Hydraulic control start-stop concrete hopper and method

A concrete and hopper technology, which is applied in the field of concrete pouring hoppers and concrete hoppers, can solve problems such as cumbersome operations, lower operating efficiency, and unsafe concrete pouring operations, and achieve the effects of convenient use, reduced manufacturing and use costs, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

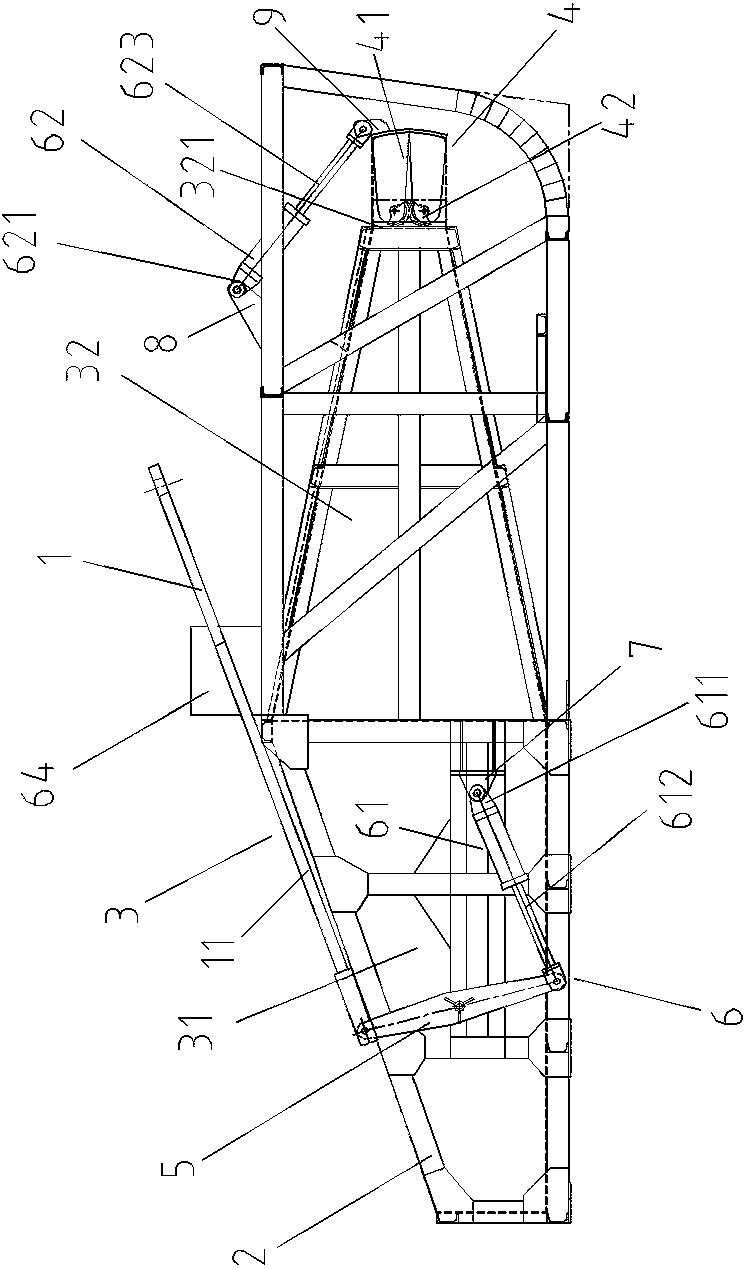

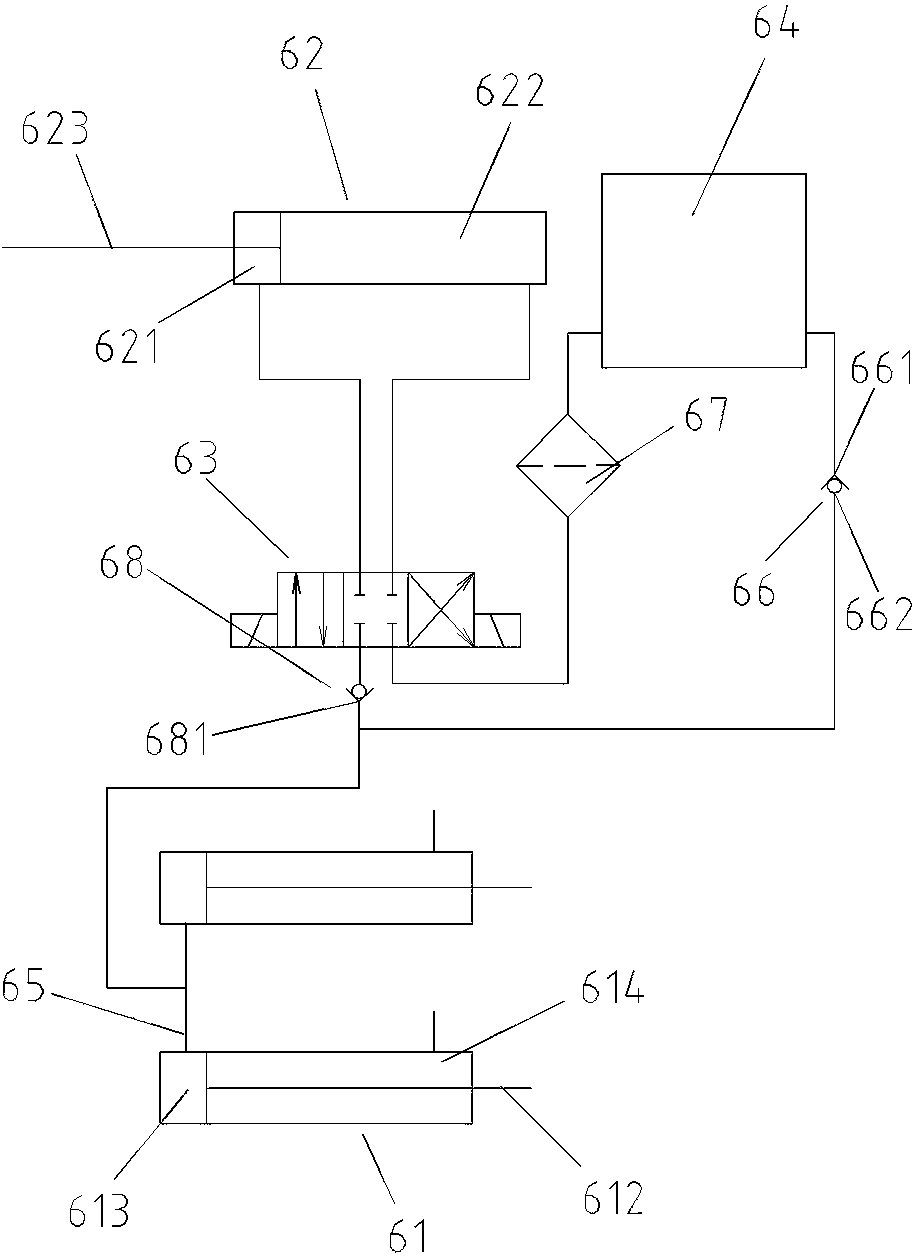

[0021] Such as figure 1 and figure 2 As shown, the present invention includes a door hanger 1, an outer frame 2, a hopper 3, a hopper opening and closing device 4, a lever 5 and a hydraulic control device without a power source 6, and the door hanger 1 and the outer frame 2 are all welded by channel steel. The horizontal projection of the outer frame 2 is a rectangle, the upper part of the door hanger 1 is triangular, and the two ends of the vertical bars 11 on both sides of the lower part are respectively hinged with the two sides of the middle part of the outer frame 2. The hopper 3 welded by the steel plate is welded and fixed in the outer frame 2. The left end of the hopper 3 is a material storage box 31 for receiving concrete, and the right end is a pyramid-shaped guide tube 32 which is large inside and small outside and runs through front and back. The right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com