Preparation method for carbon nanotube or graphene nano-carbon material

A carbon nanomaterial and carbon nanotube technology, which is applied in the field of metal-free catalytic preparation of carbon nanotubes or graphene nanocarbon materials, can solve the problems of small graphene size, difficult product transfer, uneven distribution, etc., and achieves easy operation, The effect of strong controllability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]First, clean the surface of 6H-SiC(000-1), soak in 20% hydrofluoric acid solution for 5 minutes to remove surface oxides, then rinse with deionized water, ethanol, and acetone in order to remove residual hydrogen fluoride on the surface acids and organics. After being placed in a vacuum chamber, it is heated to about 650°C to degas for several hours.

Embodiment 2

[0036] After cleaning and degassing, the 6H-SiC samples were vacuum-conditioned (3.0×10 -10 mbar) was heated to 1700°C under direct current and kept for 60 minutes. At this time, the color of the sample changed from light green to black, forming a surface carbon layer structure with a thickness of several microns.

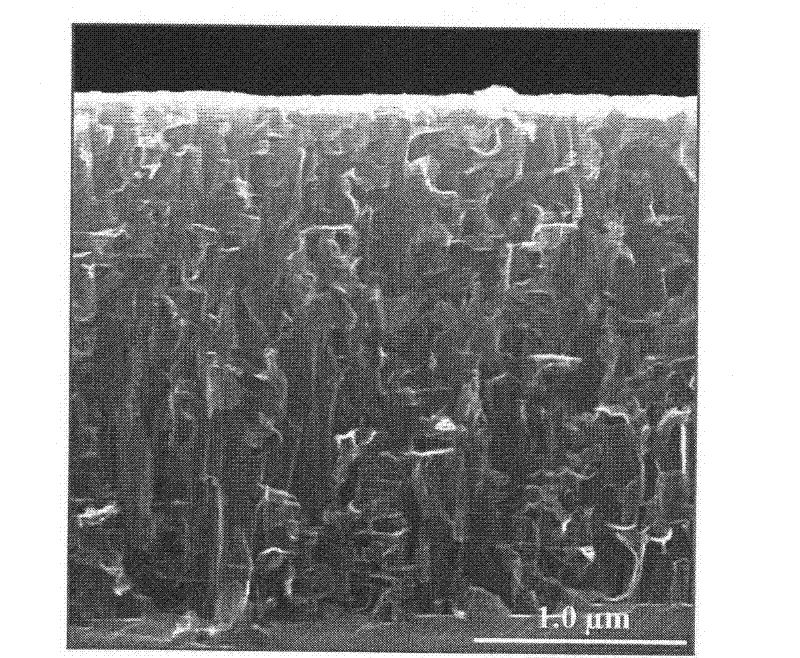

[0037] figure 1 SEM cross-sectional view of the graphene material prepared for this example. The interface between the surface carbon layer and the silicon carbide substrate can be clearly distinguished from the bottom of the figure. The surface carbon layer structure is about 2.4 μm thick and consists of vertical graphene structures.

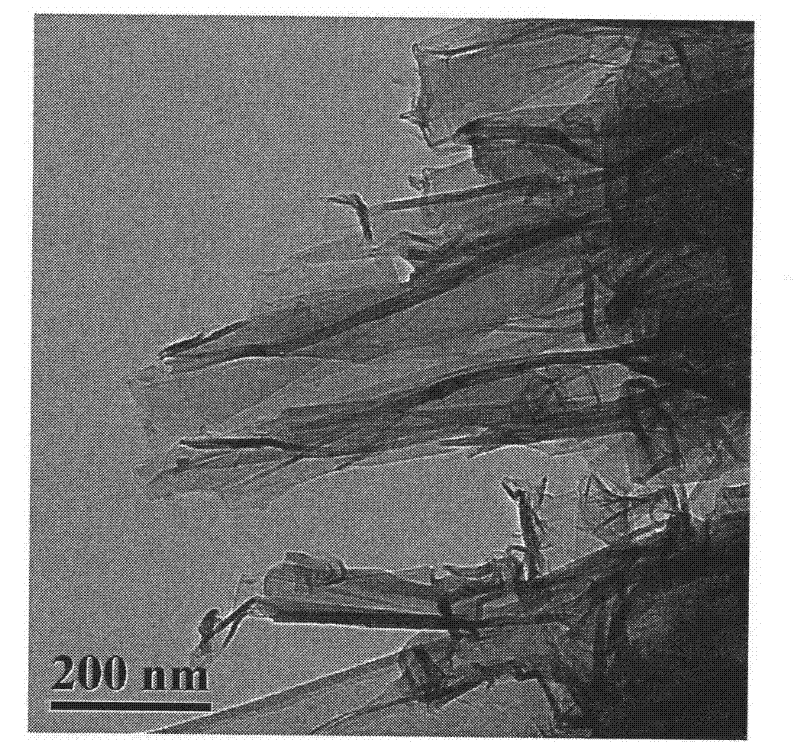

[0038] figure 2 A transmission electron microscope image of graphene.

Embodiment 3

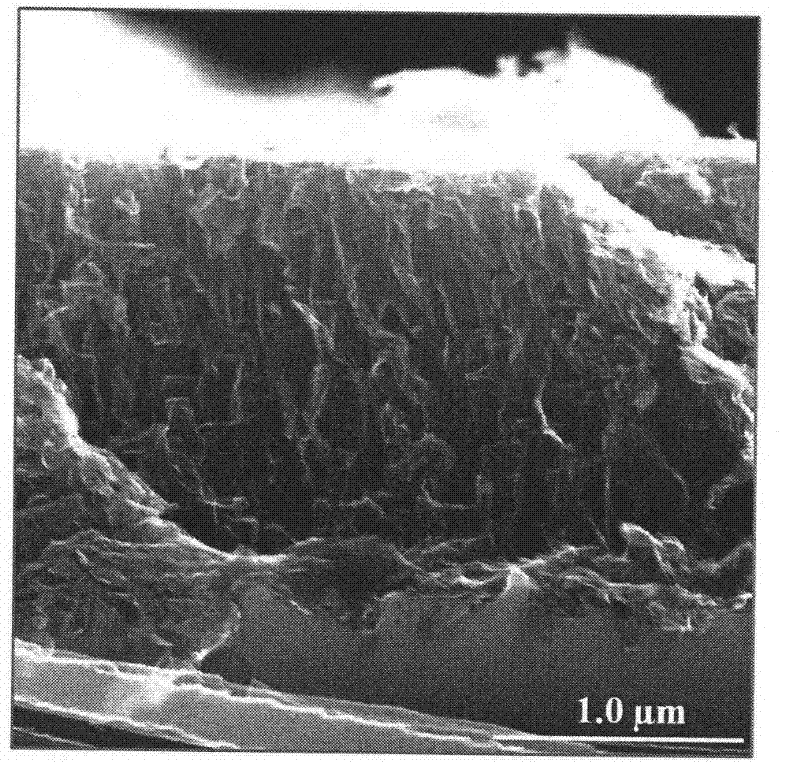

[0040] After the 6H-SiC sample was cleaned and degassed, argon gas was introduced into the vacuum chamber through the control leak valve, and the vacuum was maintained at 1.3×10 -5 mbar. The sample was then heated to 1700°C in direct current for 60 minutes. The sample turned from light green to black. The surface is a graphene array structure with a thickness of about 1 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com