Preparation method of ferritic stainless steel for stopper rod

A ferritic and stainless steel technology, applied in the field of preparation of ferritic stainless steel for stoppers, to achieve the effect of microstructure, excellent performance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

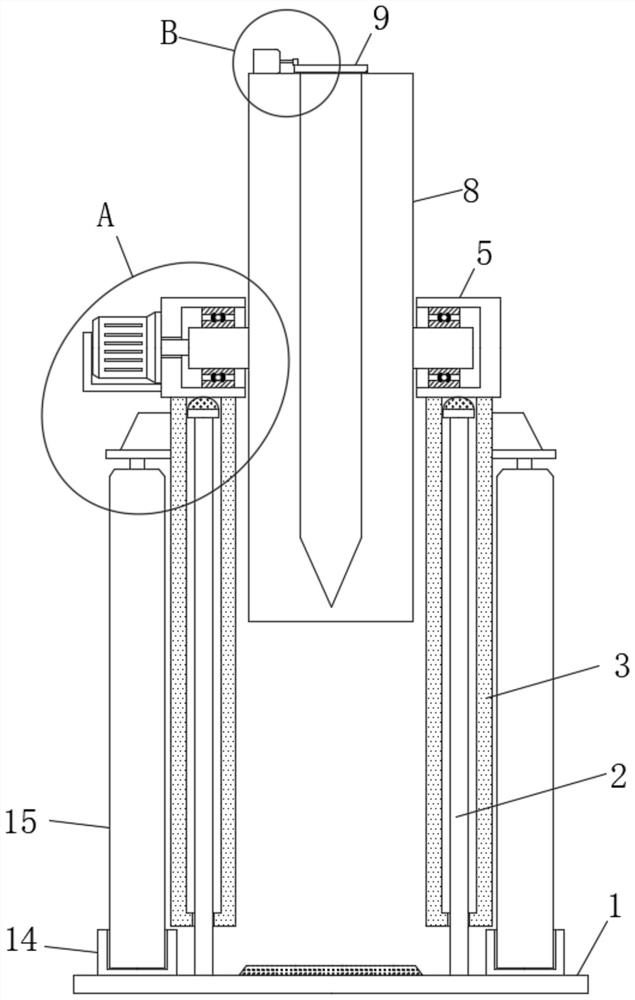

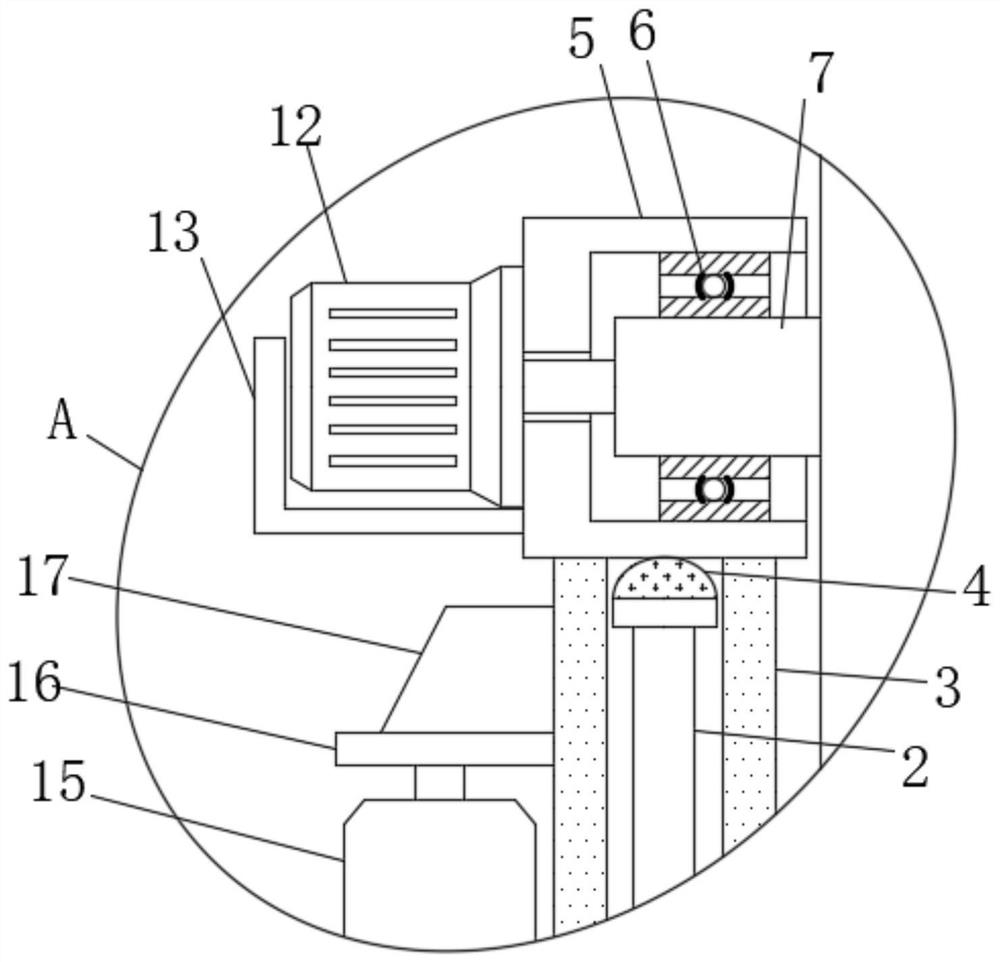

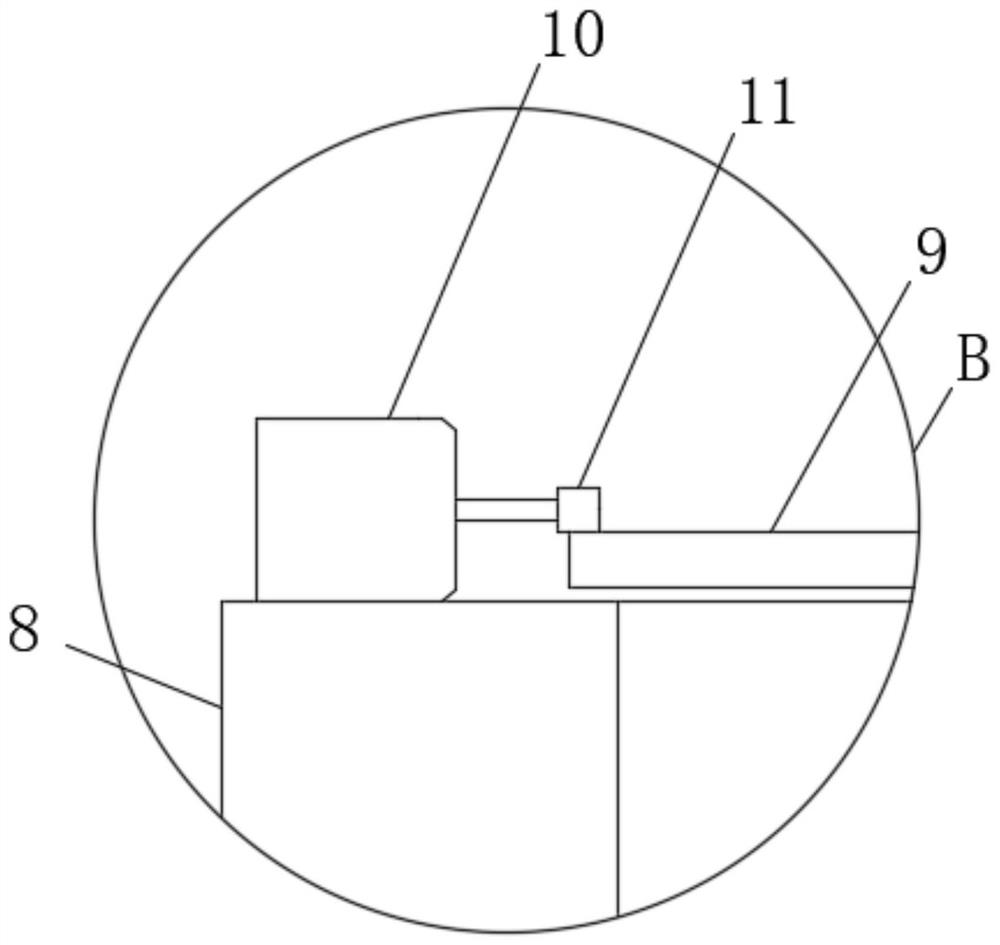

Image

Examples

Embodiment 1

[0027] The invention provides a technical solution: a ferritic stainless steel for a stopper, the formula of the ferritic stainless steel for a stopper includes the following components: Cr 24.0%, C 0.1%, N 0.10%, and the rest are trace elements.

[0028] Among them, trace elements are Cu and Ni.

[0029] A method for preparing a ferritic stainless steel for a stopper as described above, the preparation method comprises the following steps:

[0030] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0031] S2: Smelting: Vacuum induction + electroslag process is used to smelt, and the purity and chemical composition of molten steel are strictly controlled;

[0032] S3: Forging / rolling: Through the comparison of different forging process tests, the billet heating temperature is controlled at 900°C, and the final forging / rolling temperature is 750°C.

Embodiment 2

[0034] The invention provides a technical solution: a ferritic stainless steel for a stopper, the formula of the ferritic stainless steel for a stopper includes the following components: Cr 25.0%, C 0.15%, N 0.15%, and the rest are trace elements.

[0035] Among them, trace elements are Cu and Ni.

[0036] A method for preparing a ferritic stainless steel for a stopper as described above, the preparation method comprises the following steps:

[0037] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0038] S2: Smelting: Vacuum induction + electroslag process is used to smelt, and the purity and chemical composition of molten steel are strictly controlled;

[0039] S3: Forging / rolling: Through the comparison of different forging process tests, the billet heating temperature is controlled at 1100°C, and the final forging / rolling temperature is 650°C.

Embodiment 3

[0041] The invention provides a technical solution: a ferritic stainless steel for a stopper, the formula of the ferritic stainless steel for a stopper includes the following components: Cr 24.40%, C 0.12%, N 0.11%, and the rest are trace elements.

[0042] Among them, trace elements are Cu and Ni.

[0043] A method for preparing a ferritic stainless steel for a stopper as described above, the preparation method comprises the following steps:

[0044] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0045] S2: Smelting: Vacuum induction + electroslag process is used to smelt, and the purity and chemical composition of molten steel are strictly controlled;

[0046] S3: Forging / rolling: Through the comparison of different forging process tests, the billet heating temperature is controlled at 980°C, and the final forging / rolling temperature is 680°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com