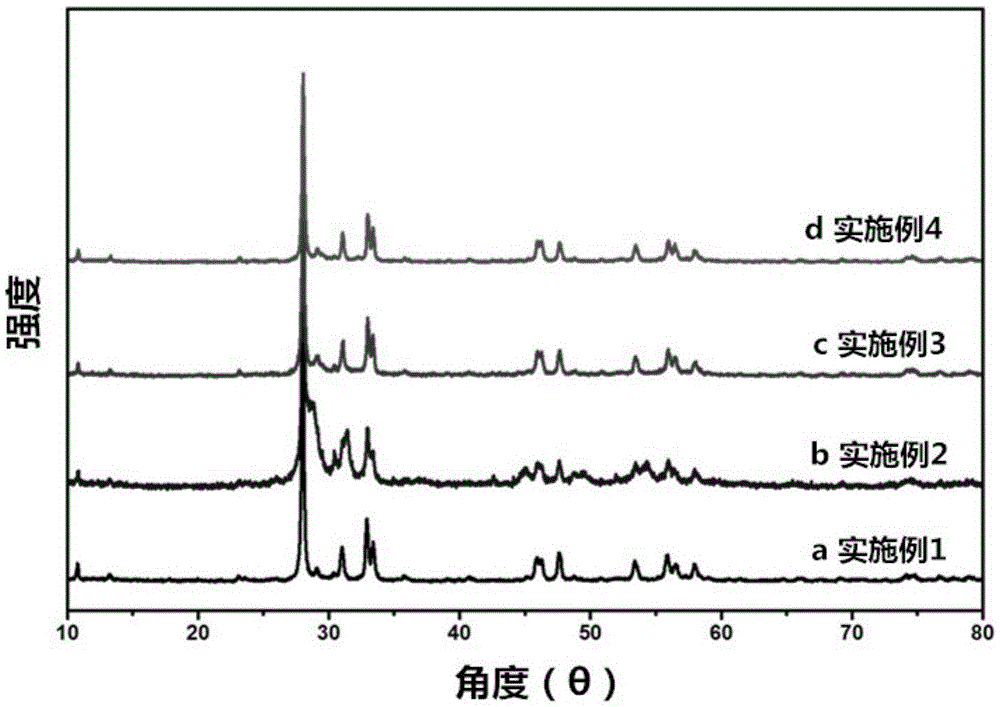

Nano-mesoporous micro-spherical Ln-Bi5O7I photocatalyst and preparation method thereof

A nano-mesoporous, photocatalyst technology, applied in the field of photocatalytic material research, can solve the problems of small specific surface area of sheet-like structure, and achieve the effects of good photocatalytic performance, simple process flow and improved photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

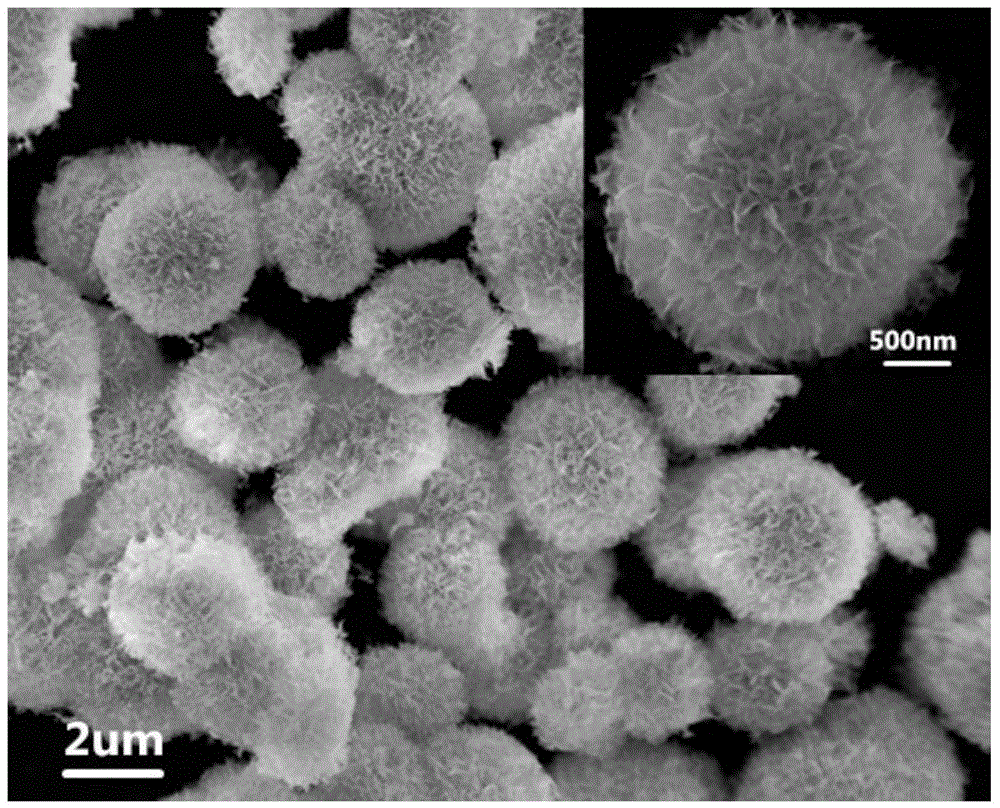

Embodiment 1

[0027] (1) Put 3mmol KI in 20mL ethylene glycol solution, oscillate at 80Hz for 30min until it is completely dissolved, and prepare iodine salt solution A; 2.7645mmolBi(NO 3 ) 3 ·5H 2 O and 0.0855mmolEu(NO 3 ) 3 ·6H 2 O was placed in 30mL and 2mL ethylene glycol solutions respectively, oscillated at 80Hz for 30min until it was completely dissolved, and prepared into bismuth salt solution B and Eu salt solution C.

