Rapid generation method for three-dimensional machined technological document

A process file and three-dimensional technology, which is applied in the field of rapid generation of three-dimensional machining process files, can solve problems such as insufficient systematization, standardization, unskilled three-dimensional technology, and random model modification methods, so as to improve the efficiency of process preparation and facilitate rapid process preparation Tool, the effect of reducing manual operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

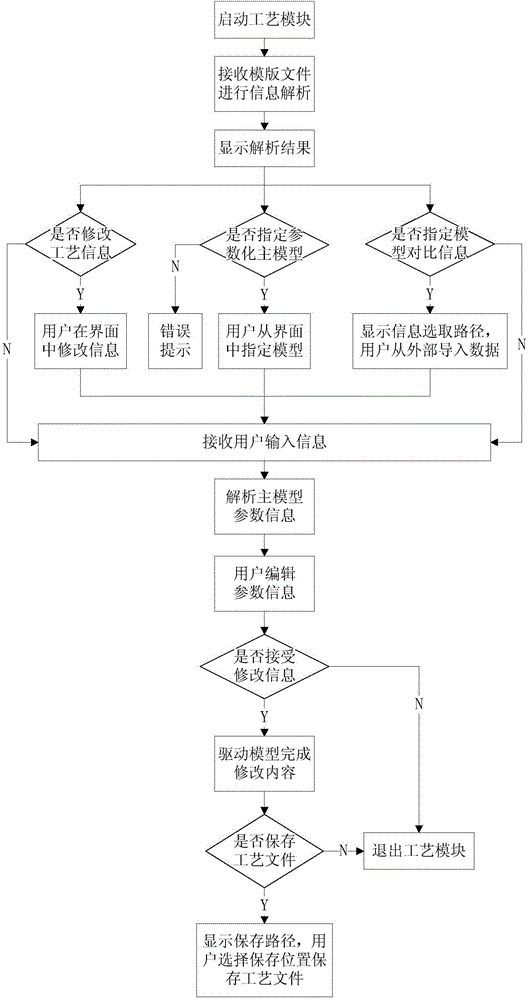

[0022] This embodiment provides a method for quickly generating a three-dimensional machining process file, which is characterized in that: the method for quickly generating a three-dimensional machining process file is based on a process design platform and includes a process information analysis module, a process information input module, and a model Four parts of the information analysis module and the process file generation module;

[0023] (1) Process information analysis module

[0024] Analyze the parameterized template process file data package specified by the user into information that can be read by humans. The parsed information includes 3D data models and process information such as part names, part numbers, models, editions, and materials;

[0025] (2) Process information input module

[0026] This module receives the analytical information of the process file and displays the information to the user. The process information such as the part name, part number, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com