Patents

Literature

43results about How to "High efficiency of preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

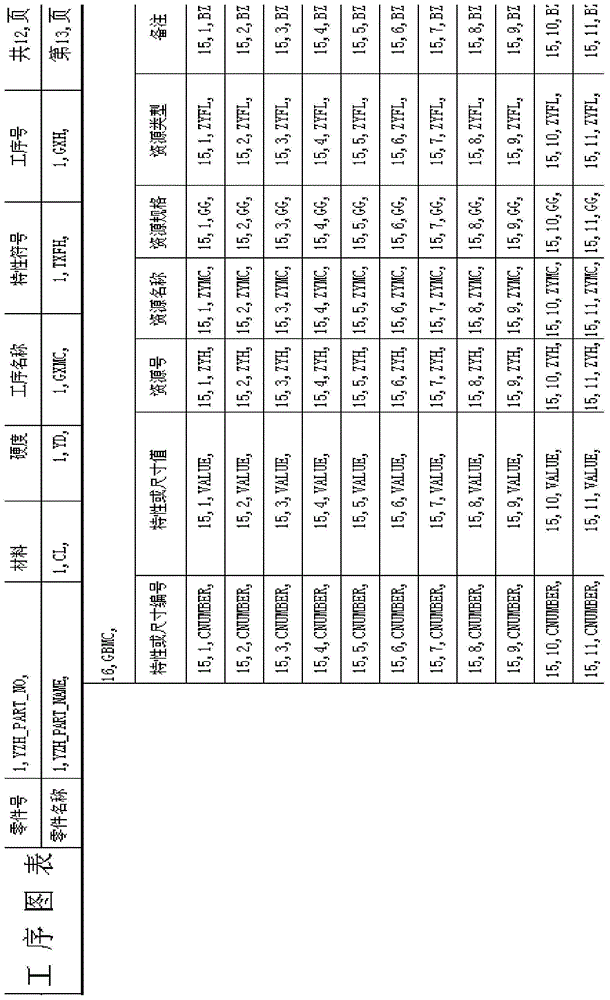

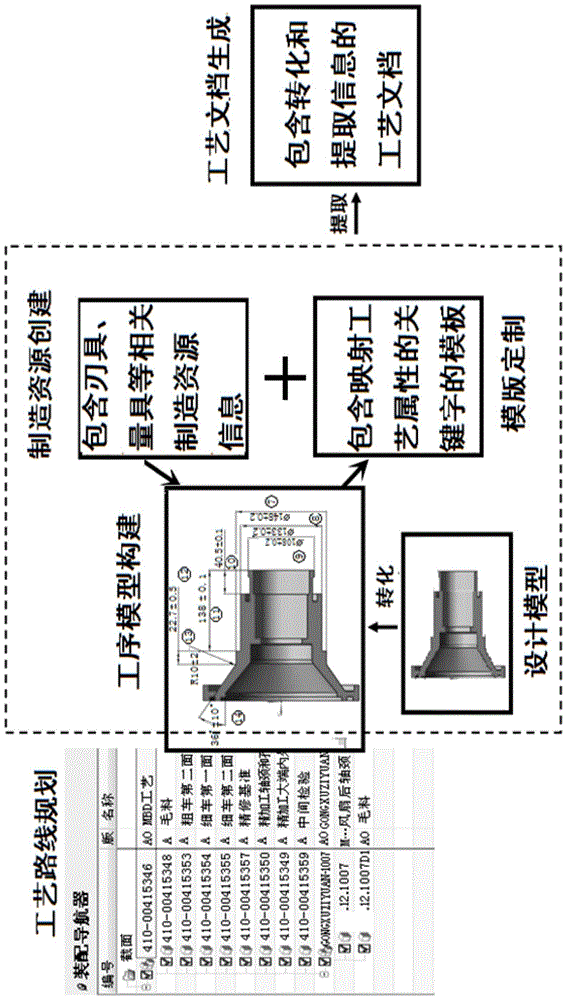

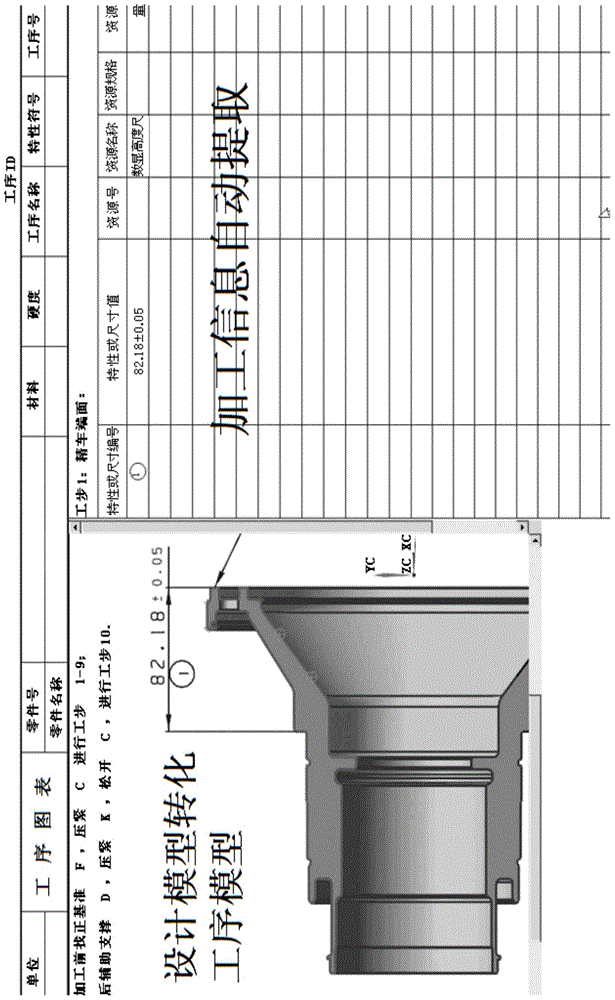

Data conversion and extraction method for model based definition (MBD)

InactiveCN104408240ARealize automatic extractionSave the process of converting 2D drawingsSpecial data processing applicationsData sourceComputer science

The invention relates to a data conversion and extraction method for model based definition (MBD). The method comprises the following steps: establishing an MBD design model on the basis of a unique data source provided by a design department; converting the MBD design model into an MBD process model; collaboratively establishing an MBD procedure model according to different demands of the MBD process model; establishing a process file template according to the demands of different departments, wherein the template contains keywords mapping process information attributes; acquiring data in the current MBD procedure model, exporting corresponding data structures according to the demands of different departments, and replacing the keywords in the process fie template to realize automatic conversion and extraction of MBD model information according to the demands of different departments. According to the method disclosed by the invention, the unique data source MBD model provided by the design department is taken as a basis, machining and manufacturing information is expressed by making full use of a three-dimensional measure, manual intervention of the consistence and integrity of process data is not required, automatic extraction of MBD model data according to different service demands can be realized, and paperless machining is realized.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

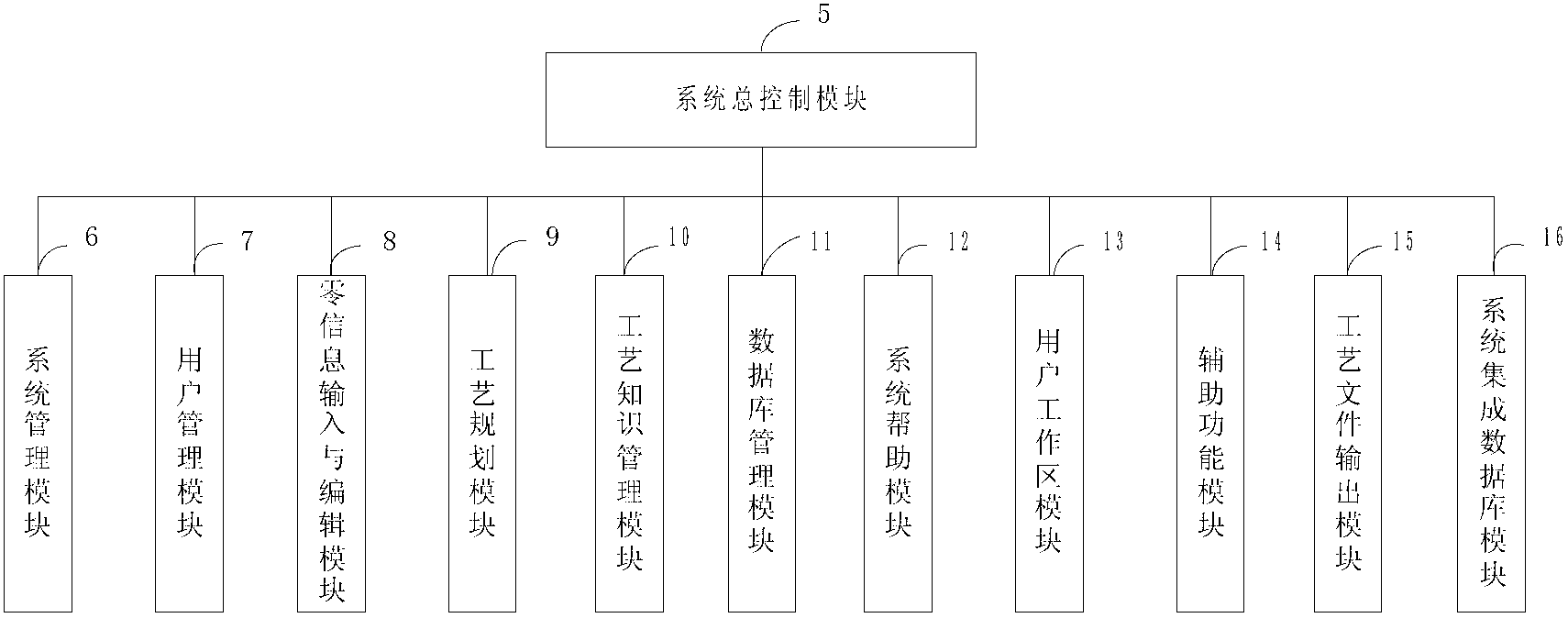

CAPP (computer aided progress planning) system of sheetmetal

InactiveCN103077448ARich management methodsEmphasis on participationResourcesSystems managementComputer-aided

The invention discloses a CAPP (computer aided progress planning) system of sheetmetal, which comprises a system master control module, a system management module, a user management module, a planning module, a process knowledge management module, a database management module, a system help module, a user work area module and the like. The system adopts a modularized concept in design and has higher development flexibility; a system of the system has good expandability and a maintenance function; the system has a powerful man-machine interaction function and a user interface, and simplicity and convenience in operation, meanwhile the system provides help and learning functions so as to guide a user to complete a sheetmetal process planning conveniently and quickly; the system provides a special auxiliary function module, has high openness and directs to requirements of the user; the system can replace handwork of technologists, complete the preparation and the audit of a sheetmetal machining technology, and reduce the labor intensity of the technologists, at the same time, the system also can ensure the consistency of the technology, improve the preparation efficiency of the technology, and shorten a product development cycle.

Owner:XIAN TECHNOLOGICAL UNIV

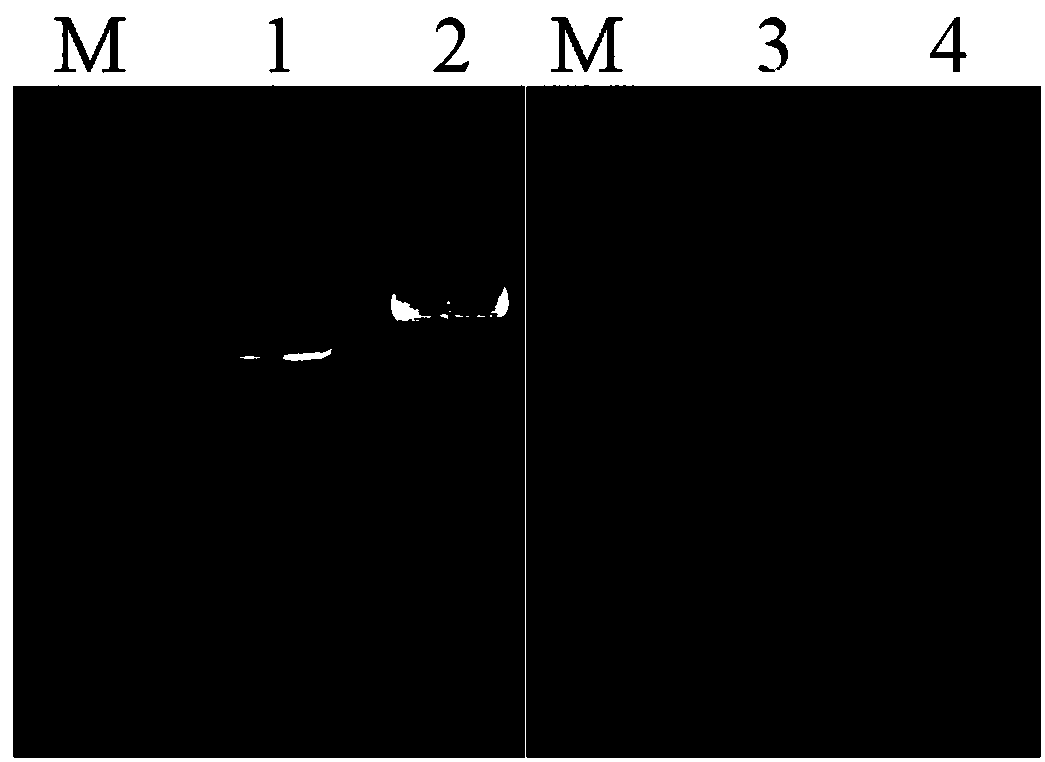

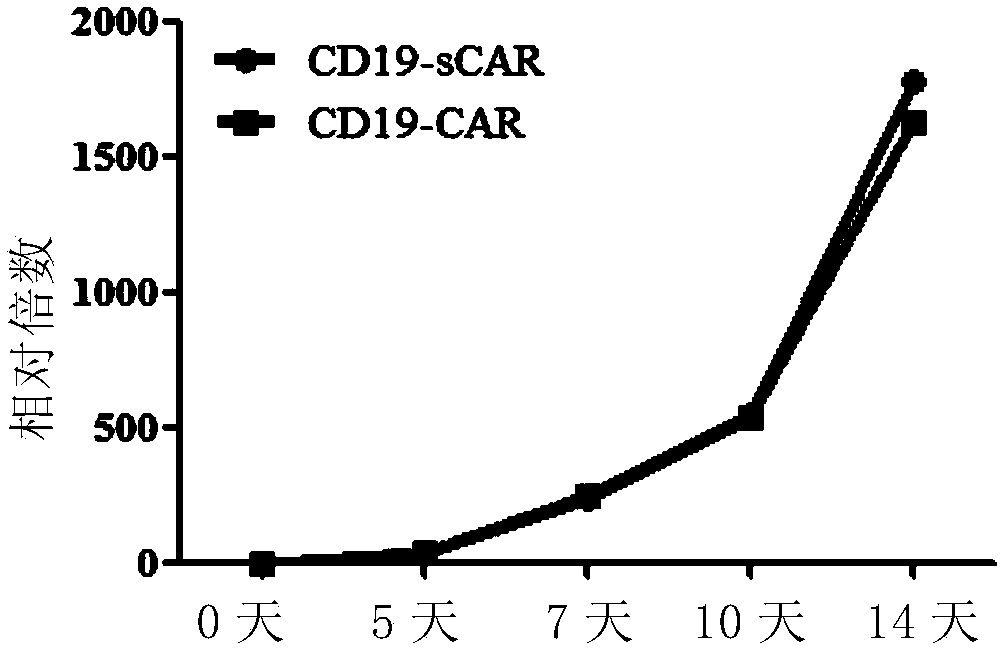

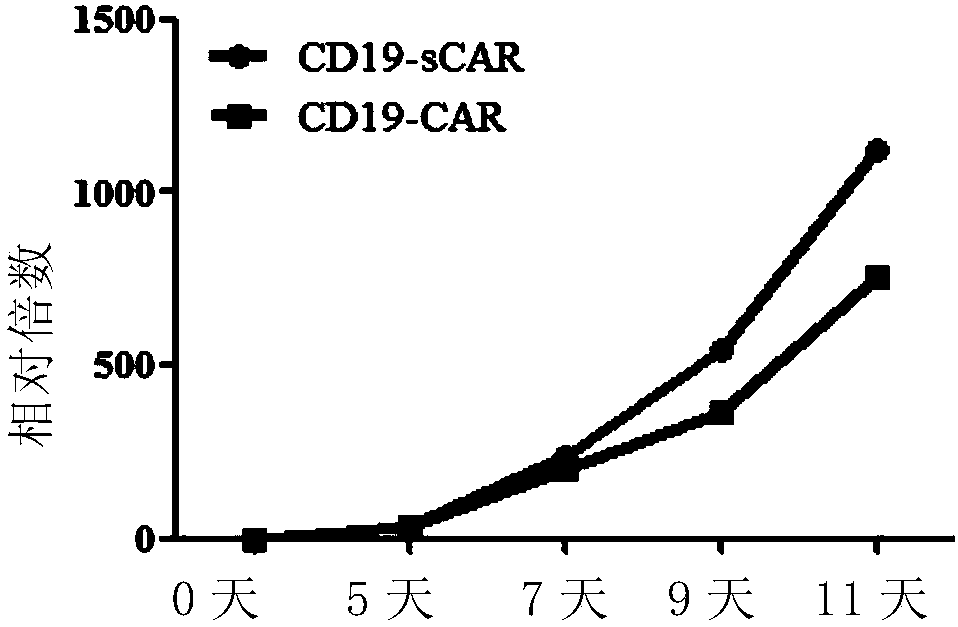

Chimeric antigen receptor for high-efficiency orientation amplification in vitro and application thereof

ActiveCN108017717AIn vitro specific selectivityHigh purityPolypeptide with localisation/targeting motifImmunoglobulin superfamilyAntigenChimeric antigen receptor

The invention provides a chimeric antigen receptor for high-efficiency orientation amplification in vitro and an application thereof, and specifically, provides a CAR-encoding molecule having specificselectivity in vitro. Through use of a humanized sorting domain, after infection with target cells, the target cells positive in CAR expression are efficiently sorted through a secondary sorting method so that the in-vitro directional amplification is achieved, the ratio of the CAR-positive target cells in the final product is significantly increased and the process preparation efficiency of CARgene-modified immune cell products is improved. The chimeric antigen receptor provides the table technical assurance for clinical promotion and application of the type of technical products.

