Manufacturing method for airspace engine combustion chamber inner wall blank

An aerospace engine and manufacturing method technology, applied in the direction of engine components, machines/engines, rocket engine devices, etc., can solve the problem of mechanical properties, low electrical conductivity and thermal conductivity, difficulty in adapting to liquid hydrogen and liquid oxygen engines, and insufficient aging Strengthening and other issues to achieve high mechanical properties and electrical and thermal conductivity, eliminate casting defects, simple tools and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

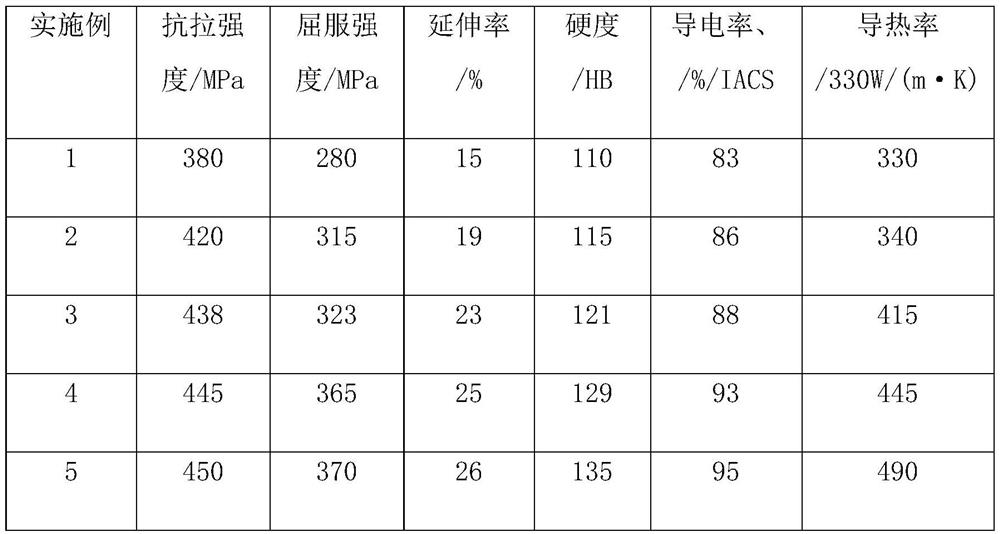

Examples

Embodiment 1

[0036] Embodiment 1: the technical solution of the present invention is: a kind of manufacturing method of aerospace engine combustor inner wall blank, comprises the following steps:

[0037] S1, ingredients;

[0038] According to the mass percentage content, respectively weigh 0.5% of Cr; 0.03% of Zr and the remaining Cu; wherein, Cu is added in the form of electrolytic copper plate, Cr is added in the form of master alloy CuCr25, and Zr is added in the form of master alloy CuZr50. Alloys CuCr25 and CuZr50 are wrapped with copper skin;

[0039] S2, smelting;

[0040] Using a vacuum intermediate frequency induction furnace for smelting, first spread a layer of electrolytic copper plate obtained in step S1 in the crucible of a vacuum intermediate frequency induction furnace, then spread the intermediate alloy CuCr25 and CuZr50 wrapped in the copper skin obtained in step S1 on the surface of the electrolytic copper plate, and finally the remaining The electrolytic copper plate...

Embodiment 2

[0055] Embodiment 2: a kind of manufacturing method of aerospace engine combustor inner wall blank, comprises the following steps:

[0056] S1, ingredients;

[0057] According to the mass percentage content, Cr 0.8%, Zr 0.15% and the balance of Cu were weighed respectively; wherein, Cu was added in the form of electrolytic copper plate, Cr was added in the form of master alloy CuCr25, and Zr was added in the form of master alloy CuZr50. Alloys CuCr25 and CuZr50 are wrapped with copper skin;

[0058] S2, smelting;

[0059] Using a vacuum intermediate frequency induction furnace for smelting, first spread a layer of electrolytic copper plate obtained in step S1 in the crucible of a vacuum intermediate frequency induction furnace, then spread the intermediate alloy CuCr25 and CuZr50 wrapped in the copper skin obtained in step S1 on the surface of the electrolytic copper plate, and finally the remaining The electrolytic copper plate is laid flat on the top of the crucible, and t...

Embodiment 3

[0074] Embodiment 3: a kind of manufacturing method of aerospace engine combustor inner wall blank, comprises the following steps:

[0075] S1, ingredients;

[0076]According to the mass percentage content, respectively weigh Cr 1.2%, Zr 0.3% and the balance of Cu; wherein, Cu is added in the form of electrolytic copper plate, Cr is added in the form of master alloy CuCr25, Zr is added in the form of master alloy CuZr50, and the middle Alloys CuCr25 and CuZr50 are wrapped with copper skin;

[0077] S2, smelting;

[0078] Using a vacuum intermediate frequency induction furnace for smelting, first spread a layer of electrolytic copper plate obtained in step S1 in the crucible of a vacuum intermediate frequency induction furnace, then spread the intermediate alloy CuCr25 and CuZr50 wrapped in the copper skin obtained in step S1 on the surface of the electrolytic copper plate, and finally the remaining The electrolytic copper plate is laid flat on the top of the crucible, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com