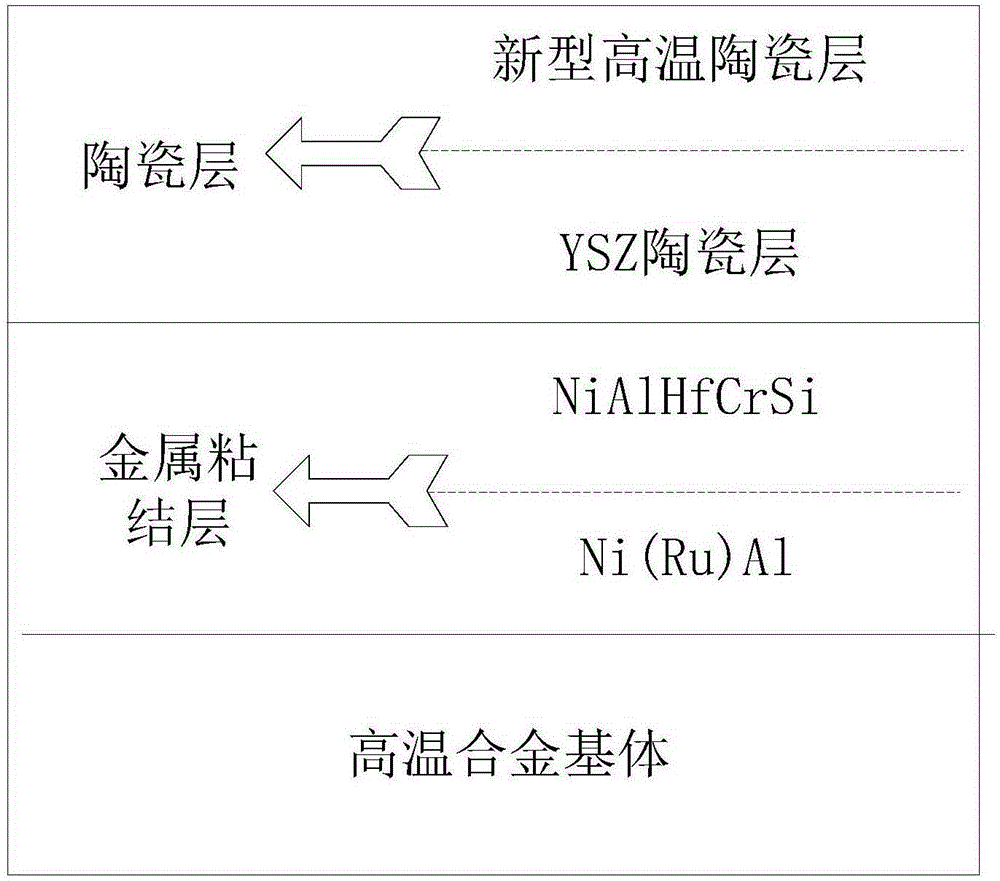

A composite adhesive layer material resistant to 1200°C high temperature oxidation and gas thermal corrosion resistance and its preparation method

