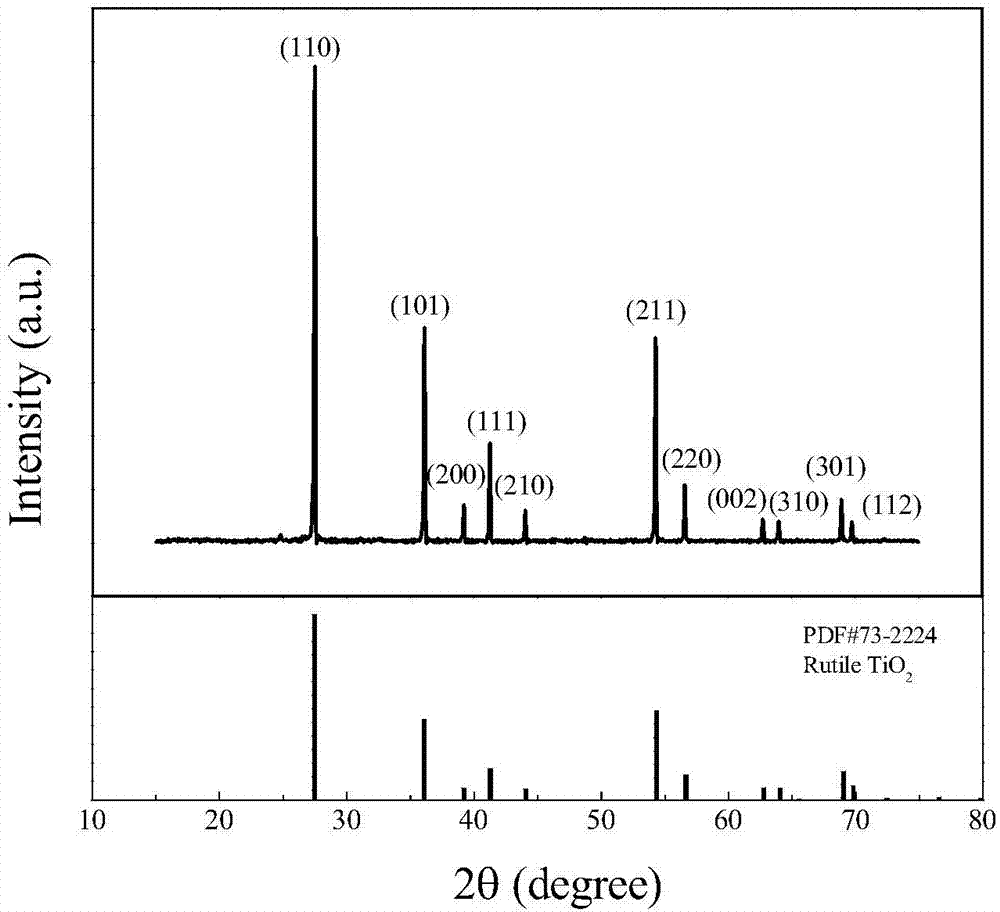

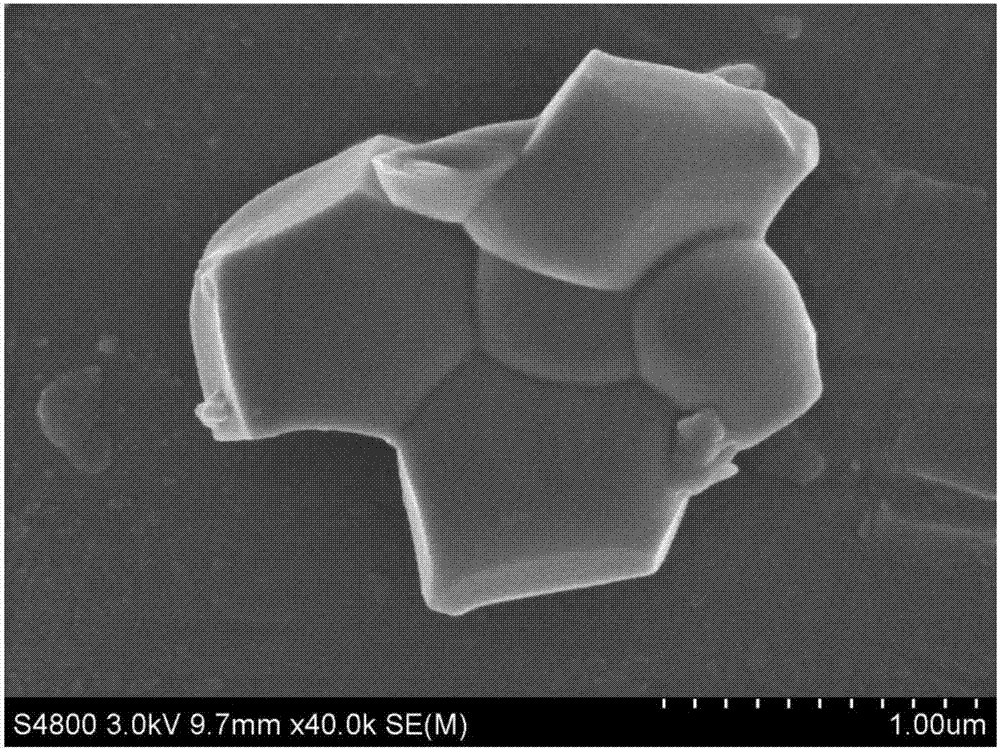

Method for preparing indium niobium co-doped titanium dioxide powder through co-precipitation method

A technology of titanium dioxide and co-precipitation method, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem of difficult uniformity of solid-phase doping, easy agglomeration of powder, and impossibility to achieve complete uniformity, etc. problems, to achieve precise control of chemical composition, narrow powder particle size distribution, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing indium-niobium co-doped titanium dioxide powder by co-precipitation, comprising the steps of:

[0037] (1) Configure the solution, and accurately weigh InCl according to the molar ratio of 1:1 3 4H 2 O and NbCl 5 , and respectively dissolved in absolute ethanol, the concentration of which is 0.06~0.08mol / L;

[0038] (2) Measure TiCl at a volume ratio of 1:6 4 , dissolved in absolute ethanol to obtain TiCl 4 Anhydrous ethanol solution;

[0039] (3) InCl prepared in step (1) 3 solution to NbCl 5 Slowly add dropwise to the solution at a rate of 1mL / min;

[0040] (4) TiCl prepared in step (2) 4 The dehydrated ethanol solution was dripped into the mixed solution A prepared in step (3) at a rate of 1 mL / min to prepare the mixed solution B, and stirred for 1 h after the dripping was completed;

[0041] (5) The solution prepared in step (4) was adjusted to pH=11 with ammonia water having a mass concentration of 25% to 28%, and the ammonia water d...

Embodiment 2

[0045] A method for preparing indium-niobium co-doped titanium dioxide powder by co-precipitation, comprising the steps of:

[0046] (1) Configure the solution and accurately weigh InCl according to the molar ratio of 1:3 3 4H 2 O, and NbCl 5 , and were respectively dissolved in absolute ethanol, the concentration of which was 0.07mol / L;

