Retaining ring and polishing head

A fixed ring and polishing head technology, which is applied in the direction of grinding devices, grinding machine tools, working carriers, etc., can solve problems such as damage, increased production costs, and decreased production efficiency, and achieve the effects of reducing production costs, reducing losses, and improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] It should be noted that the chemical mechanical polishing device includes a polishing disc and a polishing head, wherein the polishing head includes a wafer carrier and a fixed ring, and the wafer carrier is used to clamp a semiconductor wafer. The direction of rotation is carried out, chemical reaction and mechanical processing are carried out in this process, and the polishing process is carried out on the wafer.

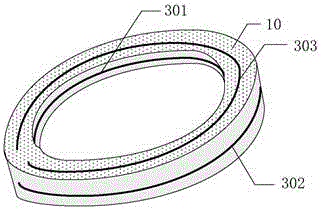

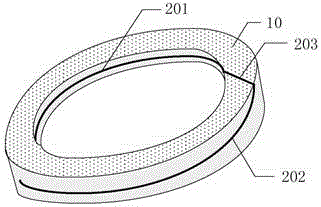

[0023] Such as Figure 2A and Figure 2B As shown, the chemical mechanical polishing fixing ring provided by the first embodiment of the present invention is used in a chemical mechanical polishing device. ) below, around the side surface of the wafer, for fixing the wafer; a frangible wire 20, which is fixed on the surface of the annular base 10, extends along the circumferential direction of the annular base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com