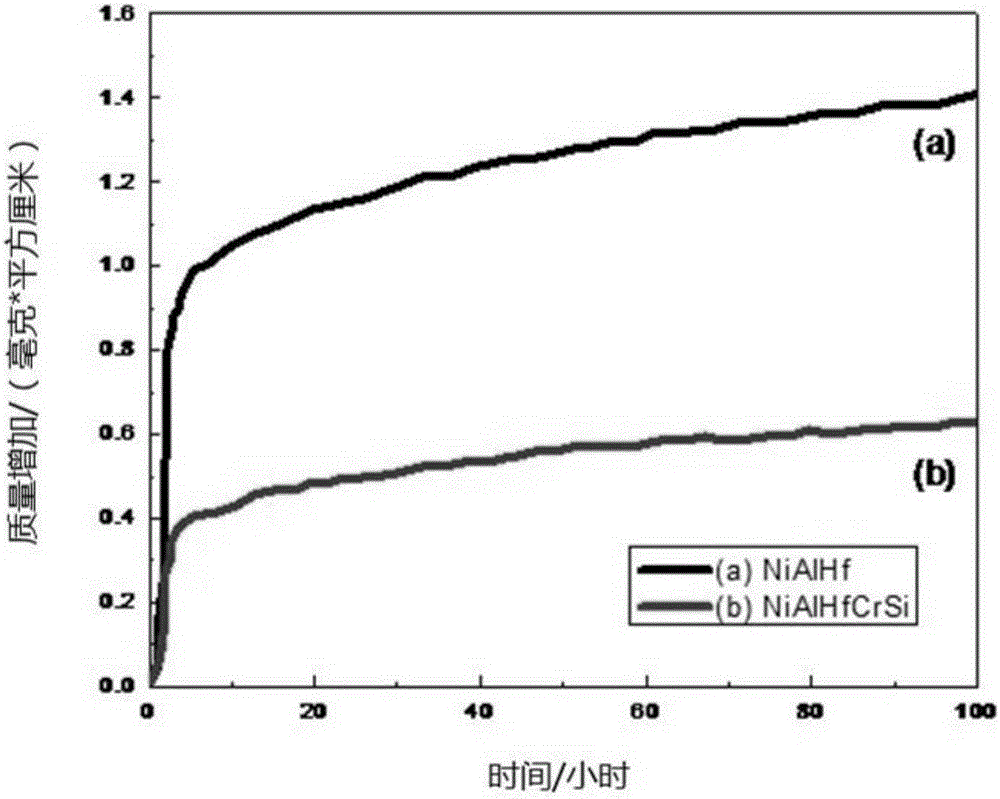

A high-temperature oxidation and bonding layer technology, which is applied in chemical instruments and methods, metal material coating technology, coatings, etc., can solve the problem of reducing the mechanical properties of high-temperature alloy substrates, coating resistance to high-temperature oxidation, and unable to cope with the working environment of turbine engines Marine corrosive environment, coating thickness, microstructure and chemical composition cannot be precisely controlled to achieve the effect of improving anti-oxidation performance, inhibiting the formation and reducing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] To prepare the Ni(Ru)Al / NiAlHfCrSi double-layer structure bonding layer, the present invention adopts the electron beam physical vapor deposition method to prepare, and the preparation method includes the following steps:

[0041] The first step is to prepare the substrate and evaporation rod;

[0042] (A) Grind the substrate with 150#, 400#, 800# SiC water abrasive paper, so that the surface roughness of the substrate is Ra<0.8; clean the polished substrate with acetone and ethanol for about 10 minutes, and dry it for later use.

[0043] (B) Using high-purity nickel (Ni), high-purity aluminum (Al), pure chromium (Cr), pure silicon (Si) and hafnium (Hf) with a purity of 99.7% (mass percentage), according to the designed composition ratio, Al The content is 40-55 at%, the content of Hf is 0.05-0.5 at%, the content of Cr is 0.5-2 at%, the content of Si is 1-3 at%, and the balance is Ni. Polish the surface of the nickel block and the aluminum block to ensure that there is...