[0028](2) Add Eu salt solution C to bismuth salt solution B, stir magnetically for 30 minutes until it completely dissolves to obtain BC mixed solution, add iodine salt solution A dropwise to BC mixed solution, wherein A, B and C The volume ratio is 1:1.5:0.05, n Bi+Eu :n I =0.95:1,n Eu :n Bi =0.03:1, magnetically stirred for 60 min to prepare the precursor Eu-BiOI solution.

[0029] (3) Put the precursor Eu-BiOI solution into a polytetrafluoroethylene reactor with a filling ratio of 65%, place the reactor in a constant temperature heating box, set the reac...

Embodiment 2

[0034] (1) Put KI in ethylene glycol solution, 70Hz ultrasonic vibration for 25min, until it is completely dissolved, and prepare iodine salt solution A with a concentration of 0.16mol / L; Bi(NO 3 ) 3 ·5H 2 O and Er(NO 3 ) 3 ·6H 2 O was respectively placed in 30mL and 4mL ethylene glycol solutions, 80Hz ultrasonic vibration for 30min, until it was completely dissolved, and prepared into 0.1mol / L bismuth salt solution B and 0.03mol / L Er salt solution C;

[0035] (2) Add Er salt solution C to bismuth salt solution B, stir magnetically for 35 minutes until it is completely dissolved to obtain BC mixed solution, and add iodine salt solution A dropwise to BC mixed solution, wherein A, B and C The volume ratio is 1:1.5:0.2, n Bi+Er :n I =0.975, n Er :n Bi =0.04, magnetically stirred for 55 minutes to prepare the precursor Er-BiOI solution.

[0036] (3) Put the precursor Er-BiOI solution into a polytetrafluoroethylene reactor with a filling ratio of 70%, place the reactor in ...

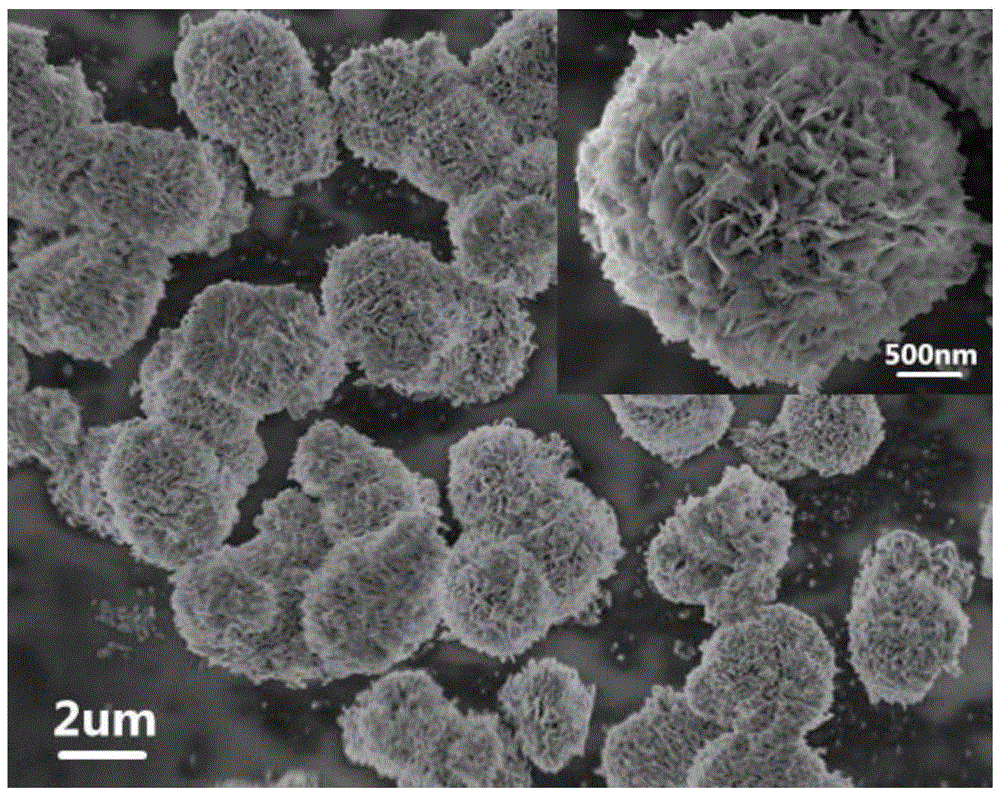

Embodiment 3

[0041] (1) Put KI in ethylene glycol solution, 70Hz ultrasonic vibration for 25min, until it is completely dissolved, and prepare iodine salt solution A with a concentration of 0.17mol / L; Bi(NO 3 ) 3 ·5H 2 O and La(NO 3 ) 3 ·6H 2 O was respectively placed in ethylene glycol solution, 100Hz ultrasonic vibration for 20min, until it was completely dissolved, and prepared into 0.095mol / L bismuth salt solution B and 0.02mol / L La salt solution C;

[0042] (2) La salt solution C was added to bismuth salt solution B, and magnetically stirred for 40 minutes until it was completely dissolved to obtain a BC mixed solution, and iodine salt solution A was added dropwise to the BC mixed solution, wherein A, B and C The volume ratio is 1:1.5:0.1, n Bi+La :n I = 0.85, n La :n Bi =0.014, magnetically stirred for 50 min to prepare the precursor La-BiOI solution.

[0043] (3) Put the precursor La-BiOI solution into a polytetrafluoroethylene reactor with a filling ratio of 68%, place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com