Owner:XUANWU HOSPITAL OF CAPITAL UNIV OF MEDICAL SCI

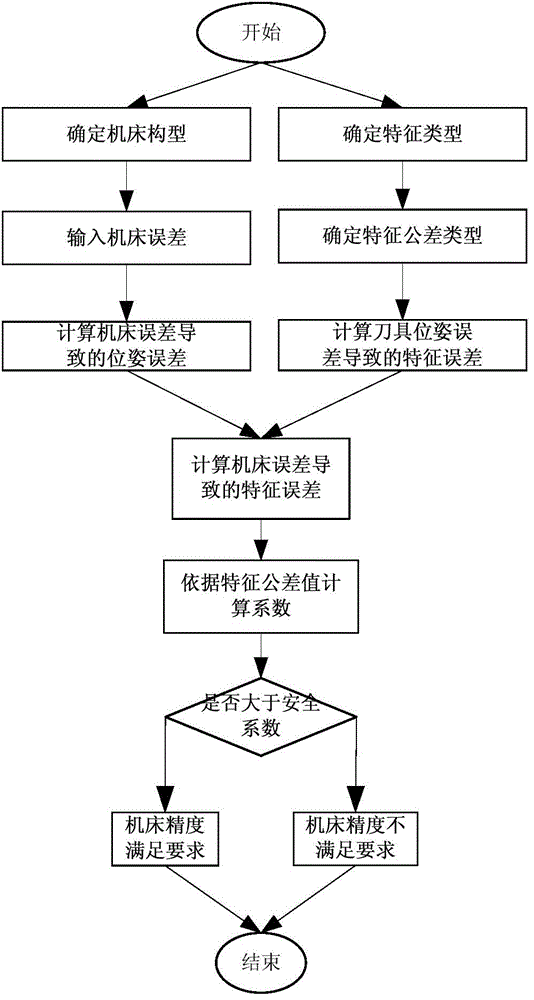

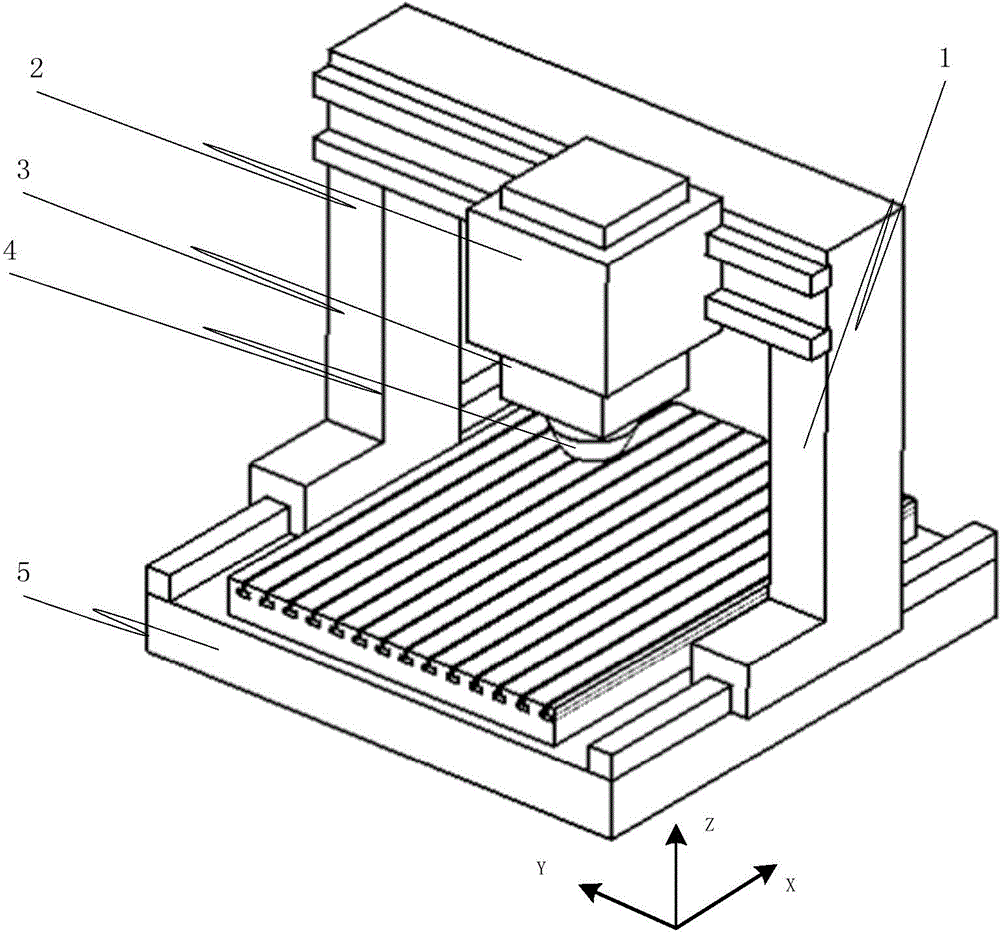

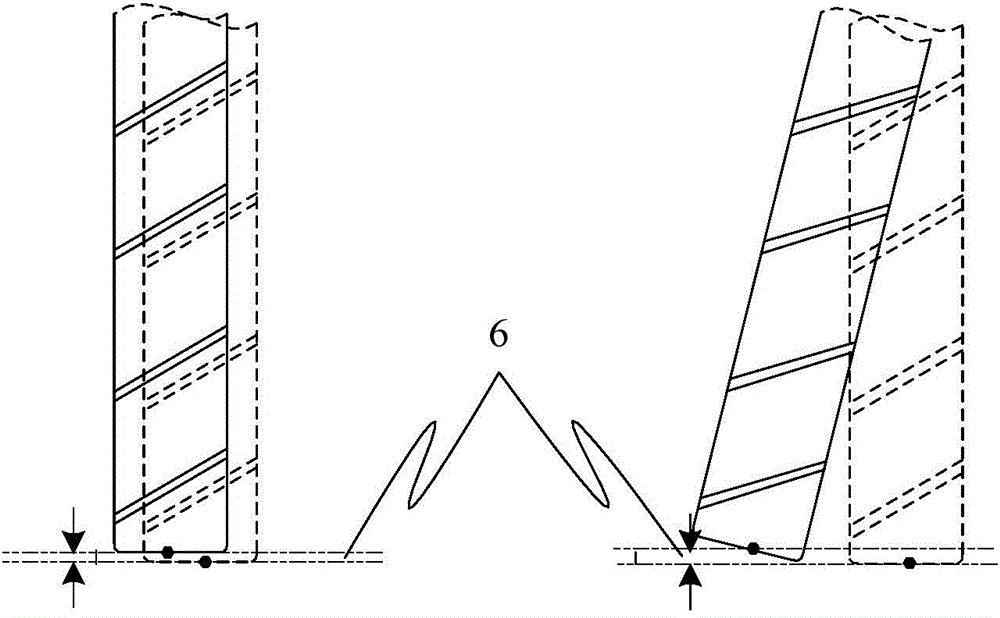

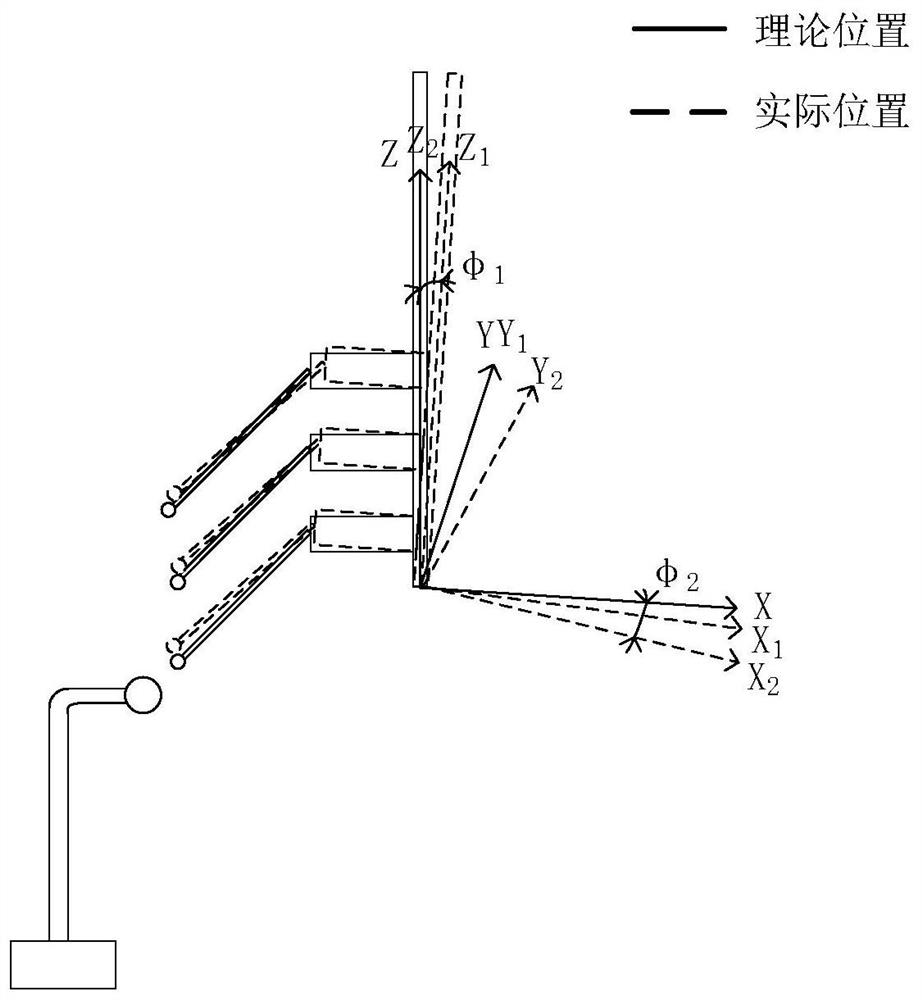

Numerically-controlled machine tool machining capacity evaluation method based on part characteristics

ActiveCN104021242AEffective determination of processing capacityIncrease profitSpecial data processing applicationsTrial and errorPosition error

A numerically-controlled machine tool machining capacity evaluation method based on part characteristics is characterized in that first, a motion matrix and an error matrix of all moving parts are established according to the modes of motion of the parts of a machine tool; then, the sequences of the matrixes are determined according to the connection relations between the moving parts of the machine tool, and position errors and posture errors of tools are obtained through matrix calculation, and the position errors and the posture errors are collectively called pose errors; next, the characteristic errors generated by the pose errors of the tools are respectively calculated according to the geometric shapes of the characteristics and the basis reference conditions of tolerance; finally, the characteristic machining errors obtained through calculation are compared with the form and location tolerance required by characteristic design, and thus whether the precision requirement of the machine tool is appropriate or not is determined. The fast and direct machine tool precision level evaluation method is provided, so that the problem that the machining capacity of the machine tool is learned by technologists by means of experience or trial and error in the numerically-controlled machining programming is solved; the technological preparation efficiency is improved, the machining cost is reduced, and the numerically-controlled machining quality is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

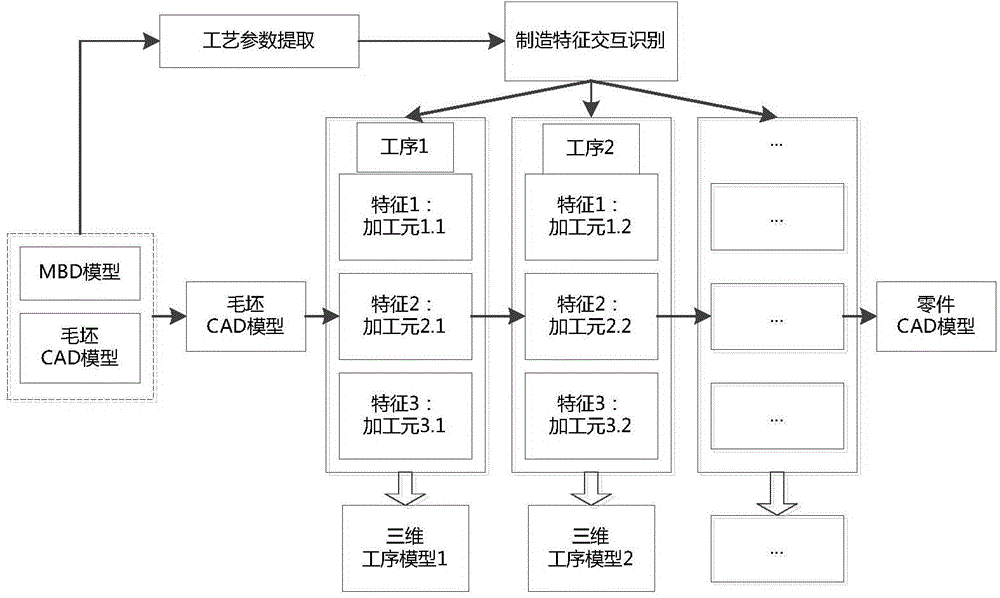

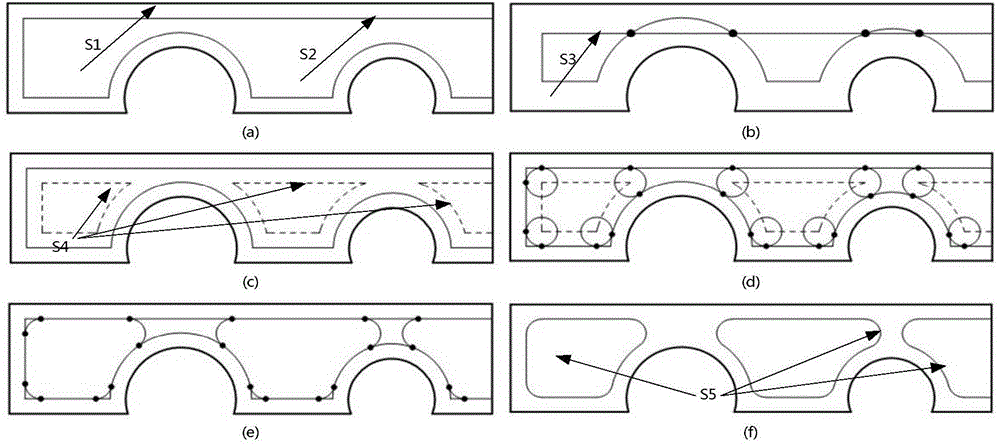

Three-dimensional process model building method based on cutter radius

The invention discloses a three-dimensional process model building method based on the cutter radius to solve the technical problem that the existing three-dimensional process model building method is poor in practicability. According to the technical scheme, the method comprises the steps of serializing manufacture features into machining elements, and performing Boolean operation on a machining element body and a precursor process model by taking the machining element body as a basic unit to generate a three-dimensional process model. The base plane ring of the manufacture features is acquired as an initial curve, offset and intersection calculation is performed on the initial curve for multiple times by taking the side margin and the cutter radius as offset parameters, the section contour line of each machining element is acquired, the start plane and the end plane of stretching are specified, the machining element body is built accurately, and the three-dimensional process model is built with the machining element body as a basic unit. As the base ring of the manufacture features is offset by a curve offset algorithm based on the cutter radius and an offset curve is stretched to generate the machining element body, generation of the machining element body is realized, and the three-dimensional process model of actual machining is reflected accurately.

