Honeycomb ceramic pulse protective agent

A technology of honeycomb ceramics and protective agents, applied in catalyst protection, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of increasing the flow resistance of reactants, reducing oil refining output, shortening the service life of catalysts, etc., to improve durability Grinding and adsorption activity, increase catalytic reaction speed, and increase the effect of production and operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

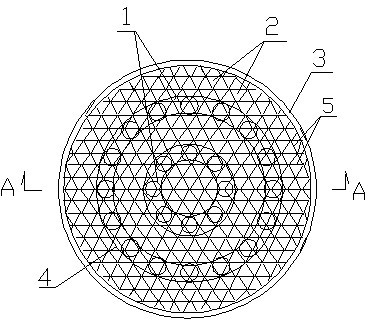

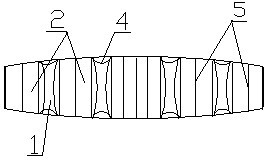

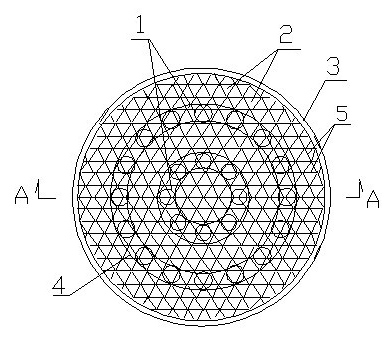

[0023] Example 1, in figure 1 and figure 2 Among them, the honeycomb ceramic pulse protective agent of the present invention includes a body 3, the body specifications are: diameter 40mm, height 15mm, honeycomb hole mesh number 300 mesh, the body is in the shape of a flat cylinder, and the upper and lower ends of the body are convex spherical ( Flying saucer shape), the upper and lower ends of the body can also be flat, the body is extruded by a mold at one time, the body has mesh honeycomb holes 2 arranged in parallel, the cross section of the honeycomb holes is triangular, square, round or other shape, the thickness of the honeycomb hole wall 5 is 0.2-0.5 mm, and two concentric circulation grooves 4 are arranged on the upper and lower end surfaces of the body. Of course, a circulation groove can also be arranged on the upper or lower end surface of the body. There are through holes 1 arranged at intervals, the through holes in the outer ring are 16 round holes (the cross s...

Embodiment 2

[0034]Embodiment 2, the honeycomb ceramic pulse protective agent of the present invention includes a body 3, the specifications of the body are: diameter 40mm, height 15mm, honeycomb hole mesh number 400 mesh, the body is extruded by a mold at one time, and the upper and lower ends of the body It is convex spherical and has mesh-shaped honeycomb holes 2 on the body. The cross-section of the honeycomb holes is square. The honeycomb holes are arranged in parallel or staggered. The end faces are provided with two concentric circulation grooves 4, and the circulation grooves are provided with through holes 1 arranged at intervals. The body is composed of 60% alumina powder, 32% silica powder, 3% magnesium oxide and 5 The kaolin composition of % is described and is prepared from by following method steps:

[0035] a. After mixing the alumina powder, silicon oxide powder, magnesia and kaolin raw materials in the above weight percentages by ball milling, sieve through 200 mesh to mak...

Embodiment 3

[0045] Example 3, the honeycomb ceramic impulse protector of the present invention can be soaked in a solution containing cobalt, molybdenum, and nickel, so that a layer of catalyst is formed on the surface of the honeycomb pores, thereby improving the activity of the honeycomb ceramic impulse protector.

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com