NiTi hydrotalcite nanosheet catalyst responding to visible light, and preparation method of catalyst

A visible light, hydrotalcite technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxygen preparation, etc., can solve the problems of catalyst nanocrystalline particle agglomeration, limited metal-oxygen-metal bonds, and limited applications, etc. Visible light catalytic performance, low cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Prepare microemulsion: Based on a 100ml three-necked flask, add 50ml of isopropanol, 1.1ml of deionized water, and 1.08g of surfactant sodium lauryl sulfate into the three-necked flask, and stir; slowly add 1-butanol 2ml, stir until clear;

[0021] 2. Put 0.004mol Ni(NO 3 ) 2 ·6H 2 O is added to the microemulsion prepared in step 1. After the salt is dissolved, TiCl is added in a closed environment. 4 Solution 0.11ml, after the smoke disappears, add 1.200g urea, crystallization and reflux at 100℃ for 27h; TiCl added 4 The solution contains 0.001mol of titanium;

[0022] 3. After the reaction is completed, the product is filtered with suction, and washed 3 times by centrifugation with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and then washed 3 times with absolute ethanol. Visible light-responsive NiTi hydrotalcite nanosheet catalysts were obtained.

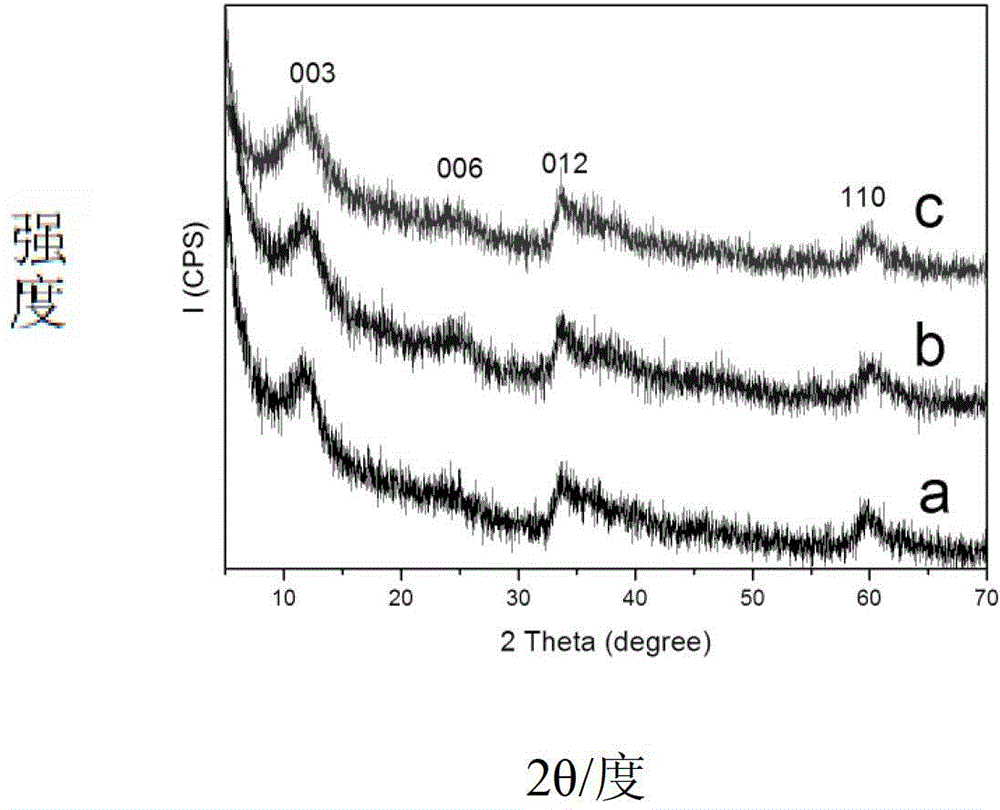

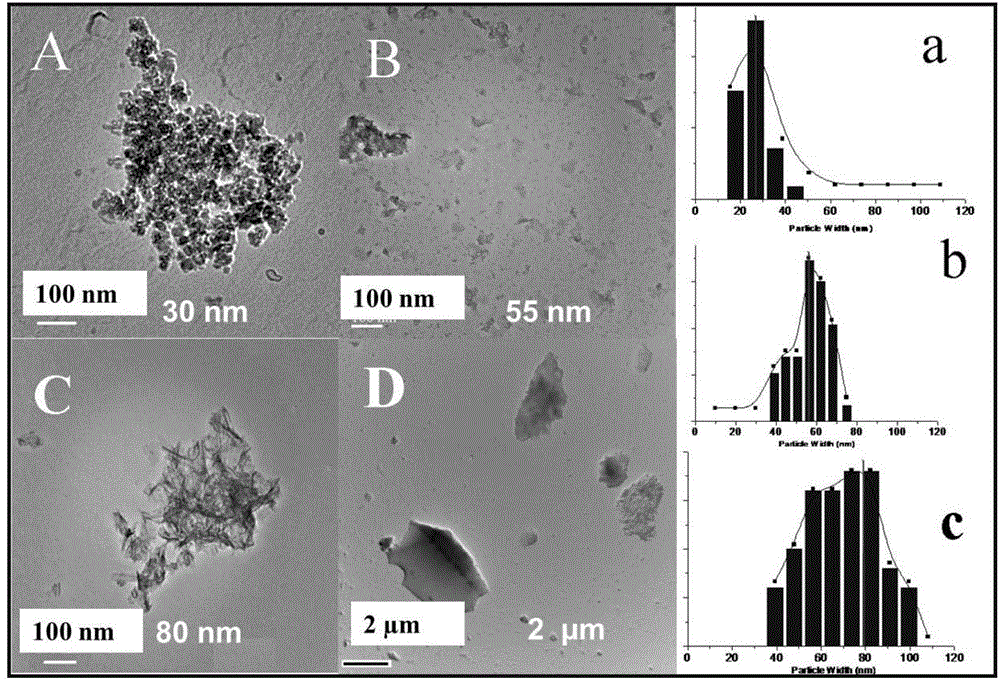

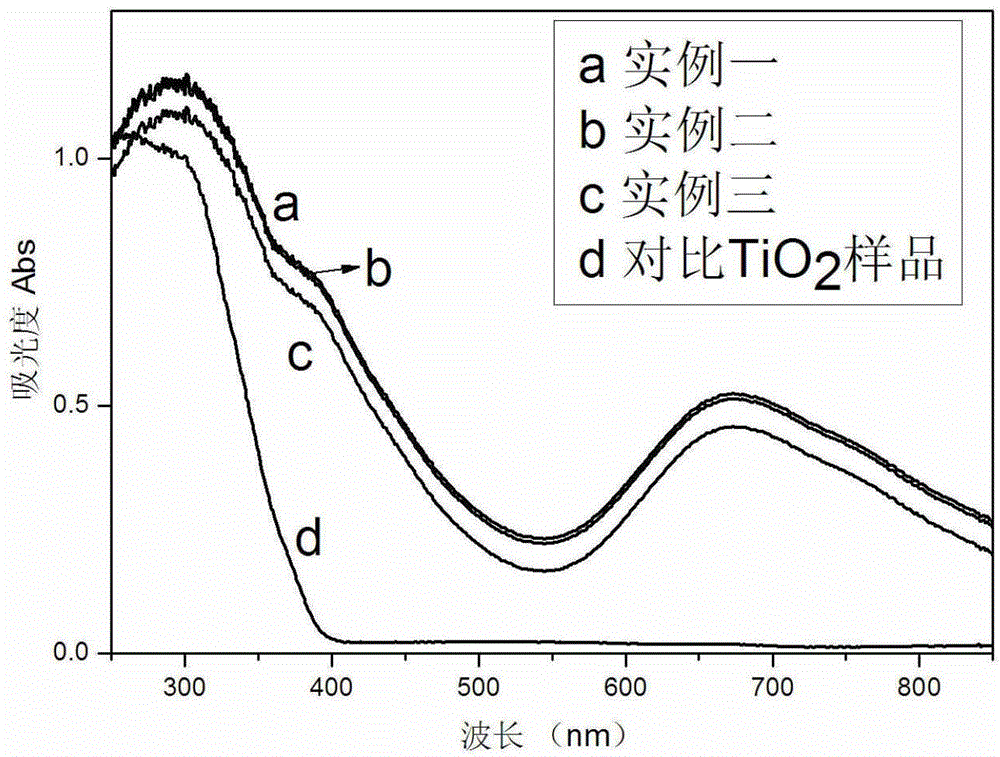

[0023] The chemical formula of the visible light-responsive NiTi hydrotalcite n...

Embodiment 2

[0027] 1. Prepare microemulsion: Based on a 100ml three-necked flask, add 50ml of isopropanol, 1.1ml of deionized water, and 0.72g of surfactant sodium lauryl sulfate into the three-necked flask, and stir; slowly add 1-butanol 2ml, stir until clear;