Owner:南京信航科创发展有限公司

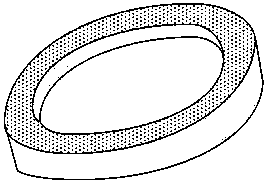

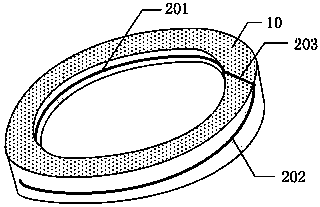

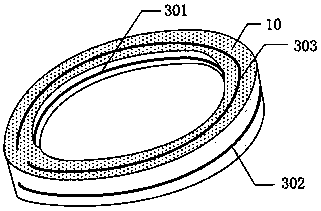

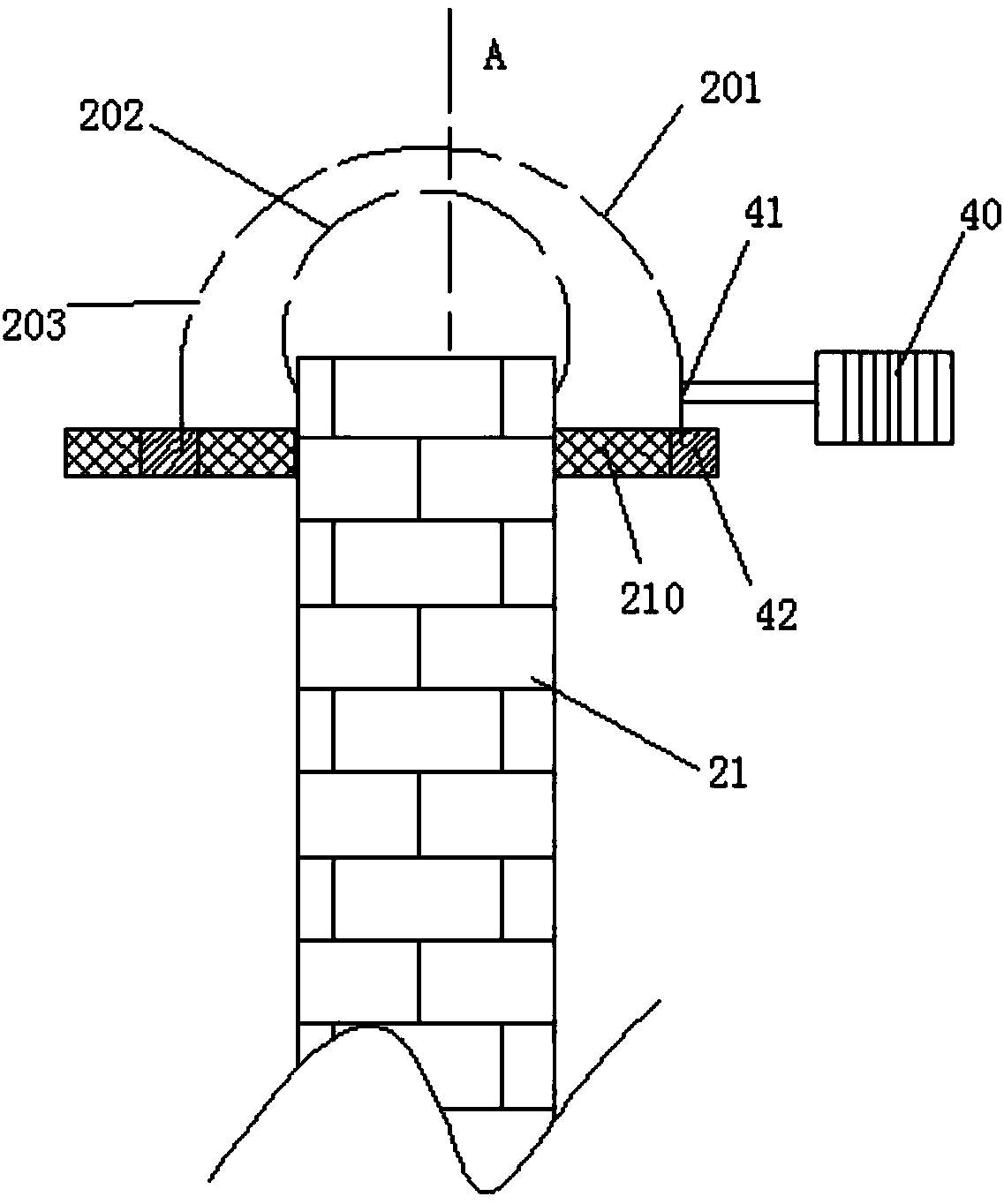

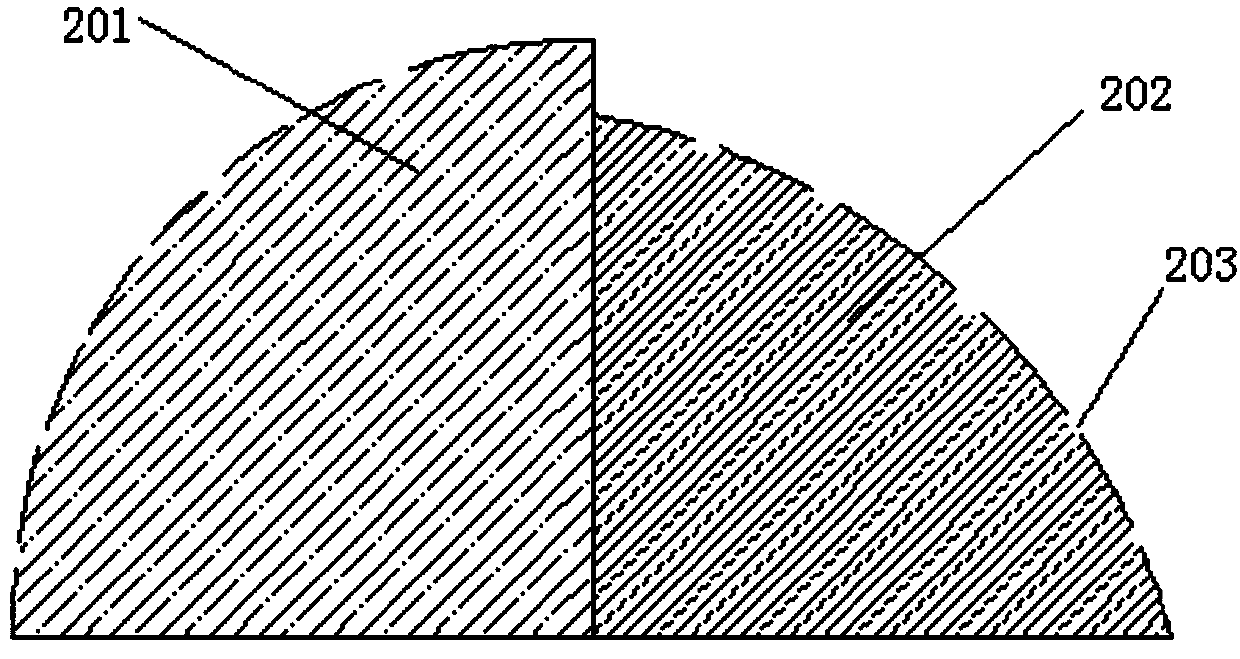

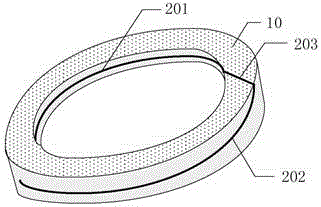

Fixing ring and polishing head

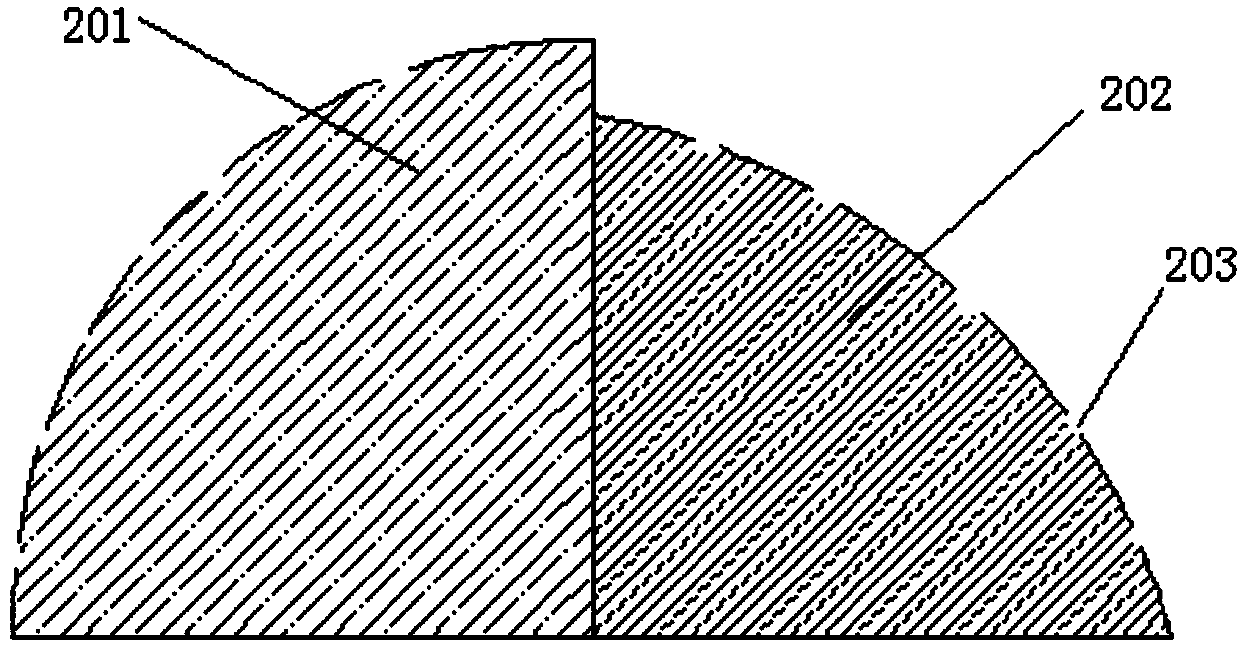

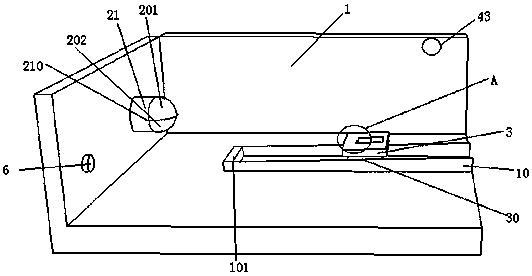

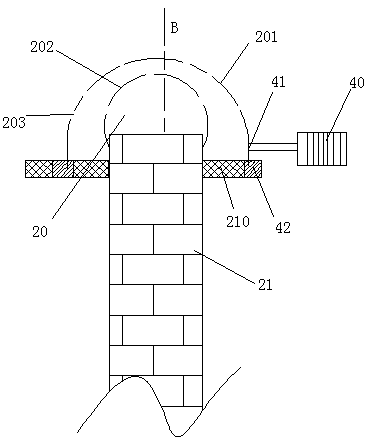

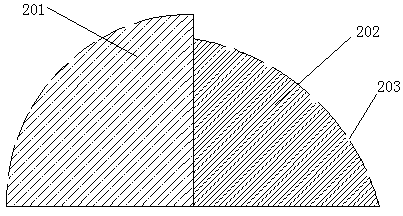

ActiveCN103639888AHigh efficiency of preparation processAccurate self-testLapping machinesWork carriersSemiconductor chipEngineering

The invention relates to a fixing ring used in a chemical mechanical polishing device. The chemical mechanical polishing device comprises a polishing disk and a polishing head. The polishing head comprises a chip carrier and the fixing ring, wherein the chip carrier is used for clamping a semiconductor chip, the polishing disk makes contact with the chip, and the polishing disk and the polishing head rotate in opposite directions respectively to polish the chip. The fixing ring comprises an annular base, at least one easy-to-break lead, an on-off state detection device and a signal processing device, wherein the annular base is arranged below the chip carrier, surrounds the side surface of the chip and is used for fixing the chip; the easy-to-break leads are fixed to the surface of the annular base, extend in the perimeter direction of the annular base and surround the annular base by one circle; the on-off state detection device is connected with all the easy-to-break leads respectively and sends an alerting signal when any easy-to-break lead is broken; the signal processing device is connected with the output end of the on-off state detection device and converts the alerting signal into a polishing stop signal which is used for instructing the polishing head and the polishing disk to stop rotating. The chemical mechanical polishing device can effectively lower loss of a technology caused by the fracture of the fixing ring, thereby being beneficial to the improvement of wafer preparation technological efficiency.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

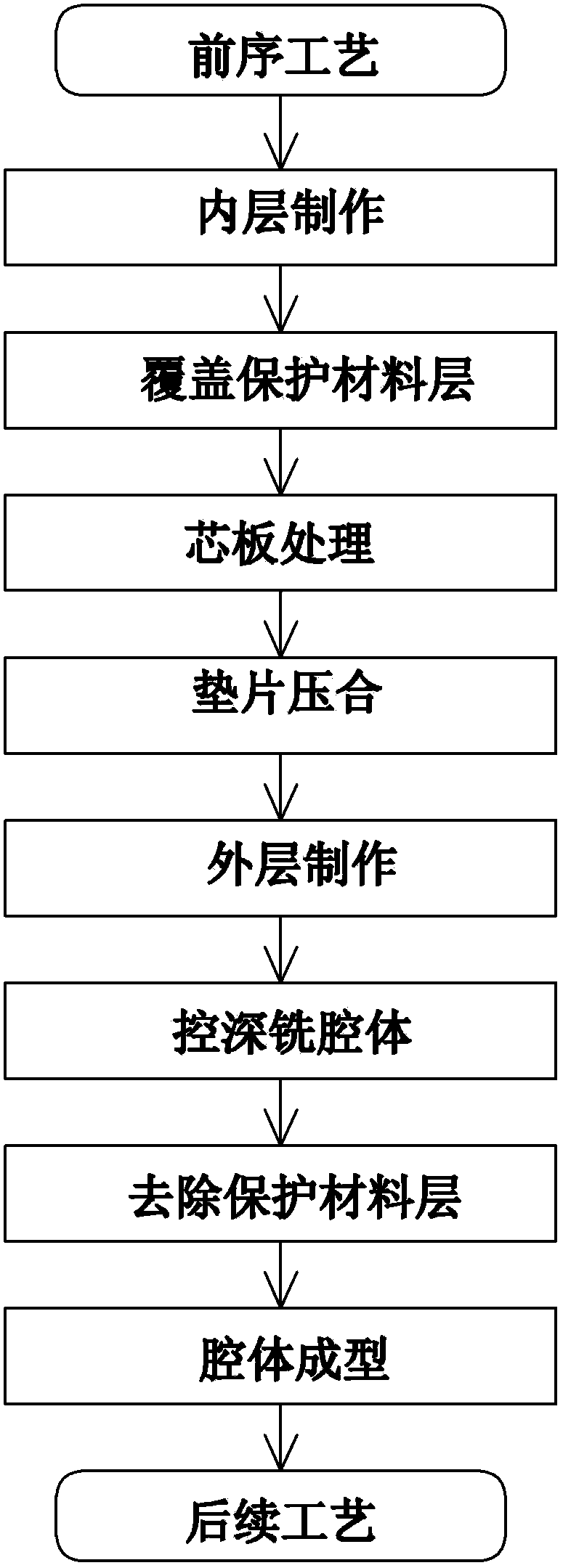

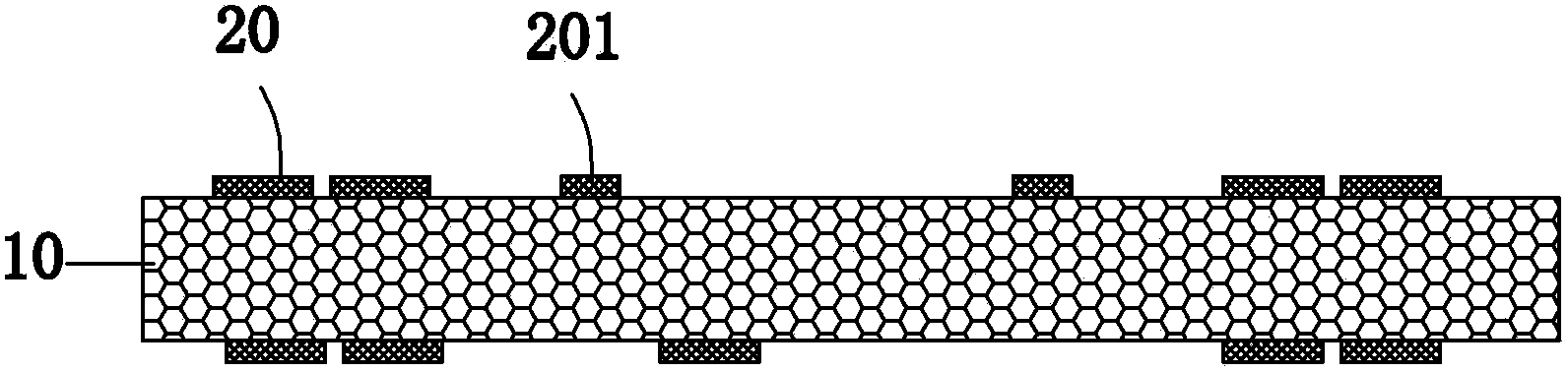

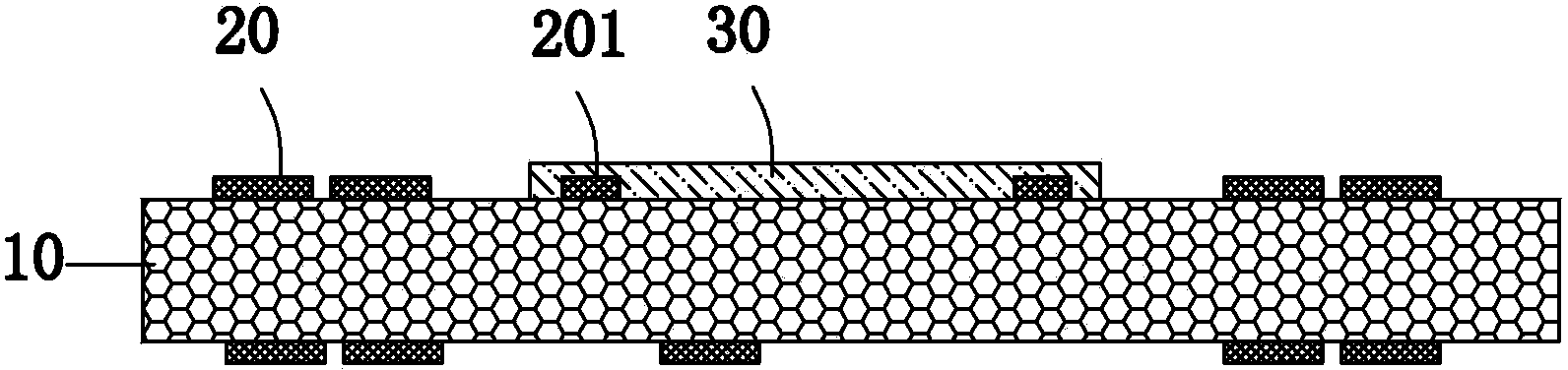

Process for manufacturing cavity of package substrate

InactiveCN103730374AGuaranteed dimensional accuracyQuality improvementSemiconductor/solid-state device manufacturingWork in processGasket

The embodiment of the invention discloses a process for manufacturing a cavity of a package substrate. The process includes the following steps that an inner layer is manufactured; a protective material layer is laid, namely, a target cavity zone is determined on a core board with the inner layer manufactured, and a bonding golden finger of the target cavity zone is covered with the protective material layer; the core board is treated; the protective material layer is overlaid with a gasket in a press fit mode; an outer layer is manufactured; cavity depth-control milling is carried out, namely, depth-control milling is carried out on the target cavity zone of the core board with the outer layer manufactured to obtain a semi-finished cavity and expose the protective material layer; the protective material layer is removed, and namely the protective material layer in the semi-finished cavity is removed through the organic stripping method to expose the bonding golden finger; cavity forming is carried out, and namely the core board and the interior of the semi-finished cavity with the protective material layer removed are treated through the surface treatment method to obtain the formed cavity. According to the process for manufacturing the cavity of the package substrate, damage to the bonding golden finger is avoided, the dimensional accuracy and quality of the cavity are guaranteed, and the efficiency of the manufacturing process is improved.

Owner:SHENNAN CIRCUITS

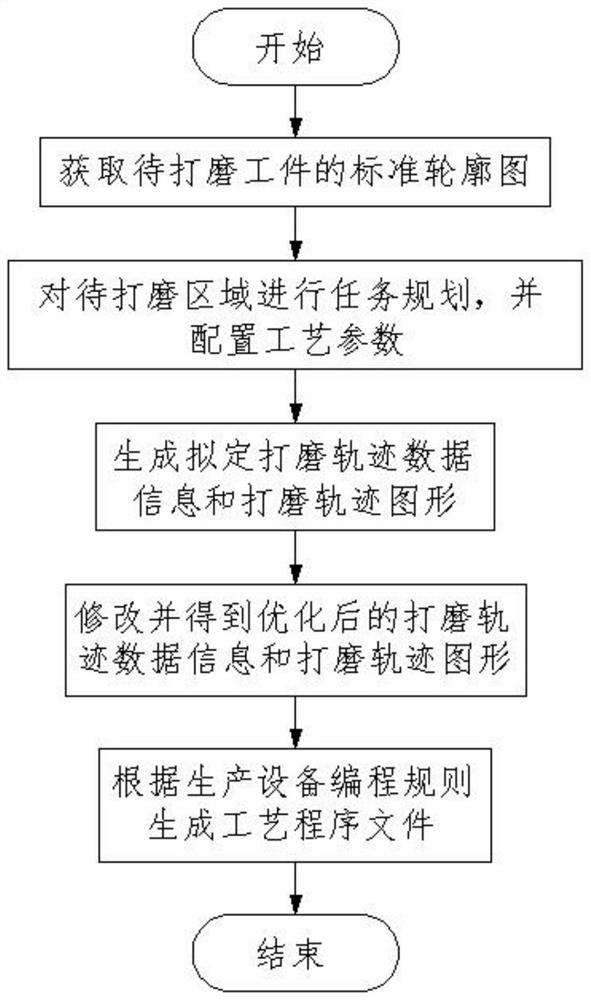

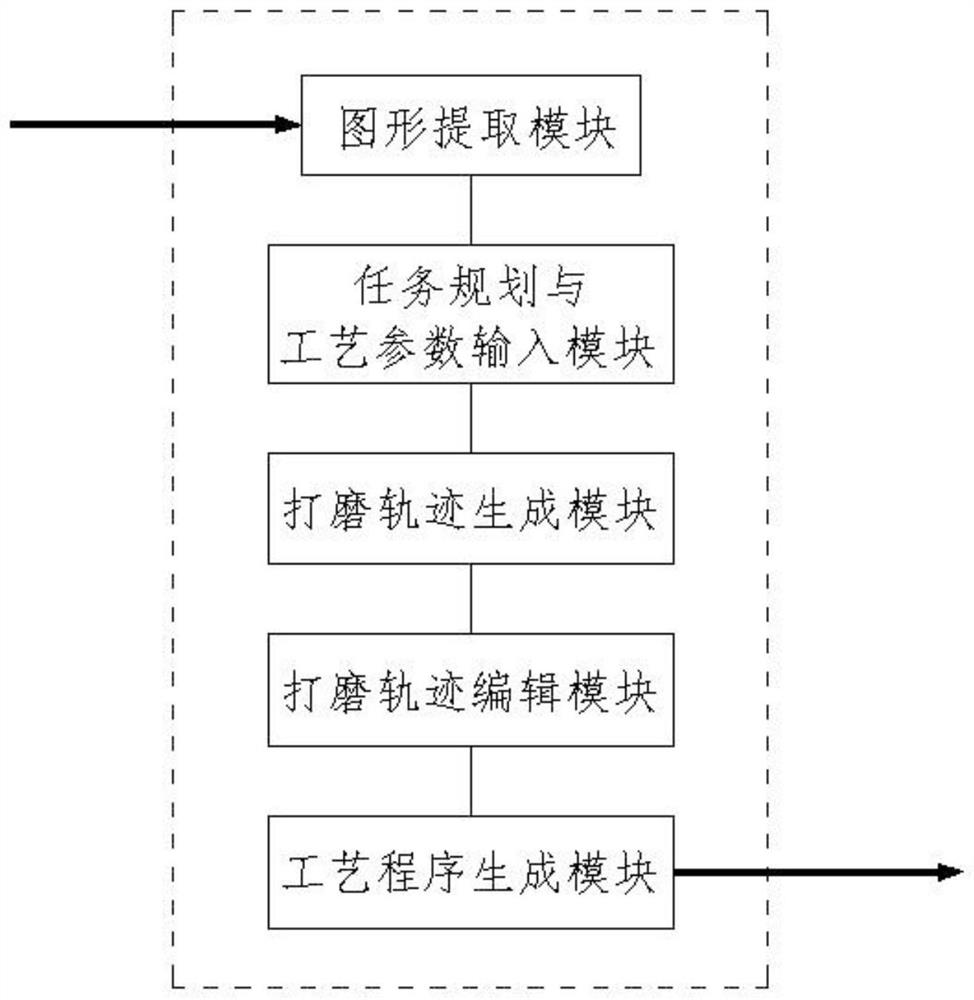

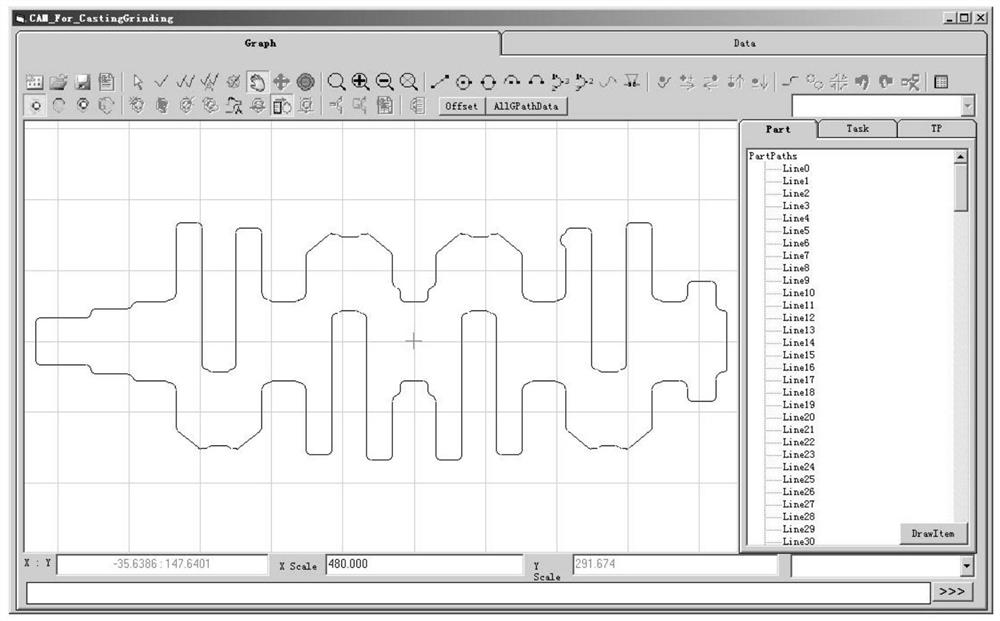

Casting grinding track generation method and system

ActiveCN112720150AIntuitive programmingEasy programmingEdge grinding machinesProgramme controlData informationProcess engineering

The invention discloses a casting grinding track generation method and system. The casting grinding track generation method comprises the following steps that a pattern extraction module obtains a standard contour map of a to-be-ground workpiece, the modification and adjustment are carried out according to the actual boundary dimension of the workpiece, and an actual contour map of the to-be-ground workpiece is obtained; a task planning and process parameter input module is used for carrying out task planning on a to-be-ground area according to the grinding process requirements and configuring grinding process parameters to obtain segmented grinding task information and process parameter configuration information; according to the information, a grinding track generation module generates proposed grinding track data information and a grinding track graph; in combination with actual production process requirements, a grinding track editing module modifies the planned grinding track data information and the grinding track graph to obtain optimized grinding track data information and grinding track graph; and a process program generation module extracts the optimized information and generates a process program file directly used for processing according to a production equipment programming rule.

