Preparation method of environment-friendly self-healing conductive hydrogel

A conductive hydrogel, self-healing technology, applied in the direction of processing and manufacturing, manufacturing auxiliary devices, liquid material additive processing, etc., can solve the problems of complex preparation process, poor electrical conductivity, unsatisfactory self-healing effect, etc. Excellent one-dimensional nanostructure, excellent electrical conductivity, ideal self-healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

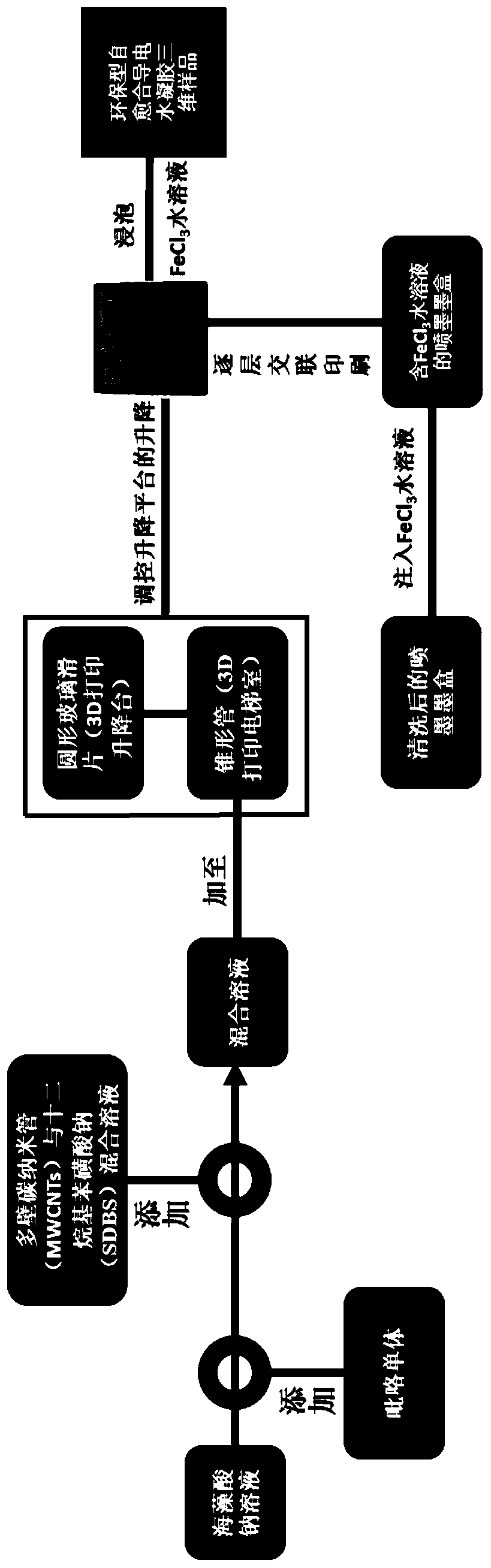

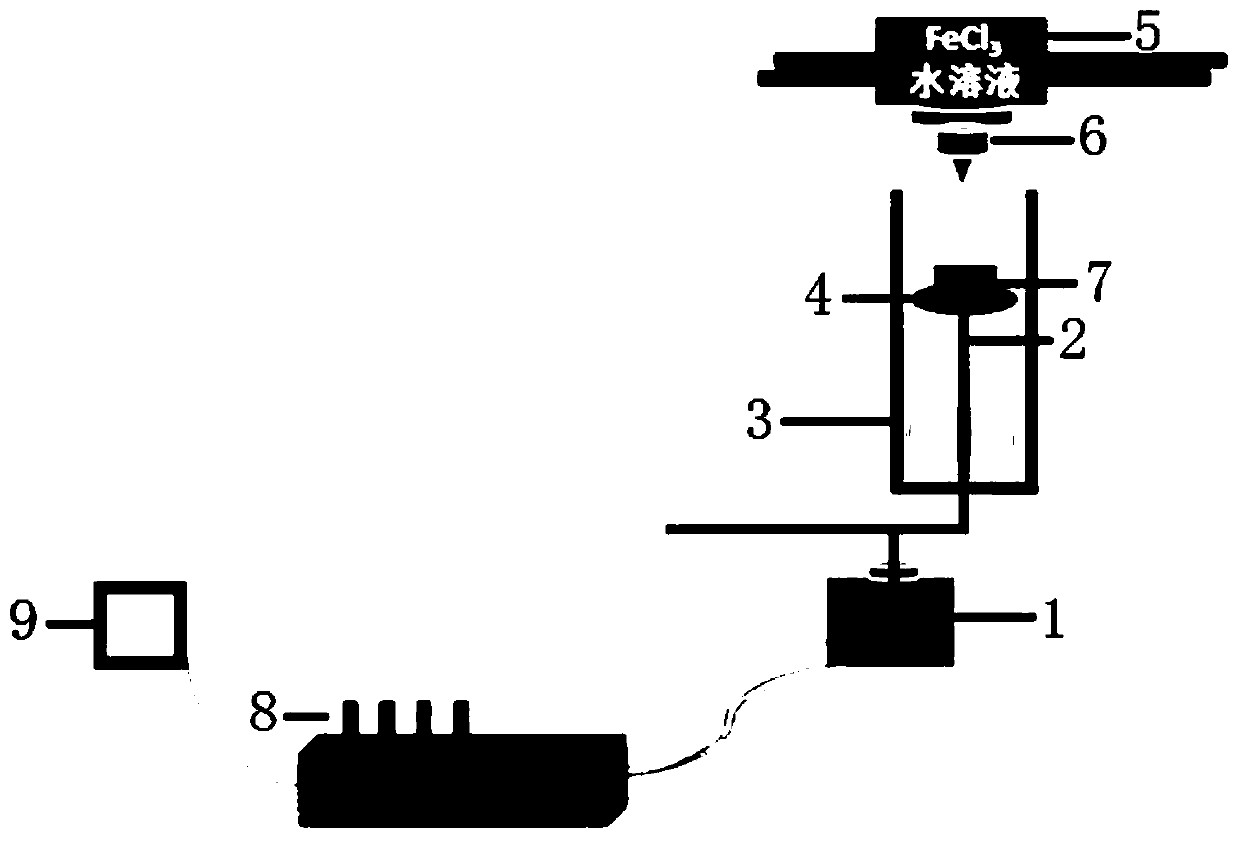

[0041] In this embodiment, the preparation method of environment-friendly self-healing conductive hydrogel comprises the following steps:

[0042] (1) Take a 100ml beaker, weigh 0.025g of sodium alginate at room temperature and add it to the beaker, add 20ml of deionized water into it, stir at a constant temperature in a water bath at 65°C for 2 hours, and record it as solution A;

[0043](2) Add 0.4 g of pyrrole monomer to the beaker of solution A in step (1), and ultrasonically disperse the resulting mixed solution in an ultrasonic instrument for 15 minutes, and record it as solution B;

[0044] (3) Take 3g of sodium dodecylbenzenesulfonate (SDBS) (mass ratio SDBS:MWCNTs=3:1) in deionized water, add 1g of multi-walled carbon nanotubes (MWCNTs) to it, and the resulting mixed solution is ultrasonically Ultrasonic dispersion in the instrument for 50 minutes to form solution C;

