Stable dispensing and high-efficiency sintering integrated device for LED lamp

A technology for LED lamps and LED lamp brackets, applied in lighting devices, semiconductor devices of light-emitting elements, semiconductor devices, etc., can solve the problems of prolonging the sintering time, affecting the curing process, slow sintering efficiency, etc., so as to reduce the sintering time and improve the process. High efficiency and high sintering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

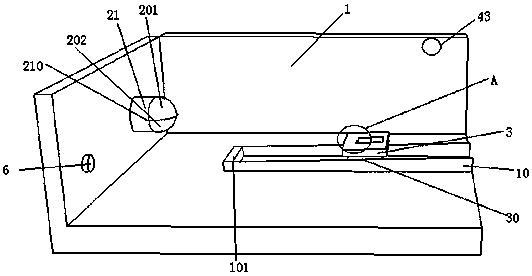

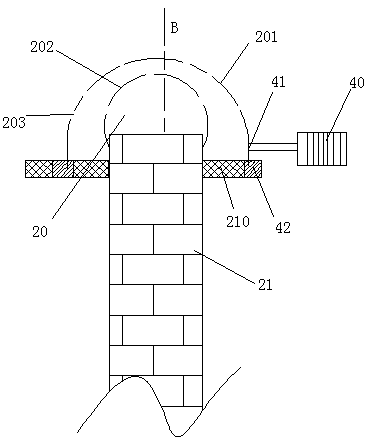

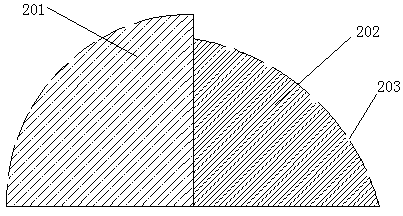

[0024] Such as Figure 1-4 As shown, an integrated device for stable glue dispensing and high-efficiency sintering of LED lamps, including a sintering oven 1, a burner 2, and a station slot 3 matched with the burner 2, the burner 2 and the station slot 3 are arranged in the sintering Inside the oven 1, the burner 2 includes a burner head 20, a burner rod 21, the burner head 20 includes a first burner head 201, a second burner head 202 and a support rod 210 fixed on the burner rod 21, and the burner head 2 includes a first The burner head 201, the second burner head 202, the first burner head 201 rotates around the support rod 210, the rotating mechanism includes a motor 40, a connecting rod 41, a bearing 42 and a controller 43, the output shaft of the motor 4 is connected with the connecting rod 41, and the One end of the rod 41 is connected to the bearing 42, the other end of the connecting rod 41 is fixed on the first burner head 201, the bearing 42 is fixed on the support r...

Embodiment 2

[0027] On the basis of the stable glue dispensing and high-efficiency sintering integrated device of an LED lamp described in Example 1, it is further optimized. A temperature sensor 6 is provided on the inner wall of the sintering oven 1, and a furnace connected to the burner 2 is provided in the sintering oven 1. The heater, the controller 43 are electrically connected with the temperature sensor 6 and the heater respectively. The controller 43 controls the heater to control the temperature in the sintering oven 1 at 150-170° C. to meet the sintering temperature process.

Embodiment 3

[0029] On the basis of the stable glue dispensing and high-efficiency sintering integrated device of an LED lamp described in Example 2, it is further optimized. The side wall of the sintering oven 1 is made of glass, and the glass is arranged on the side of the sintering oven 1 that is convenient for observing the sintering of the silver glue. on the wall. It is convenient to observe the curing condition of the silver glue, and to adjust the sintering process in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com