Owner:西安拽亘弗莱工业自动化科技有限公司

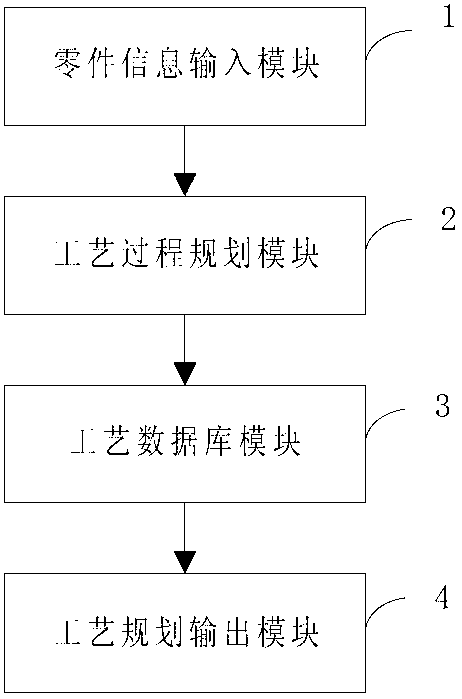

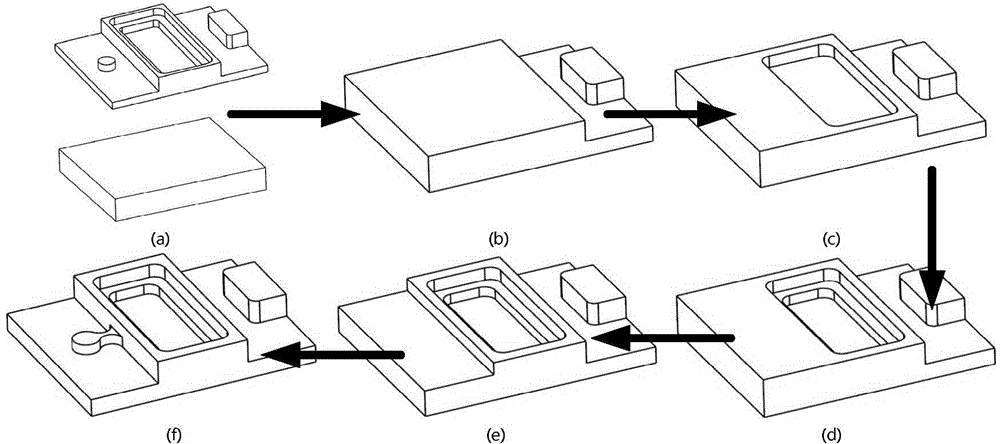

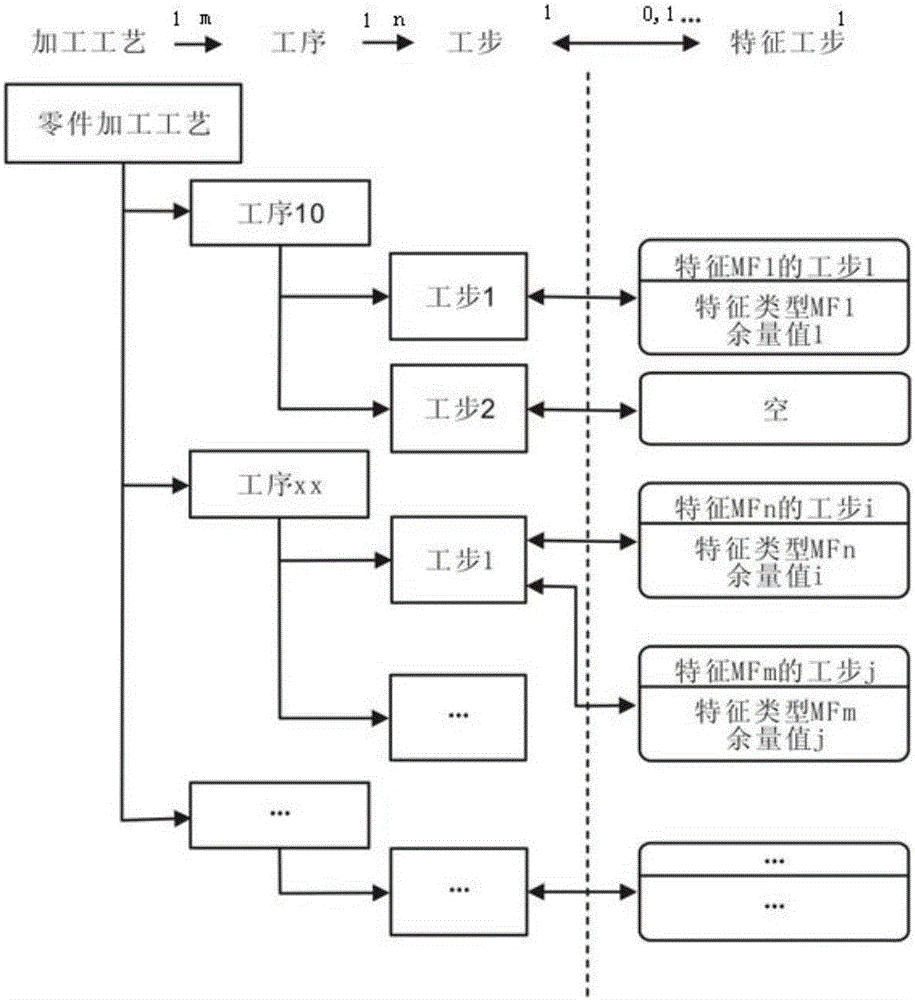

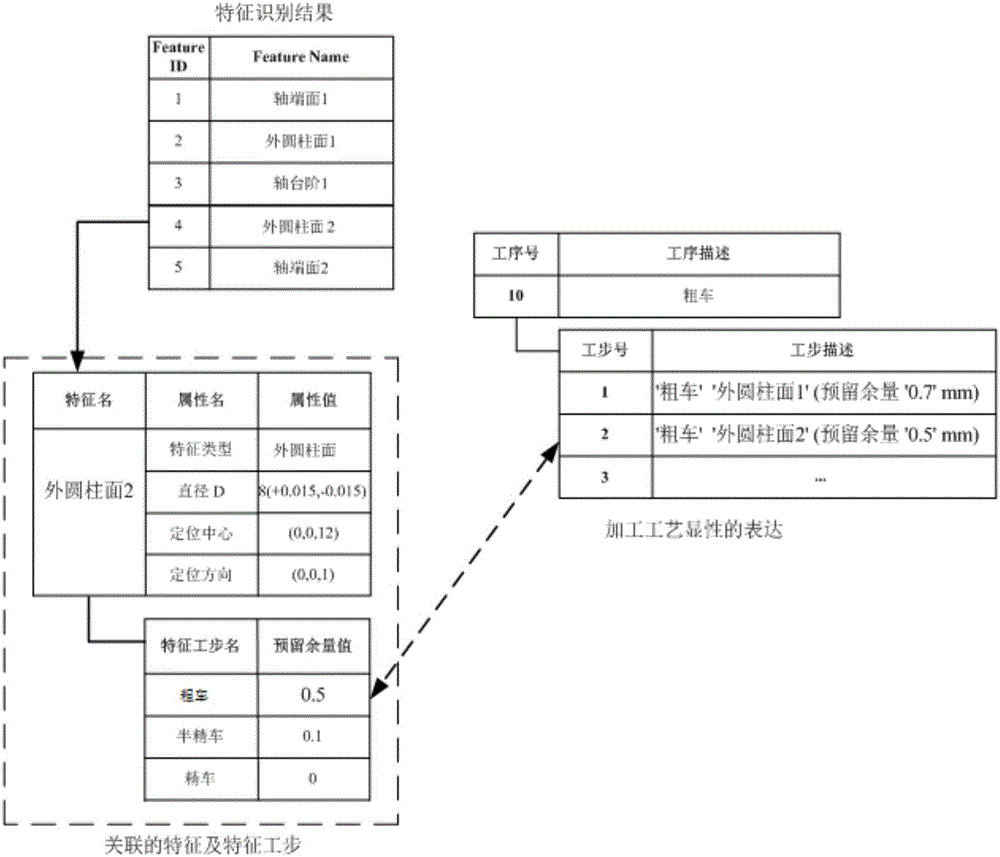

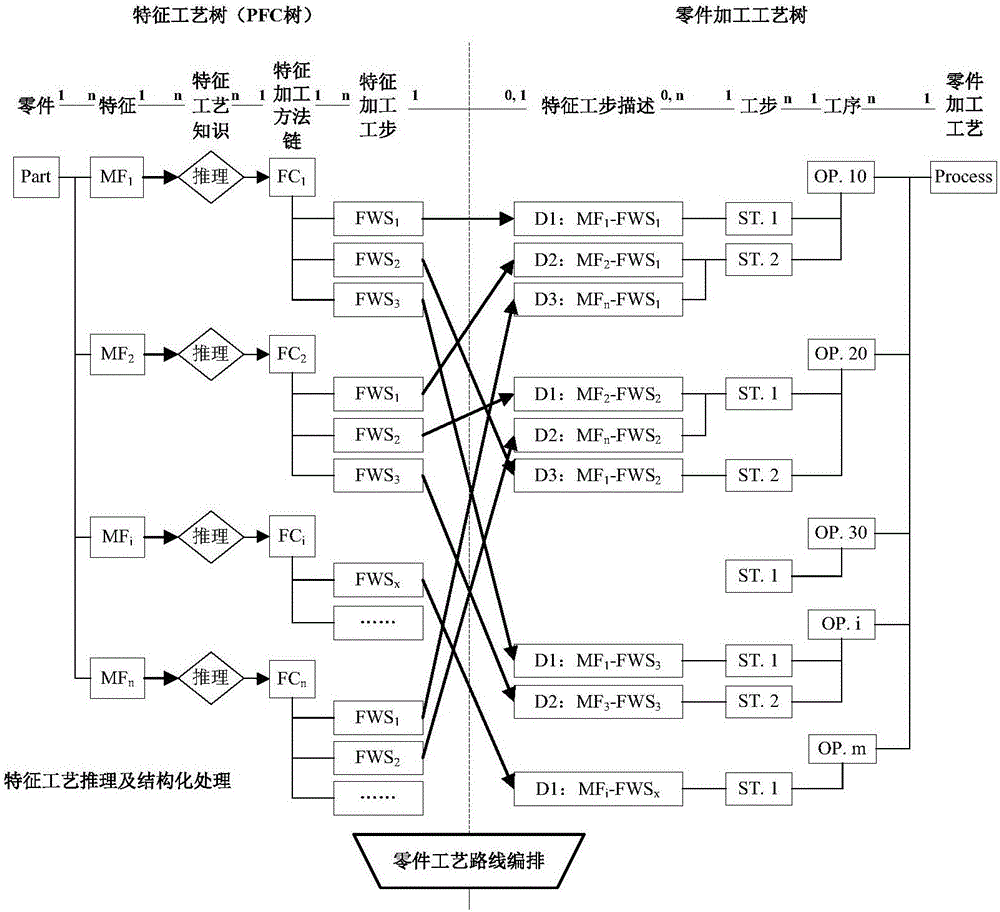

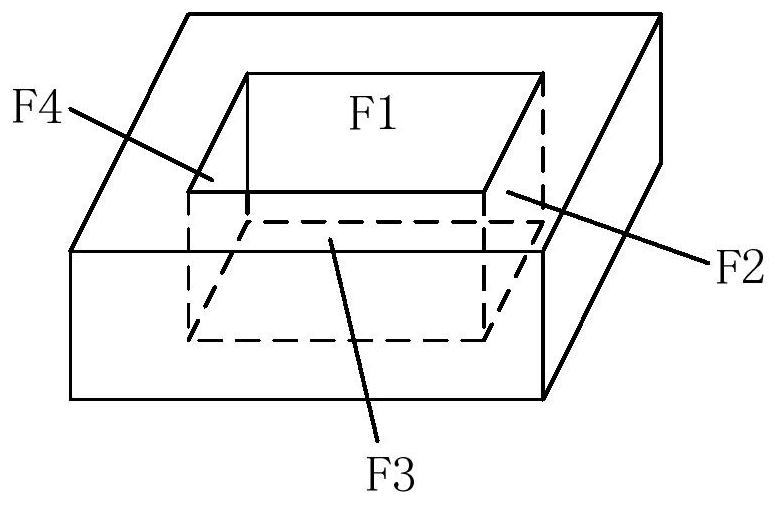

Feature-basedthree-dimensional machiningtechnology layout system and method

InactiveCN106682816AReduce stepsHigh efficiency of preparation processResourcesKnowledge organizationComputer science

The invention relates to a feature-basedthree-dimensional machiningtechnology layout system and method. The system in the same interface comprises a feature technology tree region, a feature technology attribute region, a technology leveling grid region and a process and step attribute region. The feature processing method is expressed by utilizing a feature technology tree and a feature technology attribute, and the process and the step of the part machining technology are expressed by utilizing the process leveling grid and the process and step attribute. The method comprises the first step of generatingthe feature processing method, the second step ofperforming feature step sequencing torapidly generate the part technology and the third step of combining, merging and sequencing the technology routine. After the content completion of the process and the step and through the combination, merge and sequence of each feature technology routine of parts, and the final part technology routine is obtained. The feature-basedthree-dimensional machiningtechnology layout system and methodhave the advantages of the information organization, the processing knowledge inheritance and the integration of the structural technology, and make the technology layout easier and faster.

Owner:WUHAN KAIMU INFORMATION TECH

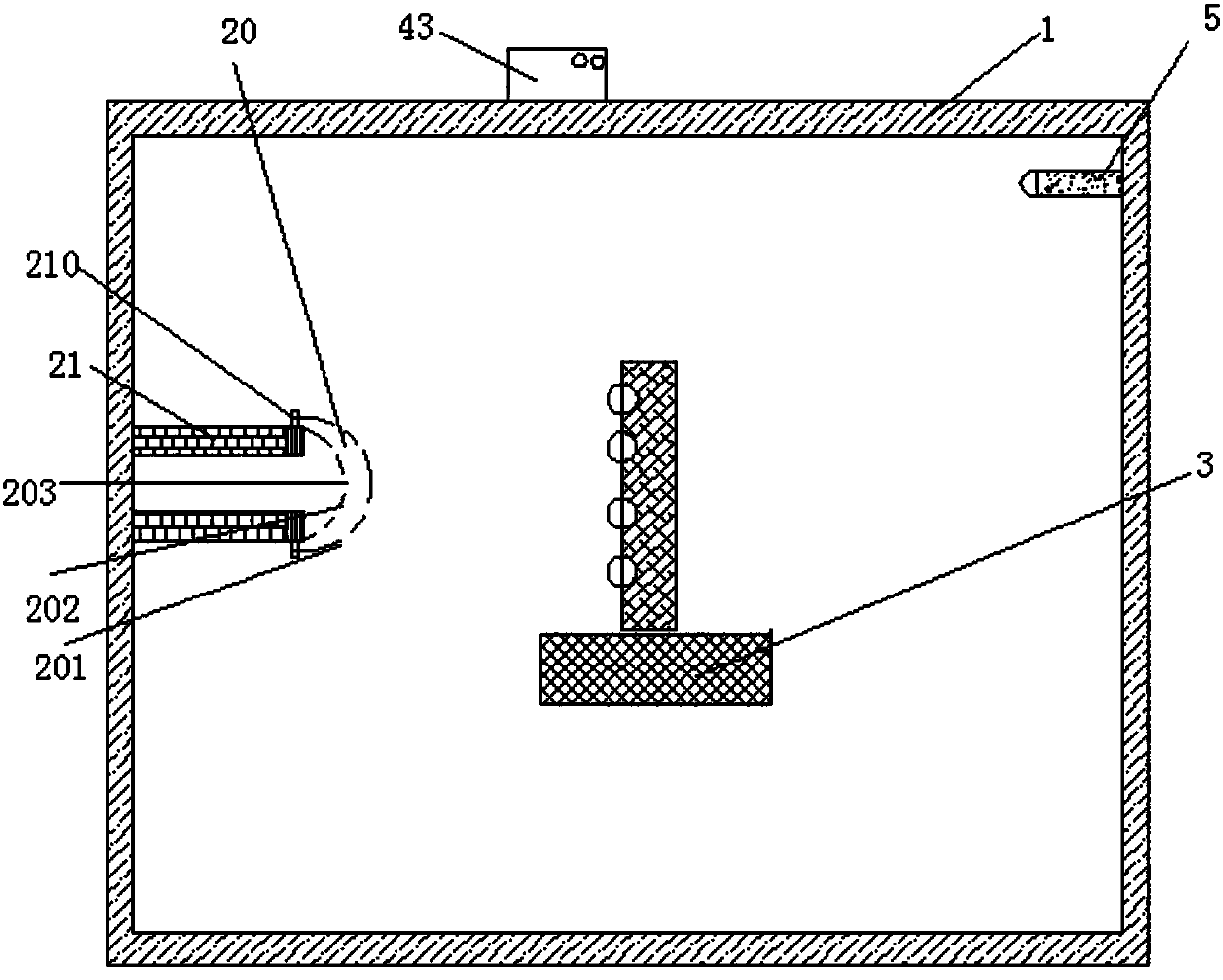

LED (light emitting diode) lamp silver glue sintering oven with stable glue dispensing effect

InactiveCN107782142AHigh efficiency of preparation processImprove sintering efficiencyCharge treatment typeFurnace typesMetallurgyColloid

The invention discloses an LED (light emitting diode) lamp silver glue sintering oven with stable glue dispensing effect. Sintering mouth ends comprise a first sintering mouth end and a second sintering mouth end, wherein the first sintering mouth end is rotated around a support rod; the second sintering mouth end is fixedly arranged on a sintering mouth support rod; the second sintering mouth endand the first sintering mouth end are respectively in a semisphere shape; the radius of the second sintering mouth end is smaller than the radius of the first sintering mouth end; the first sinteringmouth end and the second sintering mouth end are respectively provided with a plurality of small sintering mouths; the positions of the small sintering mouths correspond to the glue dispensing positions; the distance between each sintering mouth and the corresponding glue dispersing position is the same; a limiting groove is detachably connected with the sintering oven. The LED lamp silver glue sintering oven has the advantage that while an LED lamp is preheated to avoid the influence to the subsequent curing effect due to sudden heating of the silver glue, the limiting groove and the LED lamp are arranged in the sintering oven, so as to solve the problems of the prior art that the LED lamp cannot be put into the limiting groove until glue dispensing; because the silver glue is gluey, theplacing needs to be careful; in the placing groove, the limiting groove cannot be conveniently placed into the sintering oven.

