach the anti-oxidation grade at 1200 DEG C, does not have the second reaction region by vacuum diffusion for 100 hours at 1100 DEG C; meanwhile, fuel gas thermal corrosion resistance is much higher than that of a common NiAl-series metal binding layer.

Owner:BEIHANG UNIV

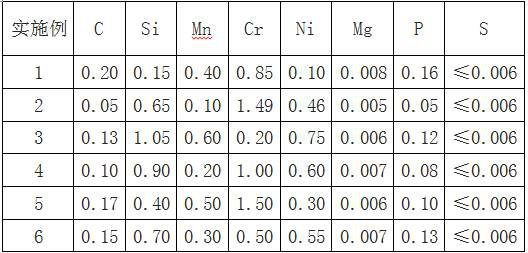

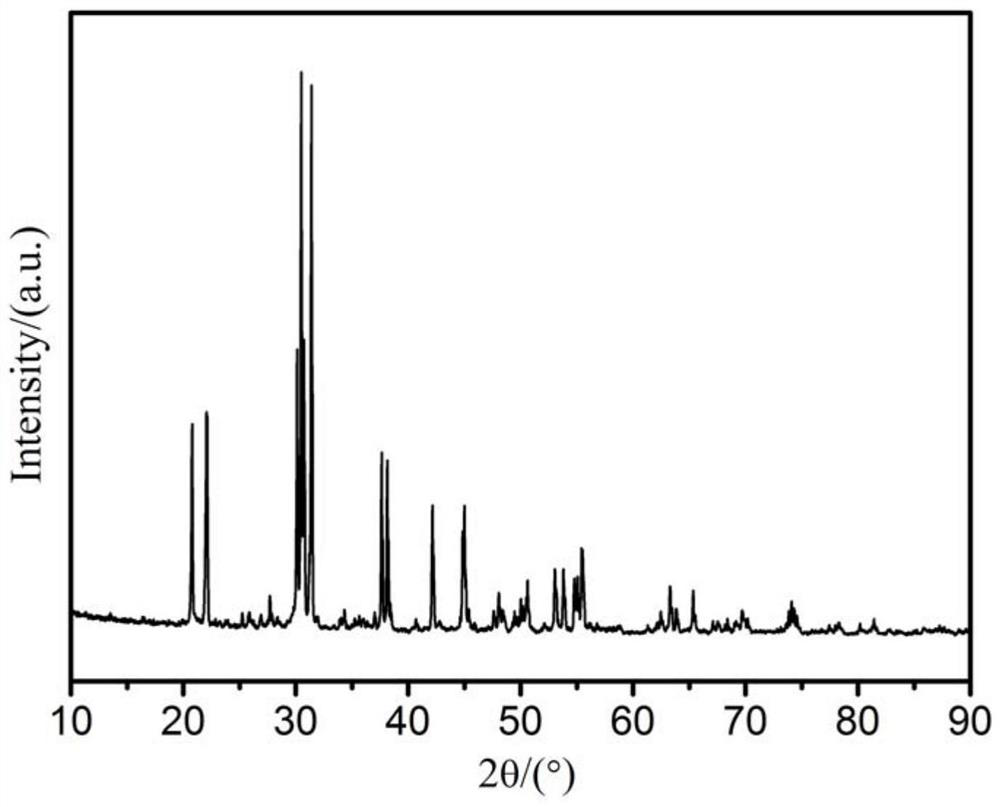

Smelting method of weathering resistant steel for direct-reading spectrum standard

The invention discloses a smelting method of weathering resistant steel for direct-reading spectrum standard. The smelting method of the weathering resistant steel for the direct-reading spectrum standard adopts a vacuum induction furnace for smelting, and comprises processes of charging, vacuum heating, degassing, deoxidation, alloying and tapping, and the processes are as follows: (1) charging: charging pure iron, chromium metal and electrolytic nickel into a crucible of the vacuum induction furnace; (2) vacuum heating: vacuumizing, and electrifying for heating until the steel and iron materials in the crucible are melted down; (3) degassing: carrying out high-vacuum degassing for 40-80 minutes under the pressure of less than or equal to 1 Pa; (4) deoxidation and alloying: argon is filled to 35000-40000 Pa, and nickel-magnesium alloy is added for deoxidation and desulfurization; after deoxidation is completed, power is cut off for cooling, and when the temperature reaches 1530-1550 DEG C, carbon powder, electrolytic manganese, ferrophosphorus, industrial silicon and the like are added for alloying; and (5) tapping: after the components of molten steel are detected to be qualified, when the temperature is raised to 20-30 DEG C above liquidus temperature of the weathering resistant steel, electrified tapping is carried out at a constant speed, and an ingot mold is a water-cooled copper ingot mold. According to the smelting method of the weathering resistant steel for the direct-reading spectrum standard, relative standard deviation SD% of cast ingot obtained through the method is smaller than or equal to 2%, and accuracy and uniformity are effectively improved.

Owner:HEBEI IRON AND STEEL

Preparation method of aluminate electron emission material for impregnated cathode

ActiveCN108751243BReasonable process designEasy to operateDischarge tube/lamp detailsAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationBarium nitrateSpray pyrolysis

A method for preparing an aluminate electron emission material used for an impregnated type negative electrode is provided. The method includes (1) accurately weighing barium nitrate, calcium nitrateand aluminum nitrate solutions, drying, calcining, and then accurately weighing the mass of the calcined barium nitrate, calcium oxide and alumina; (2) accurately measuring purity of the calcined barium nitrate, the calcium oxide and the alumina; (3) calculating the mass of pure barium nitrate obtained by drying and calcining 100 g of the barium nitrate solution, the mass of pure calcium oxide obtained by drying and calcining 100 g of the calcium nitrate solution, and the mass of pure alumina obtained by drying and calcining 100 g of the aluminum nitrate solution; (4) calculating the weights of needed barium nitrate, calcium nitrate and aluminum nitrate solutions according to the chemical constitution and the weight of an aluminate to be prepared; (5) weighing the barium nitrate, calcium nitrate and aluminum nitrate solutions according to the calculation result, and mixing the weighed solutions to obtain a mixed salt solution for coprecipitation synthesis of the aluminate electron emission material; and (6) preparing the aluminate electron emission material by adopting a process combining coprecipitation and spray pyrolysis. The method is reasonable in process and design, and simple to operate, and the prepared aluminate has an accurately controlled chemical constitution and a good degree of crystallinity.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com