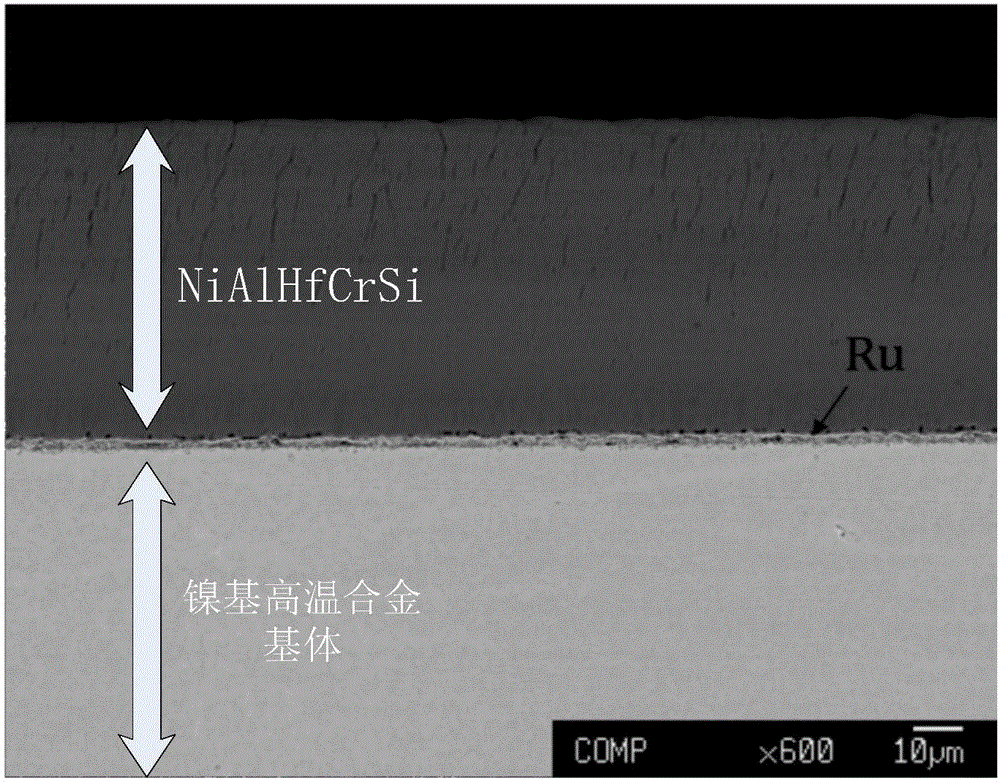

Embodiment 1

[0057] The first step is to prepare the substrate and evaporation rod;

[0058] (A) The substrate is a Ni-based single crystal superalloy, the brand is N5, and the size is 10×10×2mm; use 150#, 400#, 800# SiC water abrasive paper to polish the substrate so that the surface roughness of the substrate is Ra<0.8; Ultrasonic cleaning for 10 minutes.

[0059] (B) Using high-purity nickel (Ni), high-purity aluminum (Al), pure chromium (Cr), pure silicon (Si) and hafnium (Hf) with a purity of 99.7%, according to the designed composition ratio, the Al content is 40at% , the Hf content is 0.05at%, the Cr content is 0.5at%, the Si content is 1at%, and the balance is Ni. Polish the surface of nickel block and aluminum block to ensure the existence of fresh oxide film on the metal surface, then ultrasonically clean it with absolute ethanol and acetone for about 15 minutes, dry it, and finally make the target material by arc melting method. spare.

[0060] In the second step, a Ru layer ...

Embodiment 2

[0074] The first step, prepare the substrate and evaporation rod

[0075] (A) The substrate is a Ni-based superalloy, the brand is DZ125, and the size is 10×8×3mm; the substrate is polished with 150#, 400#, 800# SiC water abrasive paper to make the surface roughness of the substrate Ra<0.8; acetone and Ultrasonic cleaning with absolute ethanol for 10 minutes.

[0076] (B) Using high-purity nickel (Ni), high-purity aluminum (Al), pure chromium (Cr), pure silicon (Si) and hafnium (Hf) with a purity of 99.7%, according to the designed composition ratio, the Al content is 45at% , the Hf content is 0.1at%, the Cr content is 1at%, the Si content is 1at%, and the balance is Ni. Polish the surface of the nickel block and the aluminum block to ensure that there is no oxide film on the metal surface, then ultrasonically clean it with absolute ethanol and acetone for about 15 minutes, and dry it. .

[0077] In the second step, a Ru layer is deposited on the substrate;

[0078] (A) If...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com