Preparation method for copper-zinc-tin-sulfur nano powder material

A nano-powder, copper-zinc-tin-sulfur technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high price, increase operation steps and costs, and achieve low cost, high yield and short time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

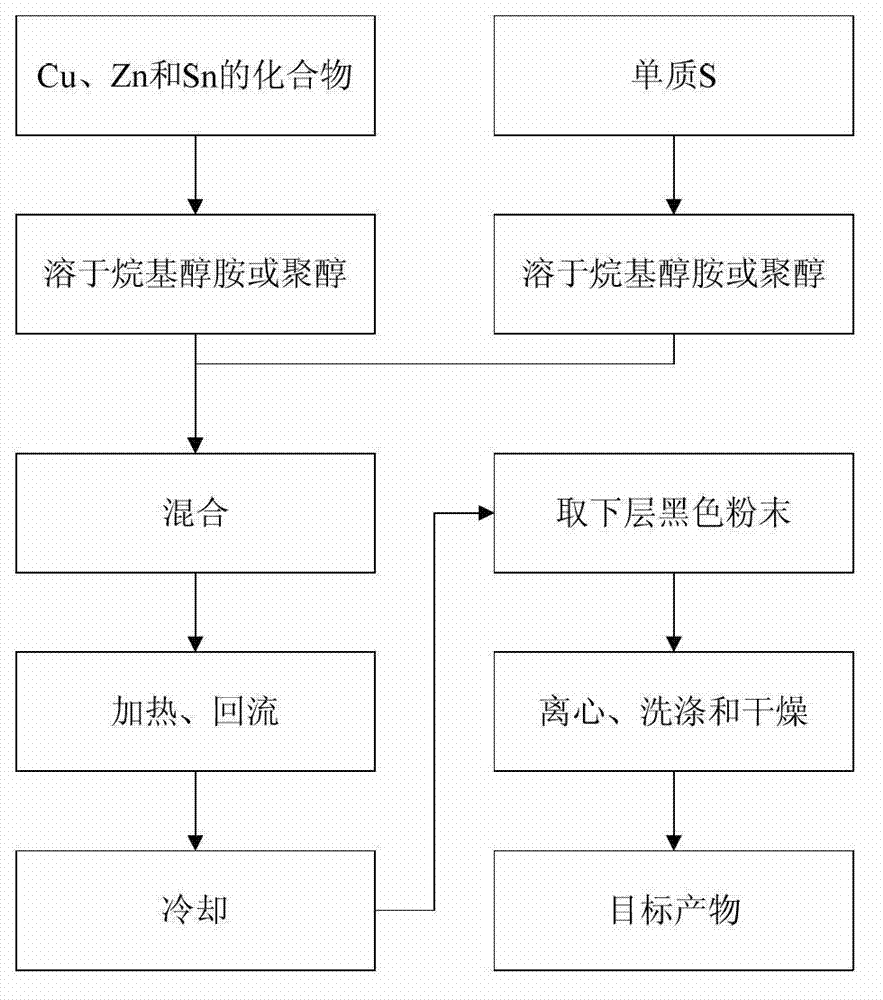

Method used

Image

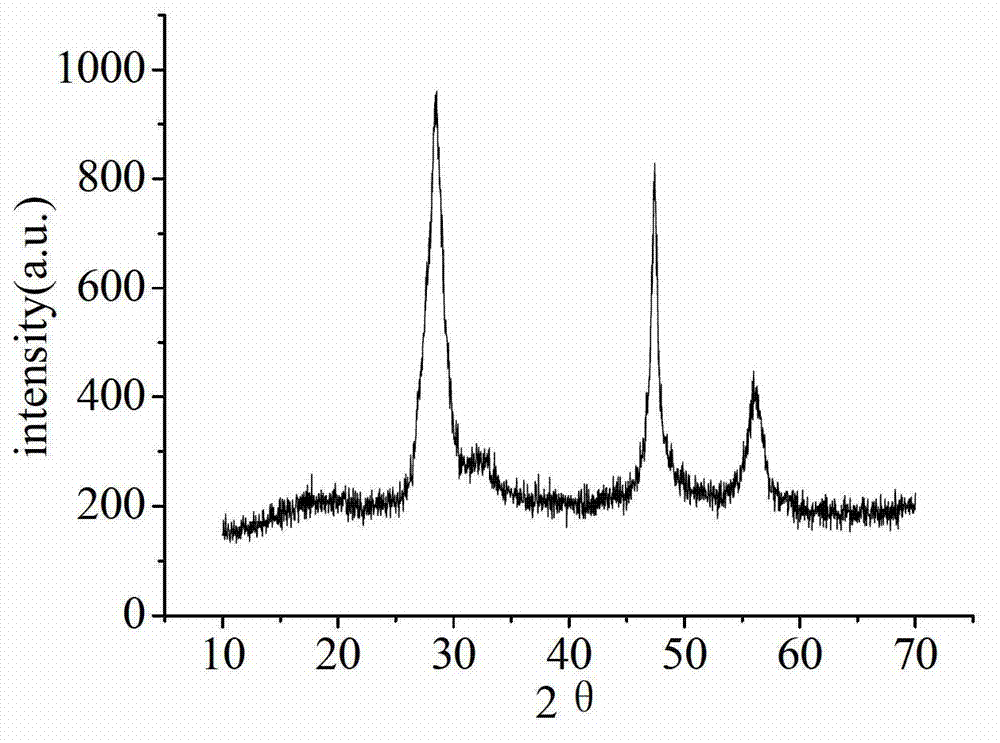

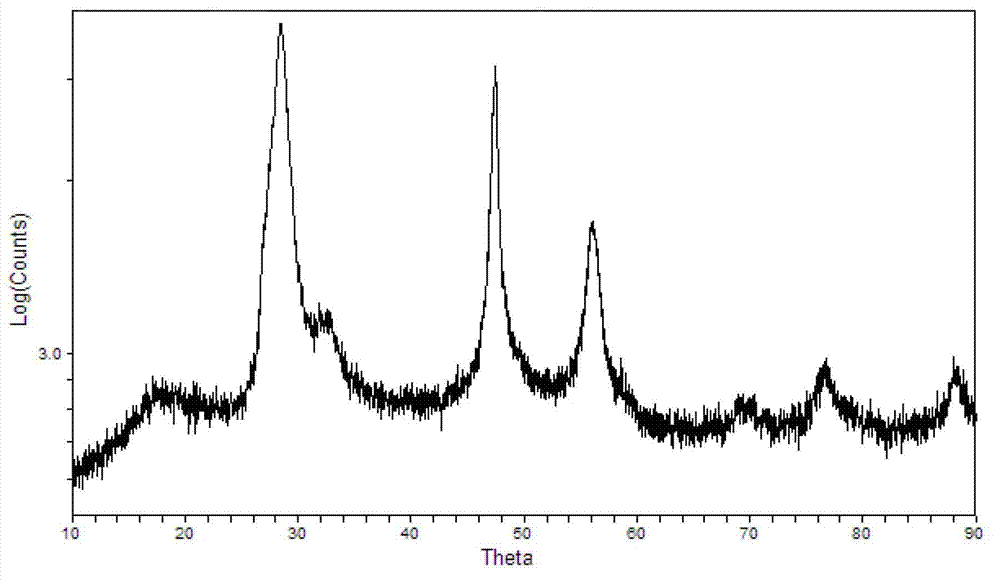

Examples

Embodiment 1

[0026] In the process of synthesizing CZTS nanopowder, triethanolamine is used as a solvent. CuCl, ZnCl 2 , SnCl 2 ·2H 2 O and S powder in the triethanolamine solution, under normal pressure at 200 ℃ reflux to form Cu 2 ZnSnS 4 Nano powder material.

[0027] Weigh 2mmolCuCl, 1mmol ZnCl 2 And 1mmolSnCl 2 ·2H 2 O in a 50mL three-necked flask containing 10mL of triethanolamine, stir under nitrogen atmosphere, and stop heating when the oil bath is heated to 160℃. The color of the solution changes from light blue to dark blue to reddish brown, which is counted as solution A . Weigh 4mmol of S powder into a 50mL three-necked flask containing 10mL of triethanolamine, slowly raise the temperature to 200°C, and record it as solution B. Quickly inject solution B into solution A at high temperature, continue stirring under the protection of inert gas, reflux for 4 hours until the reaction is complete, stop stirring, after the temperature drops to room temperature, pour out the upper liquid...