[0028] 2. Put 0.004mol Ni(NO 3 ) 2 ·6H 2 O is added to the microemulsion prepared in step 1. After the salt is dissolved, TiCl is added in a closed environment. 4 Solution 0.11ml, after the smoke disappears, add 0.900g urea, crystallization and reflux at 100℃ for 27h; TiCl added 4 The solution contains 0.001mol of titanium;

[0029] 3. After the reaction is completed, the product is filtered with suction, and washed 3 times by centrifugation with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and then washed 3 times with absolute ethanol. Visible light-responsive NiTi hydrotalcite nanosheet catalysts were obtained.

[0030]The chemical formula of the visible light-responsive NiTi hydrotalcite na...

Embodiment 3

[0034] 1. Prepare microemulsion: Based on a 100ml three-necked flask, add 50ml of isopropanol, 1.1ml of deionized water, and 0.36g of surfactant sodium lauryl sulfate into the three-necked flask, and stir; slowly add 1-butanol 1.5ml, stir until clear;

[0035] 2. Put 0.004mol Ni(NO 3 ) 2 ·6H 2 O is added to the microemulsion prepared in step 1. After the salt is dissolved, TiCl is added in a closed environment. 4 Solution 0.11ml, after the smoke disappears, add 0.900g urea, crystallization and reflux at 130℃ for 27h; TiCl added 4 The solution contains 0.001mol of titanium;

[0036] 3. After the reaction is completed, the product is filtered with suction, and washed 3 times by centrifugation with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and then washed 3 times with absolute ethanol. Visible light-responsive NiTi hydrotalcite nanosheet catalysts were obtained.

[0037] The chemical formula of the visible light-responsive NiTi hydrotalcite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com