Bismuth tungstate composite photocatalyst, preparation method thereof, and application thereof

A catalyst and composite light technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of photocatalytic efficiency and low utilization of sunlight, etc. Achieve the effect of improving photocatalytic efficiency, good photocatalytic activity, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

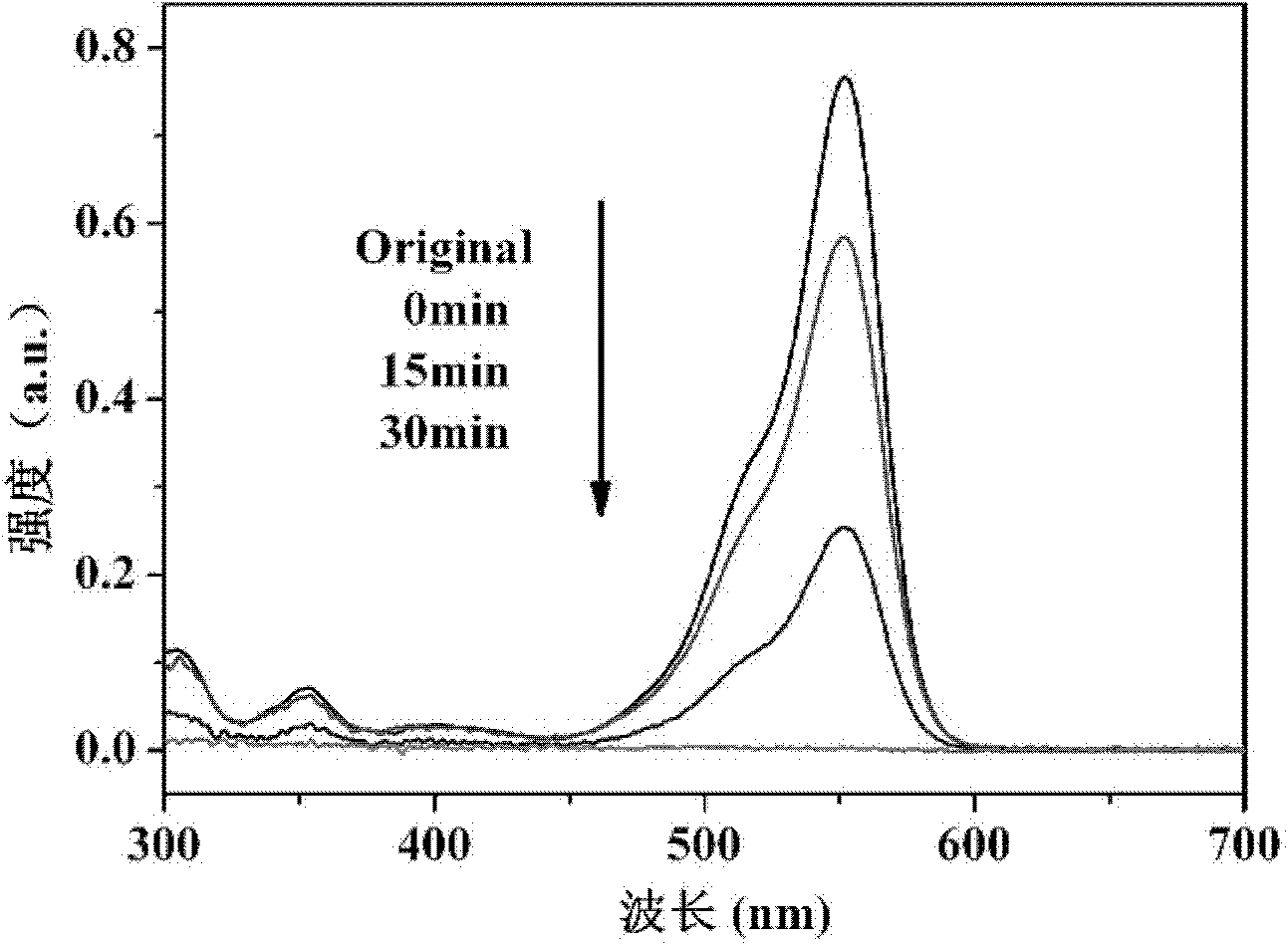

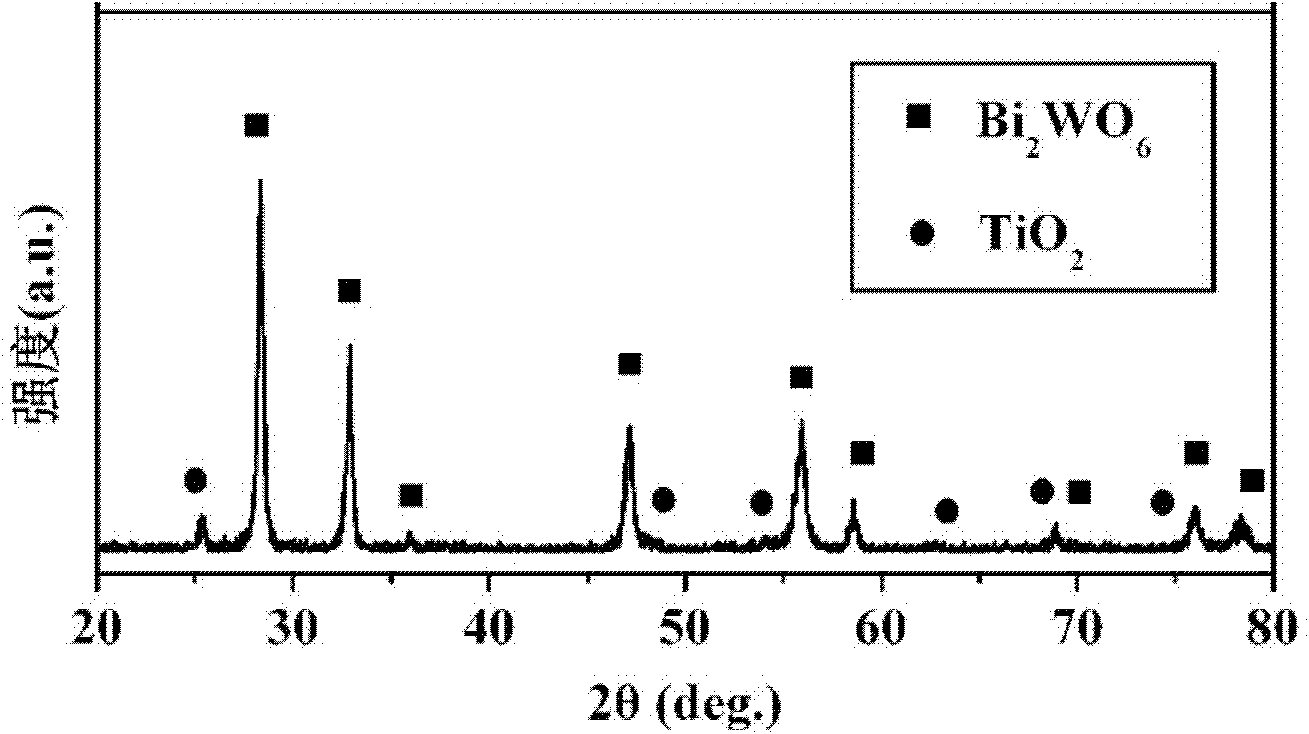

[0045] According to 98wt.% Bi 2 WO 6 -2wt.%TiO 2 Proportion preparation of Bi 2 WO 6 Composite photocatalyst, concrete steps are as follows: according to stoichiometric ratio, weigh 0.970gBi(NO 3 ) 3 ·5H 2 O and 0.330gNa 2 WO 4 2H 2 O was dissolved in 20 mL of ethylene glycol respectively, and the above two solutions were mixed uniformly to obtain a clear solution, which was then transferred to a hydrothermal kettle and heated at 160 °C for 16 hours. After the reaction, the obtained product was centrifuged, washed and then dried at 60° C. for 4 hours. Will get 0.98gBi 2 WO 6 The powder is uniformly dispersed in TiO prepared from butyl titanate 2 in the precursor fluid. Preparation of TiO 2 The main steps of the precursor fluid are: add 1 volume of butyl titanate to 10 volumes of ethanol to make a butyl titanate ethanol solution, then add 1 volume of stabilizer, stir vigorously to obtain a light yellow transparent solution, and then slowly add 2 volume of pure wa...