[0047] (2) Measure TiCl at a volume ratio of 1:7 4 , dissolved in absolute ethanol to obtain TiCl 4 Anhydrous ethanol solution;

[0048] (3) InCl prepared in step (1) 3 solution to NbCl 5 Add slowly to the solution at a rate of 1.5mL / min;

[0049] (4) TiCl prepared in step (2) 4The dehydrated ethanol solution is dripped into the mixed solution A prepared in step (3) at a rate of 1.5mL / min to prepare the mixed solution B, and it needs to be stirred for 0.5h after the dripping is completed;

[0050] (5) Adjust the pH of the solution prepared in step (4) to 11 using ammonia water with a mass concentration of 25% to 28%, and the drippin...

Embodiment 3

[0054] A method for preparing indium-niobium co-doped titanium dioxide nanopowder by co-precipitation method comprises the following steps:

[0055] (1) To configure the solution, accurately weigh InCl according to the molar ratio of 1:1 to 1:3 3 4H 2 O and NbCl 5 , and respectively dissolved in absolute ethanol, the concentration of which is 0.08mol / L;

[0056] (2) Measure TiCl at a volume ratio of 1:8 4 , dissolved in absolute ethanol to obtain TiCl 4 Anhydrous ethanol solution;

[0057] (3) InCl prepared in step (1) 3 solution to NbCl 5 Add slowly to the solution at a rate of 2mL / min;

[0058] (4) TiCl prepared in step (2) 4 The dehydrated ethanol solution was dripped into the mixed solution A prepared in step (3) at a rate of 2mL / min to prepare the mixed solution B, and stirred for 1h after the dripping was completed;

[0059] (5) The solution prepared in step (4) was adjusted to pH=11 with ammonia water having a mass concentration of 25% to 28%, and the ammonia w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com