A method of intelligently managing the welding construction site

A construction site and intelligent management technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to monitor the job site in real time, inconvenient promotion and adoption, and inability to perform quality adjustment and control in real time. Achieve the effects of improving operation efficiency, ensuring construction quality and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

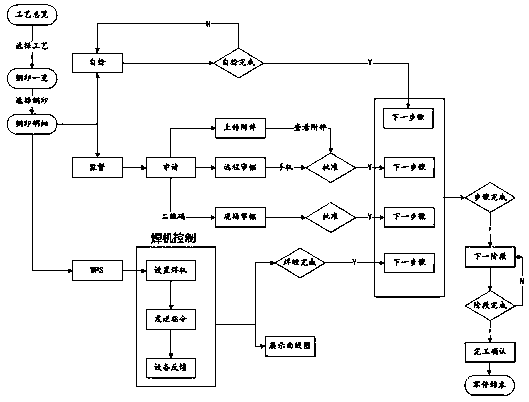

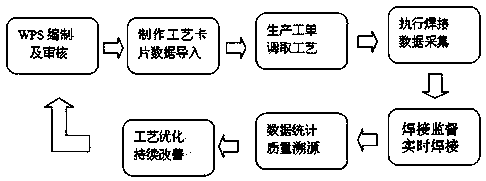

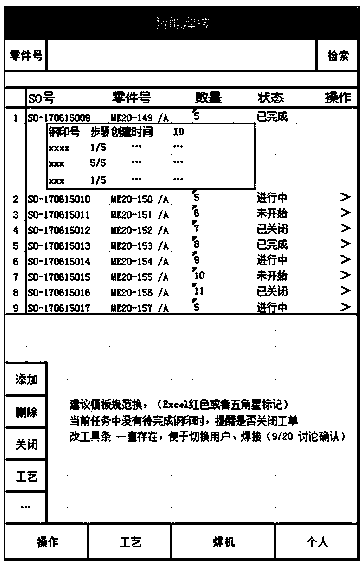

[0047] by attaching figure 1 It can be seen that the present invention relates to a method for intelligently managing welding construction sites. According to welding operation standards, various welding operation conditions are split into standard process elements one by one, and these standard process elements, as well as previous welding All the mature processes of construction are coded, coded management is implemented, and the coded information is stored in the on-site welding construction management database; when performing on-site welding construction, firstly, the status of the welding construction to be performed is recorded in accordance with the welding operation standard. It is also split into standard process elements one by one to form a code; then these codes are compared and screened through the code combination in the process overview of the on-site welding construction management database through the computer, and the corresponding code list is called by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com