Embodiment 2

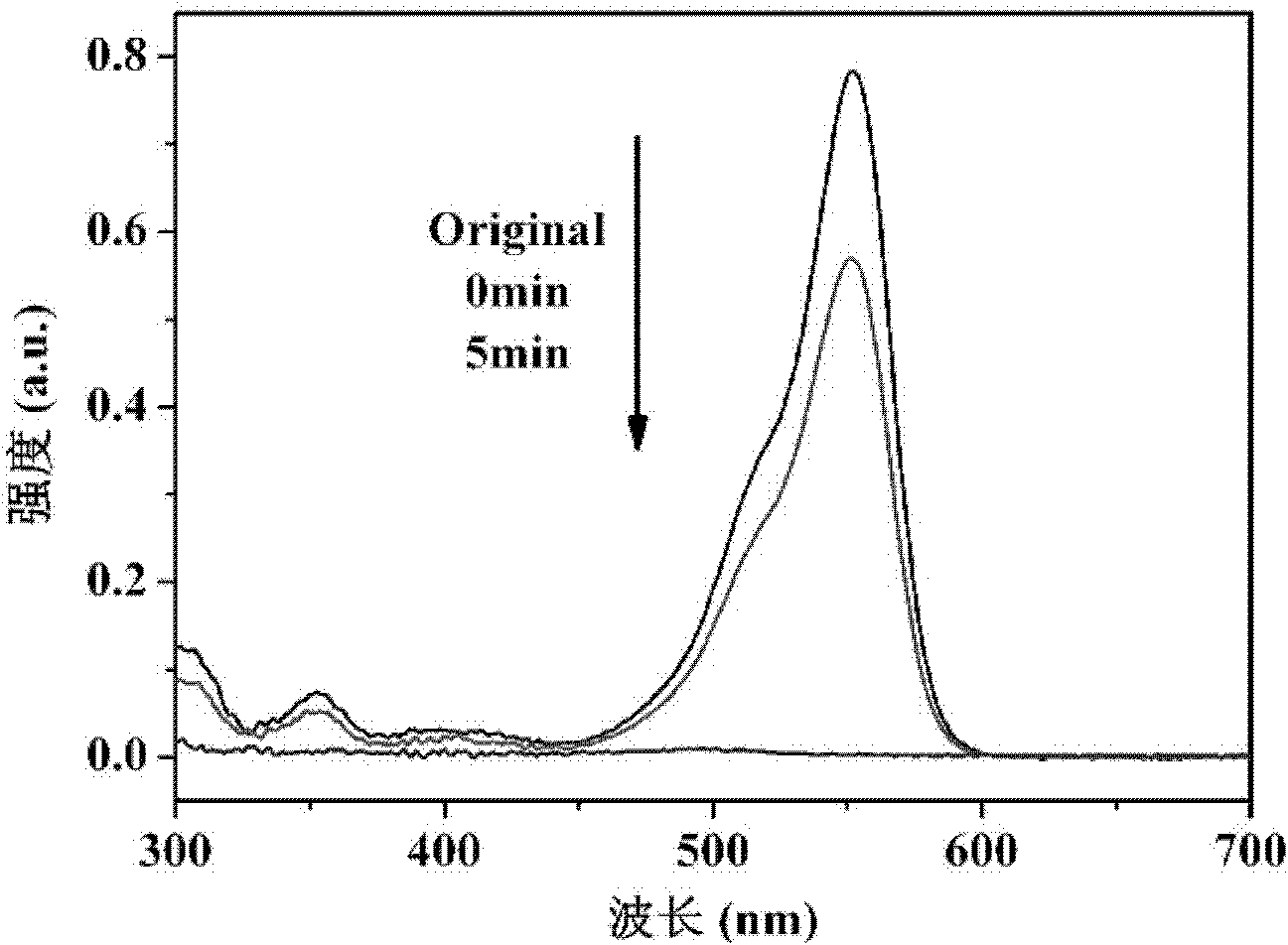

[0048] According to 80wt.% Bi 2 WO 6 -20wt.%TiO 2 Proportioning prepares composite photocatalyst, concrete steps are as follows: the TiCl of 4.1kg / hr 4 evaporation. With the help of nitrogen, steam and 2.0Nm 3 / hr of hydrogen, and 9.1Nm 3 / hr of dry air is mixed in a mixing chamber of a burner of known design, supplied via a central tube to a water-cooled flame tube at the end of which the reaction mixture is ignited, where they burn. Then in the filter the formed TiO 2 separate. Treatment with humid air at 500-700°C to remove adhering chlorides to yield TiO 2 powder. The prepared 0.5gTiO 2 Uniformly dispersed in 2.78gBi(NO 3 ) 3 ·5H 2 In 20mL nitric acid solution of O, add 0.95g Na 2 WO 4 2H 2 After 20 mL of aqueous solution of O, mix well and transfer to a hydrothermal kettle, and heat at 160 °C for 18 h. After the reaction, the obtained product was centrifuged, washed and dried at 60°C for 4 hours to obtain the 80wt.% Bi 2 WO 6 -20wt.%TiO 2 composite phot...

Embodiment 3

[0052] According to 52wt.% Bi 2 WO 6 -48wt.%TiO 2 Proportioning prepares composite photocatalyst, concrete steps are as follows: adopt the method identical with embodiment 2 to prepare TiO 2 powder, and then the prepared 0.48gTiO 2 Disperse evenly in the proportion containing 0.72gBi(NO 3 ) 3 ·5H 2 O and 0.25gNa 2 WO 4 2H 2 O in ethylene glycol 40mL solution. Mix well and transfer to a hydrothermal kettle and heat at 160°C for 18 hours. After the reaction, the obtained product was centrifuged, washed and then dried at 60° C. for 4 hours.

[0053] Bi prepared for research 2 WO 6 The performance of the composite photocatalyst in the application of sewage treatment, design the experiment of the photocatalyst in the application of air purification, use the photocatalytic degradation experiment of acetaldehyde (100ppm) gas, measure the output of carbon dioxide gas by gas chromatography, and then draw the acetaldehyde (100ppm) gas production. The degradation rate of ald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com