GH2018 alloy electroslag ingot and preparation method thereof

A GH2018, electroslag ingot technology, applied in the field of alloy manufacturing, can solve the problems of large difference in content, different reaction between metal molten pool and oxygen, uneven composition of alloy ingot, etc., to improve composition uniformity, reduce the fluctuation range of melting parameters, Guaranteed effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

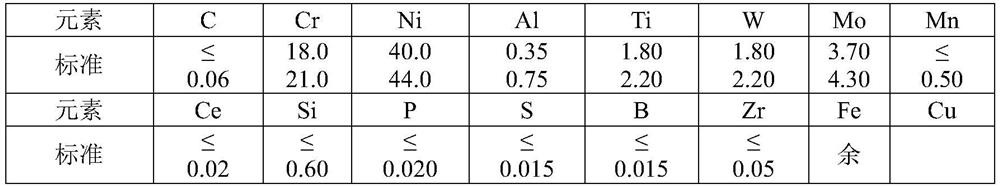

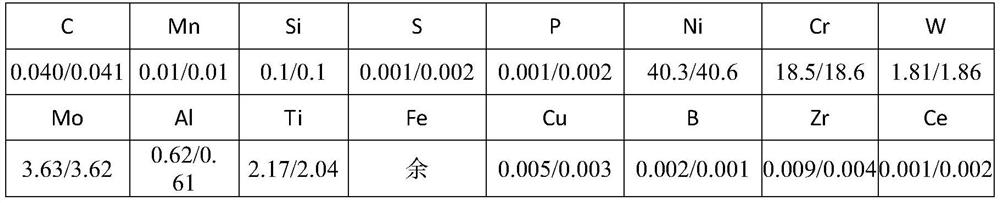

[0023] A GH2018 alloy electroslag ingot, wherein: by mass percentage, the composition content of elements in the alloy is: C 0.040wt%, Cr 18.5wt%, Ni 40.5wt%, Al 0.6wt%, Ti 2.0wt% , W 1.85wt%, Mo3.8wt%, Mn 0.01wt%, Ce 0.002wt%, Si 0.2wt%, P 0.001wt%, S 0.001wt%, B0.001wt%, Zr 0.005wt%, Cu 0.02wt% , The balance is Fe.

[0024] A preparation method of GH2018 alloy electroslag ingot, wherein: comprising the following steps:

[0025] 1) The composition of the nickel-based superalloy alloy is calculated by mass percentage: C 0.040wt%, Cr 18.5wt%, Ni40.5wt%, Al 0.6wt%, Ti 2.0wt%, W 1.85wt%, Mo 3.8wt% , Mn 0.01wt%, Ce0.002wt%, Si 0.2wt%, P 0.001wt%, S 0.001wt%, B 0.001wt%, Zr 0.005wt%, Cu0.02wt%, the balance is Fe; , Ni, W, Mo, Mn, Ce, Si, P, S, B, Zr, Cu into the crucible, put the crucible into a vacuum induction furnace for vacuum melting, add Al and Ti into the crucible for refining, and fill it with argon Then add B, Ce, Zr, cast, obtain ingot;

[0026] 2) The ingot is rolled...

Embodiment 2

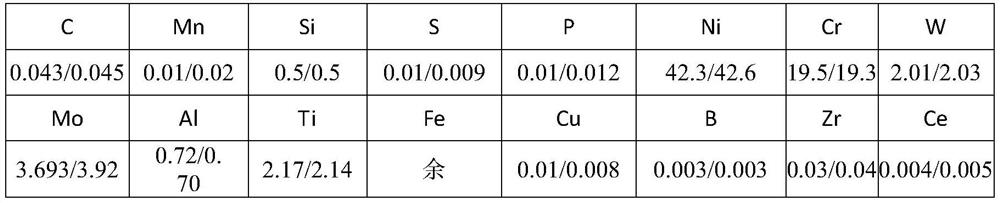

[0034]A GH2018 alloy electroslag ingot, wherein: by mass percentage, the composition content of elements in the alloy is: C 0.045wt%, Cr 19.5wt%, Ni 42.0wt%, Al 0.7wt%, Ti 2.15wt% , W 2.05wt%, Mo4.0wt%, Mn 0.02wt%, Ce 0.01wt%, Si 0.4wt%, P 0.01wt%, S 0.01wt%, B 0.005wt%, Zr 0.02wt%, Cu 0.1wt% , The balance is Fe.

[0035] A preparation method of GH2018 alloy electroslag ingot, wherein: comprising the following steps:

[0036] 1) The composition of the nickel-based superalloy alloy is calculated by mass percentage: C 0.045wt%, Cr 19.5wt%, Ni42.0wt%, Al 0.7wt%, Ti 2.15wt%, W 2.05wt%, Mo 4.0wt% , Mn 0.02wt%, Ce0.01wt%, Si 0.4wt%, P 0.01wt%, S 0.01wt%, B 0.005wt%, Zr 0.02wt%, Cu0.1wt%, the balance is Fe; , Ni, W, Mo, Mn, Ce, Si, P, S, B, Zr, Cu into the crucible, put the crucible into a vacuum induction furnace for vacuum melting, add Al and Ti respectively into the crucible for refining, and fill it with argon Then add B, Ce, Zr, cast, obtain ingot;

[0037] 2) The ingot is r...

Embodiment 3

[0047] A GH2018 alloy electroslag ingot, wherein: by mass percentage, the composition content of elements in the alloy is: C 0.050wt%, Cr 20.5wt%, Ni 43.5wt%, Al 0.7wt%, Ti2.2wt% , W 2.15wt%, Mo4.2wt%, Mn 0.03wt%, Ce 0.02wt%, Si 0.6wt%, P 0.02wt%, S 0.01wt%, B 0.01wt%, Zr 0.05wt%, Cu 0.2wt% , The balance is Fe.

[0048] A preparation method of GH2018 alloy electroslag ingot, wherein: comprising the following steps:

[0049] 1) The composition of the nickel-based superalloy alloy is calculated by mass percentage: C 0.050wt%, Cr 20.5wt%, Ni43.5wt%, Al 0.7wt%, Ti2.2wt%, W 2.15wt%, Mo 4.2wt% , Mn 0.03wt%, Ce 0.02wt%, Si 0.6wt%, P 0.02wt%, S 0.01wt%, B 0.01wt%, Zr 0.05wt%, Cu 0.2wt%, the balance is Fe; , Ni, W, Mo, Mn, Ce, Si, P, S, B, Zr, Cu were added to the crucible, and the crucible was put into a vacuum induction furnace for vacuum melting, and Al and Ti were added to the crucible for refining, and argon was filled Then add B, Ce, Zr, cast, obtain ingot;

[0050] 2) The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com