Sintering baking oven with small sintering openings

An oven and oral technology, which is applied in the field of LED lamp preparation, can solve the problems of prolonging sintering time, slow sintering efficiency, and different heating of dispensing glue, and achieve the effect of improving process efficiency, reducing sintering time and high sintering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

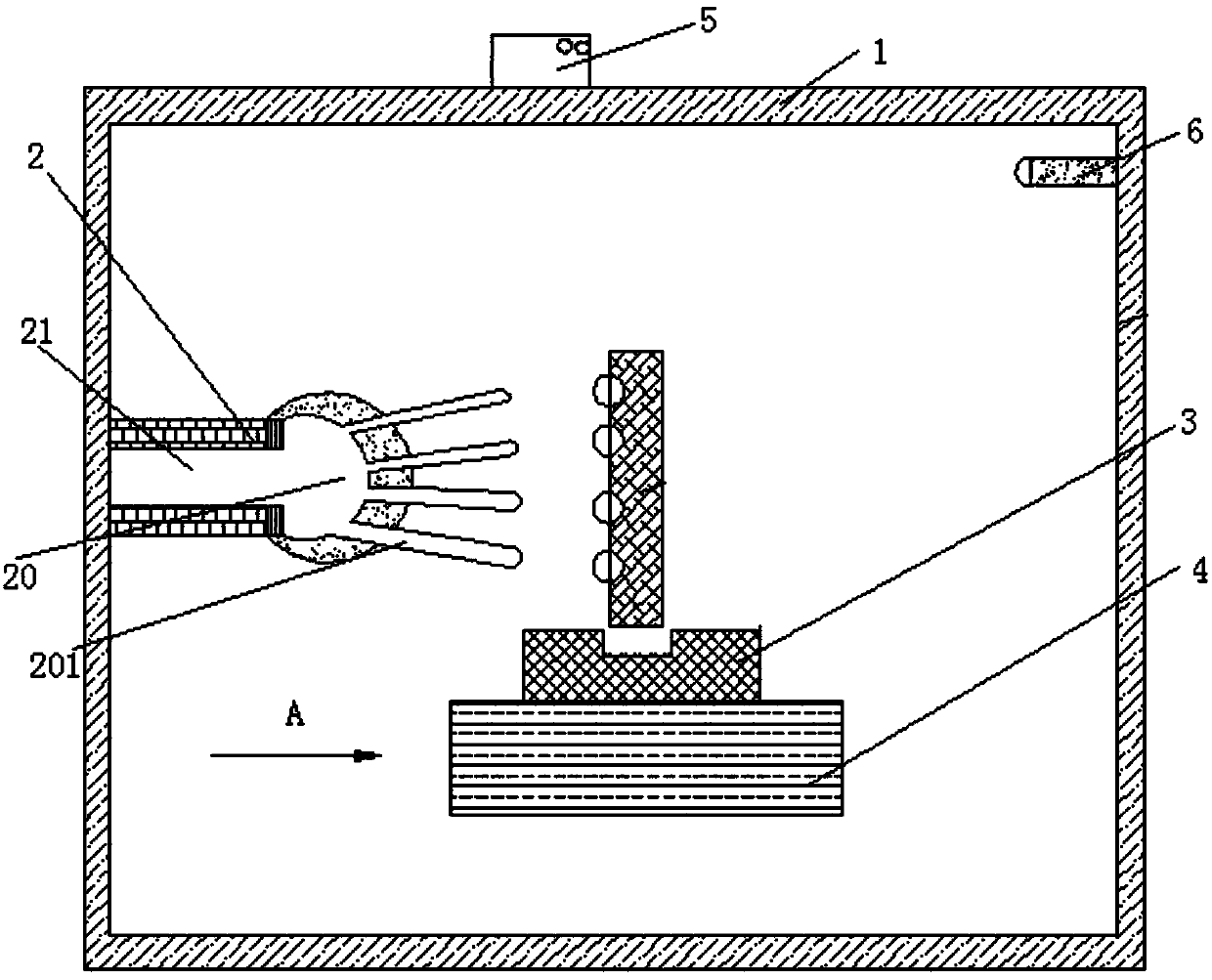

[0020] Such as figure 1 , 2 As shown, a sintering oven with a small sintering port includes a sintering oven 1, a sintering port 2 and a limiting groove 3 matched with the sintering port 2, the sintering port 2 and the limiting groove 3 are arranged inside the sintering oven 1, The sintering port 2 includes a sintering port 20 and a sintering support rod 21. The sintering port 20 and the sintering support rod 21 are threadedly connected to facilitate the replacement of sintering ports 20 of different specifications to achieve the sintering process for LED lamps of different specifications. The sintering port 20 is spherical. The spherical sintering port 20 can dissipate heat evenly. There are several small sintering ports 201 on the sintering port 20. The positions of the small sintering ports 201 correspond to the dispensing positions. The distance between each small sintering port 201 and its corresponding dispensing position is Equal; each silver glue can be cured separate...

