Method for producing copper-indium-selenium thin-film solar cell wealthy-indium optical absorption layer

A solar cell and light-absorbing layer technology, which is applied in the manufacture of circuits, electrical components, and final products, to achieve the effects of compact structure, increased contact area, and safe and practical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

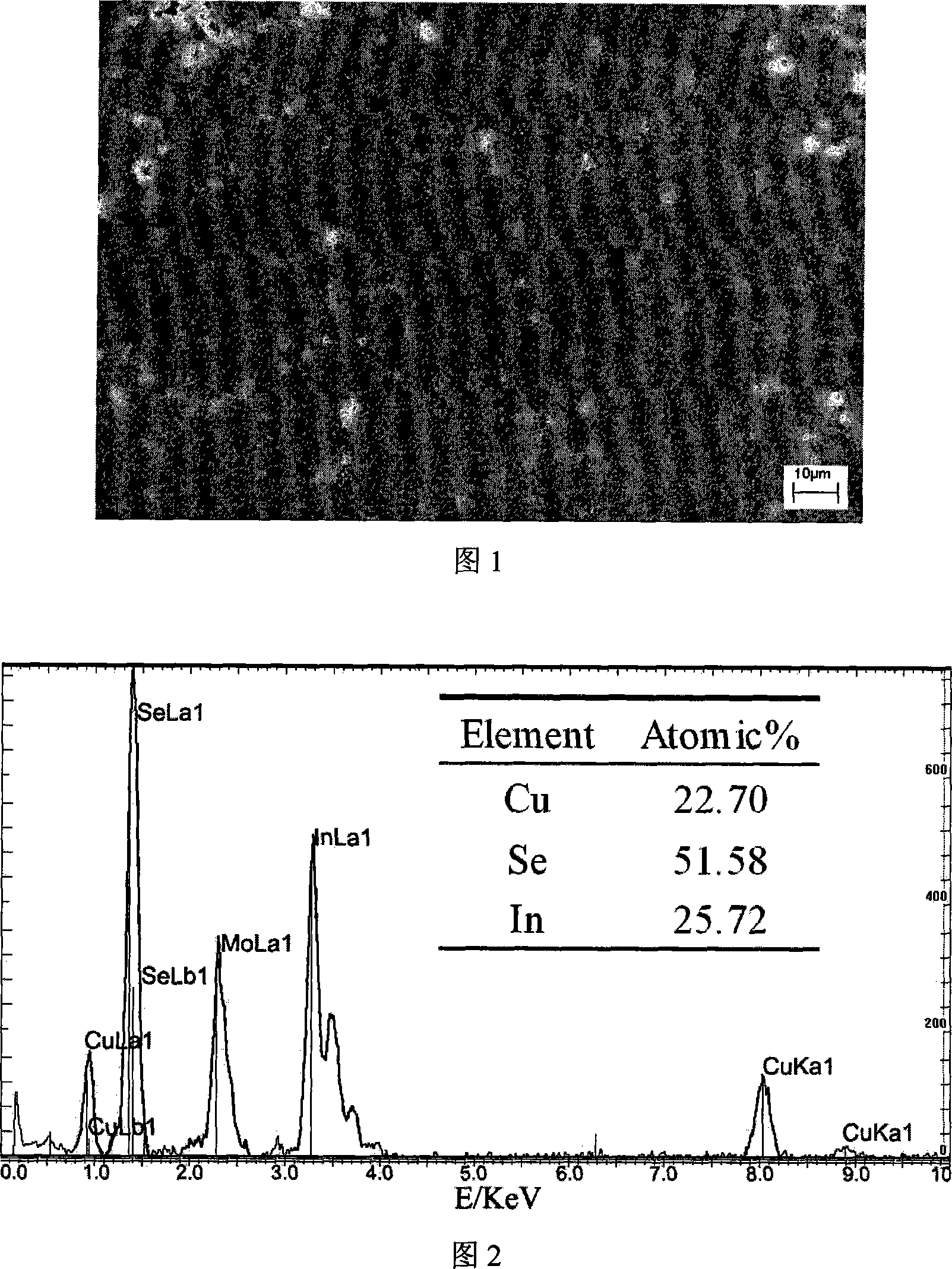

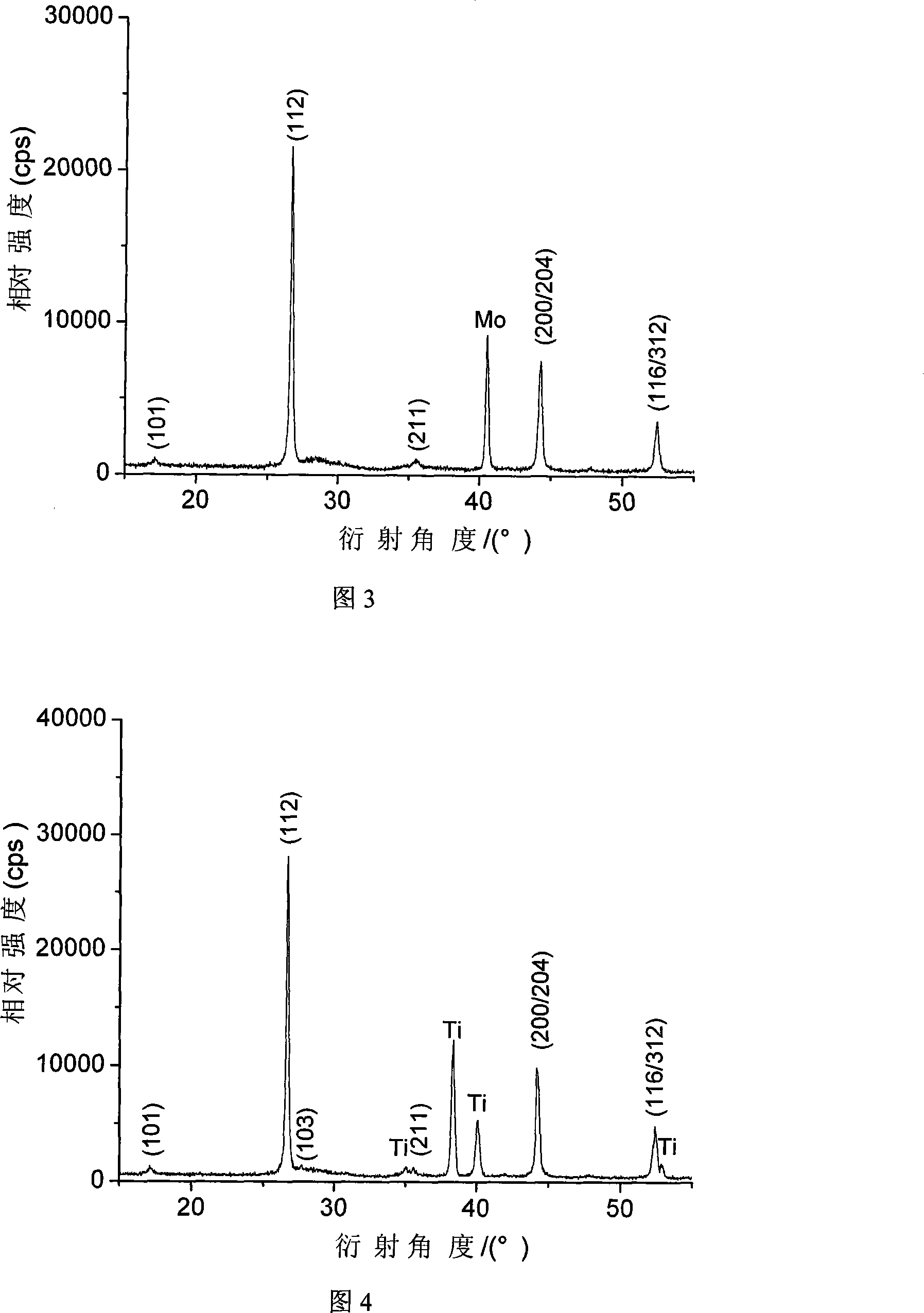

[0016] Example 1: In-rich CuInSe 2 absorbing layer in H 2 Low temperature (400°C) preparation in atmosphere

[0017] (1) Apply a pressure of 200 MPa to the precursor film formed on the metal molybdenum substrate to make it dense, and then remove the pressure to obtain a dense precursor film.

[0018] (2) Place the above-mentioned precursor thin film in a resistance furnace, pass through H 2 Exclude the air, check the purity three times, raise the furnace temperature to 50°C, and preheat at 50°C for 10 minutes.

[0019] (3) Raise the temperature from 50°C to 230°C at a rate of 5°C / min, and keep the temperature for 1 hour.

[0020] (4) Heat up from 230°C to 400°C at a rate of 5°C / min, keep warm for 1 hour, then cool to room temperature with the furnace and take it out, and finally obtain a blue-black In-rich solar cell CuInSe 2 absorbent layer.

Embodiment 2

[0021] Example 2: In-rich CuInSe 2 absorbing layer in N 2 Low temperature (400°C) preparation in atmosphere

[0022] Operation process is the same as embodiment 1, will pass into H 2 The steps are replaced by passing into N 2 . Pass N 2 After 15 minutes of excluding the air, the resistance furnace was started to heat up. After the heat treatment, the blue-black In-rich solar cell CuInSe is finally obtained. 2 absorbent layer.

Embodiment 3

[0023] Example 3: In-rich CuInSe 2 absorbing layer in H 2 High temperature (550°C) preparation in the atmosphere

[0024] (1) Apply a pressure of 10 MPa to the precursor film formed on the metal molybdenum substrate to make it dense, and then remove the pressure to obtain a denser precursor film.

[0025] (2) Place the above-mentioned precursor thin film in a resistance furnace, pass through H 2 Exclude the air, check the purity three times, raise the furnace temperature to 50°C, and preheat at 50°C for 10 minutes.

[0026] (3) Raise the temperature from 50°C to 550°C at a rate of 10°C / min, keep it warm for 0.5 hours, and then cool it to room temperature with the furnace to take it out, and finally obtain a blue-black In-rich solar cell CuInSe 2 absorbent layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com