Embodiment 2

[0029] In the process of synthesizing CZTS nanopowders, triethanolamine is still used as a solvent.

[0030] The two precursors were prepared by the above method, and the two solutions were cooled to room temperature, mixed at room temperature under a nitrogen atmosphere, and then heated to 220° C. and refluxed for 4 hours. Cool, wash and dry.

Embodiment 3

[0032] In the process of synthesizing CZTS nanopowder, polyethylene glycol-400 is used as a solvent.

[0033] Weigh 4mmolCuCl, 2mmolZnCl 2 And 2mmolSnCl 2 ·2H 2 O was placed in a 100mL three-necked flask containing 25mL polyethylene glycol-400, stirred under inert gas protection, and heated to 180°C in an oil bath. CuCl, ZnCl to be added 2 And SnCl 2 ·2H 2 After the O is completely dissolved, stop heating and cool to room temperature.

[0034] Weigh 8mmol of S powder and add it to a 100mL three-necked flask containing 25mL of polyethylene glycol-400, slowly raise the temperature to 180°C, stir until the sulfur powder is completely dissolved, stop heating and cool to room temperature. The two precursors prepared were mixed at room temperature, stirred under inert gas protection, slowly heated to 220°C in an oil bath, and refluxed for 8 hours until the reaction was complete. Stop stirring. After the temperature dropped to room temperature, pour out the upper liquid , Centrifuge the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com