Owner:SICHUAN ZHONGYONG PHARMA CO LTD

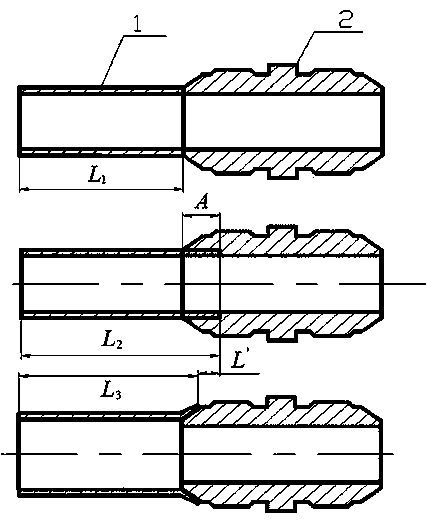

Length control method of flared catheter based on digital manufacturing

ActiveCN109063315ASimplify the design modeling processImprove modeling efficiencyGeometric CADDesign optimisation/simulationMedicineCatheter

The invention discloses a flared catheter length control method based on digital manufacturing, which provides a flared catheter end modeling method oriented to digital manufacturing, simplifies the flared catheter design modeling process, and improves the flared catheter modeling efficiency. Defined the flare compensation, and through the finite element simulation and flare test, determined the flare compensation of different materials, different specifications of the pipe, formed the process parameter table, as the process control of the flare pipe manufacturing, improve the flare pipe manufacturing process preparation efficiency, can improve the processing quality of the flare pipe, effectively control the length of the flare pipe; The shrinkage of the tube flared is determined, and theshrinkage of the tube flared with different materials and specifications is determined by experiments, and the technological parameter table is formed, which is convenient for the measurement and inspection by the laser vector measuring machine after the tube flared is finished.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Sintered metal fiber felt separation net and preparation method thereof

ActiveCN103774144AImprove bindingExtended service lifeSuperimposed coating processPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a sintered metal fiber felt separation net and a preparation method thereof. According to the separation net, a stainless steel screen with the net pore size of 10-50 meshes and the wire diameter of 0.1-5mm is used as a base net, and an aluminum oxide ceramic coating of 20-25mu m in thickness is coated on the base net through hot dip aluminum plating and micro-arc oxidation. The separation net is used for separating two layers of metal fiber felts in the vacuum sintering process. The separation net is reasonable in structure, simple in preparation process, low in cost, high in binding force of an in-situ Al2O3 ceramic coating on the separation net, and long in service life, and is an ideal sintered metal fiber felt separation net and a preparation method of the separation net. The process is high in preparation efficiency and applicable to industrial production.

Owner:HARBIN INST OF TECH AT WEIHAI

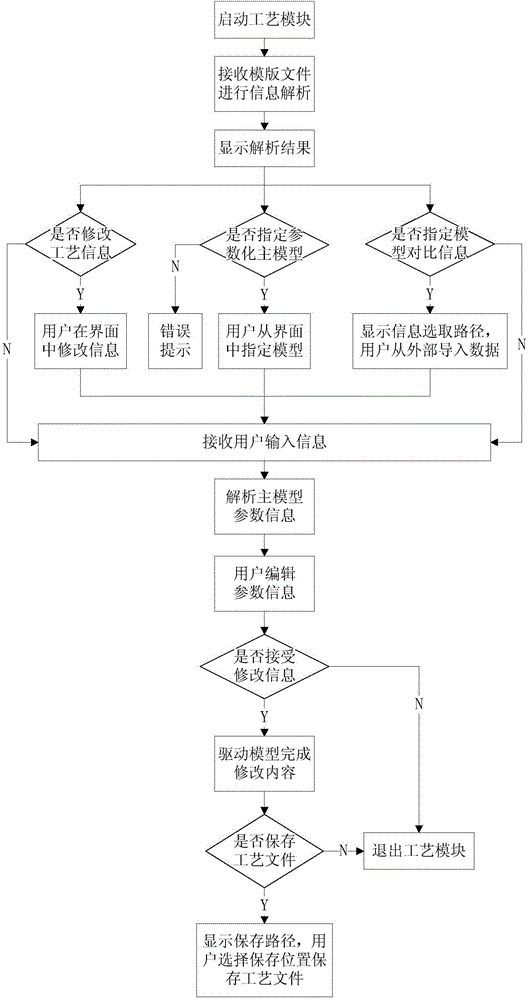

Rapid generation method for three-dimensional machined technological document

ActiveCN105589867AConvenient and fast process preparation toolReduce manual operation timeSpecial data processing applicationsInformation analysisThree dimensional data

The invention relates to a rapid generation method for a three-dimensional machined technological document. The method is based on a technological design platform and comprises four parts: a technological information analysis module, a technological information input module, a model information analysis module and a technological document generation module. According to the technological information analysis module, analysis information comprises technological information like a three-dimensional data model, a part name, a part number, a model, a version, material and the like. According to the technological information input module, information is modified in a newly generated technological document. According to the model information analysis model, parameter information in a parameter master model is analyzed, the data represented by each parameter is displayed in a form manner, and a schematic drawing of a design template and a schematic drawing of a technological template are displayed on a form interface. According to the technological document generation module, a user can modify parameter information of the master model according to new design information. The method has the advantages of providing a rapid and convenient technology planning tool for technologists, reducing manual operation time, and improving the technological planning efficiency of medium and small series of documents.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

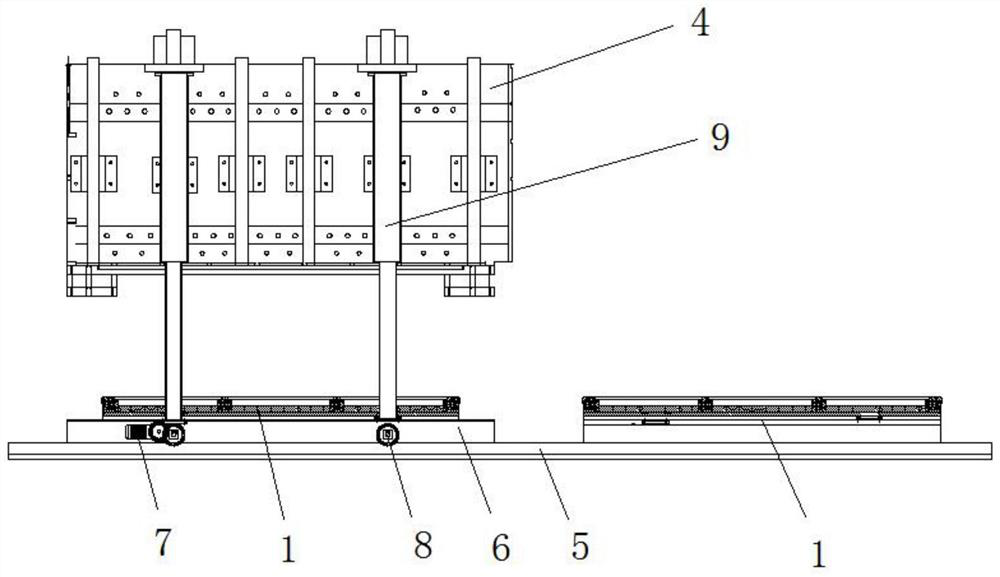

Lifting movable heat treatment bell-type furnace

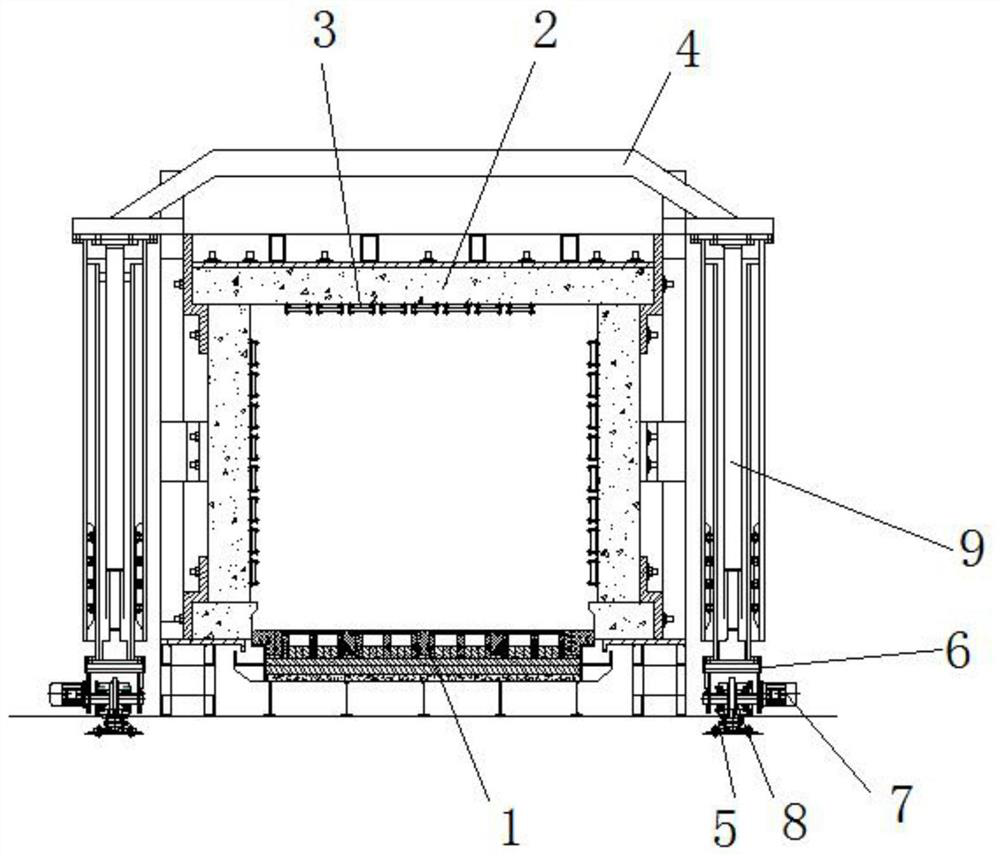

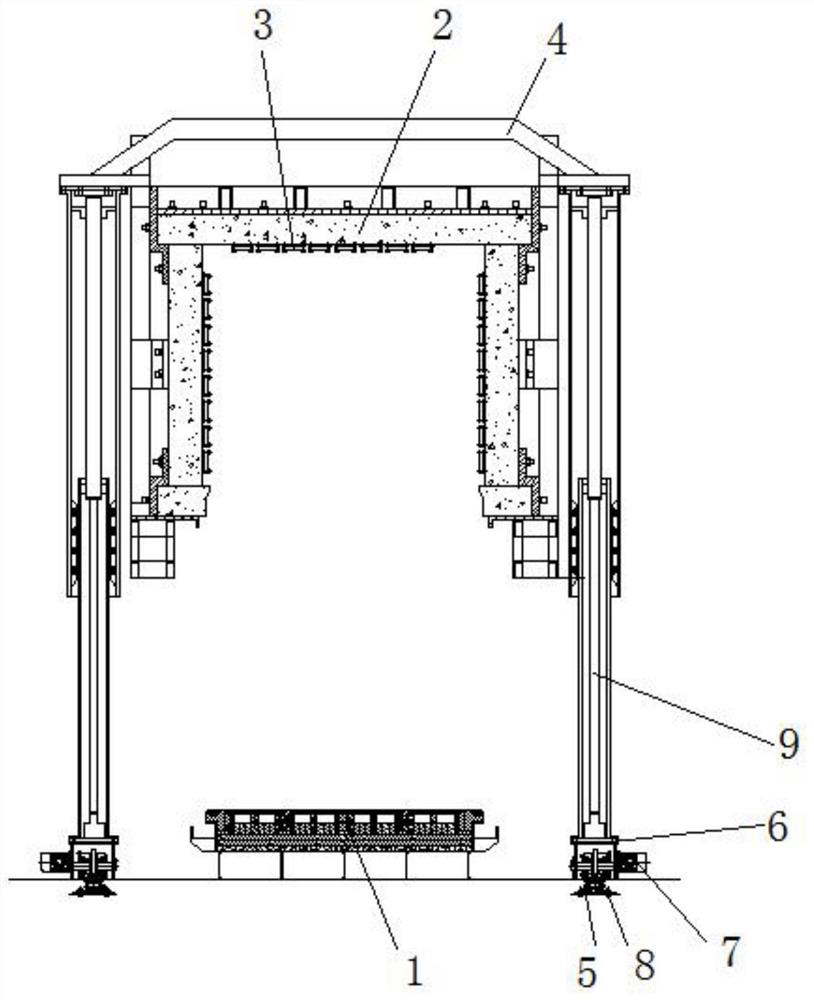

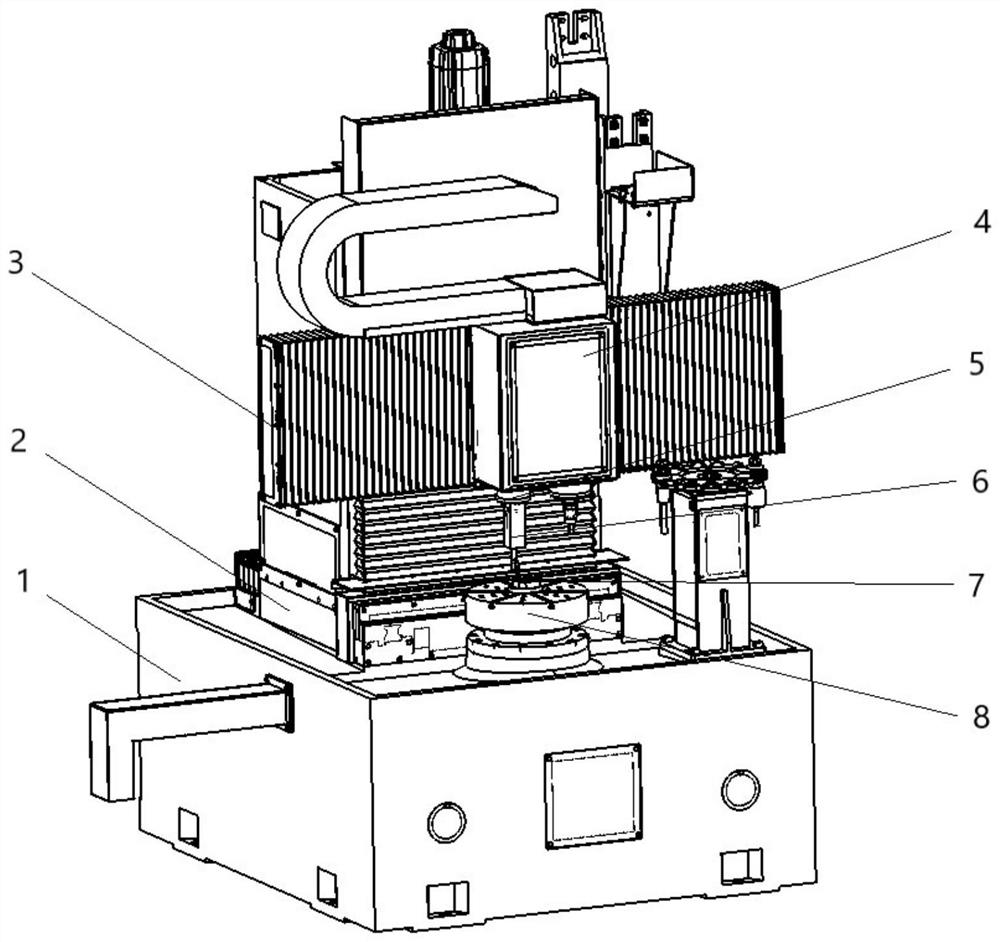

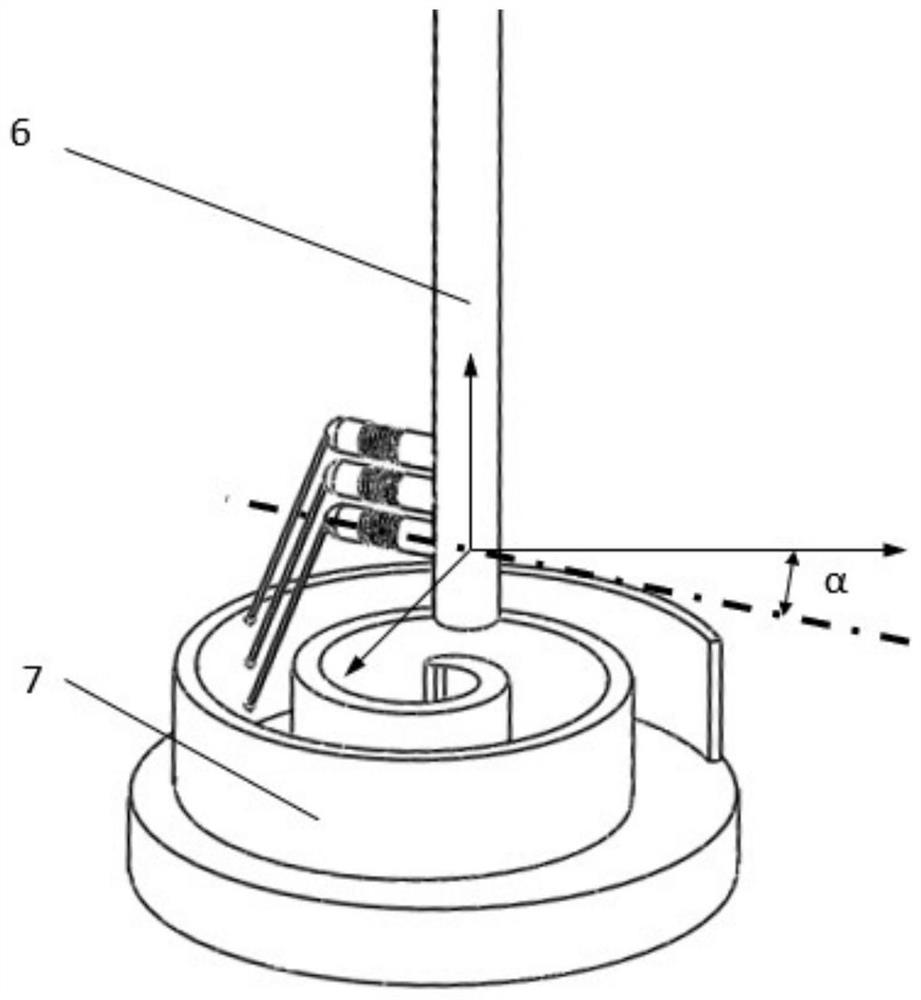

PendingCN111850267AImprove heat treatment efficiencyImprove process preparation efficiencyFurnace typesHeat treatment furnacesElectric machineryDrive motor

The invention discloses a lifting movable heat treatment bell-type furnace. The furnace comprises furnace tables, a furnace lining, heating elements, a shell supporting structure, tracks, motor base frames, driving motors, rolling wheels and lifting devices; the two furnace tables are arranged, and are laterally arranged at an interval; the furnace lining is arranged above the furnace tables, andan embedded part is prefabricated in the furnace lining; the heating elements are wrapped around and suspended from the inner wall of a side furnace plate and the inner wall of a top furnace plate through corundum ceramic nails, and the shell supporting structure is wrapped around the outer wall of the furnace lining; and the tracks are arranged on the two sides of the furnace tables and are symmetrically arranged in parallel, the bottom surface of the track on each side is fixedly connected to the ground through bolts, the motor base frames are arranged on the top surfaces of the tracks in the same direction, the rolling wheels rotate with the motor base frames through rotating shafts, the driving motor is arranged on one side of the motor base frame of each side, and the lifting devicesare arranged on the two sides of the top surfaces of the motor base frames. According to the furnace, the same furnace cover is provided with two furnace table structures, the working efficiency is high, the heat preservation effect of the furnace tables is strong, the lifting devices are stable in structure, and the shell supporting structure is firm in structure.

Owner:丹阳市恒泰电炉有限公司

Scroll plate body error on-machine measurement method based on four-axis numerical control milling machine

ActiveCN112729086AImprove detection efficiencyHigh measurement accuracyPoint coordinate measurementsNumerical controlMilling cutter

The invention discloses a scroll plate body error on-machine measurement method based on a four-axis numerical control milling machine, and aims to solve the problem of three-dimensional body error on-line rapid measurement in the scroll plate machining process. The measurement method comprises the following steps that based on a scroll plate numerical control machining tool, a milling cutter and a measuring head have a same installation connector, and after milling is completed, the milling cutter is replaced with the measuring head in a cutter changing mode. and the measuring head is a three-parallel inductance integrated measuring head, three sets of detection data in the vertical direction of a scroll plate can be obtained through one-time measurement after installation and calibration, and scroll body error evaluation of the scroll plate is completed. Based on the on-machine measurement method for the scroll plate error, the influence of repeated clamping errors when the scroll plate is measured on a traditional measuring instrument is avoided, and the measurement efficiency and the measurement precision are improved. Based on evaluation of errors of a three-dimensional vortex body, manufacturing errors of a vortex surface caused by workpiece and clamping errors or cutter local abrasion are evaluated in time in the machining process, and the limitation that only a single vortex line is subjected to error evaluation in traditional measurement is overcome.

