Intelligent spinning management system and method for ring spindles

A technology of intelligent spinning and management system, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of inconvenient comprehensive, accurate and timely acquisition, poor real-time data, poor correlation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

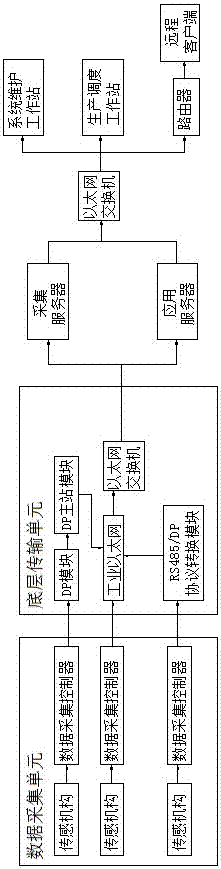

[0040] as attached figure 1 As shown, the ring spindle intelligent spinning management system includes a data acquisition unit, a bottom transmission unit, an acquisition server, an application server, an upper transmission unit, a power supply unit and a monitoring unit; the data acquisition unit is set in the workshop to collect the Equipment data, workshop equipment includes but not limited to spinning workshop equipment and auxiliary equipment, spinning workshop equipment includes but not limited to blowing carding equipment, combing equipment, drawing equipment, roving equipment, spinning equipment, winding equipment , packaging equipment and storage equipment, auxiliary equipment including but not limited to air conditioning equipment, air compressor equipment and dust removal equipment; the underlying transmission unit is connected between the data acquisition unit and the acquisition server, and is used to send the above equipment data to the acquisition server; The ac...

Embodiment 2

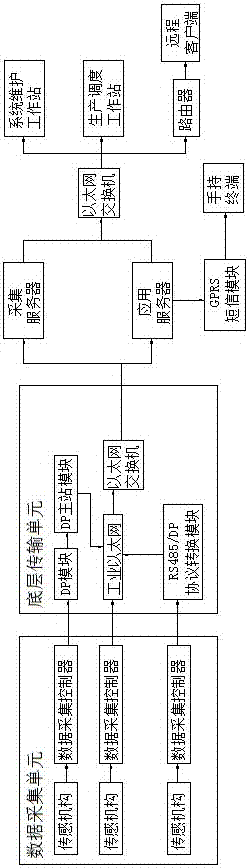

[0063] as attached figure 2 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is: it also includes a GPRS short message module and a handheld terminal, and the application server is connected with the GPRS short message module through a wired transmission module. The SMS module is wirelessly connected to the handheld terminal, and the application server has a built-in early warning calculation module and a periodic data statistics module; through the early warning calculation module, the application server can count, calculate and analyze equipment data and generate early warning information. The operation status, the energy consumption status of each workshop equipment, the opening status of each variety of spinning products, and the production progress of each variety of spinning products are given early warning, and warnings are provided to relevant staff to facilitate the normal spinning...

Embodiment 3

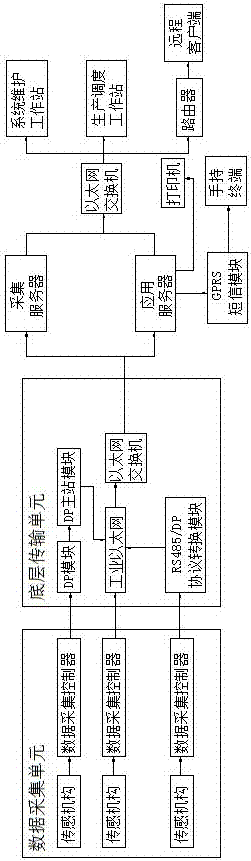

[0067] as attached image 3 As shown, this embodiment is a further improvement on the basis of Embodiment 2. The difference between this embodiment and Embodiment 2 is: a printer is also provided, the printer is connected to the application server, and the printer is used to print the above-mentioned data sheets, such as car workers scheduling Data sheet, energy consumption analysis table of workshop equipment, output table of workshop equipment, etc., facilitate management of employees and control of spinning process.

[0068] In this embodiment, the working process of the ring spindle intelligent spinning management system of the present invention is consistent with that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com