Three-dimensional process model building method based on cutter radius

A tool radius, process model technology, applied in 3D modeling, image data processing, instruments, etc., can solve problems such as poor practicability, and achieve the effect of improving efficiency and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

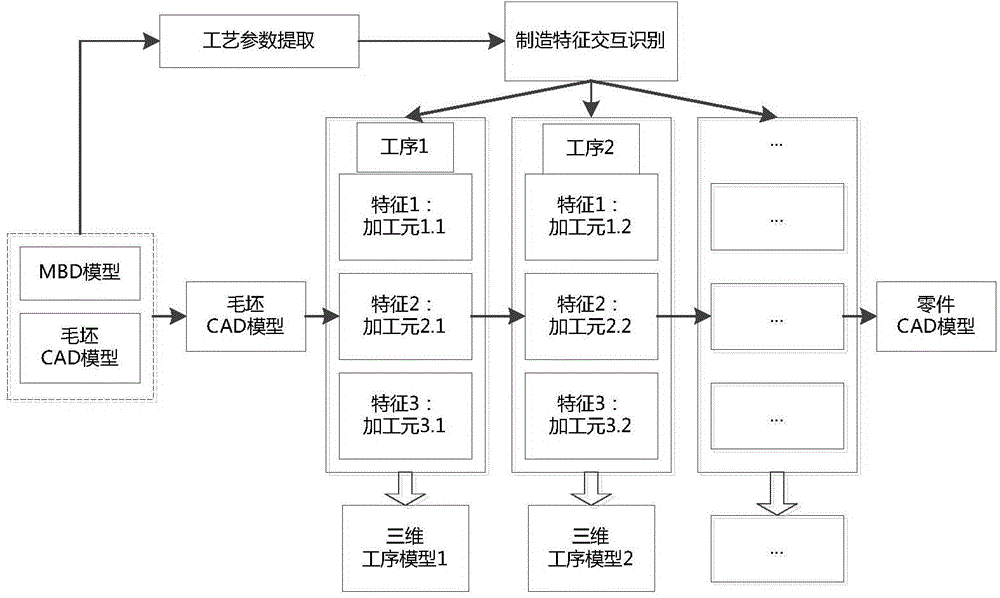

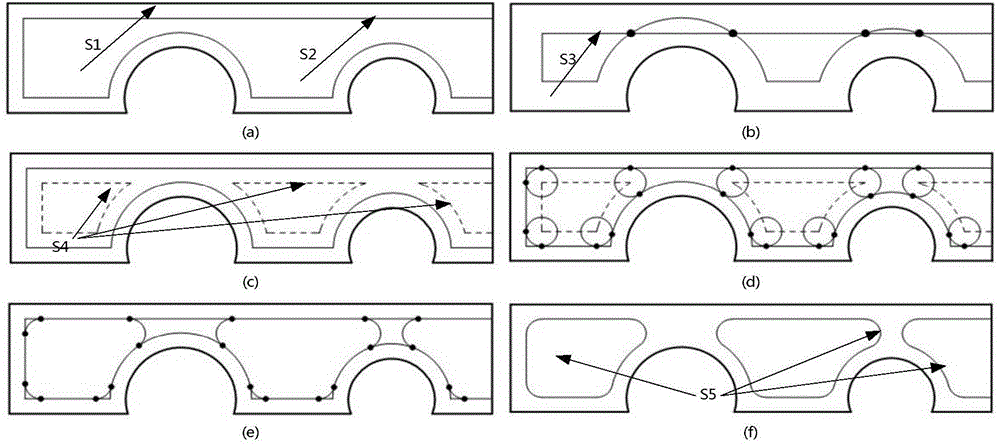

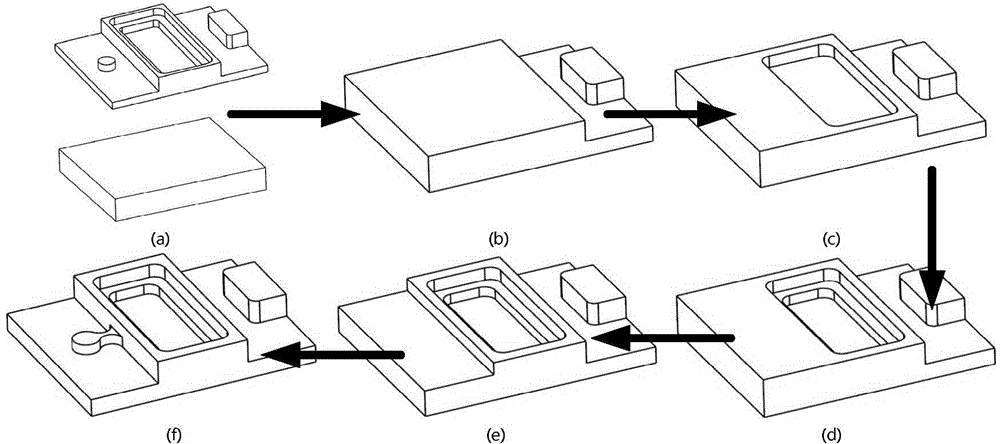

[0033] refer to Figure 1-3 . The specific steps of the three-dimensional process model construction method of the fusion tool radius of the present invention are as follows:

[0034] Given the rough machining process content and process parameters of a part (as shown in Table 1), a three-dimensional process model is constructed by using the method of fused tool radius.

[0035] Table 1 Rough machining process content of a certain part

[0036]

[0037] (a) Input the registered part design model M a and blank model M b .

[0038] (b) Extract the manufacturing feature set from the part design model, and specify the base surface, extrusion start surface and extrusion end surface of each manufacturing feature.

[0039] MF i =(bf i ,sf i ,tf i ), 0≤i≤n (1)

[0040] In the formula, MF i Indicates the i-th manufacturing feature, n is the total number of manufacturing features, bf i 、sf i and tf i Respectively denote as the base plane of the i-th manufacturing featur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com