Owner:XI AN JIAOTONG UNIV

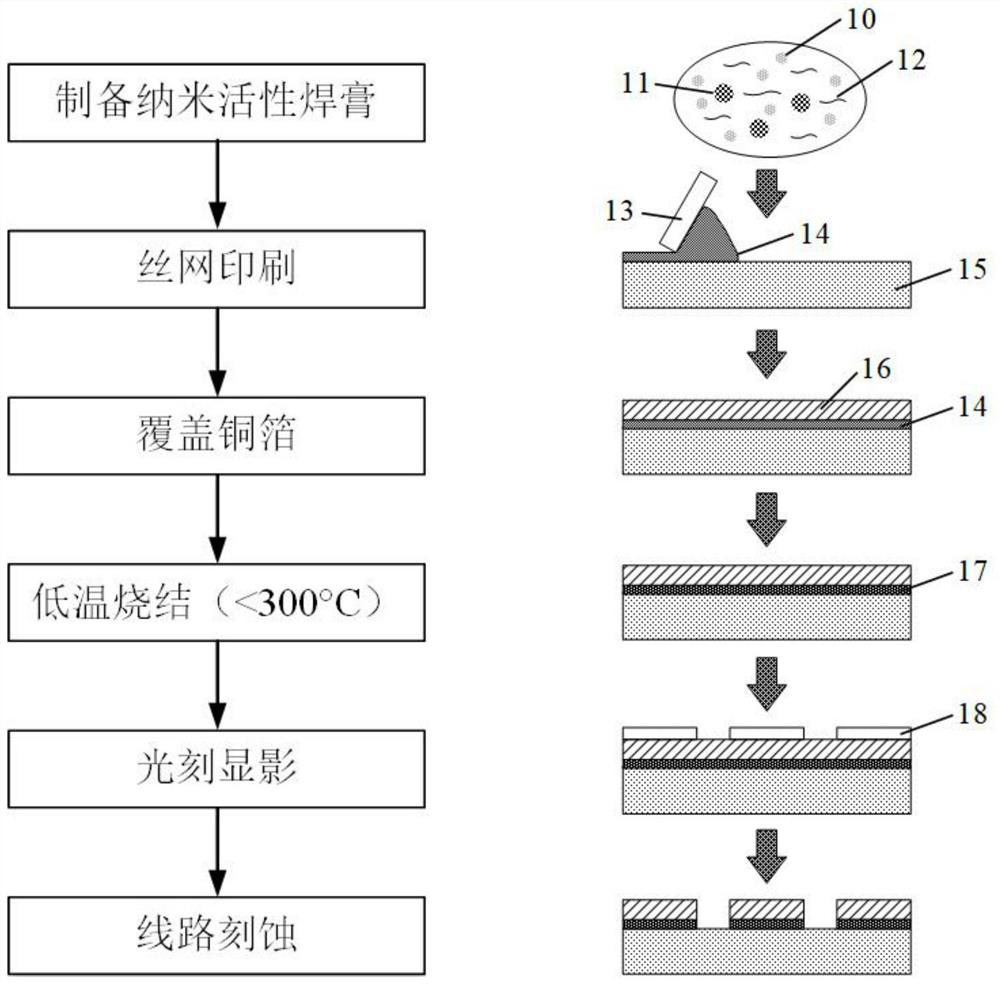

Method for preparing ceramic circuit board through low-temperature sintering

PendingCN113795091AAvoid destructionAvoid sizeInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentScreen printingOrganic solvent

The invention discloses a method for preparing a ceramic circuit board through low-temperature sintering, and the method comprises the steps: firstly adding active metal particles into nano metal particles, adding an organic solvent, and carrying out the stirring and defoaming treatment to obtain nano metal active soldering paste; coating the surface of the ceramic substrate with active soldering paste through silk-screen printing; covering copper foil on the active soldering paste layer, and carrying out the sintering at low temperature (less than 300 DEG C) to obtain the ceramic copper-clad plate; and finally, forming a pattern on the copper layer through photoetching, developing and etching processes to obtain a single-sided or double-sided ceramic circuit board. The copper foil and the ceramic substrate can be directly bonded by using the active metal element, and the nano metal particles are adopted to reduce the sintering temperature, so that the high-strength ceramic copper-clad plate is obtained. Compared with an existing preparation method of a thick film printing ceramic substrate (TPC), a direct bonding copper-ceramic substrate (DBC) and an active metal welding ceramic substrate (AMB), the preparation method is simple in process and low in sintering temperature, and meets the packaging and heat dissipation requirements of power devices.

Owner:HUAZHONG UNIV OF SCI & TECH +1

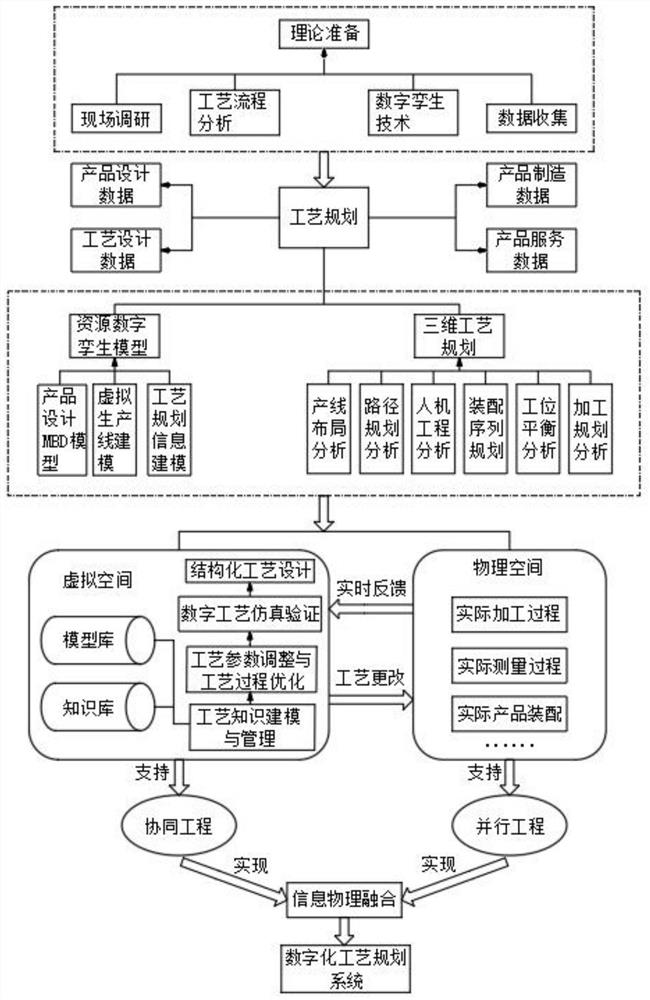

Manufacturing industry workshop process planning system based on digital twinning

PendingCN113673104AImprove consistencyImprove efficiency and qualityDesign optimisation/simulationResourcesProcess systemsManufacturing sector

The invention discloses a manufacturing industry workshop process planning system based on digital twinning, and relates to the field of workshop process planning. The digital twinning-based manufacturing workshop process planning system comprises theoretical preparation, process planning, a virtual space and a physical space, wherein the process planning is performed through the theoretical preparation, the virtual space and the physical space are established according to the process planning, the physical space is fed back to the virtual space in real time, and the virtual space performs process change on the physical space. The virtual space supports collaborative engineering, the physical space supports parallel engineering, the collaborative engineering and the parallel engineering realize information physical fusion, and a digital process planning system is established. According to the manufacturing workshop process planning system based on digital twinning, a simulation model of the virtual space and an entity of the physical space can be mutually mapped, seamless connection from design data to a process is achieved, the consistency of manufacturing and design data is improved through implementation of a three-dimensional process system, and efficiency and quality are improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Silver sol sintering oven for LED lamps

InactiveCN107860227AHigh efficiency of preparation processImprove sintering efficiencyTemperatue controlCharge treatment typeMetallurgyLED lamp

The invention discloses a silver sol sintering oven for LED lamps. A sintering mouth comprises a sintering mouth head, a sintering supporting rod and a supporting rod fixed to the sintering supportingrod. The sintering mouth head comprises a first sintering mouth head body and a second sintering mouth head body, the first sintering mouth head body rotates around the supporting rod, the second sintering mouth head body is fixed to the sintering supporting rod, the second sintering mouth head body and the first sintering mouth head body are both semispherical, the radius value of the second sintering mouth head body is smaller than that of the first sintering mouth head body, the second sintering mouth head body and the first sintering mouth head body are provided with a plurality of smallsintering mouths, the positions of the small sintering mouths correspond to dispensing positions, and the distances between the small sintering mouths and the corresponding dispensing positions are equal. A limiting tank is in sliding connection with the bottom of a sintering oven body and can move. Meanwhile, the first sintering mouth head body moves, the limiting tank is matched with the first sintering mouth head body, and thus a better preheating effect on LED lamps is achieved, and the situation that silver sol is suddenly heated and consequently the later curing effect is affected is prevented.

Owner:SICHUAN ZHONGYONG PHARMA CO LTD

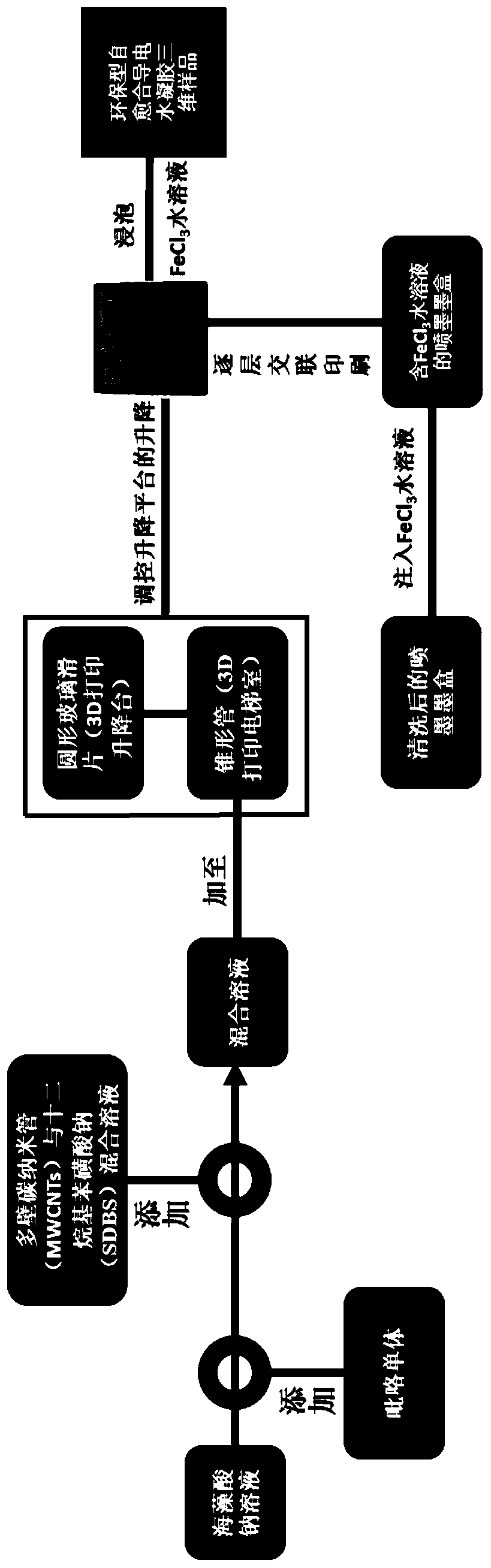

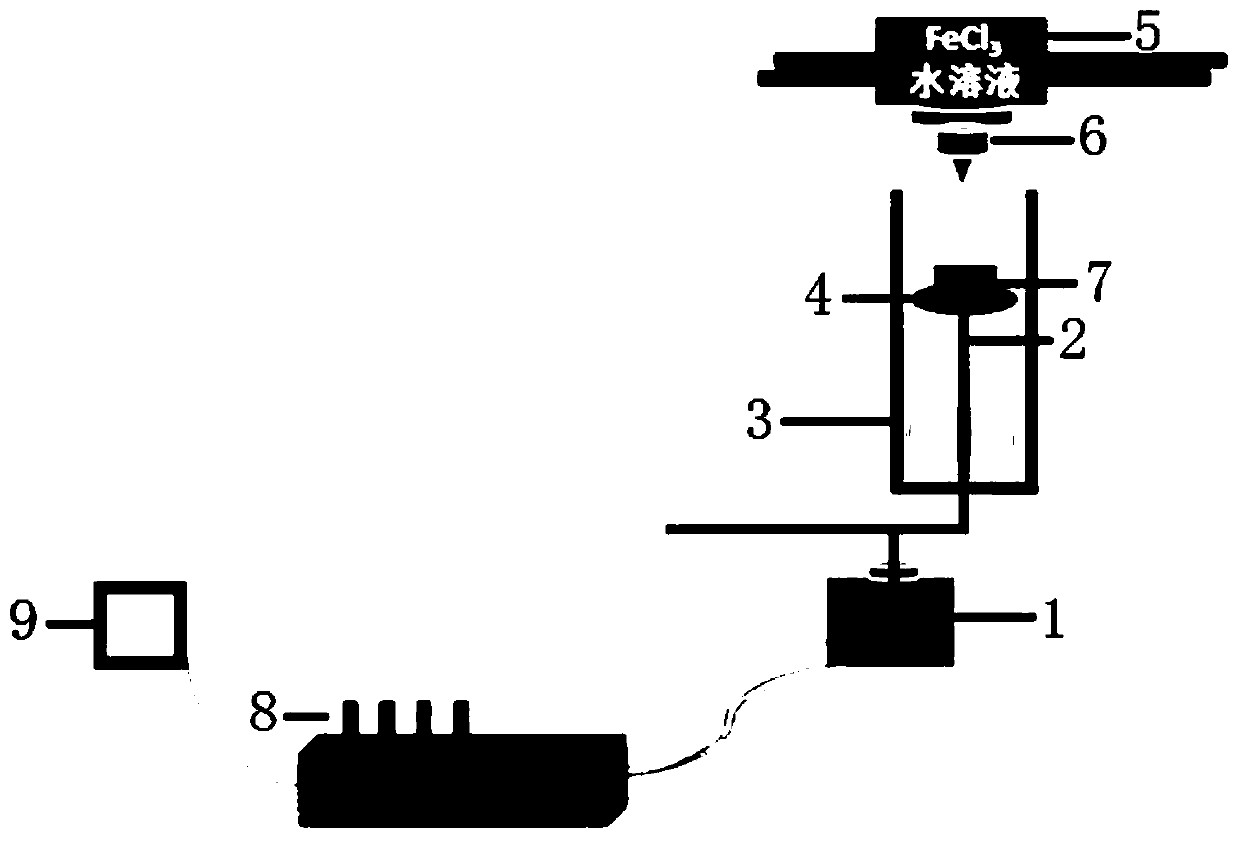

Preparation method of environment-friendly self-healing conductive hydrogel

PendingCN111333864AStrong mechanical propertiesGood mechanical propertiesAdditive manufacturing apparatusAdditive manufacturing with liquidsCarbon nanotubeConductive materials

The invention belongs to the field of conductive hydrogel, and particularly relates to a preparation method of environment-friendly self-healing conductive hydrogel. The process of the method is as follows. Preparing a sodium alginate aqueous solution as a solution A; adding a pyrrole monomer to form a solution B; adding a mixed solution C of sodium dodecyl benzene sulfonate and a multi-walled carbon nanotube to the solution B to form a solution D; adding the mixed solution D to the glass conical tube fixed with the circular glass slide sheet; carrying out cross-linking printing on the eCl3 solution to obtain an environment-friendly self-healing conductive hydrogel three-dimensional structure sample. According to the invention, sodium alginate is used as a matrix, and carbon nanotubes andpolypyrrole are used as conductive materials. The environment-friendly self-healing conductive hydrogel is prepared by adopting a 3D printing preparation process. According to the invention, the problems of poor conductivity, complex preparation process and unsatisfactory self-healing effect of the traditional conductive hydrogel are solved.

Owner:东北大学秦皇岛分校

Sintering baking oven with small sintering openings

InactiveCN107871807AHigh efficiency of preparation processImprove sintering efficiencySemiconductor devicesSilver colloidLED lamp

The invention discloses a sintering baking oven with small sintering openings. The sintering baking oven comprises a sintering baking oven, a sintering opening and a limiting groove matched with the sintering opening, wherein the sintering opening and the limiting groove are arranged inside the sintering baking oven; the sintering opening comprises a sintering opening head and a sintering supporting rod, the sintering opening head is in threaded connection with the sintering supporting rod, the sintering opening head is spherical, a plurality of small sintering openings are formed in the sintering opening head, the positions of the small sintering openings correspond to dispensing positions, and the distances between each small sintering opening and the corresponding dispensing position are the same; glass is adopted on one side wall of the sintering baking oven, and the glass is arranged on the side wall of the sintering baking oven facilitating to the observation of a silver colloidsintering condition. The small sintering openings corresponding to the dispensing positions are formed, compared with an existing sintering technology, the sintering efficiency in the technology is higher, each silver colloid can be solidified respectively, the solidification time is approximately the same, and the solidification time of the colloid at each position is different during integral sintering to cause that the sintering time is increased, so that the sintering time is also reduced in the technology, and the efficiency in the whole LED lamp preparation technology is improved.

