Method for preparing copper-zinc-tin-selenium nano powder material

A nano-powder, copper-zinc-tin-selenium technology, applied in the field of preparation of nano-copper-zinc-tin-selenium powder photovoltaic materials, can solve the problems of increased operation steps, cost, and high price, and achieve low cost, fast and effective cost, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

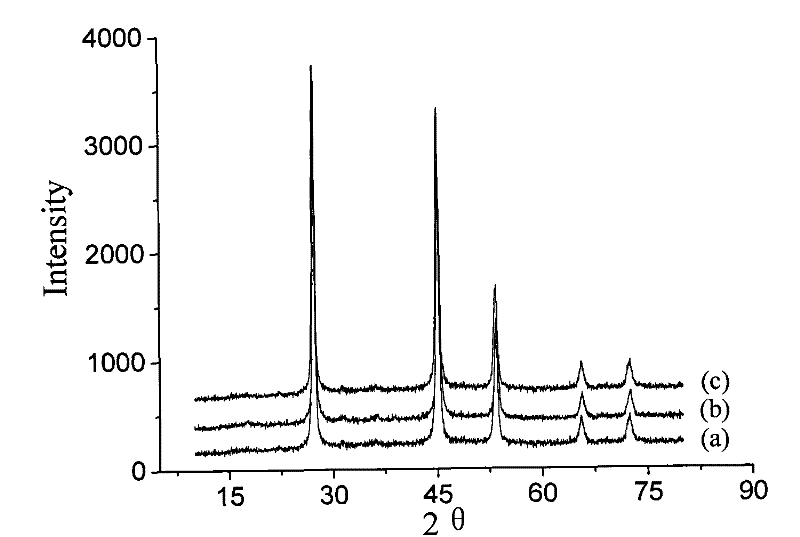

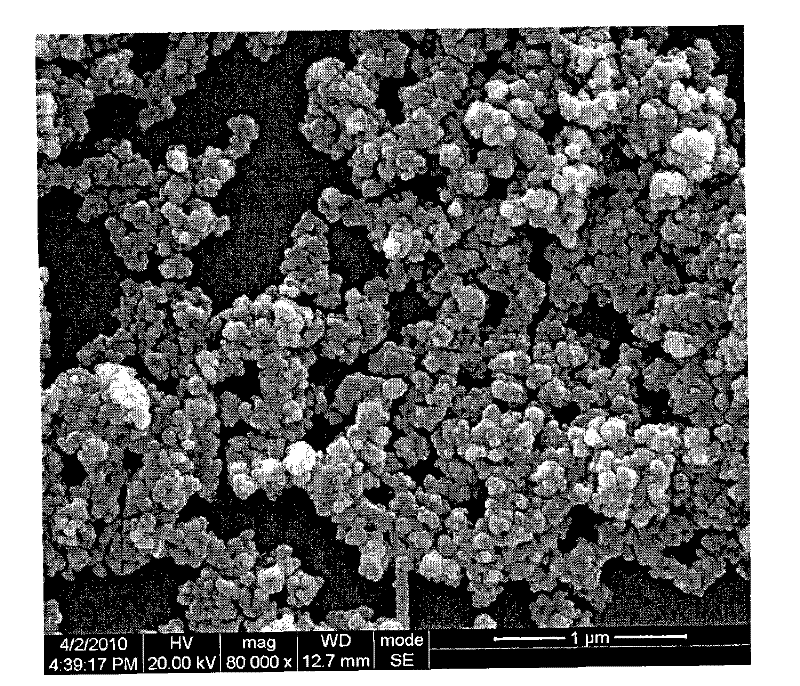

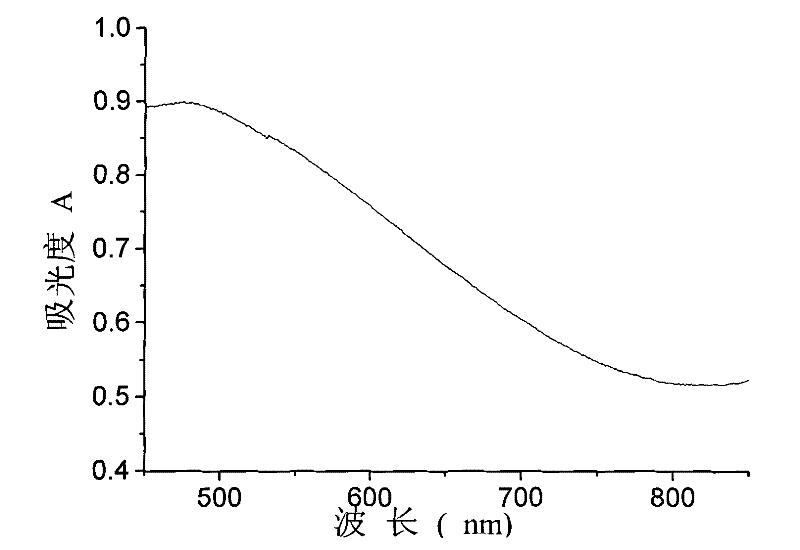

[0028] The copper-zinc-tin-selenide nanopowder is synthesized according to the following process steps.

[0029] a. Prepare the following two solutions respectively:

[0030] Solution A: Weigh 4mmolCuCl, 2mmolZnCl 2 , 2mmolSnCl 4 2H 2 O was placed in a 100mL three-necked flask containing 40mL of triethanolamine, stirred under the protection of an inert gas, and heated to 180°C in an oil bath. The color of the solution changed from green to dark blue to brown, and stopped heating when all the solids were dissolved.

[0031] Solution B: Weigh 8 mmol of Se powder and add it into another 100 mL three-necked flask containing 40 mL of triethanolamine, and slowly raise the temperature to 180°C. After the Se powder is completely dissolved, the solution turns reddish brown.

[0032] b. After solution A and solution B are cooled, mix solution A and solution B under the protection of inert gas under normal temperature and normal pressure, and fully stir.

[0033] c. Slowly heat the m...

Embodiment 2

[0040] The copper-zinc-tin-selenium nanopowder is synthesized according to the following process steps.

[0041] a. Prepare the following two solutions respectively:

[0042] Solution A: Weigh 2mmol copper(II) acetylacetonate, 1mmol zinc acetate, and 1mmol tin(II) chloride in a 100mL three-necked flask filled with 25mL triethanolamine, stir under inert gas protection conditions, and heat the oil bath to 120 °C, the color of the solution changed from green to dark blue and then to brown, and the heating was stopped when all the solids were dissolved.

[0043] Solution B: Weigh 4mmol of Se powder and add it into another 100mL three-neck flask containing 25mL of triethanolamine, and slowly raise the temperature to 200°C. After the Se powder is completely dissolved, the solution turns reddish brown.

[0044] b. Heat solution B to 240°C, quickly add solution A to solution B, the color of the solution immediately turns black, and continue to stir.

[0045] c. The mixed solution wa...

Embodiment 3

[0051] Synthesize copper-zinc-tin-selenide nanopowder according to the following process steps, and use diglycolamine as solvent.

[0052] a. Prepare the following two solutions respectively:

[0053] Solution A: Weigh 2mmol of cuprous (I) acetate, 1mmol of zinc citrate, and 1mmol of stannous chloride (II) in a 100mL three-neck flask filled with 25mL of diglycolamine, stir under inert gas protection conditions, and place in an oil bath Heating to 160°C, the color of the solution changed from colorless to dark blue and then to brown, and stopped heating when all the solids were dissolved.

[0054] Solution B: Weigh 4mmol of Se powder and add it to another 100mL three-necked flask containing 25mL of diglycolamine, and slowly raise the temperature to 200°C. After the Se powder is completely dissolved, the solution turns reddish brown.

[0055] b. After solution A and solution B are cooled, mix solution A and solution B in an inert gas protection under normal temperature and pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com