Casting grinding track generation method and system

A track and casting technology, which is applied in the field of the generation method and system of casting grinding track, can solve the problems of low efficiency, difficult application of automatic grinding equipment, and low efficiency of new product launch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

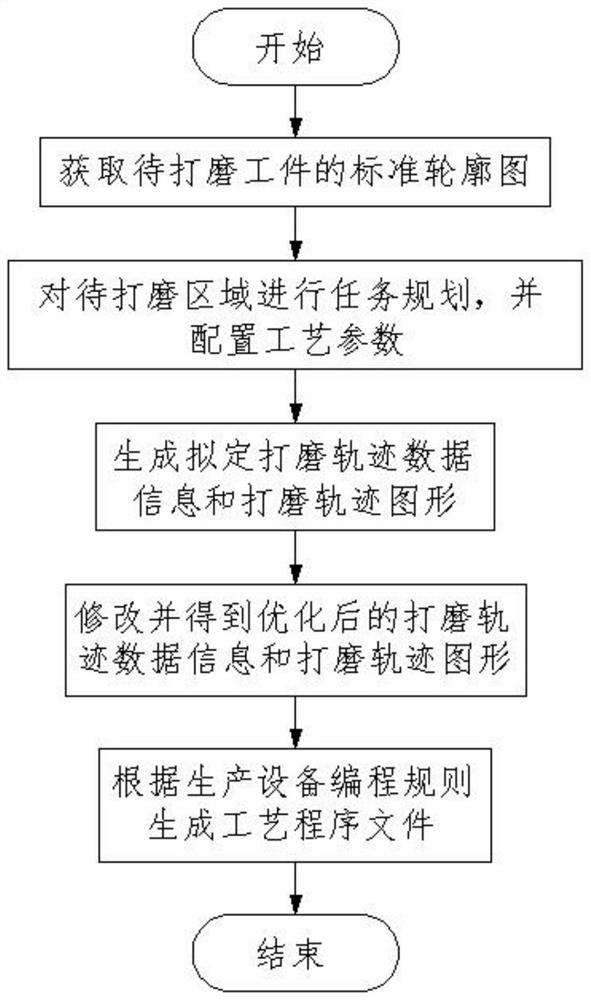

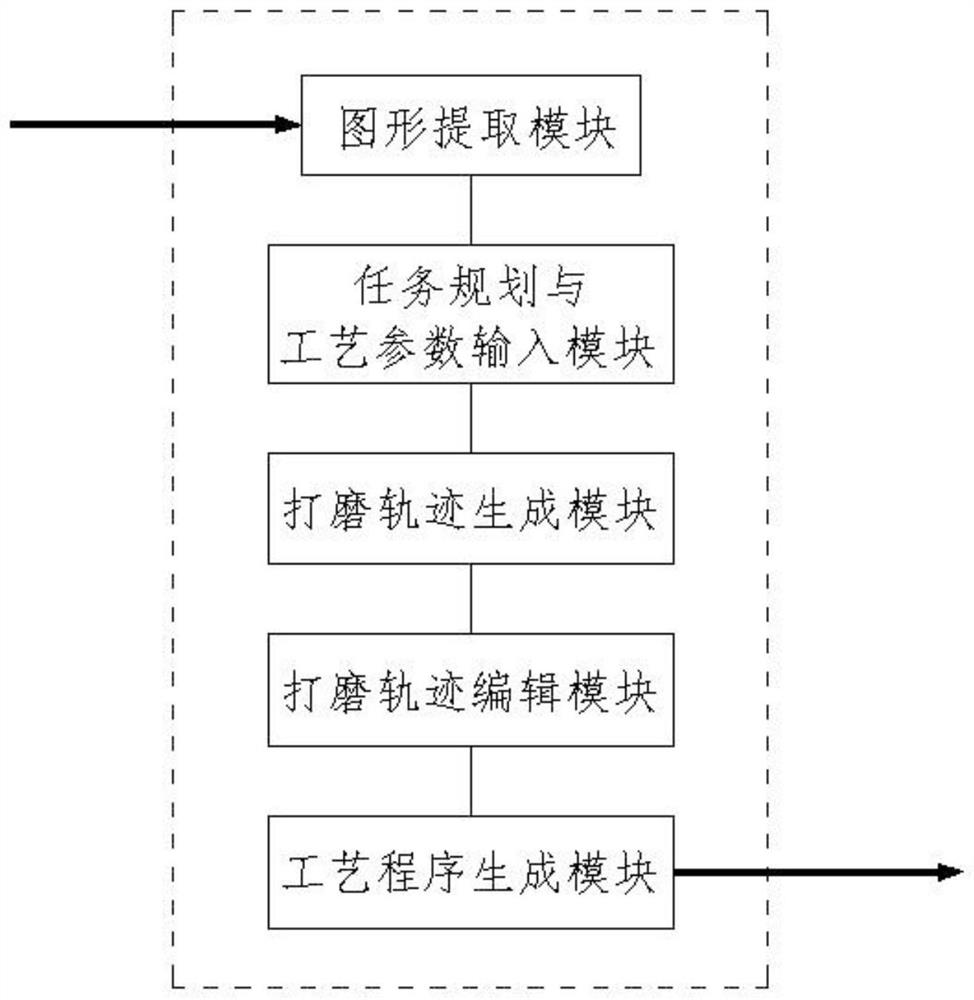

Method used

Image

Examples

Embodiment

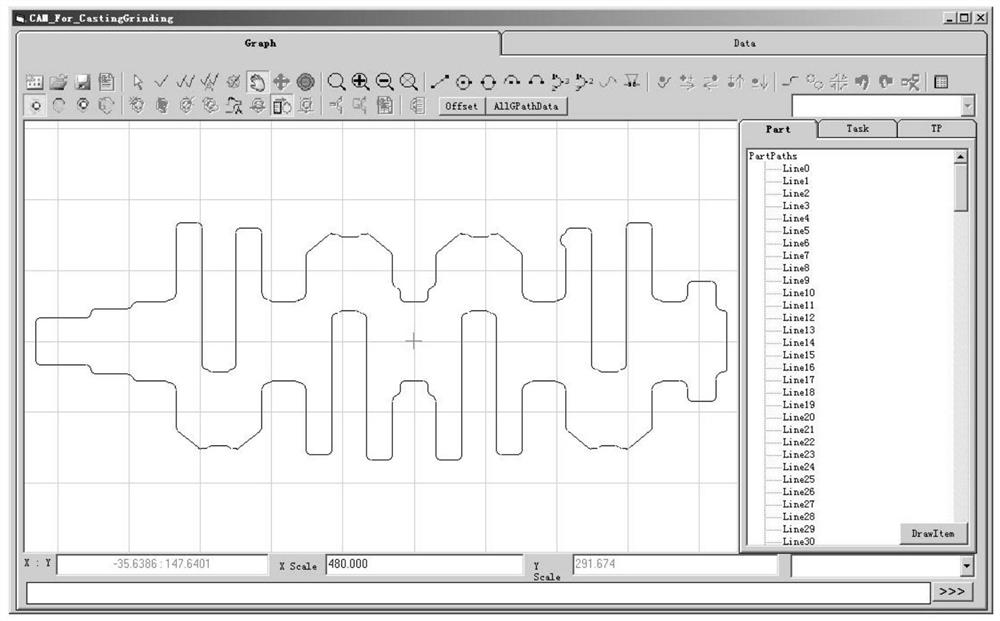

[0070] Taking a certain crankshaft casting as an example, the selected tool is a sheet grinding wheel with a width of 12 mm. Diamond abrasives are attached to the outer surface of the tool and the 30 mm annular area near the outer edge of the tool side. During the grinding process, the tool is positioned on the workpiece to be ground. above. The profile of the parting surface read by the graphic extraction module is as follows: image 3 As shown; combined with its actual shape, the task planning and process parameter input module plans the area to be polished in sections according to the actual grinding process requirements, so as to meet the configuration of different grinding process parameters or subsequent special process additions and modifications, such as Figure 4 , Figure 5 shown.

[0071] Specifically, 1) Obtain the standard contour drawing of the casting through the graphic extraction module, which is the CAD drawing of the parting line. The CAD drawing required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com