Owner:SICHUAN ZHONGYONG PHARMA CO LTD

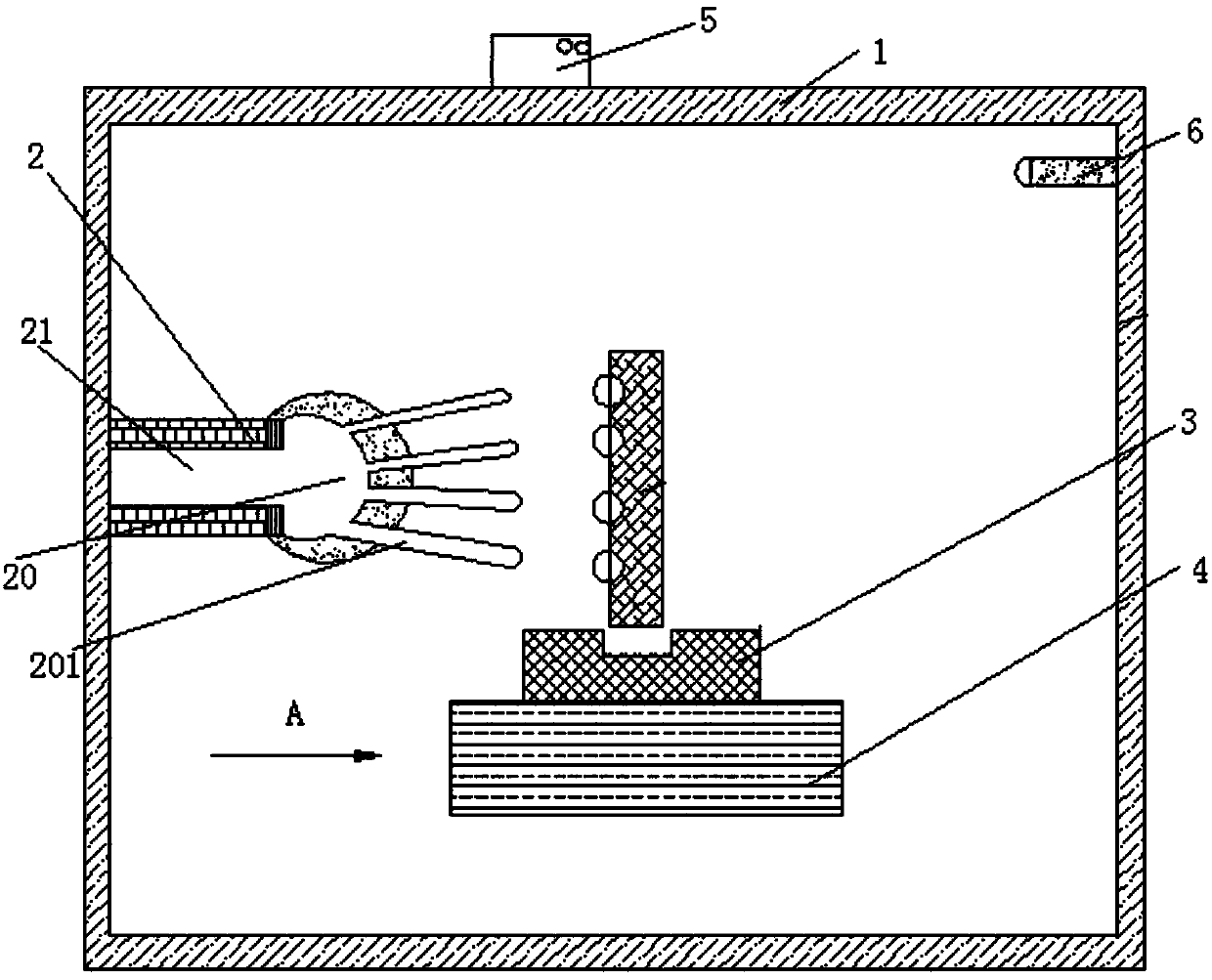

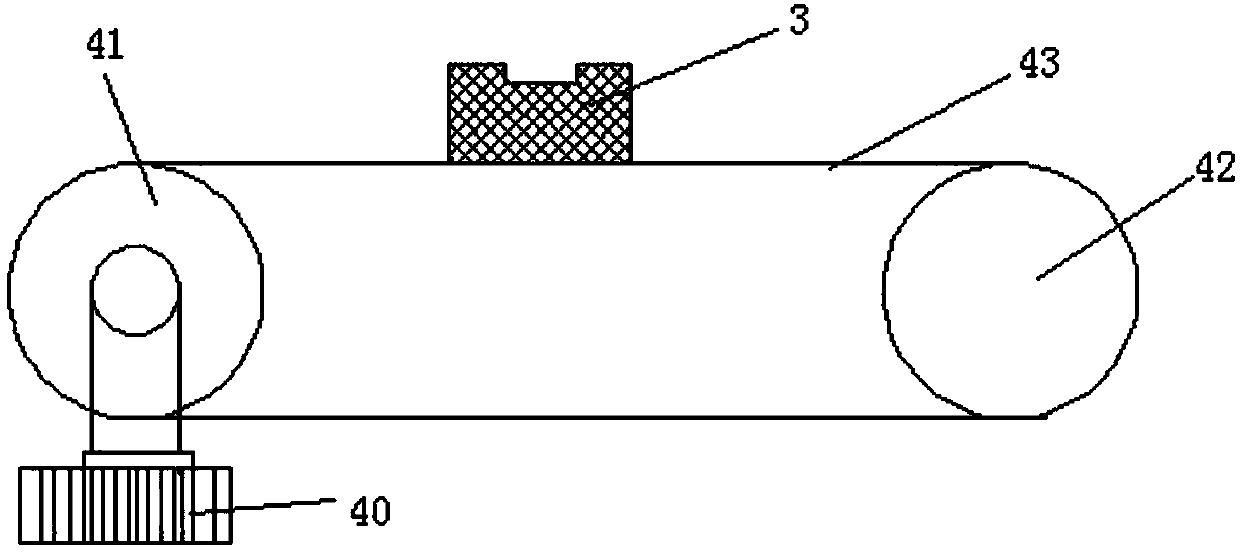

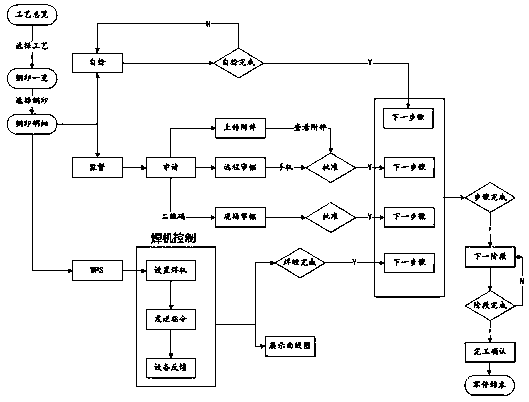

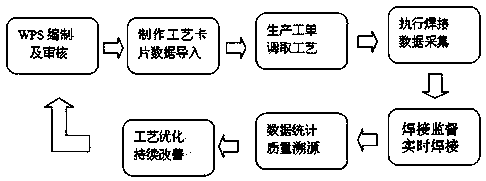

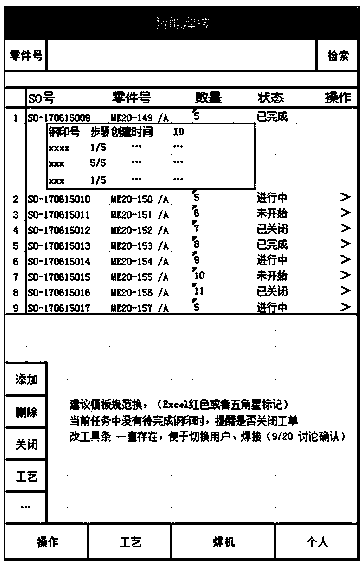

A method of intelligently managing the welding construction site

ActiveCN109202339BIntelligent managementEasy to writeWelding/cutting auxillary devicesAuxillary welding devicesWelding Procedure SpecificationProcess engineering

The invention discloses a method for intelligently managing a welding construction site. The method includes the steps of dividing various welding operation conditions and prior welding construction processes into standard process factors according to welding operation standards, coding the standard process factors, performing coding management, and storing coded information in an on-site weldingconstruction management database; during on-site welding construction, selecting process schemes from a process overview of the on-site welding construction management database by a computer, retrieving a corresponding code list, and performing welding construction after confirmation of code details; during welding construction, operation is realized in a manner of carrying out welding and inspection at the same time; retrieving welding procedure specifications according to coding information, sending operation information of the procedure specifications to operation management equipment to guide operators to conduct welding, and inspecting welding construction operations simultaneously; step-by-step welding construction operation is carried out in a manner of cross-operation of welding construction and real-time inspection.

Owner:WELL TECH ELECTRONIC TECH CHANGZHOU CO LTD

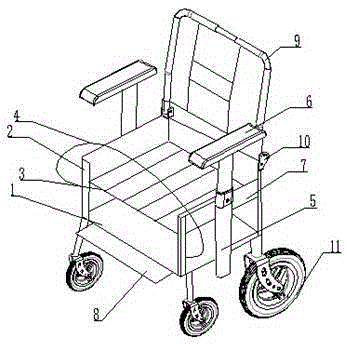

Child safety seat and manufacturing technology thereof

InactiveCN105253183AHumanized structure designEasy rideCarriage/perambulator accessoriesCarriage/perambulator with multiple axesManufacturing technologyEngineering

The present invention discloses a child safety seat; The child safety seat comprises a seat chassis; four seat columns are respectively fixed on four sides of the seat chassis; a seat frame is fixedly disposed among the seat columns; a sponge cushion is fixed on the seat frame; and a safety belt is disposed between the two front seat columns. The manufacturing technology of the child safety seat comprises manufacture of each part and assembly of the integral body. The child safety seat has humanized structure design and is high in security coefficient, and children can ride the child safety seat conveniently. The manufacturing technology of the child safety seat is high in technology manufacturing efficiency, and pipelining production is achieved.

Owner:太仓市中峰模具塑胶有限公司

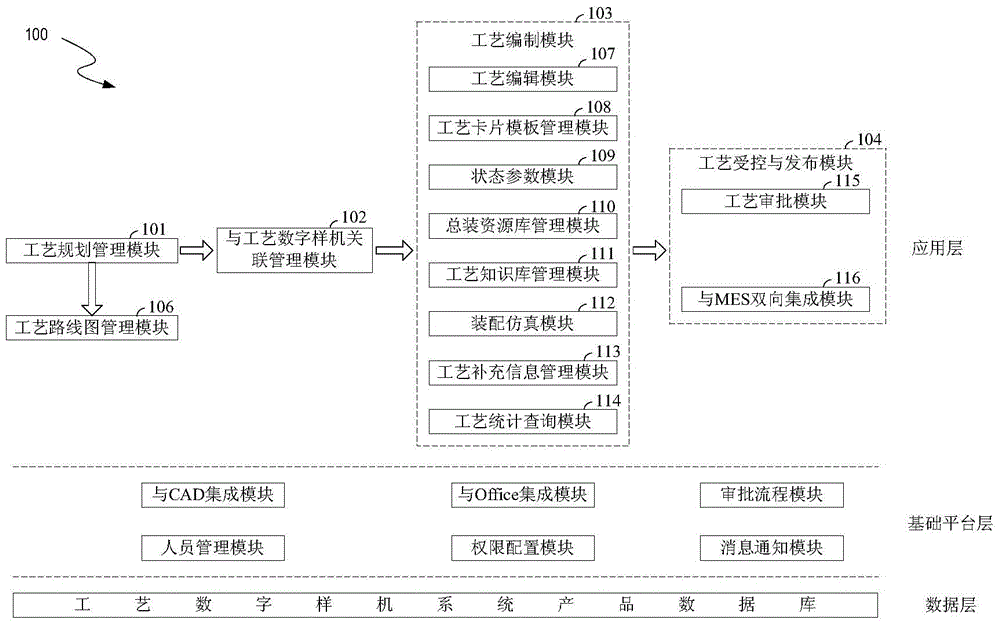

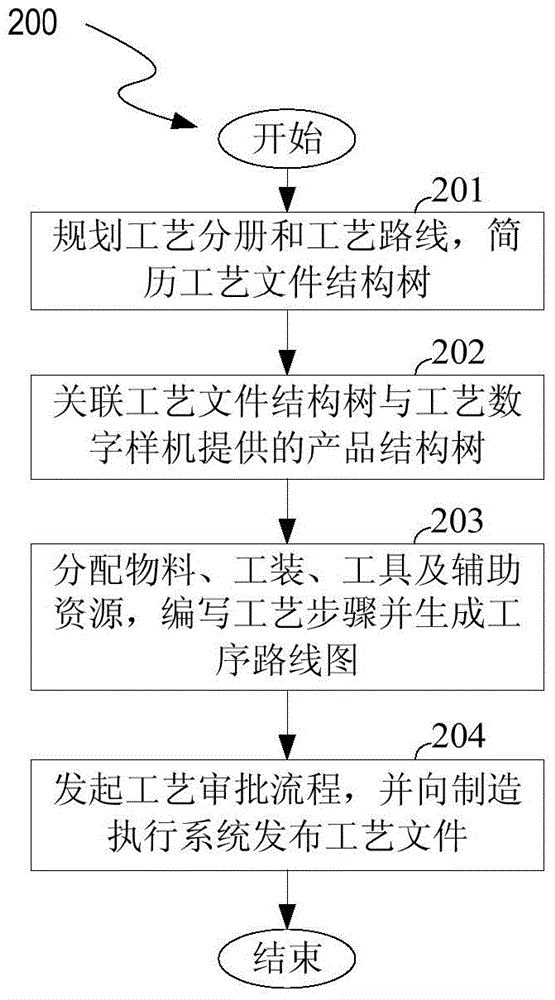

Three-dimensional structured process design system and design method for spacecraft assembly

InactiveCN103605857BClosely relatedRealize the structureSpecial data processing applicationsManufacture execution systemComputer module

The invention discloses a spacecraft assembly oriented three-dimensional structured process design system and method. The three-dimensional structured process design system comprises a process planning management module, a process digital prototype associated management module, a process compiling module, a process controlled and publishing module. The process planning management module is used for planning process volumes and a process route and establishing a process file structure tree; the process digital prototype associated management module is used for being associated to the process file structure tree and a product structure tree provided by a process digital prototype; the process compiling module is used for allocating materials, tooling, tools and auxiliary resources, compiling process sequences and generating a working procedure route map; the process controlled and publishing module is used for initiating a process approval flow and publishing process files to a field manufacturing execution system. By the spacecraft assembly oriented three-dimensional structured process design system and method, the process digital prototype is taken as a unique data source, close association between the process file structure tree and the product structure tree is realized, and process compiling efficiency is improved by taking typical process statements as templates.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

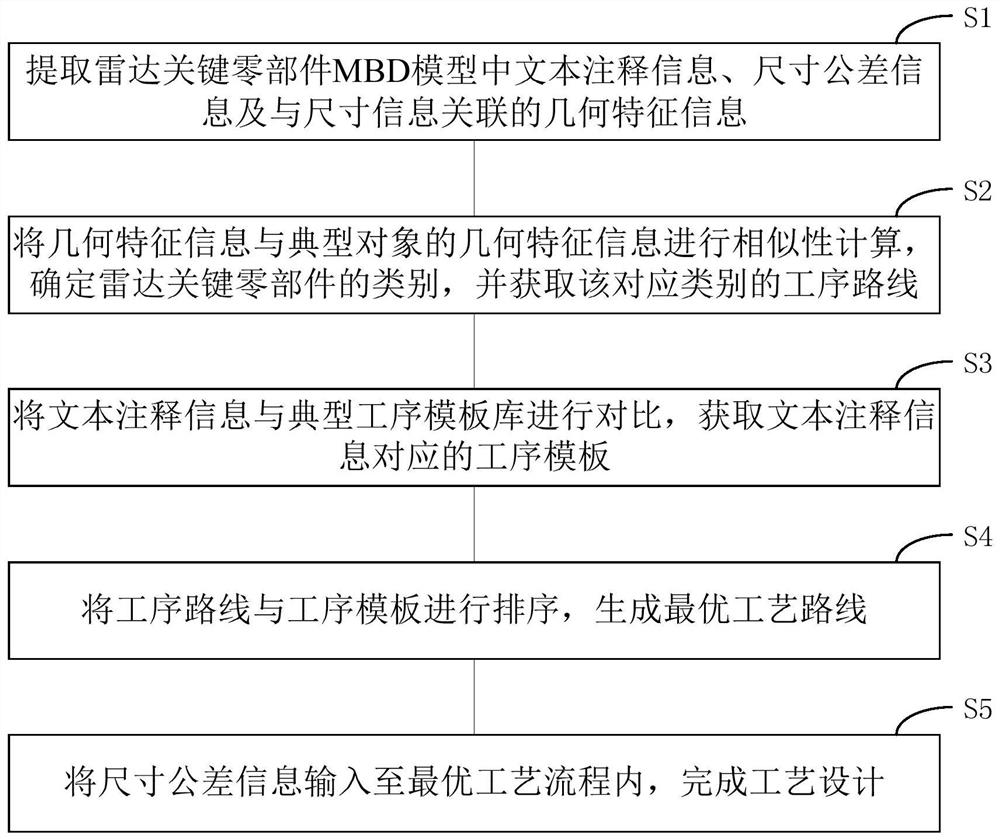

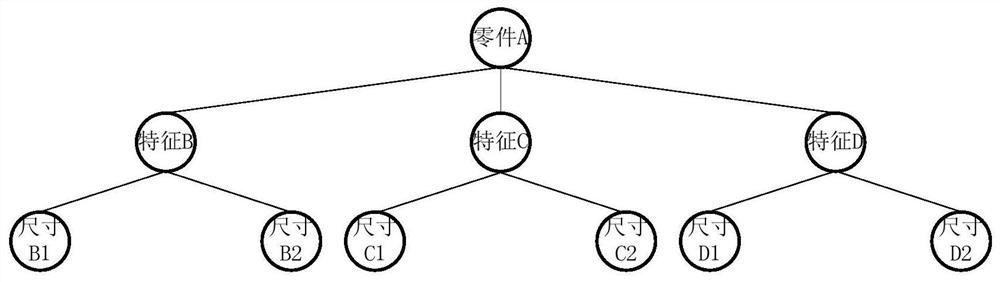

Radar key part process design method based on PMI information

PendingCN112001047AReduce error rateImprove efficiencyGeometric CADDesign optimisation/simulationText annotationEngineering

The invention provides a radar key part process design method based on PMI information. The method comprises: extracting text annotation information, dimensional tolerance information and geometric feature information associated with the dimensional tolerance information in a radar key part MBD model; carrying out similarity calculation on the geometrical characteristic information and the geometrical characteristic information of the typical object, determining the category of the radar key part, and obtaining a process route of the corresponding category; comparing the text annotation information with a typical process template library to obtain a process template corresponding to the text annotation information; sorting the process route and the process template to generate an optimal process route; and inputting the dimensional tolerance information into the optimal technological process, and completing technological design. According to the method, the process route is obtained byevaluating the feature similarity of the target part and the typical part, the process content is inferred according to the PMI information, meanwhile, the geometric tolerance information is directlycalled, the error rate of information input is reduced, and the process design efficiency is improved.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

Stable dispensing and high-efficiency sintering integrated device for LED lamp

InactiveCN107910429AHigh efficiency of preparation processImprove sintering efficiencySemiconductor/solid-state device manufacturingSemiconductor devices for light sourcesSilver pasteSilver colloid

The invention discloses an integrated device for stable glue dispensing and high-efficiency sintering of an LED lamp, wherein the burner head includes a first burner head and a second burner head, the first burner head rotates around a support rod, and the second burner head is fixed on the burner On the rod, both the second burner head and the first burner head are hemispherical, the radius of the second burner head is smaller than the radius of the first burner head, and there are several small burners on the second burner head and the first burner head, The position of the small burners corresponds to the dispensing position, and the distance between each small burner and the corresponding dispensing position is equal; the station slot and the junction oven are detachably connected. While preheating the LED lamp to prevent the silver glue from being suddenly heated to affect the curing effect in the later stage, the station slot and the LED lamp are put into the sintering oven together, which avoids placing the LED lamp in the sintering oven after dispensing the glue in the prior art. In the station tank, since the silver glue is colloidal, care must be taken during the security process. At the same time, during the installation process, the station tank is in the sintering oven, which is inconvenient to install.

Owner:成都易活动科技有限公司

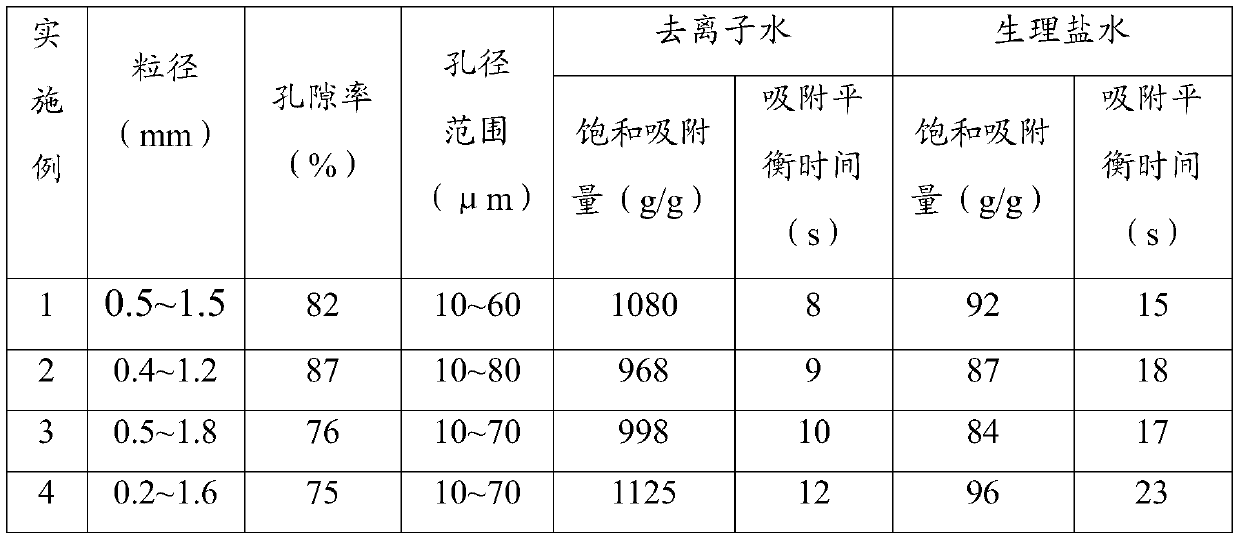

Method for synchronously preparing high water absorption rate polymer through integrated polymerization, pore formation and pelleting

InactiveCN110003391AHigh efficiency of preparation processHigh polymerization efficiencyAbsorption ratePolymeric surface

The invention discloses a method for synchronously preparing a high water absorption rate polymer through integrated polymerization, pore formation and pelleting. The method comprises the following steps: by taking olefine acid salts, olefine acid monomers and a grafting polymer as polymerization monomer mixtures, an initiation system as a water-soluble oxidant and a natural product reducing agent, carrying out compounding so as to obtain the polymer, and putting the polymer into a cooling device to reduce the temperature of the system, wherein the system has no chemical change at the moment;in preparation, putting a suspension medium and a dispersant into the reaction system, reducing the temperature of the reaction system to minus 15 DEG C to minus 20 DEG C to initialize completion of apolymerization reaction, carrying out a constant temperature reaction to complete polymerization, depositing generated spherical polymer granules to the bottom, separating so as to obtain polymer granules, melting at the normal temperature, finally, dehydrating and drying by using a dehydration agent, thereby obtaining a product. By adopting the method for synchronously preparing the high water absorption rate polymer through integrated polymerization, pore formation and pelleting, synchronous completion of polymerization reactions, pore forming and pelletizing, later pore formation and preprocessing can be avoided, and the liquid absorption rate of a liquid can be greatly increased because of uniform and continuous pores in the surface and inside the prepared super high water absorptionrate polymer.