Embodiment 2

[0022] Based on the sintering oven with a small sintering port described in Example 1, a layer of rubber is provided on the inner wall of the limiting groove 3 . The rubber can act as a buffer when the LED lamp is placed on the limiting groove 3, preventing the position of the silver glue from moving when placed.

Embodiment 3

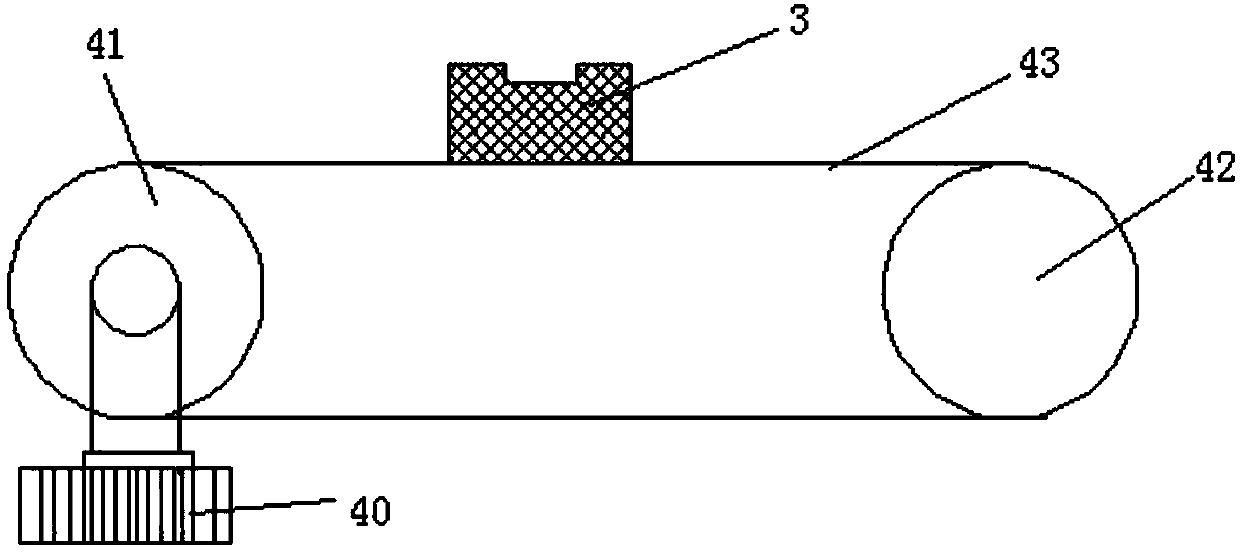

[0024] On the basis of a sintering oven with a small sintering port described in Embodiment 1 or 2, further optimization, the bottom of the limit groove 3 is provided with a rotating structure 4, and the rotating structure 4 includes a motor 40 and a driving wheel connected to the output shaft of the motor 41. The slave pulley 42 driven by the driving wheel and the belt 43 covered on the driving pulley 41 and the driven pulley 42 , the bottom of the limiting groove 3 is fixed at the center of the belt 43 . The rotating structure 4 rotates to realize the movement of the limiting groove. Before the sintering starts, the limiting groove is driven to move, which can realize the preheating of the LED lamp and prevent the silver glue from being suddenly heated to affect the later curing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com