Pipeline welding process batch planning system and method based on characteristics

A technology of batch process and welding process, applied in special data processing applications, instruments, geometric CAD, etc., can solve the problems of low efficiency of spacecraft pipeline welding process design, and achieve the effect of improving normative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

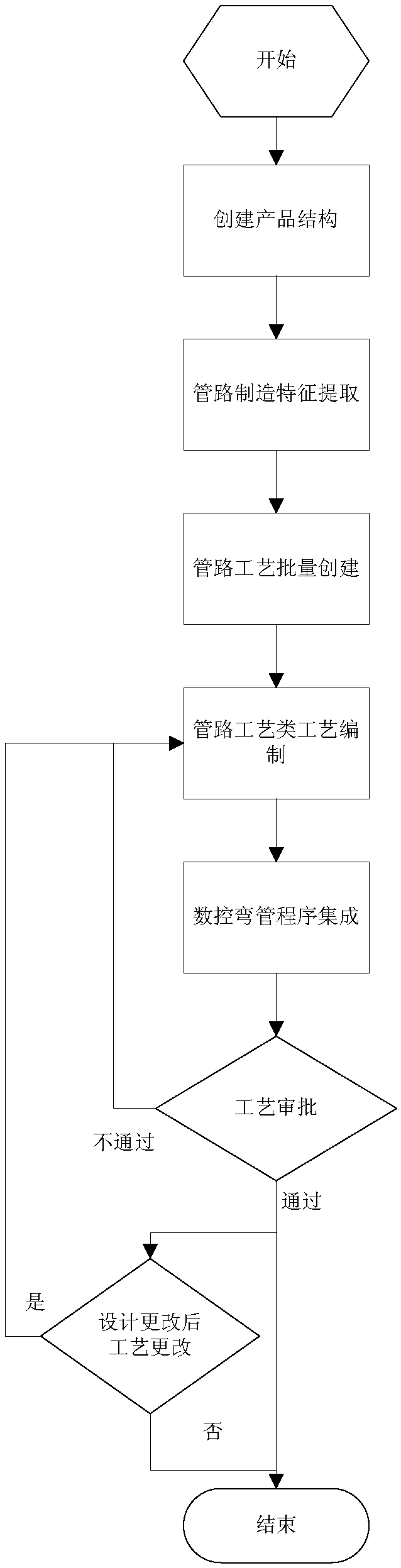

[0052] A welding process batch planning method for spacecraft pipeline products, the steps are:

[0053] Step 1: The pipeline model receiving module (1), according to the mission requirements of the spacecraft model, receives the low-temperature internal circuit pipeline grouping of the TGWT model under the medium work cabin (mainly composed of joints, nuts, conduits, and welds), and creates model pipeline products PBOM node TGWT_X-10 / A-work cabin low temperature inner circuit pipeline group 1, TGWT_X-20 / A-work cabin low temperature inner circuit pipeline group 2, TGWT_X-30 / A-work cabin low temperature inner circuit pipeline group 3, TGWT_X-10 is the product code, A is the node version, and the grouping of the low-temperature internal circuit piping in the working cabin is the Chinese name;

[0054] Step 2: The pipeline model feature extraction module (2) extracts the manufacturing features of the model according to the effective model obtained in step 1, and uses the manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com