Mica and its calcining method

A mica calcination and mica technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as health hazards of operators, low mica purity, waste of heat energy, etc., and achieve good sand and gravel separation effect. Provide work efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

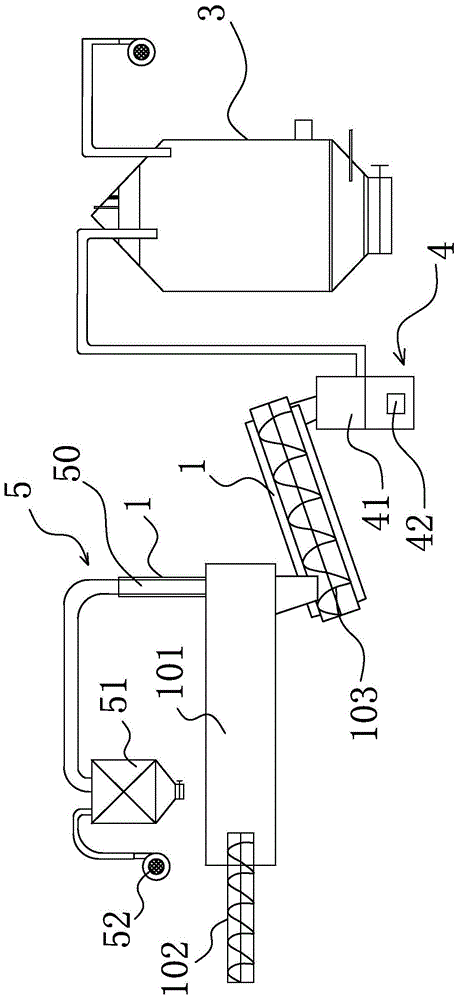

[0031] Such as Figure 1-5 Shown, a kind of mica calcining method comprises the following steps:

[0032] A, use the first mica conveying mechanism 102 to put the mica into the calciner 101 for calcination, and the calciner 101 is connected to the dedusting mechanism 5 for dedusting;

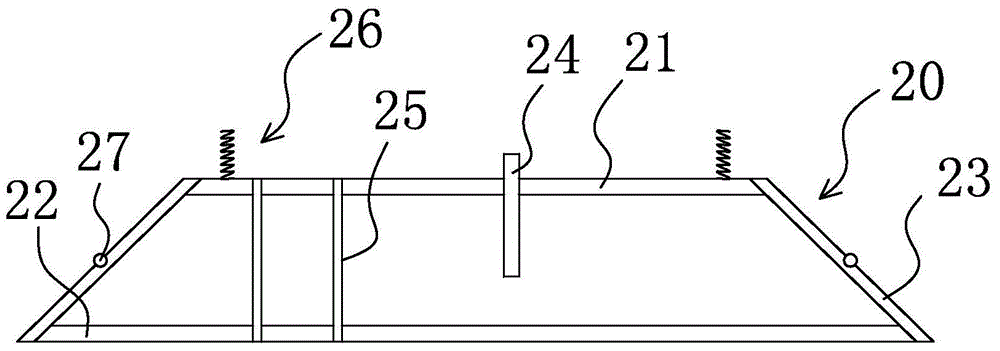

[0033] B, the mica in the calciner 101 is discharged in the second mica conveying mechanism 103, and the mica in the second mica conveying mechanism 103 is cooled with cooling jacket mechanism 1;

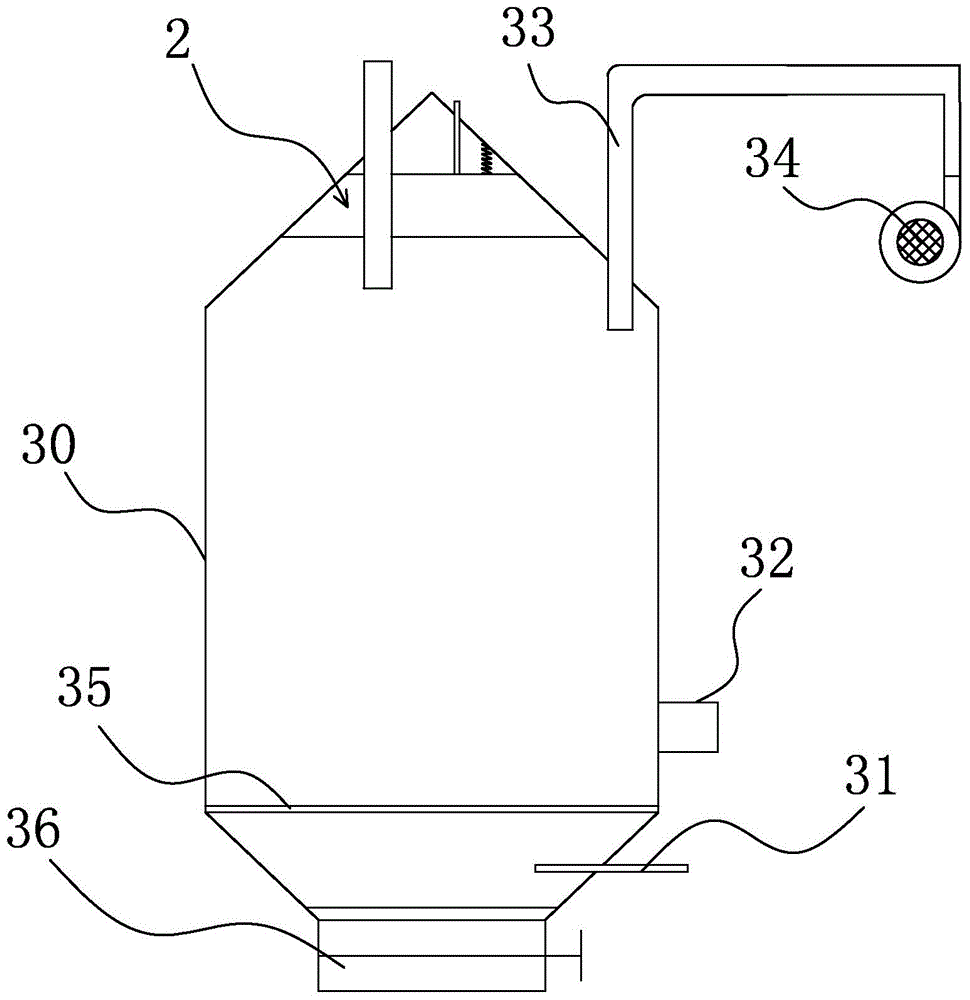

[0034] C. The cooled mica is sucked into the mica cooling tower 3 by negative pressure, sprayed and cooled, and rinsed to obtain pure mica.

[0035] Preferably, in step C, the mica after the cooling is sucked into the mica cooling tower 3 after passing through the sand and gravel settling mechanism 4; The settling box 41 connected, the bottom of the settling box 41 is provided with an openable and closed gravel discharge door 42, the side wall of the settling box 41 is located above the gravel disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com