A core head for vertical semi-continuous casting thin-walled hollow casting pipe

A semi-continuous, core-head technology, applied in the field of core heads for vertical semi-continuous casting of thin-walled hollow casting tubes, can solve the problems of narrow casting space for thin-walled hollow casting tubes, affecting casting temperature and fluidity, and avoiding the The effect of cooling leakage, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

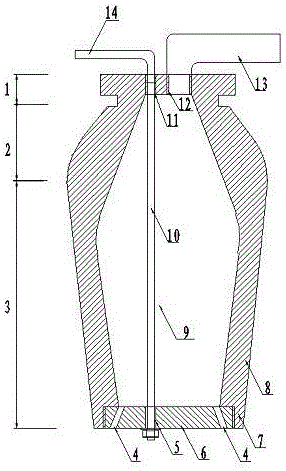

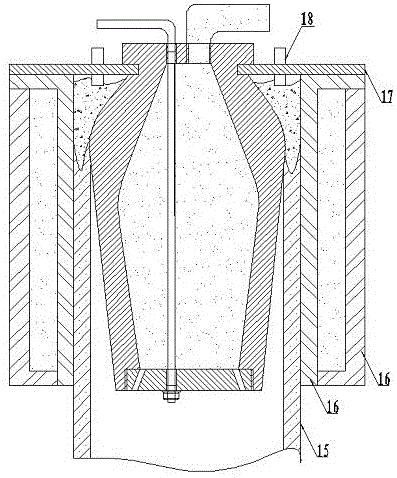

[0019] Such as figure 1 shown, and refer to figure 2 , a core head for vertical semi-continuous casting thin-walled hollow cast pipe, the core head is a structure with a spindle-shaped inner cavity 9, from top to bottom are connecting section 1, casting diameter section 2 and cooling crystallization section 3; the pouring sizing section 2 and the cooling crystallization section 3 are located in the crystallizer 16, the connecting section 1 protrudes from the crystallizer 16 and is connected with the crystallizer 16 as a whole through the clamp 17; the pouring sizing section The outer wall surface of section 2 is an arc-shaped surface that gradually expands from top to bottom and smoothly transitions, forming a large enough pouring space in the upper part with the inner wall surface of the crystallizer, and the arc-shaped surface that pours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com