Owner:LIMING VOCATIONAL UNIV

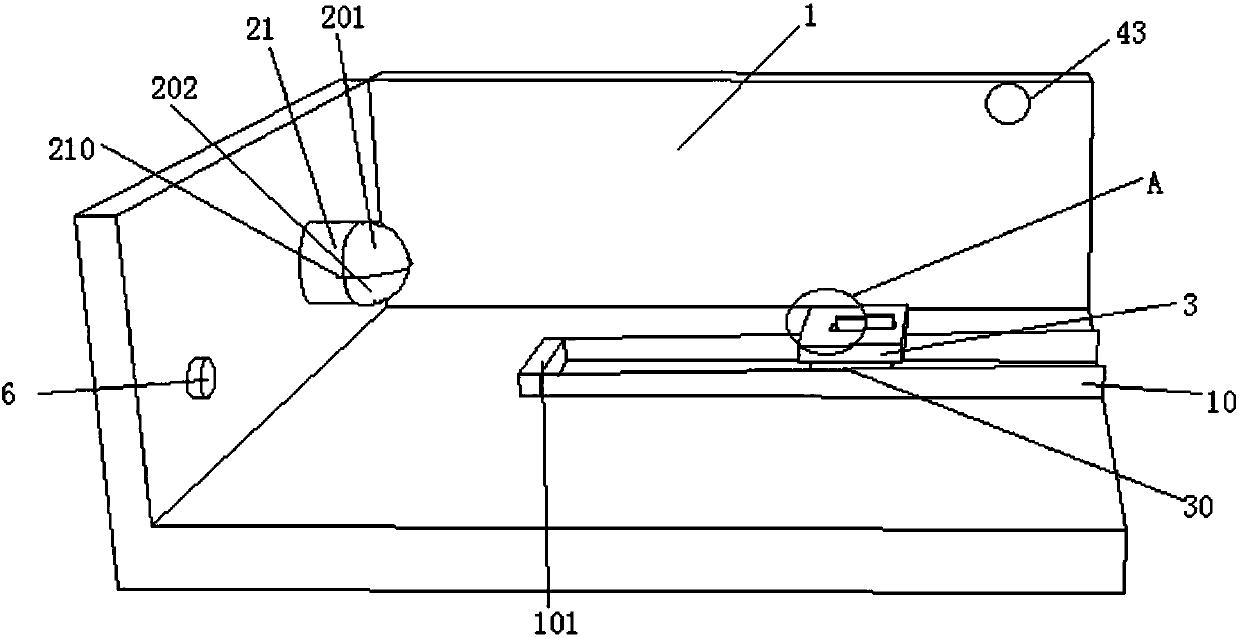

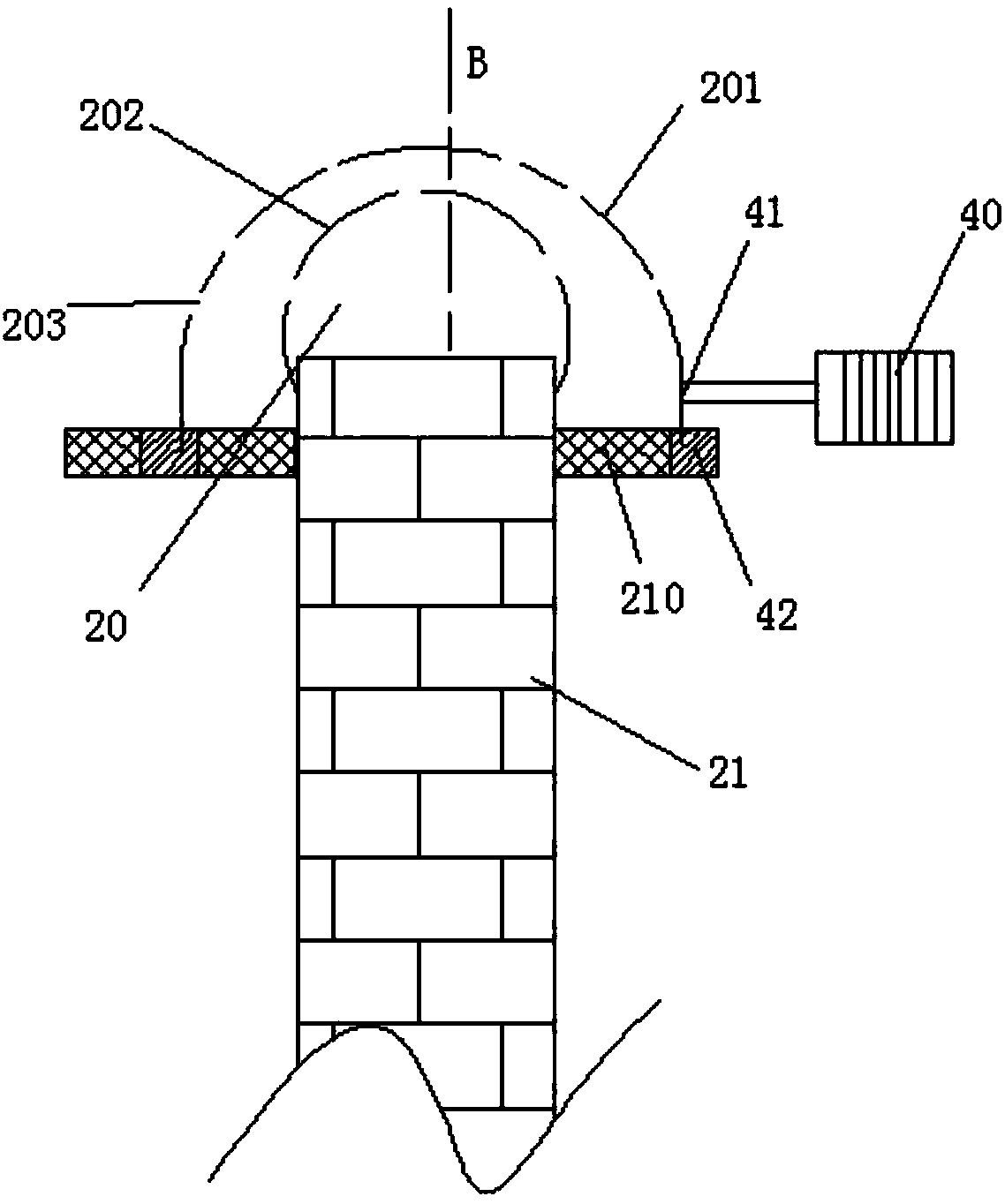

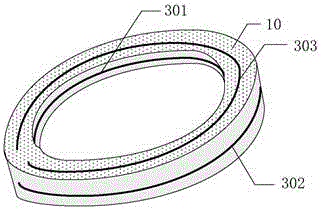

Retaining ring and polishing head

ActiveCN103639888BHigh efficiency of preparation processAccurate self-testLapping machinesWork carriersSemiconductor chipChip carrier

The invention relates to a fixing ring used in a chemical mechanical polishing device. The chemical mechanical polishing device comprises a polishing disk and a polishing head. The polishing head comprises a chip carrier and the fixing ring, wherein the chip carrier is used for clamping a semiconductor chip, the polishing disk makes contact with the chip, and the polishing disk and the polishing head rotate in opposite directions respectively to polish the chip. The fixing ring comprises an annular base, at least one easy-to-break lead, an on-off state detection device and a signal processing device, wherein the annular base is arranged below the chip carrier, surrounds the side surface of the chip and is used for fixing the chip; the easy-to-break leads are fixed to the surface of the annular base, extend in the perimeter direction of the annular base and surround the annular base by one circle; the on-off state detection device is connected with all the easy-to-break leads respectively and sends an alerting signal when any easy-to-break lead is broken; the signal processing device is connected with the output end of the on-off state detection device and converts the alerting signal into a polishing stop signal which is used for instructing the polishing head and the polishing disk to stop rotating. The chemical mechanical polishing device can effectively lower loss of a technology caused by the fracture of the fixing ring, thereby being beneficial to the improvement of wafer preparation technological efficiency.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

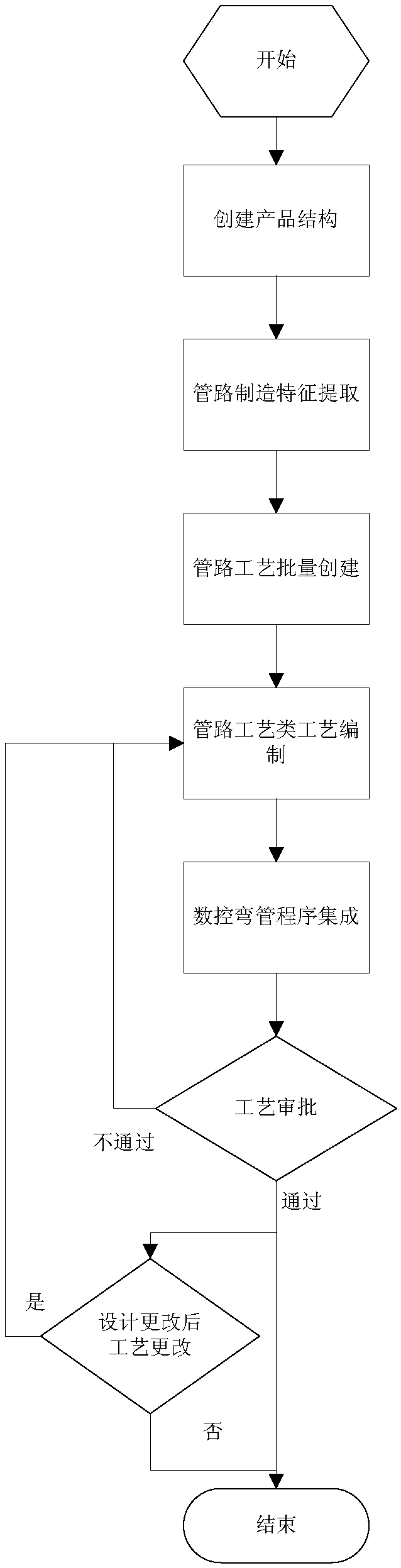

Pipeline welding process batch planning system and method based on characteristics

ActiveCN109583050AImprove normativeHigh efficiency of preparation processGeometric CADSpecial data processing applicationsProcess engineeringManufacturing engineering

The invention discloses a pipeline welding process batch planning system and method based on characteristics. The method comprises the following steps of Firstly creating a product structure accordingto tasks and descriptions; performing Product structure version, STATE, EFFICIENCY MANAGEMENT, extracting manufacturing characteristics and then associating with a product structure; selecting a product structure according to the current task to create a pipeline welding process; executing the batch creation of the pipeline welding process; planning the process content of each pipeline welding process; specific process contents are further completed; a numerical control pipe bending procedure is integrated for a pipeline welding process; The method comprises the following steps of: directly extracting manufacturing characteristics as project contents of actual measurement records in an output actual measurement record chart according to related process contents, pipeline manufacturing characteristics and a corresponding relation between the pipelines and welding seams in pipeline welding processes as required, and finally, carrying out approval control on the pipeline welding processes and carrying out version control on the processes related to the pipelines.

Owner:BEIJING SATELLITE MFG FACTORY

High-temperature-resistant oxidation-resistant roller shutter door and preparation process thereof

The invention discloses a high-temperature-resistant oxidation-resistant roller shutter door and a preparation process thereof. The high-temperature-resistant oxidation-resistant roller shutter door comprises a roller shutter door and is characterized in that a protective layer coats on the surface of the roller shutter door, and the protective layer comprises the following components: 115-120 parts of glass powder, 15-25 parts of an ethylene-tetrafluoroethylene copolymer, 3-7 parts of a flatting agent, 15-22 parts of a binder, 6-9 parts of an antioxidant, 18-20 parts of epoxy resin, 38-42 parts of water, and 11-19 parts of composite rare earth. According to the invention, the service life of the roller shutter door is prolonged, and potential safety hazards in life are reduced.

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

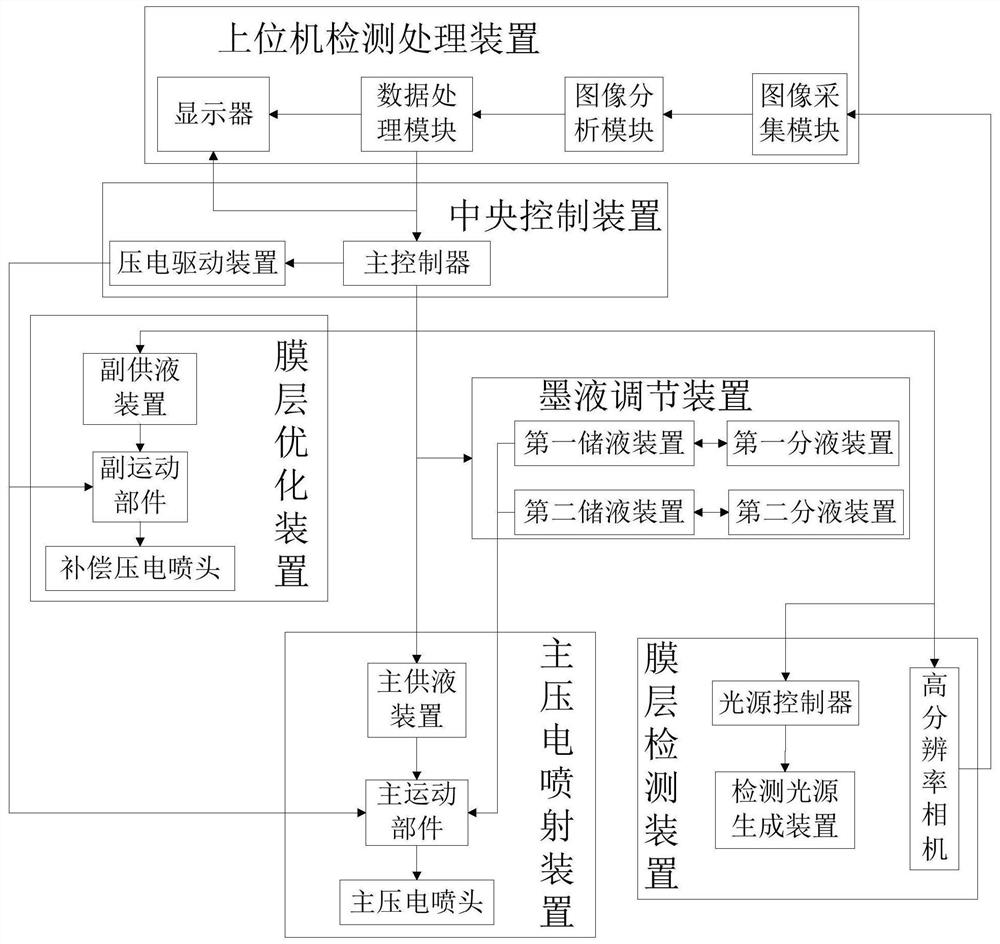

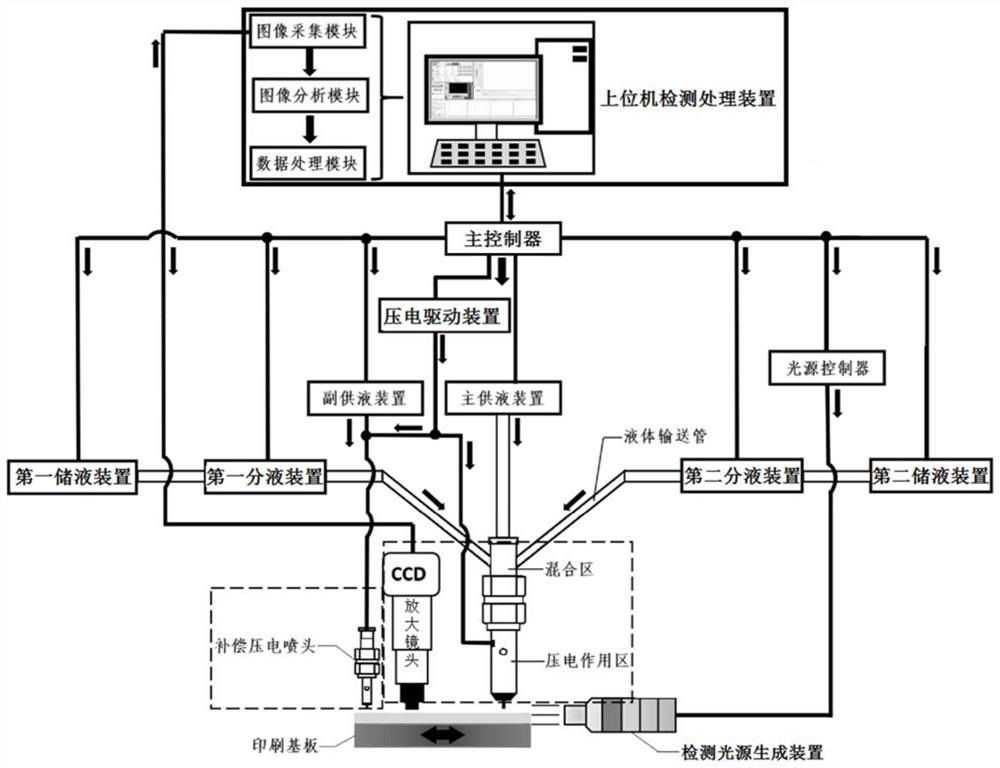

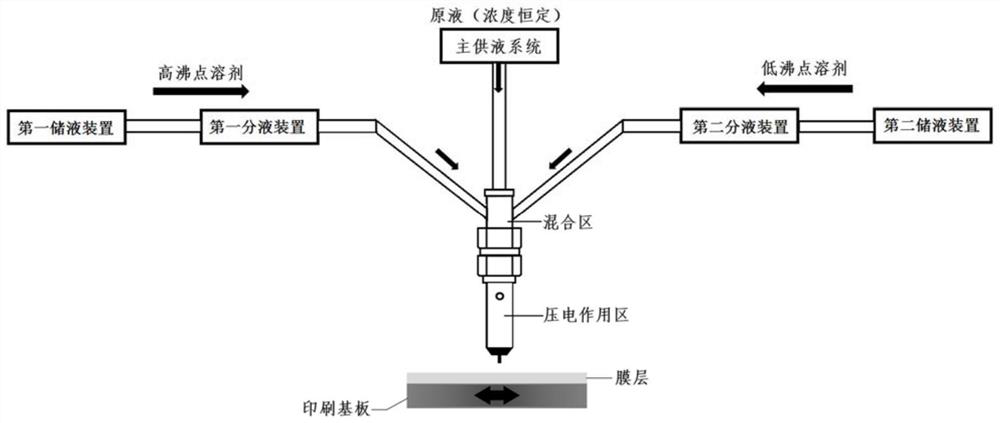

A piezoelectric control system and method for printing and preparing high-uniform device film layers

ActiveCN113210158BImprove stabilityAchieve film quality optimization effectSpraying apparatusControl systemEngineering

The invention discloses a piezoelectric control system and method for printing and preparing a high-uniform device film layer. The system includes: a central control device, a main piezoelectric injection device and an ink adjustment device, a main piezoelectric injection device, and an ink adjustment device They are respectively connected to the central control device; the central control device is equipped with a main controller and a piezoelectric drive device, the main controller is used to generate and transmit printing instructions to control the printing process of ink and electric nozzles, and the piezoelectric drive device is used to drive the main pressure The electrospray device; the ink adjustment device is provided with a first liquid dispensing device and a second liquid dispensing device, and the first liquid dispensing device and the second liquid dispensing device adjust the delivery rate of the solvent and set the total flow to maintain a constant value. The present invention controls the solvent volatilization of ink droplets sprayed in different time periods by changing the delivery volume of the first solvent and the second solvent respectively through the first liquid distributing device and the second liquid dispensing device, so that the ink droplets sprayed before and after show a difference in boiling point gradient, The technical effect of further improving the uniformity of film formation.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com