Smelting method of weathering resistant steel for direct-reading spectrum standard

A direct-reading spectrum and smelting method technology, applied in the field of steelmaking, can solve the problems of difficult effective control of composition segregation, large gap in technical requirements, and dependence on imports, etc., to improve the shape and distribution of inclusions, improve accuracy and uniformity, Guarantees precise control over levels of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0016] Embodiment 1-6: The smelting method of weathering steel for direct reading spectrum standard adopts the following process.

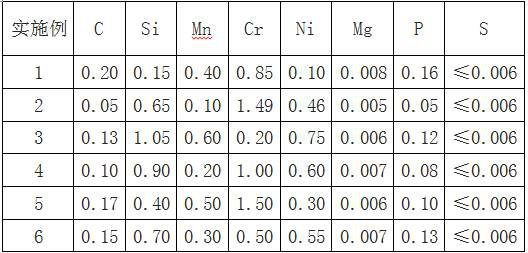

[0017] (1) The composition and content of the weathering steel for the direct reading spectrum standard are (wt): C 0.05%-0.20%, Si0.15%-1.05%, Mn 0.1%-0.6%, P 0.05%-0.16% , S ≤ 0.006%, Cr 0.2% ~ 1.5%, Ni 0.10% ~ 0.75%, Mg 0.005% ~ 0.008%, the balance is Fe and unavoidable impurities. See Table 1 for the target content of weathering steel components described in each embodiment.

[0018] Table 1: Target content (wt%) of weathering steel components described in each example

[0019]

[0020] In Table 1, the balance of the components is Fe and unavoidable impurities.

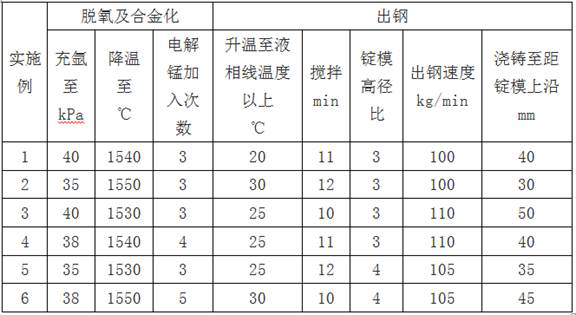

[0021] (2) The equipment uses a vacuum induction furnace with a rated capacity of 500kg to smelt weathering steel for direct reading spectrum standard steel, with a rated power of 350kw and an ultimate vacuum of 6.67×10 -2 Pa; The production process includes furnace loading, vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com