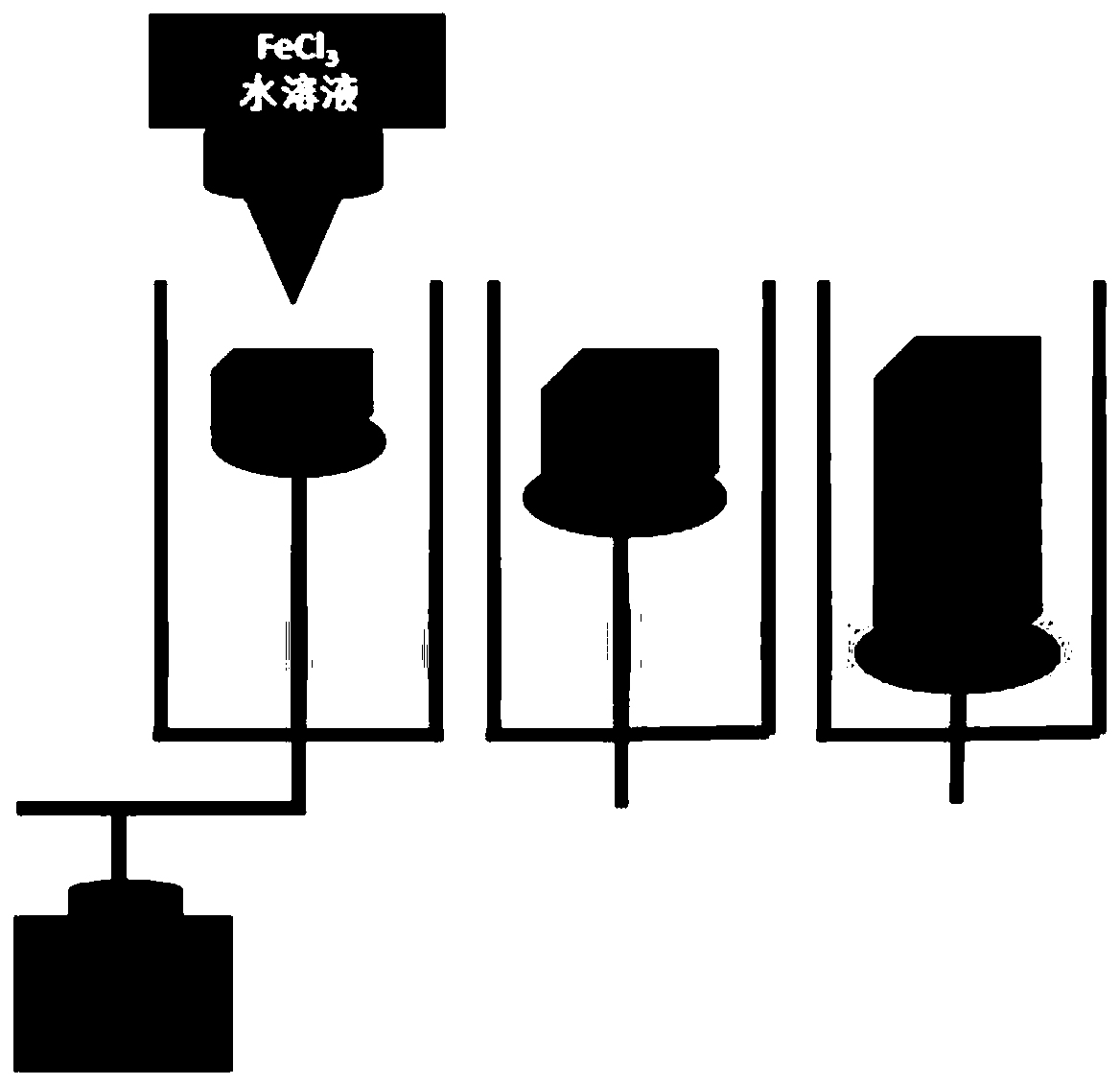

[0045] (4) Mix solution B in step (2) with solution C in step (3), and ultrasonically disperse the ...

Embodiment 2

[0055] The difference from Example 1 is: in step (3), sodium dodecylbenzenesulfonate (SDBS):multi-walled carbon nanotubes (MWCNTs)=2:1, and the others are the same as in Example 1.

Embodiment 3

[0057] The difference with Example 1 is: in step (9), get the FeCl of molar concentration 0.2mol / L 3 Aqueous solution 1.5ml, other are all the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com