Radar key part process design method based on PMI information

A technology of process design and parts, applied in the field of process design of key radar parts based on PMI information, can solve the problems of low level of intelligence in process design, different process routes, and inconsistent process route planning, so as to improve efficiency and intelligence The level of optimization, the improvement of error correction rate, and the effect of reducing error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

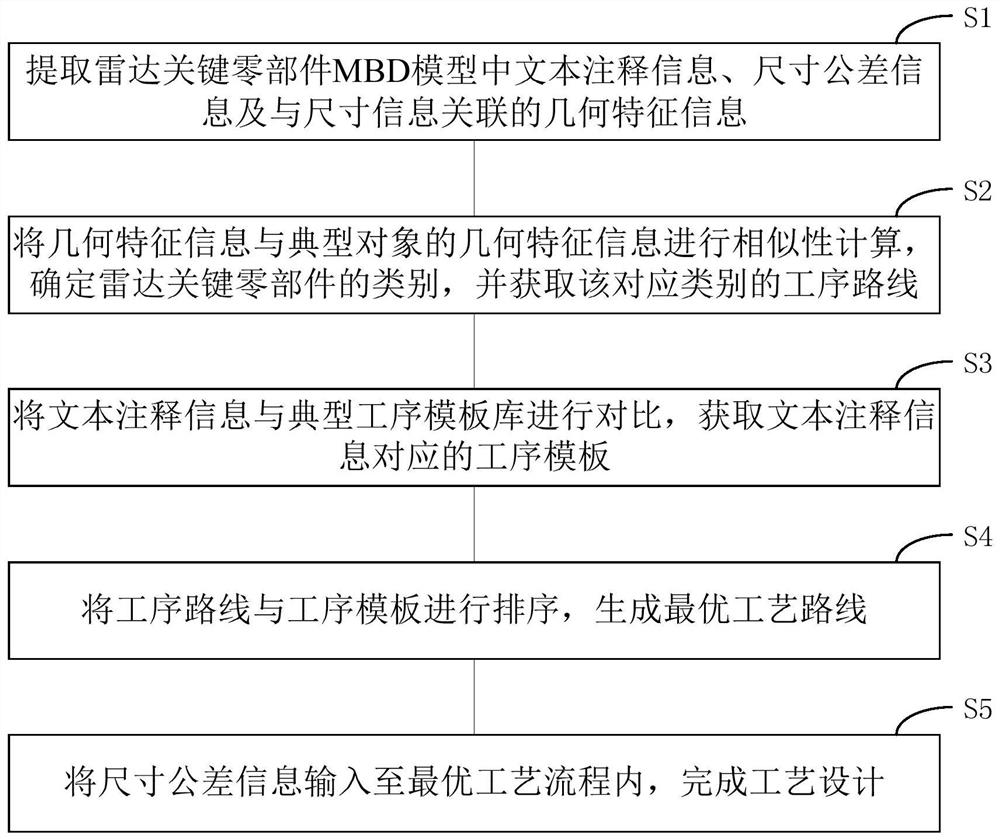

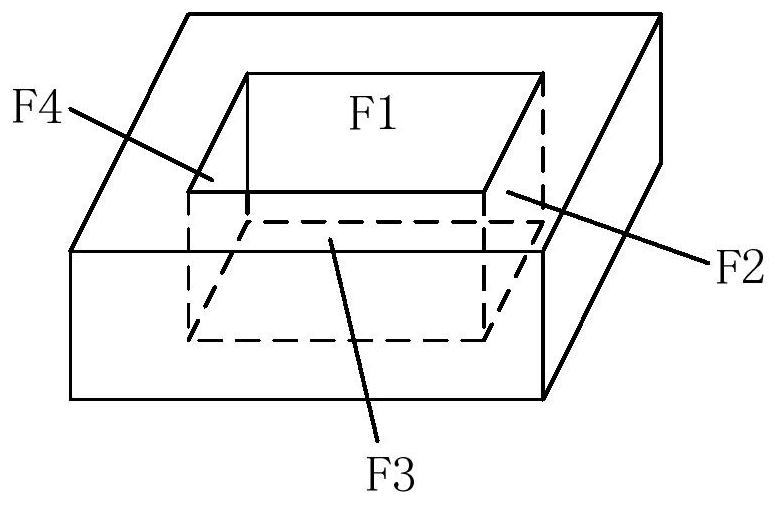

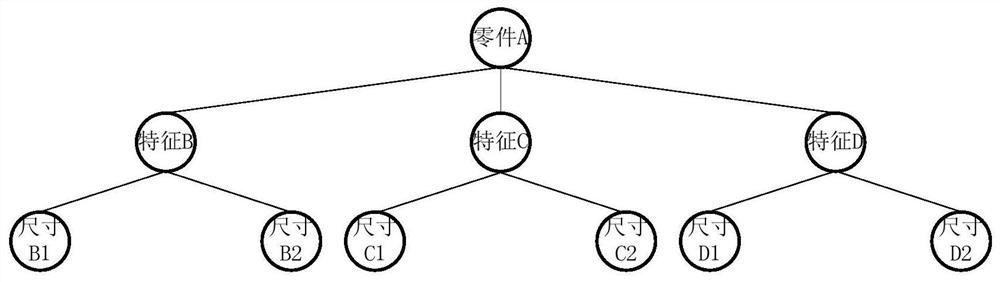

[0033] Through the following examples, combined with the attached Figure 1-5 , the technical solution of the present invention will be further specifically described.

[0034] as attached figure 1 As shown, the present invention provides a kind of radar key component process design method based on PMI information, comprises the following steps:

[0035] Step S1: Extract text annotation information, dimensional tolerance information and geometric feature information associated with dimensional information in the MBD model of key radar components;

[0036] Step S2: Calculate the similarity between the geometric feature information and the geometric feature information of typical objects, determine the category of key radar components, and obtain the process route of the corresponding category;

[0037] Step S3: comparing the text annotation information with the typical process template library, and obtaining the process template corresponding to the text annotation informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com